All Categories

History

This section provides an overview for lifting equipment as well as their applications and principles. Also, please take a look at the list of 18 lifting equipment manufacturers and their company rankings. Here are the top-ranked lifting equipment companies as of July, 2025: 1.Bison Lifting Equipment, 2.Elephant Lifting Products, 3.Lifting & Material Handling.

Table of Contents

Categories Related to Lifting Equipment

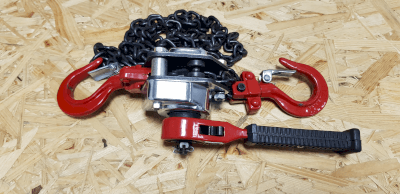

Lifting equipment refers to metal fittings designed to handle the loads required for suspending, moving, or securing goods and materials.

Lifting equipment refers to metal fittings designed to handle the loads required for suspending, moving, or securing goods and materials.

Available in various sizes and capacities, lifting equipment ranges from simple kitchen ladle hangers to complex slinging equipment used in crane operations across construction and civil engineering fields.

Specifically designed for hospital use, fixed lifting equipment, such as those used for hanging curtain rails, typically features a V-shaped design to evenly distribute the load on ceiling boards, essential in areas like hospital beds.

Lifting equipment is found in everyday applications, including S-shaped hooks in kitchens for utensils and rags, and more specialized indoor uses like hanging hops from ceilings with eyebolts.

Materials like plastic, wire, and steel are commonly used. For heavier duties, such as in building construction sites, steel U-shaped shackles are employed to lift steel materials and transfer heavy factory materials. These shackles, available in screwed and bolted types, are vital for heavy lifting and come in various forms like hook and ring types.

The defining feature of lifting equipment is the design of its connecting parts. U-shaped shackles, which can be screwed or bolted, are standard in the industry for their reliability in lifting heavy steel materials. Hook and ring types are other common forms.

Clap-type lifting equipment is used for horizontally suspending items like steel plates. The end loops in the hoisting wires, crucial for manual securing during slinging, make them suitable for heavy material lifting.

Fixed lifting equipment, typically installed on ceilings or top surfaces with steel or wire fittings and fixing screws, serves a crucial role in safely suspending heavy items.

Lifting equipment collectively referred to as slings, includes various types like nylon slings, used when the lifted object lacks a suspension ring. These nylon slings are band-shaped, attached to hooks, and wrap around the object, allowing for flexible slinging without surface damage.

Nylon slings are advantageous for their adaptability and surface protection but require careful centering of the load to prevent rotation.

Balances, a type of lifting equipment, are used for lifting columns, panels, and large construction equipment, especially when conventional slings are insufficient or the center of gravity is unstable.

They work by hanging from a crane hook, with multiple hooks from the balance itself used to lift the object. Some balances can accommodate chain blocks or wires, enabling load rotation post-lifting.

Available in various designs, balances can lift massive objects and are integral in large-scale lifting operations.

*Including some distributors, etc.

Sort by Features

Sort by Area

NMB Technologies Corporation, founded in 1951 with facilities in the USA, is a MinebeaMitsumi Group company and a manufacturer of electromechanical and semiconductor components such as small motors, backlights, sensors, and wireless technology. The company's products include cooling fans, precision small motors, mechanical bearing assemblies, battery protection components, and programmable drivers. NMB Technologies Corporation also offers custom design, engineering, and manufacturing to its customers in the automotive, robotics, medical, consumer technology, and industrial markets.

Elephant Lifting Products, founded in Gonzales, Louisiana, is a manufacturer of manual chain hoists, electric chain hoists, and pneumatic chain hoists. The company's product portfolio includes Hand Chain Hoists, Manual Chain Hoists, Lever Hoists, Pneumatic Hoists, Trolleys & Beam Crawls. Their products are used in shipyard, petrochemical, power, pulp / paper, construction, mining, offshore, and automotive industries. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

Ingersoll Rand Inc. is a manufacturer of flow creation and industrial products, founded in 1871, and headquartered in Davidson, North Carolina. It provides an array of compressors, from centrifugal to gas, reciprocating, high-pressure, and oil-free options. Additionally, it offers BOP handling systems, balancers, hoists, winches, and barring motors. Its services encompass replacement and repair, catering to various industries such as aerospace, construction, electronics, and power generation. The company quality management is reflected in ISO 9001 certification across most manufacturing facilities, and its products conform to international standards like ATEX, CE, DNV, and ABS.

