All Categories

History

This section provides an overview for oilless bearings as well as their applications and principles. Also, please take a look at the list of 23 oilless bearing manufacturers and their company rankings. Here are the top-ranked oilless bearing companies as of February, 2026: 1.Zhejiang Waxing Electromechanical Co., Ltd., 2.Ivy Fine Chemicals, 3.JBSTEC.

Table of Contents

Categories Related to Oilless Bearings

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

Gland packing is a sealing material that is attached to the outer surface of a rotating or reciprocating shaft to seal the inside and outside of a machine or facility.

Gland packing is used for shaft sealing of shaft penetrations in machinery and equipment. Gland packing is defined as "a generic term for packing that is square or round in cross section and used for stuffing into stuffing boxes."

Note that gland packing is not a perfect axial seal and is subject to some leakage. In pumps, however, leakage between the shaft and gland packing may be necessary to lubricate and cool the gland packing.

The gland packing principle of the gland packing is that the inner surface of the gland packing (shaft side) adheres to the outer surface of the shaft and the outer surface of the gland packing (housing side) adheres to the inner surface of the stuffing box, filling the gap between them and preventing fluid leakage by the contact surface pressure.

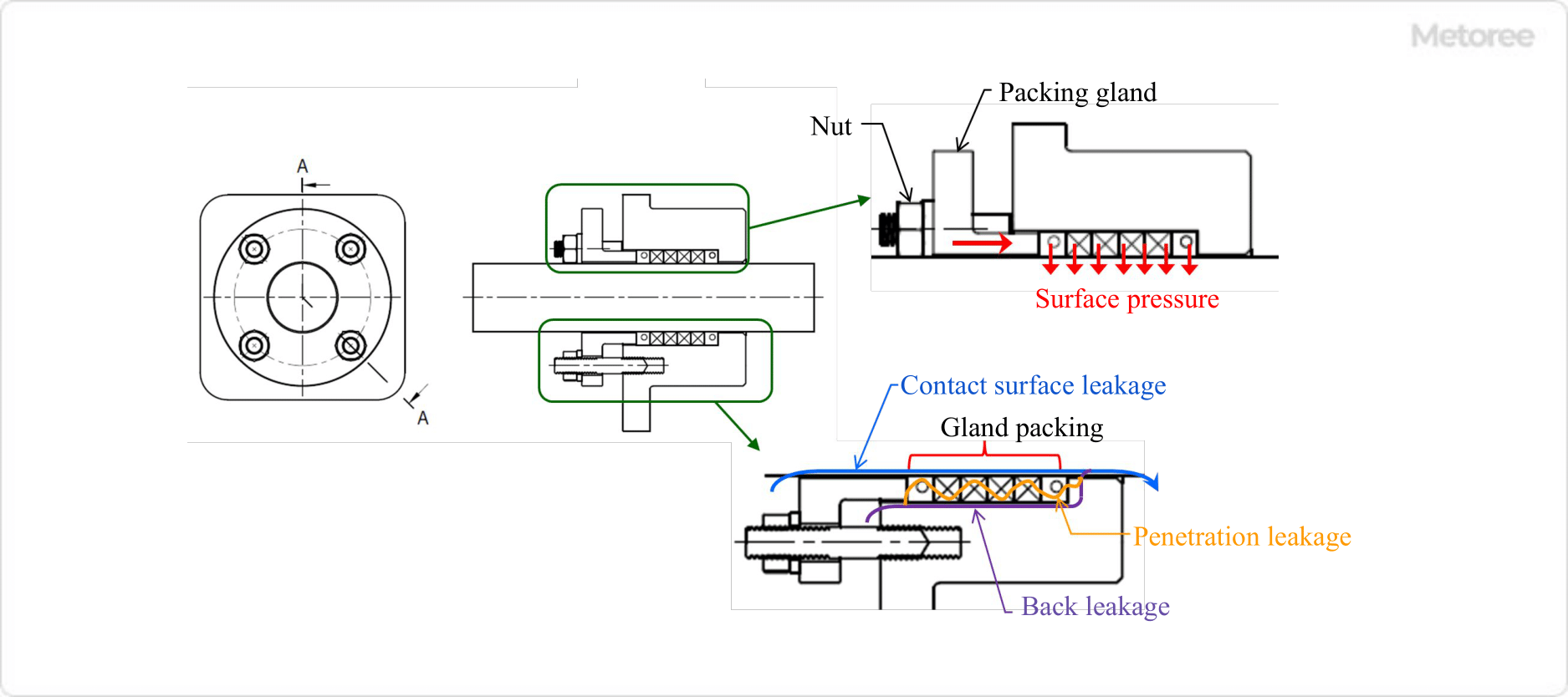

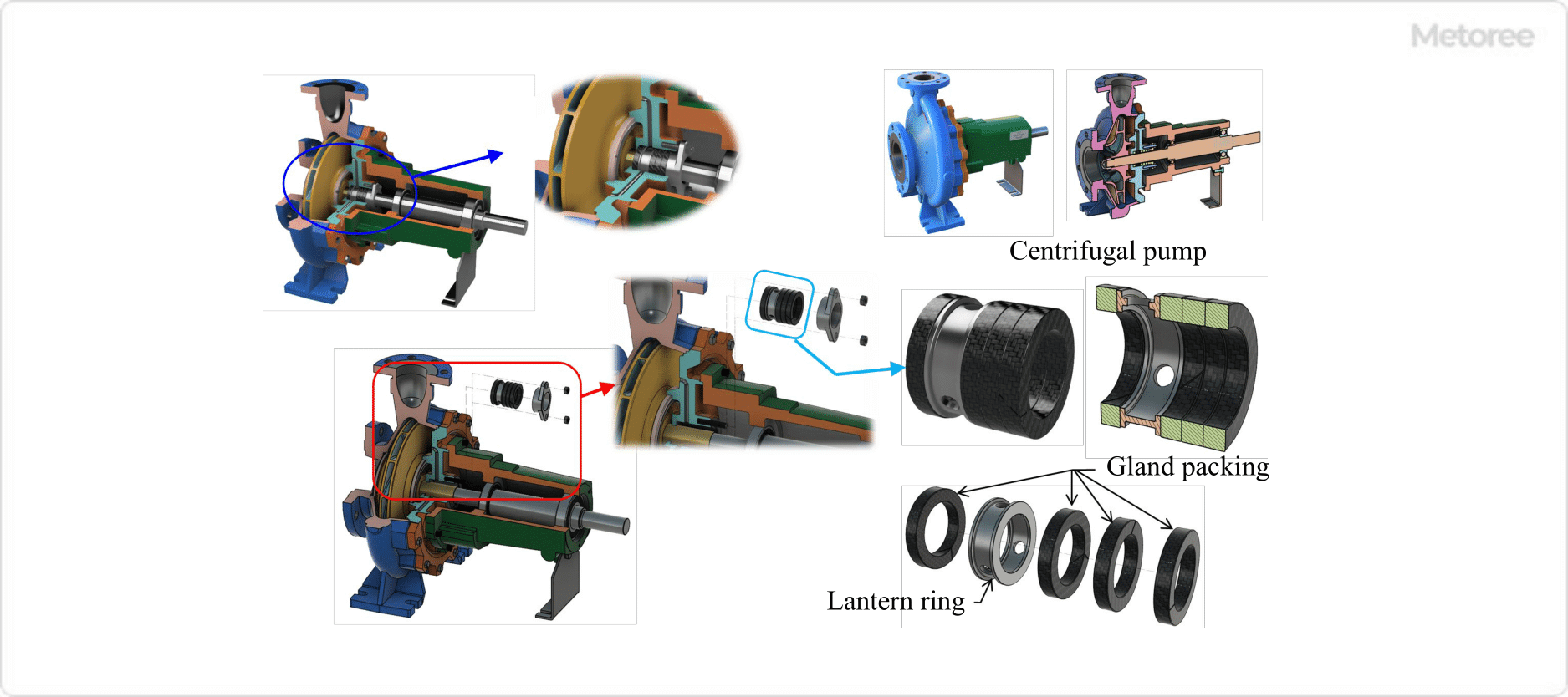

Figure 1. Principle of gland packing

The above surface pressure is caused by the gland packing being pushed by the packing gland (the part that holds the packing) when the nut is tightened, causing the gland packing to expand in the inner and outer radial directions. The more strongly the nut is tightened, the higher the surface pressure.

If the nut is tightened too much, the frictional resistance due to adhesion becomes too high, and a large load is placed on the rotating or reciprocating shaft. Care must be taken because this may interfere with the operation of the equipment. However, if the tightness is too weak, the fluid will easily leak.

There are three types of gland packing leakage, as described below.

