All Categories

History

This section provides an overview for extension springs as well as their applications and principles. Also, please take a look at the list of 30 extension spring manufacturers and their company rankings. Here are the top-ranked extension spring companies as of February, 2026: 1.The D.R. Templeman Co., 2.Dongguan Huiyang Precision Spring Co., Ltd, 3.Federno.

Table of Contents

Categories Related to Extension Springs

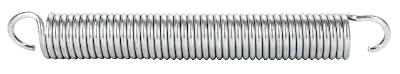

An extension spring, also known as a tensile spring or pull spring, is a type of spring that primarily expands and contracts when subjected to a pulling force.

It is created by coiling long wires into a spiral shape and is commonly used for various applications, ranking second only to compression coil springs. Due to their tightly wound structure with no gaps between coils, they can generate substantial pulling force in a relatively confined space.

This capability enables the transmission of significant forces within limited spaces and allows for customization by adjusting wire thickness and coil diameter to suit different requirements.

However, it's essential to note that while extension springs excel at responding to pulling forces, they have limited resistance when compressed. It's crucial to use them in the correct orientation to prevent deformation or breakage. Additionally, considering material properties and elastic limits is vital.

Extension coil springs find use in various applications, leveraging their robust tensile strength. The following are common applications of extension coil springs.

Motorcycle and bicycle side stands are employed to stabilize the vehicle while parked. Some side stands incorporate mechanisms for retracting them when not in use, often facilitated by extension springs.

Extension springs are widely used in household appliances and furniture drawers. They store energy when doors and drawers are closed, ensuring smooth operation. Additionally, they play a vital role in the mechanisms of sofas and beds, enabling reclining and unfolding movements.

In sports and fitness equipment, extension springs serve to control specific functions, frequently found in the adjustable parts of training equipment or the moving components of sports gear. Examples include expanders used in training equipment.

They are also employed in the moving parts of toys and model applications. You can often find them in the deployment mechanisms of airplane and vehicle models.

The principle governing extension springs is based on the elastic deformation property resulting from the spiral winding of wire. It exhibits a response to pulling forces, with elastic deformation and Hooke's law as key principles. When an external pulling force is applied to an extension spring, the wire elongates and deforms.

This deformation is temporary, and upon removal of the external force, the spring attempts to return to its original shape, following the principles of elastic deformation as defined by Hooke's law.

Hooke's law states that the force exerted on a spring is directly proportional to its displacement. By multiplying the displacement by the spring constant, one can determine the stored force. Extension springs can repeatedly undergo elastic deformation as long as they remain within the elastic limit of the material.

However, exceeding the elastic limit can result in permanent deformation or fracture. Therefore, when selecting and designing materials, it's crucial to consider the elastic limit appropriately.

Several factors must be considered when choosing extension coil springs.

The choice of material for extension springs significantly impacts their strength and durability. Common materials include steel and stainless steel. Material selection should align with the expected load and environmental conditions.

The spring constant, which relates displacement to force, plays a pivotal role. A higher spring constant results in greater force for the same displacement. Thus, it's essential to select an appropriate spring constant considering the required tension and displacement for your application.

The shape of the extension spring's tip influences installation and application. Hook-shaped tips are easier to install, while ball-shaped or other configurations may be suitable for specific applications. When choosing a tip shape, consider the mounting method and its interaction with the components involved.

The free length refers to the spring's length in an unloaded state. As the required spring length varies depending on the application, design dimensions, and available space for installation, it's important to choose an appropriate free length to avoid excessive compression or extension.

*Including some distributors, etc.

Sort by Features

Sort by Area

Fennell Spring Company, founded in 1945 and headquartered in New York, USA, is a manufacturer of precision springs. The company supplies precision springs and wire forms for various applications including automotive, aerospace, and medical. These springs and wire forms are offered in diameters of .005 inches to .250 inches in various raw and pre-plated materials. The product range includes torsion & clutch springs, extension springs, and compression springs. The company complies with the quality standards of ISO 9001:2015 and CQI-9.

Coiling Technologies, Inc., established in 1976 and headquartered in Houston, Texas, is an ISO certified custom spring manufacturer catering to industries like aerospace, defense, medical, and transportation. Holding ISO 9001:2015 certification for quality management, the company produces various springs such as compression springs for shock absorption, extension springs for tension, torsion springs for energy storage, wave springs for controlled motion, and wire forms for various applications. Beyond springs, It also offers services like heat treating, powder coating, and assembly.