Duff-Norton is a division of Columbus McKinnon Corp and was originally founded in 1883, now headquartered in Charlotte, North Carolina. Duff-Norton is an automation machinery manufacturer for aerospace, defense, automotive, entertainment, pharmaceutical, food processing, paper, energy, rail/road, and energy supply industries. Duff-Norton manufactures standard and customer-designed screw jacks (mechanical actuators), linear actuators (electro-mechanical actuators), modulator actuators, swivel joints, electric cylinders, rotary unions (rotating joints), acme and ball screws, nuts and rail maintenance equipment to customers globally.

Bison Lifting Equipment, established in 1988 and headquartered in Oakland, New Jersey, USA, is a manufacturer of lifting and material handling equipment. Electric chain hoists, lever hoists, hand chain hoists, and an assortment of specially constructed jib and gantry cranes are all part of the product line. These superior products have sturdy construction, stability, and precision, which make them essential tools for an array of lifting tasks. It provides effective and secure solutions for lifting and material handling operations across a broad range of industries, including manufacturing, construction, logistics, and warehousing.

Lift-All Co., Inc., founded in 1964 with headquarters in the USA, is a manufacturer of rigging, hoisting, and crane equipment and accessories. The company's products include tie-down assemblies, sling protection, rigging hardware, load hugger cargo control straps, and winches. Lift-All Co. also designs, engineers, and manufactures custom below-the-hook lifting devices to meet client-specific requirements and are used by individual contractors, commercial operators, and manufacturers for lifting and material handling. The company's products are available to drop shippers and distributors through the company's website.

Sinotech is based in Portland, Oregon with offices in China. Sinotech is a distributor for custom-engineered electrical motors, motor components, and mechanical components manufactured in China. Sinotech’s motors include AC motors, DC motors, brushless DC motors, slotless high speed BLDC motors, stepper motors, cordless motors, gear motors, servo motors, and miniature motors. Motor components include laminations, wound coils, armature and field coils, brushes, and communicators. Mechanical components include assemblies, die castings, investment castings, sand castings, shafts, steamed metal parts, tubular metal parts, machined extrusions, plastic parts, rubber parts, and secondary processing.

Handling Concepts, founded in 2005 and headquartered in Stoke Prior Bromsgrove, Worcestershire, is a manufacturer of manual handling solutions. The company offers a diverse product portfolio, including bespoke lifting equipment, below-the-hook lifting devices, and mobile lifting equipment. These handling solutions find applications in various industries, including panel boards and sheets, paper, and flexibles, and pick and packing. It aims to enhance the safety and efficiency of businesses. Additionally, it extends services like full installation of the machines, equipment training, and sales of critical spare packages.

Ayerbe Industrial de Motores, S.A., founded in 1992 and located in Ayerbe, Spain, is a manufacturer of electrogenerator sets. The company offers a broad range of products, including electrogenerator sets, industrial engines, welding equipment, and water pumps, serving the power generation and industrial machinery sectors. It holds ISO 9001 certification for stability and performance, and its electrogenerator sets provide stable and consistent power generation, offering benefits like consistent energy supply and the ability to operate in diverse environments. These adaptive products find applications in various industries, including construction, agriculture, emergency backup power, and more.

Oz Lifting Products LLC, established in 2004 and based in Winona, Minnesota, United States, is a manufacturer of lifting and material handling equipment. The company produces various products such as chain hoists, beam trolleys, winches, and lever hoists in oil & gas, construction, mining, aviation, and automotive industries. The company also manufactures davit cranes, which are built with safety features to prevent product overload. The hoist capacities offered by the company range from 500 lbs to 1000 lbs to use in different applications.

Pewag International GmbH is a manufacturer and distributor of chains and related products for the industrial sector originally established in Klagenfurt, Kärnten, Austria, in 1479. The company primarily produces standard chains for industrial applications such as hauling or forestry, snow chains for ensuring vehicle safety in icy conditions, and tire protection chains for protecting tires in rugged environments. It also offers lifting points for securing riggings and hoists in conjunction with its selection of chains. The company chiefly serves clients in the automotive and transportation sectors.

