All Categories

History

This section provides an overview for cylindrical grinders as well as their applications and principles. Also, please take a look at the list of 22 cylindrical grinder manufacturers and their company rankings. Here are the top-ranked cylindrical grinder companies as of February, 2026: 1.KAAST Machine Tools, Inc., 2.Weldon Solutions, Inc., 3.Kent Machine, Inc..

Table of Contents

Categories Related to Cylindrical Grinders

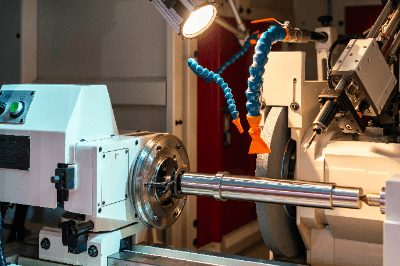

A cylindrical grinder is a machine tool that grinds the outer diameter of cylindrical workpieces using a rotating grinding wheel.

Its basic structure includes a wheel head that moves back and forth on the bed via a slide mechanism, utilizing ball screws and servo motors. Additionally, there is a table that can move in the left and right directions to any desired position.

The workpiece is supported at both ends in the center and rotated by the spindle head at the left end of the table and by the center press head at the right end. As the wheel head advances, the rotating grinding wheel contacts and grinds the workpiece.

The primary application of a cylindrical grinder is the precision machining of the outer surfaces of cylindrical shafts.

Cylindrical grinders are mainly utilized for machining cylindrical, stepped, and tapered shafts of machine parts, automotive components, and electronic devices. They grind the external surfaces of cylindrical workpieces by supporting them at both ends with centers.

The advantage of using a cylindrical grinder lies in its ability to finish workpieces with a high degree of accuracy. Additionally, the support at both centers means the grinding process is not affected by grooves or imperfections on the workpiece's outer diameter, ensuring better roundness and cylindricity.

The main drawback of cylindrical grinders is the time required to set up and remove workpieces, making centerless grinders more efficient for mass production. However, cylindrical grinders are ideal for small-quantity, high-diversity production, especially for workpieces requiring complex shapes and high precision.

Some universal cylindrical grinders feature a swivel table that supports both the wheel head and the workpiece, enabling not just cylindrical grinding but also internal, taper, and end-face grinding.

Cylindrical grinders employ three primary grinding methods:

In traverse grinding, the table moves side to side, allowing the grinding wheel to cut across the workpiece. This method is suitable for long cylindrical workpieces and improves surface roughness by alternating the direction of the grind with each pass of the table.

Plunge grinding involves moving the table to the grinding position and then cutting into the workpiece with the grinding wheel, without moving the table during the grind. This method is efficient for shorter workpieces and allows for effective force transmission.

Angular grinding sets the wheel spindle at an angle to the table, enabling the grinding of both the outer diameter and end faces of cylindrical shapes, such as stepped workpieces, in one operation. After the final infeed, a spark-out period ensures improved surface roughness and roundness.

Both cylindrical grinders and lathes are used for processing the cylindrical outside diameters of workpieces. However, in a lathe, a stationary cutting tool contacts a rotating workpiece, whereas in a cylindrical grinder, both the workpiece and the grinding wheel rotate, enabling precision grinding.

Lathes can remove more material in a single pass, making them more efficient for roughing. Cylindrical grinders, while less efficient for roughing due to slower material removal and quicker grinding wheel wear, are ideal for finishing operations, especially on hard materials like hardened steel, where lathes may struggle.

Cylindrical grinders, with their abrasive grains, bonding material, and pores, achieve high-precision machining up to an accuracy of 1 µm. They offer smoother surfaces and more accurate roundness than centerless grinders, making them superior for precision machining of long or thin workpieces, with specific measures taken to control material deflection during the process.

*Including some distributors, etc.

Sort by Features

Sort by Area

KAAST Machine Tools, Inc., established in 2009, is a manufacturer of fabrication machines, ironworkers, plate & profile rollers, band saws, and chip-making equipment such as grinders, mills, presses, and lathes used in automotive, construction, defense, aerospace, and metal working industries. The Aldan, PA company offers drilling, turning, milling & grinding, drilling, and after-sales services, including consulting & planning, installation, financing & leasing, operator training, and fabricating. The company has a warehouse in Philadelphia with 24-hour delivery in the area and 48-hour delivery in other areas.