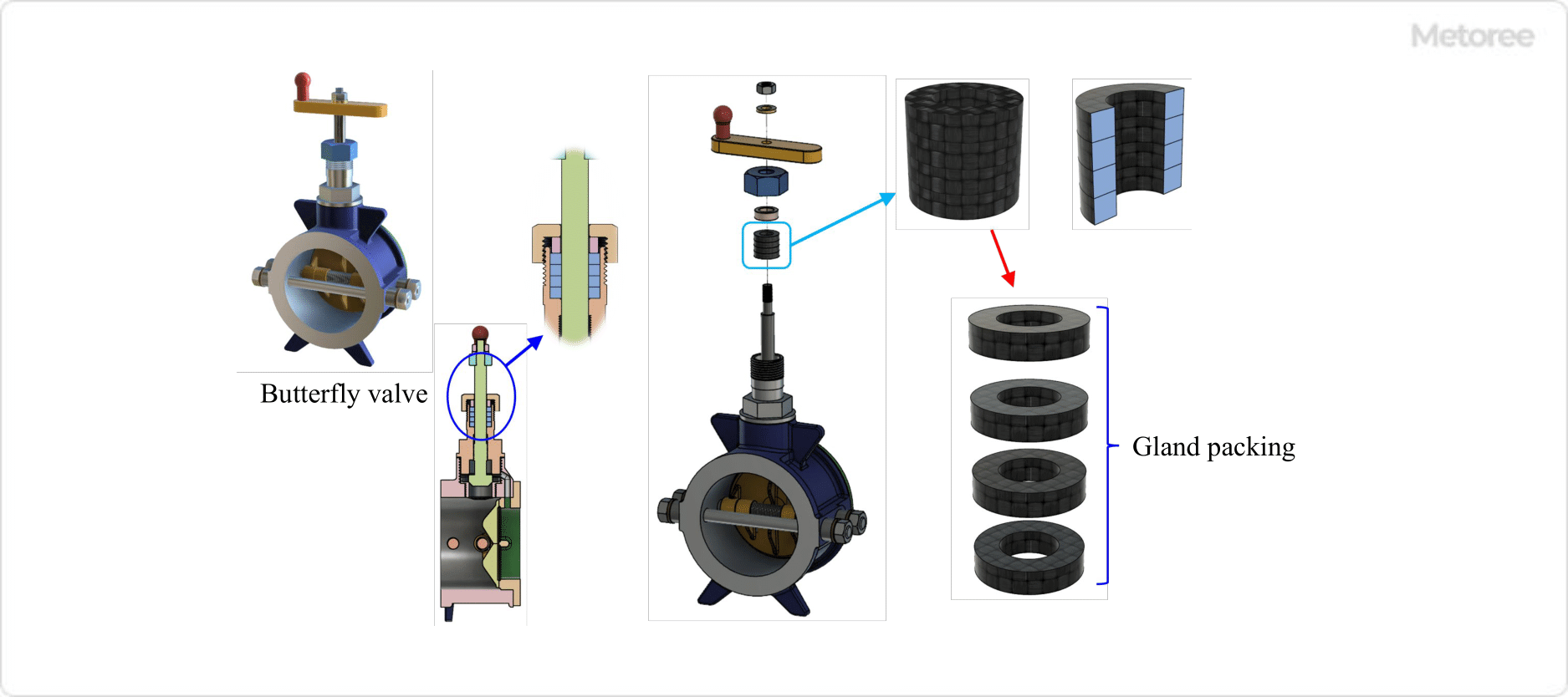

Figure 2. Example of gland packing use

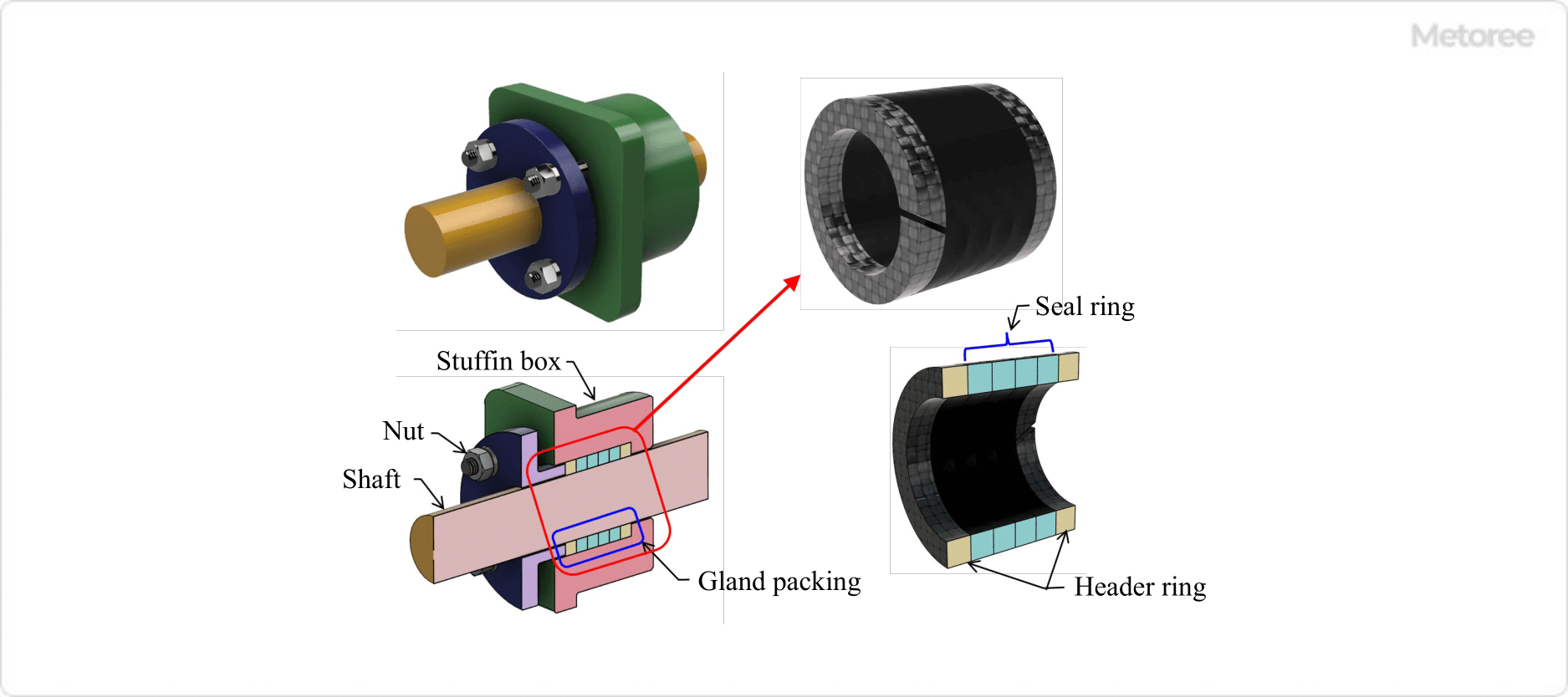

Gland packing is used in rotating or reciprocating machinery or equipment where the shaft protrudes externally through a housing or casing. These parts are used to prevent oil fluids, gases, and other gases inside the machine or equipment from leaking to the outside.

Insert the gland packing into the housing or casing stuffing box (the box that contains the packing) so that it wraps around the outer circumference of the shaft at the shaft penetration area. Push the gland packing into place by tightening