All Categories

History

This section provides an overview for black anodized aluminum as well as their applications and principles. Also, please take a look at the list of 6 black anodized aluminum manufacturers and their company rankings. Here are the top-ranked black anodized aluminum companies as of February, 2026: 1.Reliable Automatic Sprinkler Co., Inc., 2.Johnson Plastics Plus, 3.Automatic Anodizing.

Table of Contents

Categories Related to Black Anodized Aluminum

Black Anodized Aluminum is a type of color anodizing in which the surface of anodized aluminum is colored black with a dye.

Anodized aluminum is aluminum that has undergone anodizing, during which an oxide film forms on the surface through electrolysis on an anode. It is more resistant to corrosion than untreated aluminum.

The luster can be altered through various processing methods before and after anodizing. Different types of anodized aluminum, such as matte black anodized aluminum and glossy black anodized aluminum, are available to match the specific requirements of the product, including function and decorative appearance.

Black anodized aluminum is known for its high corrosion resistance, wear resistance, hardness, and insulation properties. It is widely used in various products, ranging from household items like lunch boxes, water bottles, and cooking utensils to parts for automobiles, semiconductors, industrial equipment, medical devices, and ship and aircraft interiors.

Glossy black anodized aluminum and matte black anodized aluminum are used for optical products.

Black Anodized Aluminum is produced in the following steps:

1) Anodizing of the aluminum substrate

2) Dyeing of the anodized aluminum

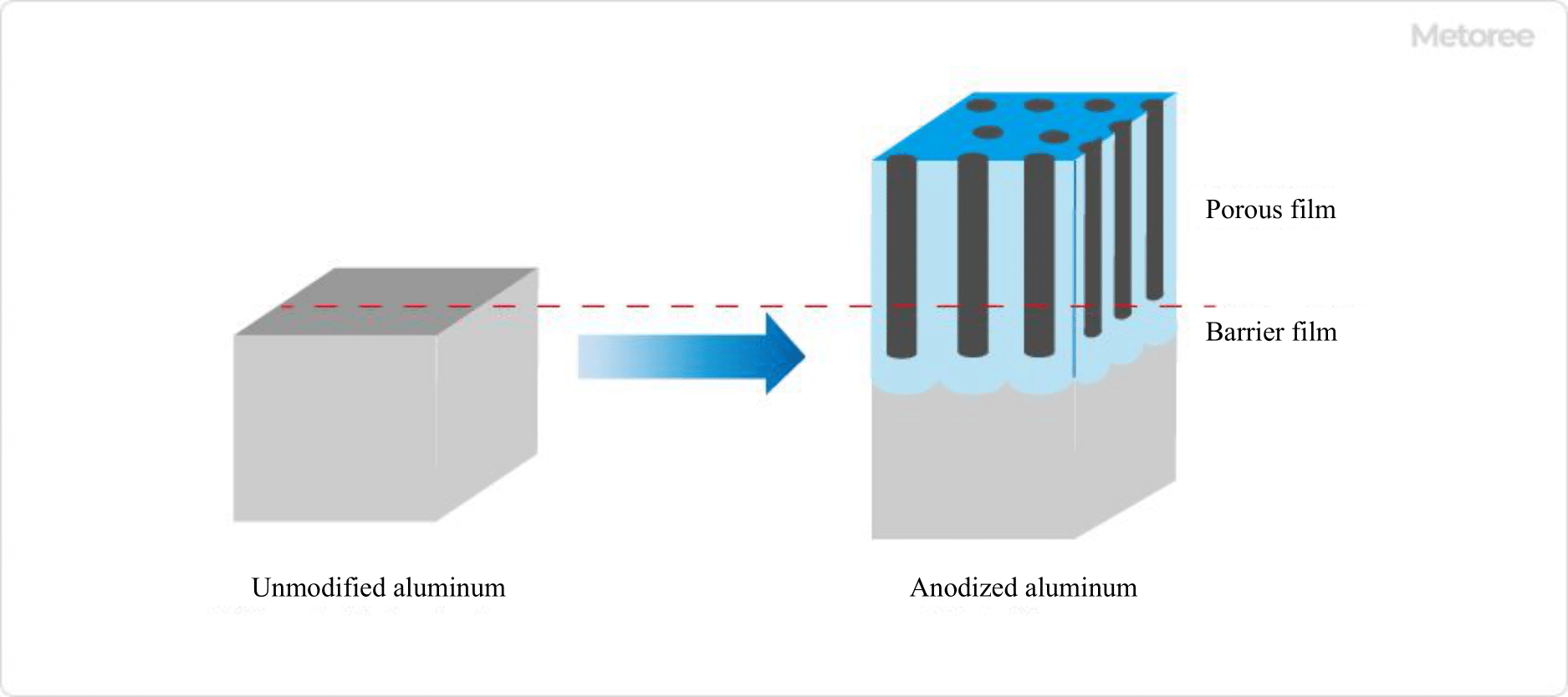

Figure 1. Schematic diagram of anodized aluminum

Anodizing is a treatment method in which an anodic oxide film forms on the aluminum surface through electrolysis, with aluminum serving as the anode. The process involves dissolving the surface of the aluminum substrate in an electrolytic solution to create the aluminate layer, resulting in a film consisting of two layers: a nonporous barrier film and a porous film.

The anodized aluminum coating is hard and offers excellent abrasion and corrosion resistance, effectively protecting the underlying aluminum substrate. Unlike plating, where a metal film is deposited on the surface using electrolysis, anodizing utilizes the aluminum substrate itself as the anode and undergoes electrolysis.