Weldon Solutions roots go back to the 1890s in York, Pennsylvania. The company is a manufacturer of CNC cylindrical grinder products, robotic automation systems, and technical support for manufacturing and material handling industries. The company operates in 2 segments: Industrial Automation and CNC Grinders. Industrial Automation provides robotic automation components handling system design, material removal, machine tending, and collaborative robots. It also includes the FANUC System Integrator for the integration of and service of FANUC robots and cobots. CNC Grinders include automated grinders and peel grinders, with 8 models overall.

Kent Machine, Inc. is a Pendleton, Indiana-based manufacturer of specialized testing, inspection, and assembly equipment founded in 1988. They produce various gauges and single-station machines, as well as precision-engineered components machined from steel, plastic, and non-ferrous materials for demanding industrial applications. The company is ISO 17025:2017 certified and utilizes automatic presses, robotic welding, CNC machining, and wire EDM on its 3,200 square feet of build floor for clients in the medical, automotive, and aerospace industries. Some of Kent Machine’s client corporations include Zimmer Biomet, Honda, Caterpillar, and GE Aviation.

H. H. Arnold, Co., Inc., established in 1930, is a company based in Rockland, United States, the manufacturer and supplier of industrial components. The company's main products include precision machined parts, custom mechanical assemblies, and industrial fasteners. These products are used in various sectors, such as aerospace, automotive, and machinery manufacturing. H. H. Arnold, Co., Inc. has remained relevant for its promise to delivering quality solutions that meet stringent manufacturing standards. With decades of expertise, the company provides standout customer service, technical support, and tailored solutions to cater to the specific needs of its clients.

JTEKT Toyoda Americas Corp., established in 1941, and headquartered in Arlington Heights, Illinois, USA, is a manufacturer that specializes in producing machine tools and machining centers. Their product range includes CNC cylindrical grinders, horizontal and vertical machining centers, and grinding machines. These products cater to the automotive, aerospace, medical, energy, and general manufacturing sectors. JTEKT Toyoda is devoted to excellence and holds ISO 9001 and ISO 14001 certifications, ensuring precision, and efficiency in machining operations for their customers.

Established in 1976, based in Torrance, CA, U.S., Sharp Industries, Inc is a supplier of machine tools to various industries. They started functioning by providing manually operated Vertical Milling Machines and later expanded to supplying precision Toolroom lathes, and more products. The company offers CNC mills&lathes, 5-axis Vertical Machining Centers, box-way VMCs, linear VMC, and small footprint Mini Mills. They also provide Surface Grinders, Cylindrical Grinders, and Radial Drills, that have industrial applications. These products are required in research labs, schools, job shops, and industries that have metal-cutting requirements.

Palmary Machinery Co., Ltd., established in 1998 and based in Taichung, Taiwan, is a manufacturer of precision grinding machines. Its product range encompasses centerless grinders, cylindrical grinders, internal grinders, vertical grinders, and surface grinders, serving a diverse array of industries such as automotive, aerospace, mechanical components, and more. The company holds CE certification and ISO9001:2015 certification, highlighting its adherence to quality standards. The company has also achieved several accolades, including the Gold Medal Award at the 89th Poland Mach-Tool Show 2017 and the 14th National Brand Yushan Award 2017.

Shigiya Machinery Works Ltd., founded in 1911, and headquartered in Hiroshima, Japan, is a manufacturer of machine tools and grinders. The company’s products include overhauling and retrofitting machine tools, CNC masterless cam grinders, and CNC centerless cylindrical grinders. These products are widely used in various sectors, including automotive, aerospace, and general engineering. The company is also known for its technological solutions and precision engineering. The company’s customer services encompass various areas, including pre-sales consultations, technical support, and after-sales assistance.

Okuma Corporation is a Japanese machine tool manufacturer that was founded in 1898 as the Okuma Noodle Machine Company before rebranding in 1918. Based in Oguchi, Aichi Prefecture, the company produces a wide selection of machines including CNC lathes, multi-axis machining centers, grinders, and multitasking machines. It also offers software and automation solutions that can be customized to improve the performance and functionality of its products. Okuma Corp. maintains a global support network via 28 subsidiaries located throughout Asia, the Americas, Europe, and the Pacific regions.

JTEKT was born from the merger of bearing maker Koyo Seiko and machine tool maker Toyoda Machine Works. JTEKT focuses on environmental sustainability to create automotive-specific components as well as industry-agnostic components including sensors, gears, displays, storage devices, and hydraulic units. JTEKT also creates and designs machine tools and equipment necessary for machine production. JTEKT is also developing "internet of everything" (IoE) solutions for modern industry.