the nut at the packing gland (the part that holds and tightens the packing) so that the inside surface of the gland packing is more tightly pressed against the outside surface of the shaft.

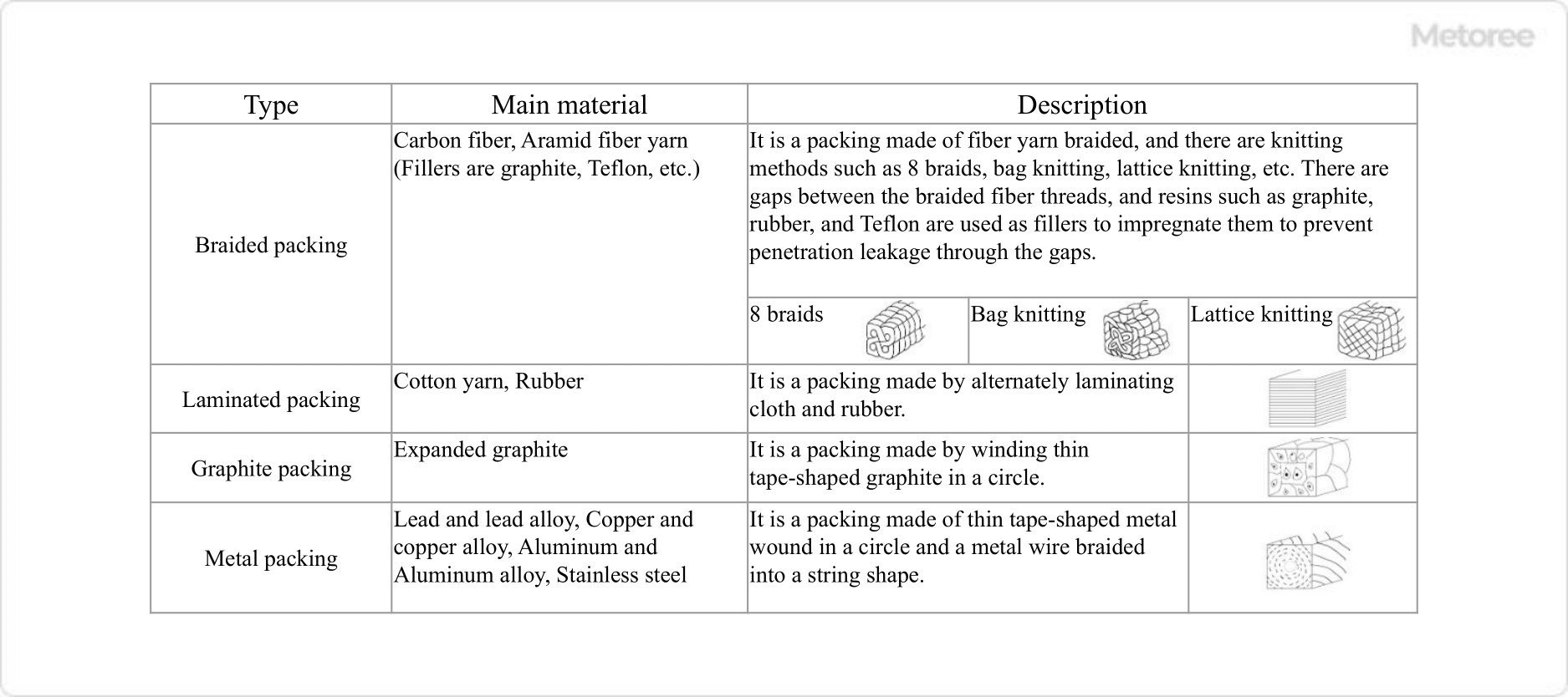

Figure 3. Types and main materials of gland packings

Gland packing is characterized by its relatively low cost as a shaft seal and simple structure compared with mechanical seals. Since each type has its own characteristics and the method of use and environment of use differ, it is important to check the manufacturer's catalog, specifications, and instruction manuals before making a selection.

