9 Detector Tube Manufacturers in 2024

This section provides an overview for detector tubes as well as their applications and principles. Also, please take a look at the list of 9 detector tube manufacturers and their company rankings. Here are the top-ranked detector tube companies as of July, 2024: 1.Uniphos Envirotronic Pvt Ltd, 2.SKC Ltd, 3.Galleon Instru-Tech Private Limited.

Table of Contents

What Is a Detector Tube?

Specific Detector Tubes for Each Gas Type

Specific Detector Tubes for Each Gas Type

Detector tubes are tools for measuring gas concentrations, such as harmful hydrogen sulfide or flammable hydrogen. Each type of gas requires a dedicated detector tube.

Variety of Detector Tubes for Short and Long-Term Measurement

Detector tubes are available for measuring gas concentrations over short or extended periods. Their ease of use involves drawing the gas through a piston.

Applications of Detector Tubes

Environmental Monitoring in Manufacturing and Construction

Detector tubes, simple to operate, are widely used in manufacturing and construction for environment monitoring and legal compliance, especially for detecting flammable gases to prevent explosions and ignitions.

Pollution Control and Research

These tubes are also utilized for controlling pollution by measuring air contaminants and analyzing gases in chemical reactions for research purposes.

How Detector Tubes Work

Gas Concentration Measurement Through Reaction

Detector tubes contain a reactive substance that changes color upon reacting with the target gas, providing a visual quantification. Each tube type has specific quantitation and detection limits.

Applications in Hazardous Environments

In high-risk or oxygen-deficient areas, remote sampling tubes are used to measure gas concentrations safely.

Specific Tubes for Specific Compounds

Each detector tube is specific to a particular compound and has an expiration date. It's crucial to check this before use and to sample at multiple points due to potential gas distribution variances.

Kitagawa Gas Detector Tubes

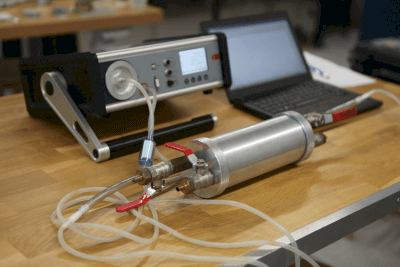

Kitagawa gas detector tubes consist of a detector and a gas sampler, used since 1947, primarily for hydrogen sulfide detection. The color change in the detector agent upon reaction indicates the gas concentration.

This method allows for rapid onsite measurement of flammable gases, preventing potential fires or explosions. The tubes are prepared with a chip cutter, inserted into the sampler, and then the discolored boundary is read for concentration assessment.

Detection Conditions for Various Gases

For ammonia gas, the measurement range is less than 30 ppm and the detection limit is about 0.2 ppm when the gas is aspirated once (100 ml). The presence of ammonia causes a neutralization reaction (2NH3 + H2SO4 → (NH4)2SO4) with sulfuric acid, which changes the indicator from pink to yellow.

The measurement range of oxygen is 3-6%, with a detection limit of about 2% for a single aspiration (100 ml). When oxygen is present, the reaction with titanium trichloride (O2 + 4TiCl3 (black) + 6H2O → 4TiO2 (white) + 12HCl) produces titanium oxide, which causes the indicator to change from black to white.

Carbon dioxide has a measurement range of 100 to 2000 ppm with a detection limit of about 20 ppm for a single aspiration (100 ml). The presence of carbon dioxide causes a neutralization reaction (CO2 + 2KOH → K2CO3 + H2O) with potassium hydroxide, which changes the indicator from light red to orange.

List of 9 Detector Tube Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Australia

- India

- Japan

- United Kingdom

-

-

-

Honeywell International Inc

Gas Detection Tubes

Manufacturer Overview

Honeywell International Inc. was founded in 1885 and headquartered in Charlotte, North Carolina. Honeywell is a diversified technology and manufacturing company to global customers in many industries such as aerospace, building technologies, performance materials, manufacturing, and safety. Honeywell produces hardware and software solutions for each industry it serves. In building technologies, Honeywell designs access controls, electrical and wiring, fire life safety, and employee training services. In aerospace, Honeywell designs cockpit systems and displays, engines, cabin management and cleaning, and health and usage monitoring.