EMAG, founded in the year 1867, based in Michigan, US, is a manufacturer and supplier of machine and tool solutions. Their product portfolio includes turning, grinding, milling, gear cutting, coupling, laser welding, and joining machines. The products are used in various applications which include agriculture, automotive, aviation construction, vehicle, medical and wind energy. The company offers innovative machinery with digitalization and automation systems. They also provide services that include retool options, retrofit remanufacturing, and control system upgrades.

As a high-precision grinding machine manufacturer in Taiwan since 1982, Jainnher Machine owns more than 40 years of experience and has developed a complete machine series to fulfill various grinding requests. Our machine series including: Centerless, Cylindrical, Internal, Plunge, Angular, Center hole, Double spindle (ID & OD), Vertical and Thread grinding machine. Grinding machines are widely used in precision aerospace and other transportation industries, cutting tools, medical parts, mold & machining parts, consumer goods. We have successful cases of customized solutions with different industries. The company holds ISO 9001:2015 certification and CE/UKCA certifications , not only to meet customer requirements for quality assurance but also to enhance customer confidence and satisfaction in our grinding machine products Jainnher has global service net to conquer the language and time zone difference. And we’re able to provide the fully technical support, field training which can benefit our dealers communicate with their customers.

Komatsu NTCs, founded in 1945 and based in Toyama, Japan, is an ISO 9001:2008 certified manufacturer of machinery equipment. The company's range of products includes transfer machines, exclusive-purpose machines, crankshaft millers, grinding machines, and semiconductor manufacturing machines. The company is a subsidiary of Komatsu Limited and was awarded the Japan Brand Prize and the Good Design Award in 2006. It has also partnered with Dalian Bohai Machine Tools to establish Dalian Bohai Nippei Machine Tool Corporation. Its products are used in various countries, including Japan, India, Thailand, Indonesia, and Germany.

KNUTH Machine Tools USA is the American subsidiary of Knuth, originally founded in 1928. The American subsidiary is headquartered in Lincolnshire, Illinois. The company is a manufacturer of industrial machinery and accessories. The company has an extensive product listing including lathes, milling machines, grinding machines, drilling machines, as well as several others. The company’s accessories include consumables for EDM and cutting machines, machining tools, and machine accessories. The company also offers start-up services, maintenance services, repair, and spare parts services.

L&W Machine Tools, Inc., established in 1953 and headquartered in Taichung City, Taiwan, is a manufacturer and supplier of PC-based CNC machine tools. The company's product portfolio includes CNC horizontal machining centers, surface grinding machines, and horizontal boring and milling machines. These products are used in various sectors, including the die casting industry, medical device manufacturing, and defense and military. The company also offers services, including a warranty covering defects in materials, customization, and product catalogs.

TSUGAMI CORPORATION was founded in 1937 and is a manufacturer and supplier of precision machine tools based in Chuo, Tokyo, Japan. The company offers various precision equipments such as opposed gang tool post, turning center, CNC lathe, vertical machining center, and CNC precision cylindrical grinding machine. The products are used in manufacturing various products such as medical equipments, digital camera, cellular phone, and optical communication devices. The company holds ISO 9001 certification for the Quality Control Management System and ISO 14001 for Environment Management System.

Fritz Studer AG., started in 1912 and based in Steffisburg, Switzerland, is a manufacturer of precision cylindrical grinding machines and is a member of the United Grinding Group. The company stocks both external cylindrical grinding machines and machines for internal cylindrical grinding and provides grinding software. Some of the ground workpieces made by the company’s machines include collets, drawing dies, and fir tree cutters. The company also has a sub-assembly and machine overhaul service for restoring machines. It is ISO 9001 and ISO 14001-certified and has delivered over 25,000 systems.

Masteel America Corp., established in 1999 and headquartered in Oakville, Canada, is a supplier of machining and fabrication equipment, including the Leadwell and L&L machine tool lines. The company’s fabricating and machining equipment includes press brakes, shearing machines, and CNC lathes. Partnering with CNC tech it ensures prompt installation, service, and retrofitting. Its metric machine tool service offers set-up, installation, and servicing for manual & CNC machines. The company’s westcam solutions specialize in CAM/DNC software, training, and support, particularly emphasizing GibbsCAM for complex multi-axis machines.