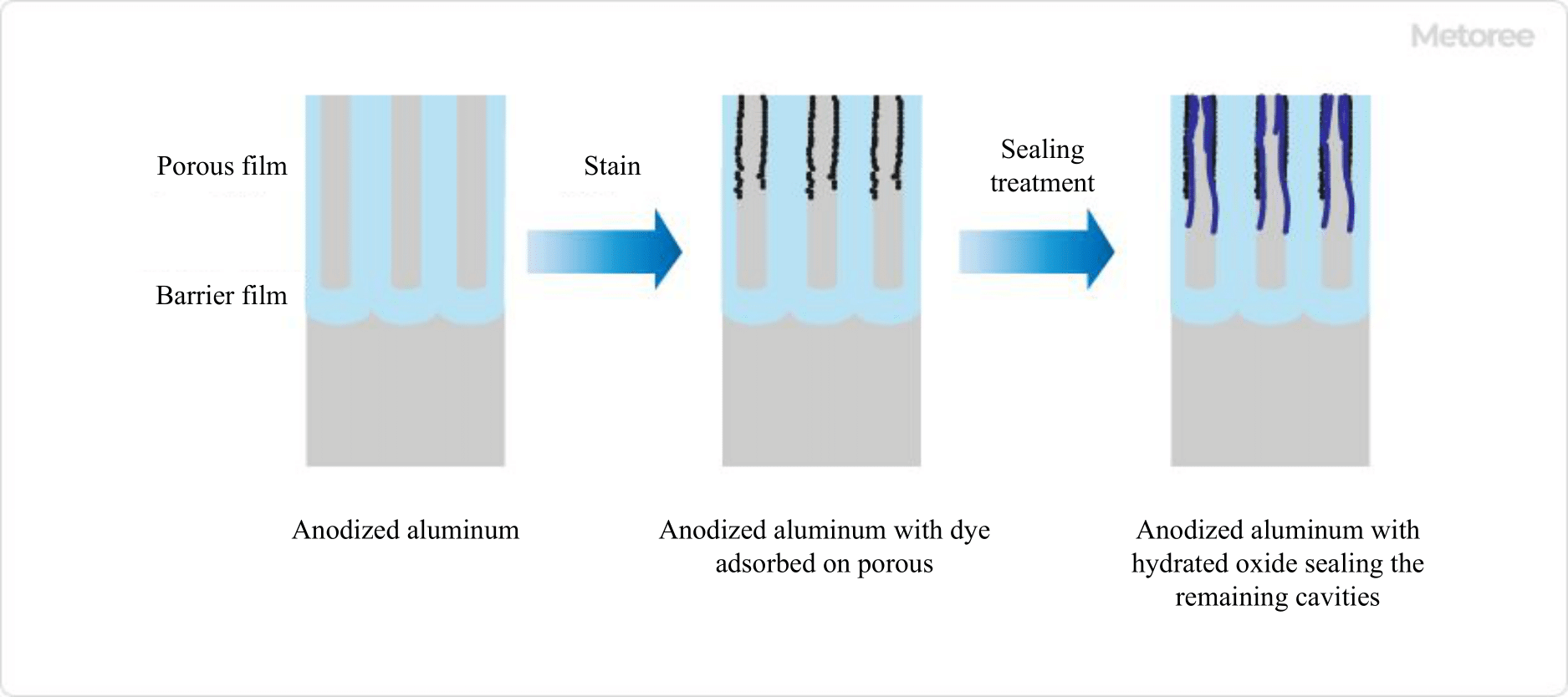

Figure 2. Staining and sealing treatment for anodized aluminum

As previously mentioned, a porous film layer forms on the anodized aluminum coating. In the production of Black Anodized Aluminum, the material is immersed in a dyeing tank, where black dye is introduced into these cavities. The dye is absorbed by the cells, and once absorbed, the cavities are sealed through a perforation process.

The amount of dye absorbed depends on the thickness of the anodized aluminum oxide film. To achieve a darker color, both the film thickness and dye absorption must be increased. Glossy black anodized aluminum and matte black anodized aluminum undergo pretreatment using chemicals.

Luster black anodized aluminum incorporates gloss into the anodized aluminum substrate, while matte black anodizing removes gloss through a matte finish.

Black Anodized Aluminum can be classified based on film thickness and dye.

The standard thickness of Black Anodized Aluminum is approximately 10 to 30 µm. Film thicknesses thinner than 10 µm result in reduced dye adherence to the surface film, affecting color quality. To achieve a consistent black color, a certain level of film thickness is necessary.

While films thicker than 30 µm can be created, they may not be suitable for physically constrained areas, such as narrow tubes or sharp edges. The film's performance depends significantly on the material, so film thickness should be considered in conjunction with dye compatibility.