-

-

-

-

-

Sensidyne, LP

Gas Detector Tubes

Company Overview

Sensidyne is an American manufacturer and distributor of industrial air monitoring and safety equipment founded in 1983 and acquired by the German company Schauenburg International GmbH in 2008. Based in St. Petersburg, Florida, the company offers various products including aerosol and heat stress monitors, sound and vibration measurement equipment, air sampling instrumentation, and gas detector tube systems. Sensidyne also provides additional OEM, in-house calibration, and maintenance services for clients requiring additional support.

-

-

-

-

-

GASTEC CORPORATION

Detector tube

Manufacturer Overview

GASTEC CORPORATION, established in 1970 in Kanagawa, Japan is a manufacturer and supplier of gas measurement systems. The company's product range includes Gas Detector Tube Systems, Detector Tubes, Gas Sampling Pump Kits, and Calibration Gas Generation Systems. These systems are crucial for environmental monitoring, safety control, and contamination testing. They predominantly serve sectors like firefighting, shipping, and residential monitoring. In addition, the company offers technical support, quality assurance, and calibration services.

-

-

-

-

-

Dräger

Gas Detection Tubes

Manufacturer Overview

Dräger, established in 1889, and headquartered in Lübeck, Germany, is a manufacturer and supplier of advanced safety and medical technology products. They offer a range of solutions, including gas detection systems, respiratory protection equipment, patient monitoring systems, ventilators, and anesthesia machines, which are designed for industries such as oil and gas, chemical, firefighting, healthcare, and mining. Dräger is certified with ISO 9001 for quality management and ISO 13485 for medical devices.

-

-

-

-

-

Instrumex

Gas Detector Tubes

Company Overview

Instrumex, established in 1995, is a distributor of precision measurement instruments based in the United States. The company specializes in providing a wide range of quality measuring tools and equipment to industries like manufacturing, engineering, and research. Their product portfolio includes digital calipers, micrometers, force gauges, and more, designed to meet the diverse needs of their target audience. Instrumex aims to empower professionals with the tools they need to ensure precise measurements and optimal performance. The company's devotion to quality and customer satisfaction is evident in their partnerships with reputable manufacturers and their consistent attention on delivering cutting-edge measurement solutions.

-

-

-

-

-

Gastech

Detector Tubes

Company Overview

Gastech, established in 1978 and based in Frenchs Forest, New South Wales, Australia, is an ISO 9001-certified manufacturer and supplier of gas detection systems. The company offers fixed gas detectors utilizing electrochemical technology, portable gas detectors for adverse field conditions, and emissions analyzers for measuring flue gas emissions. It also offers flame detectors for self-contained or harsh industrial environments. The company’s products are used by clients in the energy, oil and gas, and chemical industries.

-

-

-

-

-

-

-

-

-

Uniphos Envirotronic Pvt Ltd

Gas Detector Tubes

-

-

Detector Tube Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Uniphos Envirotronic Pvt Ltd |

20.0%

|

| 2 | SKC Ltd |

20.0%

|

| 3 | Galleon Instru-Tech Private Limited |

13.3%

|

| 4 | Instrumex |

13.3%

|

| 5 | Gastech |

6.7%

|

| 6 | Sensidyne, LP |

6.7%

|

| 7 | Dräger |

6.7%

|

| 8 | GASTEC CORPORATION |

6.7%

|

| 9 | Honeywell International Inc |

6.7%

|

Derivation Method

The ranking is calculated based on the click share within the detector tube page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Dräger: 16,219

- GASTEC CORPORATION: 180

Newly Established Company

- Galleon Instru-Tech Private Limited: 2010 (14 years ago)

- Instrumex: 1990 (34 years ago)

- Gastech: 1978 (46 years ago)

Company with a History

- Dräger: 1889 (135 years ago)

- SKC Ltd: 1962 (62 years ago)

- GASTEC CORPORATION: 1970 (54 years ago)

Detector Tube Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Detector Tube Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 28.6% |

India

India

|

2 | 28.6% |

Japan

Japan

|

1 | 14.3% |

Australia

Australia

|

1 | 14.3% |

United Kingdom

United Kingdom

|

1 | 14.3% |

List of Detector Tube Products

10 products are listed.