Dayton Lamina is a subsidiary of MISUMI Group Inc. formed in 2014 in Ohio and is the manufacturer and supplier of a diverse range of metal stamping products, dies, punches, and more. Dayton Lamina is subsumed by other brands namely, Lempco, Danly IEM, Lamina, and Dayton Progress. Each of these brands has its own production line such as Lempco serves the canning, electronics, and automotive industry with its die set guidance system. Danly IEM manufactures die and mold components along with Lamina. Dayton Progress designs catalogs and brochures for the die and punch market.

Gardner Spring, Inc., since 1907, has been a manufacturer and supplier of springs such as compression springs, extension springs, disc springs, and extensions such as safety drawbar extensions, utility extensions, double-looped extensions, cot extensions, and ulta precision extensions used in OEM, industrial, kitchen appliances, aerospace components, and hardware industries. Located in Tulsa, OK, the company is woman-controlled and a member of the National Association of Manufacturers, C200, Spring Manufaturer Institute, Ahma, and Tama associations.

Peterson Spring is a manufacturer and supplier of springs, wire forms, and related products. Established in 1914, the company is headquartered in Southfield, Michigan, USA. The company's main activities revolve around designing, engineering, and producing a wide array of springs and wire forms such as springs, snap-rings, wire forms, clips, clamps, stampings, and other types of sub-assemblies for various industries including automotive, aerospace, and medical. Its main services include precision manufacturing, rapid prototyping, and engineering support. Peterson Spring also specializes in offering customized solutions to meet specific customer needs

Gifford Spring Company, established in 1984 and headquartered in Garland, Texas, United States, is a manufacturer and supplier of precision springs for original equipment manufacturers. The company's core products include wire forms, compression springs, and torsion springs. These products are used in various products and equipment, including home appliances, medical devices, and agricultural tools. Its services include prototyping, custom design, and engineering. It serves various sectors, including retail store equipment, outdoor sporting goods, and aerospace component manufacturers.

The D.R. Templeman Co. (DRT) is a Plainville, Connecticut-based manufacturer of custom springs and wire forms at sizes ranging from 0.004” to 0.080”. Founded in 1938, the company serves various multinational OEMs including Boston Scientific, Rubbermaid, ITW, and Tyco. The company produces a range of springs, such as torsion and compression models utilized in medical and electronic devices, as well as functional components like custom rings for sealing or connecting, and wire forms for fastening or guiding. DRT also offers various stock springs, along with quality control, testing, packaging and shipping services.

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Lee Spring Company, founded in 1918, is an American manufacturer headquartered in Brooklyn, New York, specializing in custom springs. The company produces various custom springs, including compression, extension, and torsion springs. Under brands such as REDUX, HEFTY, and LeeP, the company offers wave, die, and plastic composite springs. Other types of springs, like battery, constant force, and continuous length extension springs, are also available. The company also provides MIL-SPEC spring series, MS24584 and MS24586, meeting the technical requirements for military and aerospace applications. Additionally, the company offers Belleville washers, used in compression spring applications that require high loads within limited spaces.

Lesjofors Springs America, Inc., established in 1852 and headquartered in Pittston, Pennsylvania, USA, is a manufacturer of industrial springs and presses. The company offers a diverse range of products, including compression springs, extension springs, torsion springs, and gas springs. These optimal-quality springs provide solid durability, precision, and stability, delivering optimal performance in various applications. It serves a wide array of industries, including automotive, aerospace, electronics, and manufacturing, where the springs are employed in machinery, vehicles, and other critical systems.

Spring Dynamics, a company founded in 1985 and based in Michigan, the United States, is a manufacturer of custom springs and wire forms for various industries. The company manufactures a wide range of products, including counterbalance springs, custom torsion springs, extension springs, compression springs, and torsion rods. These products have several coatings and finishes options, such as phosphate and soap, Teflon PTFE, zinc, and plastisol dip. It obtained ISO/TS-16949:2009 and IATF 16949 certifications. Its products primarily serve the automotive, agricultural, construction, appliance, and appliance industries.

Spiros Industries is an ISO 13485:2016 and IATF 16949:2016-certified custom manufacturer of springs and wire forms for OEMs established in 1991 and located in West Bend, Wisconsin, USA. The company produces extension springs for providing tension when extended, compression springs for standard spring force applications such as in car suspensions, and torsion springs for rotational applications. It also offers wire forms shaped and sized to customer specifications. The company mainly serves OEMs in the automotive, machine tools, and home appliance industries.