Figure 4. Types of gland packing

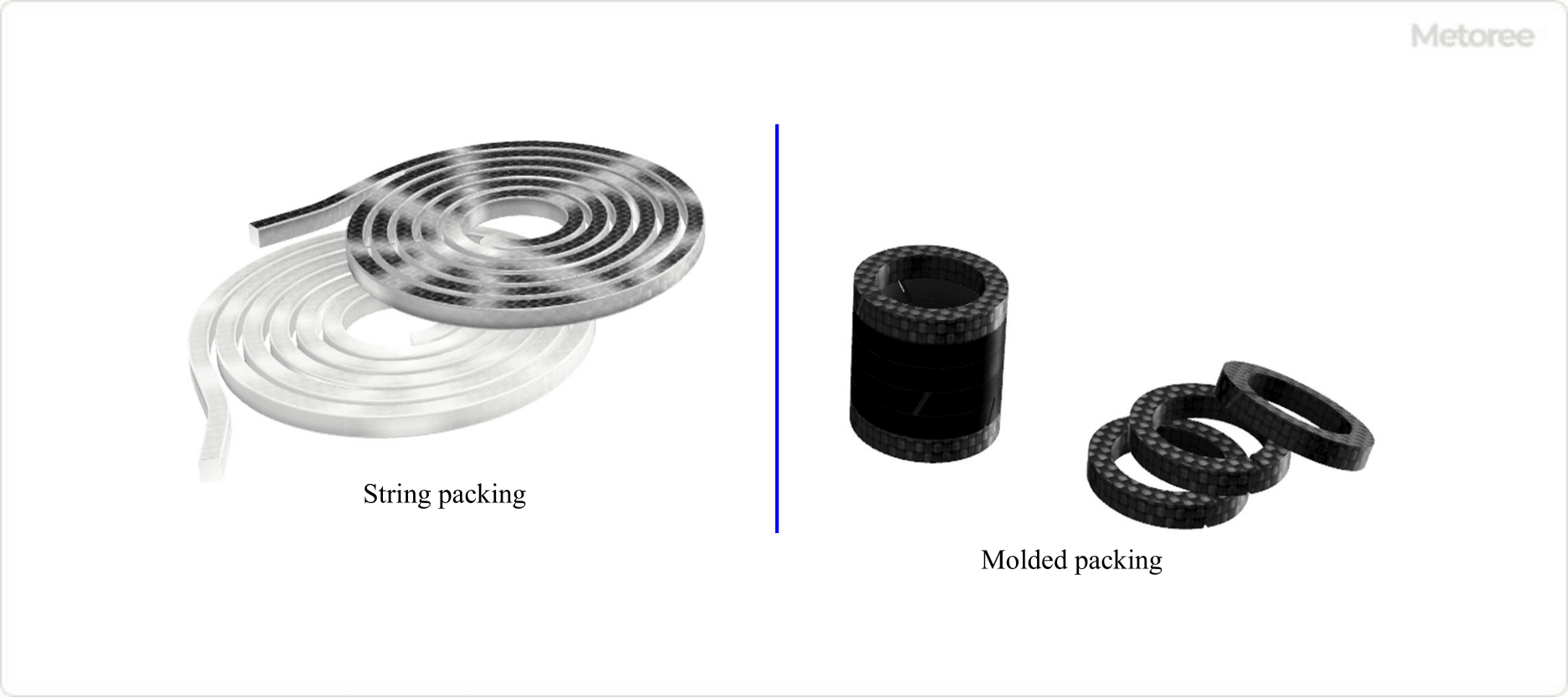

Gland packing (other than laminated packing) that is generally available on the market comes in a spiral wound form. Therefore, cut the packing to the required length according to the dimensions of the shaft and stuffing box, and insert it into the box. In addition to cutting and using the string packing, we can also produce a pre-molded ring-shaped packing to match the dimensions of the shaft and stuffing box.

The use of molded products improves the workability of packing insertion and sealing performance. In the past, asbestos packing (sealing material containing asbestos) was often used as a material for gland packing packings.

Normally, one gland packing is not used alone, but several gland packings (in layers) are stacked. Also, as shown in the figure above, using several seal rings (sealing packings) in combination with header rings (overflow prevention packings) will provide a more secure seal.

The number of gland packing (number of steps), packing material, and pressure of the fluid to be sealed vary, so refer to the packing manufacturer's product specifications or instruction manuals to determine the appropriate combination.

The uses of gland packing include the following, depending on the direction of the shaft motion.