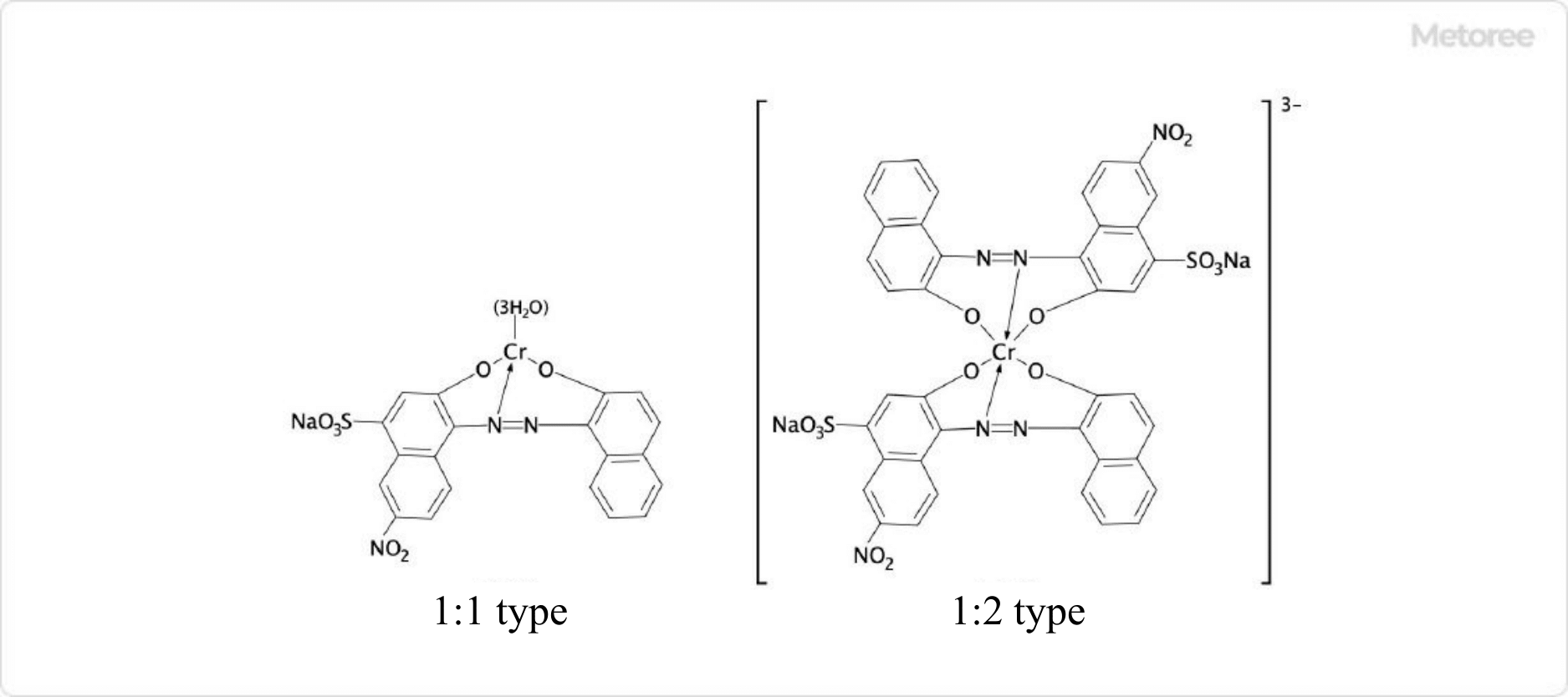

Figure 3. Structures of typical chromium complex organic azo dye

Organic chromium complex dyes are typical choices for Black Anodized Aluminum. These dye molecules feature a structure in which an organic ligand bonds with metallic chromium in either a 1:1 or 1:2 ratio.

The use of organic ligands in complexation with chromium enhances resistance to light and heat compared to single-chromium ligands. Given that the pore diameter of the film is several hundred Ångströms (Å), while dye molecules measure approximately several tens of Å, the dye molecules penetrate the film's pores and become colored through adsorption.

Key organic ligands include aromatic rings such as benzene and naphthalene, often featuring chromogenic properties in the form of substituent groups like nitro and azo groups. Dyes bonded to sulfonic acid, hydroxy, or amino groups have also been developed to enhance solubility in solvents.

In Black Anodized Aluminum, exposure to ultraviolet rays and heat from sunlight can lead to the decomposition of dye molecules, resulting in discoloration and fading. Consequently, UV-resistant dyes have been developed in recent years.

*Including some distributors, etc.

Sort by Features

Sort by Area

Riverside Sheet Metal & Contracting, Inc. is a manufacturer, supplier, and installer of metal roofing and sheet metal-related products founded in 1997 and based in Massachusetts, USA. The company specializes in the custom fabrication and installation of architectural metal products, including aluminum gutters, copper pans, edge metals, hood vents, and chimney caps. It serves diverse industries across the United States, including residential, commercial, industrial, and institutional sectors. The company is part of the National Roofing Contractors Association and the North East Roofing Contractors Association.

KIKUKAWA KOGYO CO., LTD. founded in Tokyo, Japan in 1933 is a manufacturer of architectural interior and exterior metal products. The company's product portfolio includes aluminum, stainless steel, bronze and steel standard and custom-made finishes. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and architecture. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing. They also provide custom metalwork services including minimal weld distortions, complex shapes and double curved panels.

Johnson Plastics Plus, established in 1970 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of plastic and magnetic products to the engraving and sign-making industries. The company's product line consists of sheet materials, sublimation blanks, heat transfer blanks, and UV-LED blanks. It also offers equipment like engraving machines, print and cut equipment, sublimation printers, heat presses, and other supplies. The company provides custom fabrication services and caters to various markets, such as sign fabrication, industrial, healthcare, and education.

Automatic Anodizing, established in 1947 and headquartered in Chicago, Illinois, is a manufacturer of aluminum finishing solutions. The company specializes in services such as bright dip anodizing, clear anodizing, color anodizing, and hard coat anodizing (with the Teflon option), strictly adhering to various industry standards such as Type II and III, Class 1 and 2 MIL-A-8625 and MIL-C-5541. These products excel at delivering solutions for applications such as anti-lock brake assemblies, pump components, valves, sliding parts, and more. It serves sectors including medical, military, aerospace, food, and more. It is aligned with industry associations such as AAC, NADCA, and PMPA.