Springmasters Ltd was founded in 1972 and is headquartered in Redditch, United Kingdom, as a manufacturer of coil springs. The company specializes in producing and maintaining various spring goods, including compression springs, extension springs, torsion springs, flat springs, wire forms, retention rings, and clock-type springs. The company also maintains a substantial inventory of these items. Springs of various materials and finishes can be manufactured throughout a broad spectrum, allowing for the customization of unique springs and wireforms according to individual requirements. Springmasters has emerged as a manufacturer and supplier of die and disc springs in Europe.

KERN-LIEBERS Ltd., established in 1977 and based in Gainsborough, Lincolnshire, United Kingdom, is a manufacturer of a wide range of constant force, power, and spring assemblies. The company specializes in manufacturing components and systems including springs, stamped & fine-blanked parts, wire parts, and more. These components find applications in a wide array of industries, including automotive, medical technology, electronics, and engineering sectors. The company was awarded the Industry Excellence Award in 2016 and the Innovation Pioneer Award in 2019. It holds certifications such as ISO 9001 and ISO/TS 16949 for quality management.

Fusehatu Kogyo Co., Ltd., founded in 1946 with headquarters in Higashiosaka City, Japan, is a manufacturer of springs and assemblies. The company's product line includes treated and straight-cut spring materials, custom-made springs, spring assemblies, and spring units (springs, plastics, and bolts). These products are primarily made to order, and custom products can be continually produced for clients with ongoing high-volume orders. The company serves many industries, including electronics manufacturing, appliance manufacturing, and vehicle suspension makers.

MW Industries, started in 1861 and based in North Carolina, US, is a manufacturer of a wide array of precision components and products. The company produces threaded insert screws, nuts plain, and stock extension springs. Its products are used in automotive, construction, and machinery fields across the USA, Switzerland, and China. The company holds ISO 9001, ISO 13485, and IATF 16949:2016 certifications. Its products comply with the ITAR, REACH, and RoHS standards.

Tokai Springs industries, lnc., established in 1944 and based in Osaka, Japan, is a manufacturer and supplier specializing in the production of custom-made springs. The company offers a range of metal springs, including hot-formed compression springs, cold-formed compression springs, disc springs, flat springs, and extension springs. These springs find application in various industries, including aerospace, machine tools, robotics, architecture, seismic isolation, and various other sectors. The company holds ISO 9001, ISO 14001, and JIS Q 9100 certifications, which are accredited in accordance with ISO and JIS standards.

ASRaymond, founded in 1883, is a manufacturer and supplier of springs, metal components, functional assemblies, and hardware solutions. The springs comprise compression, lock-in-place, traction, and reducible force springs with spring washers and speed reducers. Mounting hardware includes ball studs, mounting brackets, end-fittings, and accessories utilized in the construction, aerospace, lift equipment, medical, and military industries. The Ste. A Maumee, Ohio-based company is ISO and TS certified and provides application engineering services, distribution and packaging, finishing and coating, warehousing, and customisation choices.

Murphy & Read Spring Mfg. Co., Inc. (MRS) is an American ISO 9001 certified manufacturer of various springs that was established in 1917. Based in Philadelphia, Pennsylvania, the company produces custom and standard springs including compression, extension, torsion, and military specification (MILSPEC) models. They also offer limited metal fabrication capabilities such as stamping, machining, and turning for related small assemblies. MRS primarily serves clients in the aerospace, general manufacturing, transportation, and energy sectors. They maintain a network of sales offices and partner distributors across the United States, Canada, and Mexico.

Kehr-Buffalo Wire Frame is a private enterprise established in 1953, with its headquarters situated in Buffalo, New York, and holds a good position in the business as a maker of springs, wire forms, and point-of-purchase (POP) displays. Kehr-Bufallo Wire Frame currently engages in the production of wire forms, springs, and point-of-purchase displays. The company offers its clientele sophisticated functionalities about lean production and adherence to ISO standards. The organization employs a highly skilled workforce that consistently demonstrates efficiency and adaptability in meeting consumer demands.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | The D.R. Templeman Co. |