For Rotary Motion Axis

Figure 5. For rotary motion shaft of pump

It is mainly used for shaft sealing of pumps, blowers, and other shafts.

For Reciprocating Shaft

Figure 6. For reciprocating shaft of valve

They are used for shaft seals of valve stems (valve rods) such as valves.

In addition to the above, they are also used in the shaft seals of various rotating machines and machines with reciprocating shafts. They seal liquids, gases, powders, and other substances to ensure the normal operation of machinery and equipment.

The gland packing for the pump consists of three rings of braided packing and a lantern ring. This lantern ring is used for the following purposes:

Since gland packing causes some leakage, a shaft sealing device such as a mechanical seal is used when used to seal machinery, equipment, or hazardous materials with even less leakage.

Gland packing may become worn and lose filler after long-term operation of the equipment, resulting in leakage. In such cases, the nut should be re-tightened or the gland packing should be replaced. Also, once a leakage path is created along the shaft, it is difficult to eliminate the leakage even by retightening, so replacement is also necessary in such cases.

*Including some distributors, etc.

Sort by Features

Sort by Area

Ivy Fine Chemicals, founded in the United States, is a manufacturer of fine chemicals and biotech kits. The company's specialty and custom chemicals include chiral chemicals, amino acids, aromatic and heterocyclic derivatives, halogenated compounds, natural extracts, and pharmaceutical raw materials. Its products are widely used in life science, pharmaceutical, and fine chemical industries and it supplies chemicals in both bulk industry scale and R&D laboratory scale. It has a USA-based sales and marketing office with global distribution network.

Logan Actuator Co., founded in 1939 and based in Harvard, IL, USA, is a manufacturer and supplier of parts and accessories for metalworking lathes. The company's product range includes 3-jaw chucks, double gears, flat belts, toolpost sets, and drive plates. These products are used for various operations in metalworking and lathe machining. Industries such as metalworking, manufacturing, machining, and industrial production rely on its offerings. The company also offers services like direct customer sales, shipment handling, return processing, and provision of detailed instruction manuals.

Bushing MFG, founded in Jiaxing, Zhejiang, in 2006 is a manufacturer of self-lubricating bearings. The company's product portfolio includes Plain Bearings, Self-lubricating sleeve bearings that excel in low-speed and high-load applications, flanged self-lubricating bearings suitable for both radial and thrust loads, Self-lubricating thrust bearings designed to handle axial loads and Custom Bearings. Their products are used in markets such as Automotive and Transportation, Telecommunications, Industrial Automation, Healthcare and Medical Devices and Aerospace and Defense.

SANKYO OILLESS INDUSTRY,INC., established in 1964 and headquartered in Tokyo, Japan, is a manufacturer of oilless metals and machine parts. The company provides special oilless machinery such as mechanical, chemical or electronic equipment. It has developed special solid lubricants on the sliding surfaces, resulting in oilless metals that prevent failures on sliding surfaces without lubrication. These products include various oilless bearing and bearing plates for structures such as bridges and water gates, die components and standard components for sliding material. This oilless technology is useful in applications like automobiles, feed unloading plants, water power plant turbines and steel industry.

Zhejiang Waxing Electromechanical Co., Ltd., established in 2000 as Linqing Shengli Factory, is based in Zhejiang, China, as a manufacturer and supplier of various types of bearing. The company offers various types of bearing including Deep Groove Ball Bearings, Cylindrical Roller Bearings, Tapered Roller Bearings, Angular Contact Bearings, Thrust Ball Bearings, among others. These products are utilized in many industries such as automobile industry, agriculture industry, textile industry, and plastic industry as important internal components of various machineries. The company also offers custom requests to fulfill customers with special quality requirements and specifications.

Jiaxing Roncan Bearing Co., Ltd, founded in China, is a manufacturer of copper alloys. The company offers a wide variety of copper alloy ingots tailored to meet diverse industrial requirements, including brass, bronze, and special-purpose alloys and customized copper alloys to address unique and specialized application needs. It serves industries such as Power and Energy, Transmission Bearings, Power and energy, General Engineering, and Marine. It also provides technical support, product consultation, and guidance on alloy selection.

F.M. SRL, a company founded in 1974 and based in Correggio, Italy, is a manufacturer and supplier of plastic material products. The company's product portfolio includes disk packs, roller conveyors, and rotors and propellers for pumps. These products find applications in various sectors, including the ceramic industry, industrial automation, and electronics manufacturing. The company is ISO 9001:2004, ISO 45001:2009, and ISO 14001:2010 certified for its quality, safety, and environmental standards. Some of the company’s partners include Elesa, Roechling, and CRIT Research.