Reliable Automatic Sprinkler Co. Inc. is perceived as a well-known manufacturer and distributor of fire protection equipment, headquartered in the United States. Its establishment dates back to 1920. A broad array of fire protection products, such as sprinklers, valves, devices, and accessories, are offered by Reliable Automatic Sprinkler. It caters to various industries, including commercial, residential, and industrial clients, and has a global presence across several countries. Reliable Automatic Sprinkler Co. Inc. has a proven track record of delivering quality fire protection equipment, making it a trustworthy and reputable enterprise.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Reliable Automatic Sprinkler Co., Inc. |

37.5%

|

| 2 | Johnson Plastics Plus |

18.8%

|

| 3 | Riverside Sheet Metal & Contracting, Inc. |

12.5%

|

| 4 | Automatic Anodizing |

12.5%

|

| 5 | KIKUKAWA KOGYO CO., LTD. |

12.5%

|

| 6 | Toei Denka Kogyo Co., Ltd. |

6.3%

|

Derivation Method

The ranking is calculated based on the click share within the black anodized aluminum page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

1 | 50.0% |

Japan

Japan

|

1 | 50.0% |

41 products found

41 products

Japan Management Label Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

Through a technical partnership with a specialized American company, images are formed using inorganic silver salt on an aluminum alumite plate wit...

Art 1 Co., Ltd.

530+ people viewing

Last viewed: 20 hours ago

■Features Electricity passes through even though masking is not required. ``Conductive Mite'' is anodized aluminum that conducts electricity and ca...

Art 1 Co., Ltd.

500+ people viewing

Last viewed: 18 hours ago

■Features ``Heat Black'' is a special black alumite that does not discolor or fade even when heated at 300℃ for 14 days or 500℃ for 1 hour for shor...

Art 1 Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

■Features Color alumite treatment for aluminum die-casting that only our company can do. It has a shine and can display the unique pattern of die c...

Art 1 Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Features We also correct machining errors and dimensional defects after alumite treatment. Anodized to accommodate dimensional tolerances within 0...

Art 1 Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■Features Black alumite for aluminum die-casting materials that has little reflected light ``Matte Black'' Even if you alumite-treated aluminum die...

Japan Management Label Co., Ltd.

540+ people viewing

Last viewed: 7 hours ago

An alumite nameplate is a nameplate created by forming a dyed image on an alumite film, dipping an organic dye into the alumite layer, and sealing ...

Miyaki USA, Inc.

1030+ people viewing

Last viewed: 2 hours ago

Kashima coat is a hard -lubricating alumite of Miyaki original Co., Ltd., which has a self -lubricating function to the hard aluminum film and aims...

Art 1 Co., Ltd.

500+ people viewing

Last viewed: 7 hours ago

■Features Uniblack is a semi-gloss black alumite that makes it difficult to see the wrinkles and flow of hot water in die-cast aluminum. After blac...

Art 1 Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■Features Dispels the conventional concept of hard alumite. Hard alumite that can be used with all aluminum alloys. I want to achieve hardness and ...

Nikkal Shoko Co., Ltd.

540+ people viewing

Last viewed: 15 hours ago

■What is aluminum steel plate? Aluminum steel plate is a steel plate whose main components are aluminum and iron. It is lightweight yet strong and ...

Art 1 Co., Ltd.

350+ people viewing

Last viewed: 20 hours ago

■Super hard alumite “carbide alumite” which is harder than hard alumite Those who think that the hardness of hard alumite can only reach the JIS st...

Art 1 Co., Ltd.

680+ people viewing

Last viewed: 15 hours ago

■Features Practical for the first time in the world. Electricity passes through all alloy types without masking. "Conductive Mite" is anodized alum...

Art 1 Co., Ltd.

380+ people viewing

Last viewed: 20 hours ago

■Features Even ADC12 material has 1.2 times the wear resistance of JIS standards. Wear-resistant hard alumite that can be used for aluminum die-cas...

Nikkal Shoko Co., Ltd.

650+ people viewing

Last viewed: 1 hour ago

■Features ・Ideal for decorative purposes. - Compared to flat plates, scratches and distortions on the surface are less noticeable. - Embossing inc...

Art 1 Co., Ltd.

450+ people viewing

Last viewed: 20 hours ago

■Features Achieves hardness comparable to wrought material. Hard alumite treatment for aluminum casting and aluminum die casting. Our hard alumite ...