7.5%

|

| 2 | Dongguan Huiyang Precision Spring Co., Ltd |

4.5%

|

| 3 | Federno |

4.5%

|

| 4 | Ashfield Springs Ltd |

4.5%

|

| 5 | Elite Springs Pte Ltd |

4.5%

|

| 6 | Springmasters Ltd |

4.5%

|

| 7 | Spring Dynamics |

4.5%

|

| 8 | Spiros Industries |

4.5%

|

| 9 | Peterson Spring |

4.5%

|

| 10 | Lee Spring Co. |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the extension spring page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

15 | 57.7% |

Japan

Japan

|

5 | 19.2% |

United Kingdom

United Kingdom

|

2 | 7.7% |

China

China

|

2 | 7.7% |

Singapore

Singapore

|

1 | 3.8% |

Turkey

Turkey

|

1 | 3.8% |

161 products found

161 products

Toei Spring Co., Ltd.

290+ people viewing

■ Materials used Line spring ・ Stainless steel: SUS304WPB, SUS316, SUS631, etc. ・ Piano line: SWP-A, SWP-B ・ Hard steel wire: SW-C (80C), SW-B (...

3 models listed

Komura Sangyo

890+ people viewing

Last viewed: 1 hour ago

In general, it is a spring that uses the operation of pulling and returning by pulling the coil part and attaching a hook to both ends. The shape o...

Shinsei Hatsujo Industries Co., Ltd.

630+ people viewing

Last viewed: 15 hours ago

■Features Like compression springs, tension springs are often used in precision machinery, home appliances, and chair springs. In particular, with ...

Suzuki Spring Manufacturing Co., Ltd.

460+ people viewing

The tension spring supports the function of producing "return". Our company supplies products mainly to the automotive field. We stably supply prod...

Accurate Co., Ltd.

610+ people viewing

■Summary Ultraspring series tension coil spring standard. A total of 882 types. ■Spring characteristics The UltraSpring tension coil spring series...

Riken Hatsujo Industries Co., Ltd.

330+ people viewing

Last viewed: 1 hour ago

Riken Hatsujo Kogyo can manufacture various shapes. We will consider the shape of the hook according to the application in order to satisfy the spe...

2 models listed

Kyoshin Hatsujo Co., Ltd.

340+ people viewing

A spring with hooks on both ends that is used by pulling. These springs can be used in a wide variety of industries and applications, including aut...

Showa Hatsujo Manufacturing Co., Ltd.

530+ people viewing

Last viewed: 16 hours ago

■Sun-S spring With a rich lineup of 919 types of compression springs, 424 types of tension springs, 104 types of one-size-fits-all tension springs,...

Riken Hatsujo Industries Co., Ltd.

410+ people viewing

Riken Hatsujo Kogyo's ultra-fine and ultra-small springs are available in a variety of shapes, including compression coil springs, tension coil spr...

Samini Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Unit price by order quantity (yen) ・1-4:650 ・5-9:600 ・10-19:550 ・20-50:500

Samini Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■Unit price by order quantity (yen) ・1-9:450 ・10-29:420 ・30-420:380

Samini Co., Ltd.

410+ people viewing

■Unit price by order quantity (yen) ・1-4:210 ・5-9:165 ・10-19:100 ・20-49:66 ・50-99:43 ・100-199:40 ・200-499:36 ・500-999:32 ・1,000-1,999:27 ...

2 models listed

Samini Co., Ltd.

530+ people viewing

This product is made to order, so please refrain from canceling your order.

Samini Co., Ltd.

290+ people viewing

Last viewed: 5 hours ago

This product is made to order, so please refrain from canceling your order. ■Unit price by order quantity (yen) ・Volume 11-12: 1-2 pieces (780), ...

Samini Co., Ltd.

340+ people viewing

This product is made to order, so please refrain from canceling your order. ■Unit price by order quantity (yen) ・50-100mm: 1-2 pieces (2,000), 3-...

Samini Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■Unit price by order quantity (yen) ・1-19: 3,100 ・20-22: 2,800

Samini Co., Ltd.

310+ people viewing

Last viewed: 32 minutes ago

■Features ・Bone springs support external loads and viscoelastic bodies absorb vibrations. ・Spring that does not bounce ・Patent applied for ■Uni...

Samini Co., Ltd.

360+ people viewing

■Features A general-purpose buffer spring for suspension and tension. Used to support pipes and heavy cables. For buffering other vibration isolato...

Yoshikawa Shoko Co., Ltd.

240+ people viewing

Last viewed: 20 hours ago