Tiger Lifting is located in Amble, Morpeth, UK, and has been a manufacturer and distributor of material handling and lifting equipment since 1963. The company is ISO 9001:2015 certified and provides clamping, supra digital chips, yokes manual, and pneumatic hoisting. The company's products can withstand heavy-duty applications and ensure the efficiency of lifting operations in different industries. The company also offers 3D product drawing, user guides, bespoke lifting solutions, product documentation, and support services to customers.

Airpes is a manufacturer and supplier of heavy machine equipment and weighing systems intended for customers in the wind energy and industrial markets. The company was established in 1988 and situated at Sabadell Spain The company offers a range of products and services such as overhead cranes, lifting beams, weighing systems, load cells, and custom lifting solutions. The company is known for its engineering proficiency and allegiance to develop tailored solutions that meet the specific needs of its clients.

Toyota Material Handling is a manufacturer and distributor of forklifts and other material-handling equipment. It is headquartered in Columbus, Indiana, and was established in 1956. The company's products include electric forklifts, gas forklifts, reach trucks, order pickers, and pallet jacks. It also offers services, such as parts and services, financing, and training. The company also offers other material handling equipment, such as pallet jacks, order pickers, and automated guided vehicles. Toyota Material Handling products are used in multiple industries, including manufacturing, warehousing, and distribution. Toyota Material Handling is a subsidiary of Toyota Industries Corporation, a Japanese multinational conglomerate.

TAWI North America, established in Sweden in 1923, is a supplier of ergonomic lifting solutions. The company offers lifting equipment like vacuum lifters, hoists, and cranes, designed to streamline material handling processes across various industries. Driven by a devotion to creating safe and efficient workplaces, TAWI North America provides lifting solutions that reduce the risk of injuries and improve productivity. Their products cater to manufacturing, logistics, and healthcare sectors, enabling workers to handle heavy loads with ease.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Bison Lifting Equipment |

11.2%

|

| 2 | Elephant Lifting Products |

9.3%

|

| 3 | Lifting & Material Handling |

8.9%

|

| 4 | Duff-Norton |

7.6%

|

| 5 | NMB Technologies Corporation |

7.1%

|

| 6 | Lift-All Co., Inc. |

6.9%

|

| 7 | Tiger Lifting |

6.0%

|

| 8 | Oz Lifting Products LLC |

5.8%

|

| 9 | TAWI North America |

5.0%

|

| 10 | Martec Co., Ltd. |

5.0%

|

Derivation Method

The ranking is calculated based on the click share within the lifting equipment page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 50.0% |

Spain

Spain

|

2 | 14.3% |

United Kingdom

United Kingdom

|

1 | 7.1% |

Japan

Japan

|

1 | 7.1% |

Austria

Austria

|

1 | 7.1% |

Taiwan

Taiwan

|

1 | 7.1% |

Sweden

Sweden

|

1 | 7.1% |

1,481 products found

1,481 products

Taiyo -maker Kogyo Co., Ltd.

670+ people viewing

Last viewed: 1 day ago

■ It is possible to attach and detach the sling With the removable link, the connection with various slings such as wire lap slings can be easily w...

2 models listed

Ozak

680+ people viewing

Last viewed: 8 hours ago

"Pull and hang. It keeps the hanging load safely and reliably." Since the hook's own weight or imbalance does not come off, each hook can be safe a...

Ozak

2210+ people viewing

Last viewed: 2 hours ago

Lightweight and compact hanging balance ・ Because it is ultra -light than the conventional product, it is easier to replace the balance. ・ The size...

8 models listed

ibig Co., Ltd.

280+ people viewing

Last viewed: 4 hours ago

This is a safe and secure high quality domestic JIS standard wire rope. There are various types of work involved, and in recent years there has bee...

Ozak

460+ people viewing

Last viewed: 21 hours ago

An improved type of innovative hanging device "Nobunaga's arm". With a total of four hooks and a hook storage case, while keeping the hook chain ex...

Miki Neturen Co., Ltd.

920+ people viewing

Last viewed: 8 hours ago

■Features 1. The structure is designed to engage with stronger force as the lifting load increases. 2. The cam can be closed or locked in the open ...

10 models listed

ibig Co., Ltd.

250+ people viewing

Last viewed: 3 hours ago

This is a safe and secure high quality domestic JIS standard wire rope. There are various types of work involved, and in recent years there has bee...

AWJ Co., Ltd.

230+ people viewing

Last viewed: 21 hours ago

Four advantages of elastomers that are ideal for support fittings ■ Can be used at 98℃ at all times The elastomer we use has a embrittlement temper...