Willis Machinery, founded in 1963, is a supplier of metalworking machine tools with a warehouse in Toledo, Ohio. The product line has CNC & conventional lathes, vertical & CNC mill machines, variable speed & geared head drill presses, radial drills, and surface grinders. Lathe chucks, specialty work holding equipment, portable drilling machines, and bridge-type CNC vertical machining centers are offered. The company is a member of The Association of Manufacturing Technology, supplying tools to Michigan, Indiana, Ohio, and Pennsylvania.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | KAAST Machine Tools, Inc. |

10.0%

|

| 2 | KNUTH Machine Tools USA, Inc |

9.1%

|

| 3 | EMAG |

8.9%

|

| 4 | Fritz Studer AG |

8.9%

|

| 5 | Weldon Solutions, Inc. |

6.9%

|

| 6 | Kent Machine, Inc. |

6.3%

|

| 7 | H. H. Arnold, Co., Inc. |

5.0%

|

| 8 | SHIGIYA MACHINERY WORKS LTD. |

4.8%

|

| 9 | JTEKT Toyoda Americas Corp. |

4.6%

|

| 10 | Chevalier Machinery USA |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the cylindrical grinder page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 43.8% |

Japan

Japan

|

5 | 31.3% |

Taiwan

Taiwan

|

3 | 18.8% |

Germany

Germany

|

1 | 6.3% |

101 products found

101 products

JTET Machine System

870+ people viewing

Last viewed: 3 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

JTET Machine System

410+ people viewing

Last viewed: 3 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

2 models listed

JTET Machine System

610+ people viewing

Last viewed: 1 day ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

Manu Seisakusho Co., Ltd.

490+ people viewing

Last viewed: 16 hours ago

The definitive edition for small rubber roll grinding. Is the grinding machine you are using too large for the workpiece being processed? This save...

JTET Machine System

700+ people viewing

Last viewed: 1 day ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

Manu Seisakusho Co., Ltd.

510+ people viewing

Last viewed: 1 day ago

We specialize in processing small metal products, significantly reducing initial investment and running costs. It is small and lightweight, and the...

JTET Machine System

380+ people viewing

Last viewed: 9 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

2 models listed

JTET Machine System

550+ people viewing

Last viewed: 1 day ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

Manu Seisakusho Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

We have manufactured a cylindrical grinder specifically for grinding rubber products, etc.

2 models listed

JTET Machine System

380+ people viewing

Last viewed: 1 day ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

2 models listed

EARS Co., Ltd.

480+ people viewing

Last viewed: 23 hours ago

■Device overview This equipment performs cylindrical grinding and orientation flat grinding of SiC and lithium tantalate (other compounds) ingots. ...

JTET Machine System

360+ people viewing

Last viewed: 16 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

3 models listed

JTET Machine System

670+ people viewing

Last viewed: 22 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

JTET Machine System

580+ people viewing

Last viewed: 8 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

Kashifuji Co., Ltd.

560+ people viewing

Last viewed: 3 hours ago

■Product features ・Vertical hobbing machine ・Sliding surface scraping processing ・Table B/E (table backlash removal device) ・Automation ・Machi...

JTET Machine System

730+ people viewing

Last viewed: 4 hours ago

"Sho Thai" that realizes "high -precision and high -speed grinding" required for the outer diameter grinding of bearings Pthesales grinding board "...

JTET Machine System

450+ people viewing

Last viewed: 22 hours ago

"Sho Thai" that realizes "high -precision and high -speed grinding" required for the outer diameter grinding of bearings Pthesales grinding board "...

JTET Machine System

630+ people viewing

Last viewed: 6 hours ago

The shaft with steps was grinded at once with a width of 400mm, and the overwhelming space productivity was realized. In the past, the production l...

JTET Machine System

580+ people viewing

Last viewed: 17 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

JTET Machine System

330+ people viewing

Last viewed: 22 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

7 models listed

JTET Machine System

290+ people viewing

Last viewed: 22 hours ago

This is an industry top -class centerless grinder with high -efficiency options such as "Laser Dimensions", "Discharge Tsuru -swing", and "Unmanned...

6 models listed

JTET Machine System

900+ people viewing

Last viewed: 22 hours ago

"Sho Thai" that realizes "high -precision and high -speed grinding" required for the outer diameter grinding of bearings Pthesales grinding board "...

Toyo Advanced Technologies

480+ people viewing

Last viewed: 15 hours ago

Lineup with maximum machining diameter of Φ650mm. Adopts a 2-shoe magnet type workpiece support system. Ideal for processing bearings that require ...

Toyo Advanced Technologies

550+ people viewing

Last viewed: 9 hours ago

A vertical grinder that supports stable high-precision machining and complex machining with a unique mechanical configuration and a wide range of o...

Taiyo Kogyo

540+ people viewing

Last viewed: 21 hours ago

We handle various manufacturing equipment and labor-saving equipment to make production lines more comfortable. We will help you improve productivi...