VIIPLUS Bearing Company, established in 2016 and headquartered in Zhejiang, China, is a manufacturer that specializes in providing self-lubricating bushings and oilless bearing materials. The company offers a wide range of products, including plain bearings, wrapped bronze bearings, bronze bushings, and bimetal bearings. It also offers thrust washer pom self-lubricating holes, self-lubricating bronze bushing, solid bronze bearings, and plugged graphite bronze parts couplings. Its products are dirt-resistant, insertable at high temperatures, and made with solid lubricant bronze material. The company has achieved ISO 9001:2015 and RoHS Certification. It serves industries such as automotive, machinery and equipment, electronics, construction, and more.

VIIPLUS INTERNATIONAL., founded in China, is a manufacturer of standard bronze oilless parts and self-lubricating bushing, wear plates for dry applications. The company's product portfolio includes a wide selection of bronze bushings suitable for different applications, ensuring reduced friction and maintenance-free operation, flanged bearings come in various sizes and configurations, providing excellent support and alignment for rotating shafts, s high-precision sleeve bearings that operate quietly and with minimal friction and custom bronze oilless parts.

A&A Material Corporation, established in 2000 and based in Kanagawa, Japan, is a manufacturer of building and industrial materials. The company specializes in producing and selling noncombustible building materials, including boards for manufacturing, decoration, and construction. It offers advanced thermal control technology, emphasizing noncombustible and flame-resistant products for safety in living spaces. The company also provides industrial solutions like alumina fiber and heat-resistant cloth, used for thermal insulation, air conditioning, and soundproofing. The company also provides services like design and implementation of steel fireproof coating work, heat insulation and fire resistance construction.

A.S. International, founded in 2008 and based in Mumbai, Maharashtra, India, is a manufacturer and distributor of bearings and chains. The company's product portfolio includes ball bearings, roller bearings, specialty bearings roller chains, and conveyor chains. These products are used in various industrial applications for efficient power transmission, material handling, and radial load handling. The company serves diverse industries such as manufacturing, automotive and transportation, agriculture, as well as mining and construction.

Mechatalk, established in -- and headquartered in Jeollabuk-do, Korea, serves as a manufacturer and distributor specializing in standard parts for factory automation such as electronics, tools, and MRO consumables for production equipment. The company's product line includes directional control valves, air cylinder accessories, air preparation equipment, modular pressure control equipment, human machine interfaces, and various other components. These products are used across diverse industries, including manufacturing, automobiles, hydraulic lifts, food preparation, factory automation systems, and more.

BOWMAN International, founded in 1974 and located in the Thames Valley, UK, is a manufacturer and supplier of plain and bespoke bearings. The company’s products are needle rollers, ball bearings, acetal washers, precision shafts, and sintered components. These products are used in automotive, construction, aerospace, lubrication, and manufacturing industries. It offers technical support, particular parts, testing, inspection, and stock holding services. The company holds BS EN 9001-2015 certification and is a member of EPTDA, BEARING Net, and Bearing Specialists Association.

SGO CO., LTD., established in 2000 and headquartered in Incheon, Korea, is a manufacturer and supplier specializing in bearing materials, including bronze bushings, self-lubricating bearings, and plain bearings. The company offers a diverse range of products, such as graphite-plugged bearings, solid bronze bearings, develon bearings, dry bearings, and more. It also provides an e-catalog for convenient access to its product offerings. Its bearings find applications in various sectors, including plastic injection molding machines, press dies & plastic molds, bearings for construction equipment, hydroelectric power plants, and steel manufacturing facilities.

Jiashan Jingye Import & Export Co.,Ltd, founded in China, is a supplier of oil less bearings and related products. The company specializes in oil-less bearings designed to operate without the need for external lubrication. These self-lubricating bearings are ideal for applications where traditional lubrication may not be practical or cost-effective. It serves a wide range of industries, including manufacturing, automotive, aerospace, medical devices, and more. It exports to over 20 countries and regions such as Germany, Italy, Spain, and Turkey.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Zhejiang Waxing Electromechanical Co., Ltd. |

21.4%

|

| 2 | Ivy Fine Chemicals |

14.3%

|

| 3 | JBSTEC |

14.3%

|

| 4 | VIIPLUS Bearing Company |

14.3%

|

| 5 | Logan Actuator Co. |

7.1%

|

| 6 | Jiaxing Roncan Bearing Co.,Ltd |

7.1%

|

| 7 | VIIPLUS INTERNATIONAL |

7.1%

|

| 8 | BOWMAN International |

7.1%

|

| 9 | Bushing MFG |

7.1%

|

Derivation Method

The ranking is calculated based on the click share within the oilless bearing page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

8 | 50.0% |

United States of America

United States of America

|

2 | 12.5% |

Japan

Japan

|

2 | 12.5% |

Republic of Korea

Republic of Korea

|

2 | 12.5% |

India

India

|

1 | 6.3% |

United Kingdom

United Kingdom

|

1 | 6.3% |

65 products found

65 products

Aiden Co., Ltd.

370+ people viewing

Last viewed: 17 hours ago

■Notes ・Pump packing ・Packing for slurry ・High quality carbon fiber and PTFE fiber ・High purity graphite lubrication ・Temperature limit 260℃ ...