Futaba Manufacturing Co., Ltd.

350+ people viewing

Last viewed: 9 hours ago

■“Speed” electric chain hoist building a new era of cargo handling work through advanced technological development The "Speed" electric chain hoist...

Miki Neturen Co., Ltd.

450+ people viewing

Last viewed: 4 hours ago

■Features 1. Special alloy steel The main body and each part are made of special alloy steel that is suitable for each. 2. Powerful cam As the lif...

3 models listed

Best Answer Co., Ltd.

270+ people viewing

Last viewed: 14 hours ago

■Applications It is used in many situations such as cargo tightening in the transportation industry, maintenance of equipment and machinery, the co...

Ozuna Co., Ltd.

250+ people viewing

Last viewed: 15 hours ago

■Reduces repulsive force by 70% Repulsion force is reduced by 70-75% compared to 6x37 A type. Since it is easy to handle and feels light, it reduce...

ibig Co., Ltd.

270+ people viewing

Last viewed: 7 hours ago

This is a safe and secure high quality domestic JIS standard wire rope. There are various types of work involved, and in recent years there has bee...

AWJ Co., Ltd.

230+ people viewing

Last viewed: 8 hours ago

Four advantages of elastomers that are ideal for support fittings ■ Can be used at 98℃ at all times The elastomer we use has a embrittlement temper...

Futaba Manufacturing Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

■“Speed” electric chain hoist building a new era of cargo handling work through advanced technological development The "Speed" electric chain hoist...

Nobuta Agricultural Machinery Co., Ltd.

230+ people viewing

Last viewed: 11 minutes ago

■Features ・No dead stroke, can be hung high ・The length of the hanging rod can be adjusted and the direction changed just by replacing the pin. ...

Miki Neturen Co., Ltd.

710+ people viewing

Last viewed: 15 hours ago

■Features 1. Clamps can be selected according to the thickness of the suspended object. 2. The structure is designed to engage with stronger force ...

7 models listed

Ozuna Co., Ltd.

250+ people viewing

Last viewed: 7 hours ago

■T-LOC processing to ensure high strength By pressing a steel sleeve in addition to the conventional aluminum clamp tube at the same time, it preve...

ibig Co., Ltd.

240+ people viewing

Last viewed: 21 hours ago

This is a safe and secure high quality domestic JIS standard wire rope. There are various types of work involved, and in recent years there has bee...

AWJ Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

Four advantages of elastomers that are ideal for support fittings ■ Can be used at 98℃ at all times The elastomer we use has a embrittlement temper...

Futaba Manufacturing Co., Ltd.

290+ people viewing

Last viewed: 14 hours ago

■“Speed” electric chain hoist building a new era of cargo handling work through advanced technological development The "Speed" electric chain hoist...

Miki Neturen Co., Ltd.

240+ people viewing

Last viewed: 14 hours ago

■Features 1. Special alloy steel The main body and each part are made of special alloy steel that is suitable for each, and are die-forged and heat...

Almetax Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

This hook S can be used in the entryway, living room, or bedroom to hang various items such as hangers and hats. The simple shape of the S hooks cr...

Ozuna Co., Ltd.

160+ people viewing

Last viewed: 21 hours ago

■High strength 6x37 The breaking load is approximately 30% higher than 6x37 A type. When used as a sling, the rope diameter can be reduced from 22φ...

ibig Co., Ltd.

290+ people viewing

Last viewed: 11 hours ago

This is a safe and secure high quality domestic JIS standard wire rope. There are various types of work involved, and in recent years there has bee...

AWJ Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

Four advantages of elastomers that are ideal for support fittings ■ Can be used at 98℃ at all times The elastomer we use has a embrittlement temper...

Futaba Manufacturing Co., Ltd.

300+ people viewing

Last viewed: 14 hours ago

■“Speed” electric chain hoist building a new era of cargo handling work through advanced technological development The "Speed" electric chain hoist...

Light Staff Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

Comes with breakaway mechanism (safety device). It is a mechanism that comes off when strong force is applied. Breakaway (safety device) This is an...

Miki Neturen Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

■Features 1. The clamper increases in proportion to the increase in load and strongly clamps the suspended object. 2. Place the lock spring on the ...

4 models listed

Almetax Co., Ltd.

210+ people viewing

This large hook can be used in the entryway, living room, or bedroom to hang various items such as bags and hats. The L hooks have a simple shape b...