All Categories

History

This section provides an overview for tube fuses as well as their applications and principles. Also, please take a look at the list of 7 tube fuse manufacturers and their company rankings. Here are the top-ranked tube fuse companies as of April, 2025: 1.SIBA, 2.Sweeta Products Corporation, 3.Littelfuse.

Table of Contents

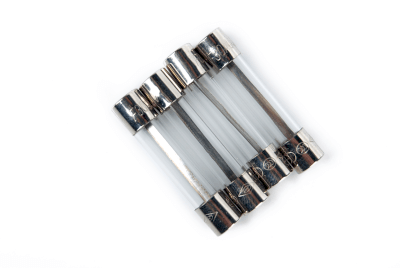

Tube fuses are safety devices used to protect electrical circuits by interrupting current flow when it exceeds safe levels. They contain a fusible metal wire within a glass or ceramic tube that melts (blows) under excessive current, thereby breaking the circuit.

Widely used in consumer electronics, automotive circuits, industrial machinery, and more, tube fuses safeguard against electrical faults. They are particularly valuable in systems where frequent current fluctuations occur, offering protection without the need for constant replacement.

The operation of tube fuses is based on the melting of a fuse element made from materials like lead, tin, or silver, whose composition determines the fuse's melting point. This feature allows tube fuses to cater to a broad spectrum of rated currents, from low-power applications to those requiring currents of 30A or more.

Selection involves ensuring the fuse's rated current exceeds the normal operational current of the circuit but responds appropriately under fault conditions. Factors such as material type, fusing speed, and application-specific requirements guide the choice of the appropriate tube fuse.

*Including some distributors, etc.

Sort by Features

Sort by Area

Littelfuse founded in 1927, is an industrial manufacturing company empowering a sustainable, connected, and safer world, headquartered in Chicago, Illinois, United States. The company's product portfolio includes the solutions for both individual and entire systems, as a global manufacturer of technologies in circuit protection, power control, and sensing. Across more than 20 countries, and with approximately 18,000 global associates, partner with customers to design and deliver advanced solutions. Serving over 100,000 end customers, their products are found in industrial, transportation, and electronics end markets.

Bel Fuse Inc. was founded in 1949 and is currently headquartered in Jersey City, New Jersey. The company designs, manufactures and distributes electronics and connectivity devices to global markets including telecommunications, commercial aerospace, transportation, and high-speed data transmission. The company sells products in 16 product segments, including optical connectivity, electrical connectivity, magnetics, power supplies, and others. The company also offers an online resource library for product configuration assistance including technical aspects and drawings, video libraries, and assembly instructions.

Pacific Engineering Corporation (PEC), established in 1961 and located in Ogaki, Gifu, Japan, is a manufacturer and supplier of automotive fuses and precision metal forming machinery. The product range includes multi slow blow fuses, battery terminal fuses, surface grinding machines, CNC floor boring machines, and various others. The company can provide cutting-edge initiatives, such as die production or press forming of high tensile strength steel, to meet a needs in the development of automobiles to ensure safety and environmental functionality related to low fuel consumption and lightweight construction.

SWEETA was established in 1995 and is headquartered in New Taipei City, Taiwan. SWEETA is a manufacturer of switches, AC sockets, and circuit breakers globally. Most products have been certified to meet international safety standards such as UL, CSA, VDE, and others. SWEETA has an extensive product line. A few listings include AC sockets, plug adapters, switches, thermostats, and test tweezers.

SIBA, founded in Nordrhein-Westfalen, Germany in 1946, is a manufacturer of high voltage fusses and miniature devices for electrical components. The company's product portfolio includes ultra-rapid fusses, low voltage fusses, miniature fuses, fuss detectors and custom-designed fuses to meet the unique requirements of specific applications and industries. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

Interpower Corporation established in 1975, and has headquarters located in the USA, and the UK, is a manufacturer of international power cords and related products to customers worldwide. The company’s North American stock of products centralized in Iowa include international power cords and cord sets, plugs and sockets, hospital-grade products, and IEC 60320 accessory power distribution units. The UK division of the company serves mainly the European market. Interpower Corporation is also ISO 9001:2015 certified.

Fuji Terminal Industry Co. Ltd. has been a manufacturer and supplier of electrical components in Japan since 1958. The company manufactures a wide range of terminals, such as solderless, insulated, compression, and more including fuses that are available as micro, cartridge-type, and thermal cut-off ones. They also design fuse-related products and crimping tools along with connectors and cable accessories. These products find applications in industries such as Consumer Electronics, Telecommunications, Medical devices, Aerospace, and Defense to name a few.

Ranking as of April 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | SIBA |

29.3%

|

| 2 | Sweeta Products Corporation |

24.1%

|

| 3 | Littelfuse |

12.1%

|

| 4 | Interpower Corporation |

12.1%

|

| 5 | Bel |

10.3%

|

| 6 | FUJI TERMINAL INDUSTRY CO., LTD. |

8.6%

|

| 7 | Pacific Engineering Corporation |

3.4%

|

Derivation Method

The ranking is calculated based on the click share within the tube fuse page as of April 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 40.0% |

Japan

Japan

|

2 | 40.0% |

Taiwan

Taiwan

|

1 | 20.0% |

60 products found

60 products

SOC

930+ people viewing

Last viewed: 3 hours ago

SOC fuses are your circuit protection solution. In order to meet our customers' individual circuit protection needs, we offer a variety of options ...

10 models listed

Kawaso Texel Co., Ltd.

200+ people viewing

■Lead-free, environmentally friendly and durable copper integrated element structure ・Improved durability due to copper integrated element structu...

SOC

160+ people viewing

Last viewed: 28 minutes ago

Rush resistant, RoHS compliant, lead free

Furukawa Electric Manufacturing Co., Ltd.

170+ people viewing

Last viewed: 4 hours ago

It is used to protect customer service lines and electrical equipment from short-circuit currents that occur in low-voltage overhead distribution l...

Custom Co., Ltd.

1040+ people viewing

Last viewed: 18 hours ago

Information on exclusive/general -purpose storage cases and test leads for each product.

10 models listed

Kawaso Texel Co., Ltd.

170+ people viewing

Last viewed: 9 hours ago

■Lead-free, environmentally friendly and durable copper integrated element structure ・Improved durability due to copper integrated element structu...

Miniter Co., Ltd.

110+ people viewing

Last viewed: 1 day ago

■PFU-1.0A For C2212 ■PFU-2.0A For C2012/C2112