Sowa Industries Co., Ltd.

460+ people viewing

Last viewed: 47 minutes ago

A gland packing made of carbonized fibers impregnated with PTFE dispersion, braided into a square cross section, and impregnated with a special lub...

Sowa Industries Co., Ltd.

410+ people viewing

Last viewed: 4 hours ago

A gland packing made of special carbon fiber impregnated with PTFE dispersion and braided into a square cross section. ■Features Excellent heat re...

Sowa Industries Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

A gland packing made of high-grade carbon fiber braided into a square cross section and treated with a special heat-resistant lubricant. ■Features...

Sowa Industries Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

Gland packing for high temperatures and medium pressures, made of graphite fiber reinforced with heat-resistant metal wire and braided into a recta...

Sowa Industries Co., Ltd.

450+ people viewing

Last viewed: 4 hours ago

This is a ground packing in which a blended yarn of aramid fiber and rock wool fiber is impregnated with PTFE dispersion, braided into a square cro...

Sowa Industries Co., Ltd.

360+ people viewing

Last viewed: 16 hours ago

Packing for high temperature and high pressure with increased strength, made of graphite fiber reinforced with Inconel wire braided into a square c...

Sowa Industries Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

This is a gland packing made of aramid fiber and rock wool fiber blend yarn impregnated with PTFE dispersion, braided into a square cross section, ...

Sowa Industries Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

A rotating packing made of expanded graphite yarn braided into a rectangular cross section. ■Features Since no metal wire is used, the shaft will ...

Sowa Industries Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

A gland packing made of white aramid fiber impregnated with PTFE dispersion, braided into a square cross section, and then completely treated with ...

Sowa Industries Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

This is a special packing made of graphite fibers containing carbon fibers, reinforced with carbon fibers, and then impregnated with a clogging age...

Sowa Industries Co., Ltd.

390+ people viewing

Last viewed: 5 hours ago

This gland packing is made by impregnating organic fiber with chemical resistance second only to PTFE with PTFE dispersion, braiding it into a squa...

Sowa Industries Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

This is a special packing made of graphite fibers reinforced with carbon fibers and then impregnated with an occlusive agent. ■Features It has exc...

Sowa Industries Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

Gland packing made of 100% PTFE fiber braided into a square cross section. ■Features Has excellent chemical resistance and is resistant to corrosi...

Sowa Industries Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

This is a special packing made by braiding graphite fibers containing carbon fibers and then covering them with carbon fibers containing a special ...

Sowa Industries Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

A gland packing made of 100% PTFE fibers impregnated with PTFE dispersion and silicone oil and braided into a square cross section. ■Features Impr...

Sowa Industries Co., Ltd.

360+ people viewing

Last viewed: 11 hours ago

This is a square packing made by braiding biosoluble fibers as knitting yarn. ■Features It has a high heat resistance and high heat insulation pro...

Sowa Industries Co., Ltd.

580+ people viewing

Last viewed: 1 day ago

A gland packing made of special 100% PTFE fibers braided into a square cross section. *For stable use in rotating equipment, please use a lubricant...

Sowa Industries Co., Ltd.

390+ people viewing

Last viewed: 16 hours ago

This is a round packing made by braiding biosoluble fibers as knitting yarn. ■Features It has a high heat resistance and high heat insulation prop...

Sowa Industries Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

This is a specially processed soot blower packing based on PTFE fiber. ■Features Excellent durability and heat resistance. Unlike expanded graphit...

Sowa Industries Co., Ltd.

420+ people viewing

Last viewed: 16 hours ago

This is a square packing made of braided heat-resistant glass fiber yarn. ■Features Excellent insulation, heat retention, and cold retention perfo...

Sowa Industries Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

A gland packing made of aramid fibers braided into a rectangular cross section and treated with PTFE dispersion and lubricant to improve sealing pe...

Sowa Industries Co., Ltd.

360+ people viewing

Last viewed: 3 hours ago

This is a round packing made by braiding heat-resistant glass fiber as yarn. ■Features Excellent insulation, heat retention, and cold retention pe...

Sowa Industries Co., Ltd.

340+ people viewing

Last viewed: 23 hours ago

This is a gland packing made of a mixture of PTFE fiber and graphite, and braided into a rectangular cross section with aramid fiber at the corners...

Sowa Industries Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

This is a gland packing made of high-performance synthetic fibers impregnated with PTFE dispersion, braided into a square cross section, and then c...

Sowa Industries Co., Ltd.

420+ people viewing

Last viewed: 1 hour ago

This is a gland packing made by braiding fibers made from a mixture of PTFE fiber, graphite, and heat-resistant lubricating oil into a square cross...

P-One Shop

380+ people viewing

Last viewed: 16 hours ago

■Content etc. No.13 With ring packing

P-One Shop

380+ people viewing

Last viewed: 1 day ago

■Content etc. set of 4

P-One Shop

390+ people viewing

Last viewed: 1 day ago

■Content etc. set of 4