All Categories

History

This section provides an overview for rotary presses as well as their applications and principles. Also, please take a look at the list of 12 rotary presse manufacturers and their company rankings. Here are the top-ranked rotary presse companies as of February, 2026: 1.Allied Machinery Group, Inc., 2.MORI MACHINERY CORPORATION, 3.GlobePharma Inc..

Table of Contents

Categories Related to Rotary Presses

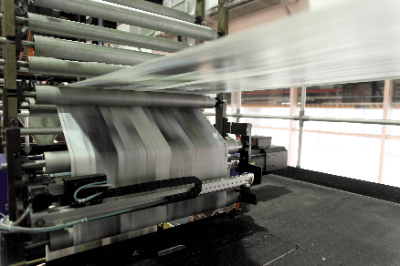

A rotary press is one of the printing presses in offset printing, capable of handling double-sided printing and multi-color printing at high speed. A roll of paper (take-up paper) is set, the printing plate is set in a rotating cylinder, and the paper is printed while being passed between the cylinders while being rewound on the other side of the press. This type of printing excels at printing large quantities of items, such as newspapers and flyers. After printing, the paper is cut to a predetermined size and finished. The printing press is very large. Rotary press printing is prone to paper shrinkage due to the use of a high-temperature dryer to dry the ink after printing. The size of the rolls that can be set is limited by the rotary press.

Rotary press printing presses that use cut sheets of paper are called sheet-fed presses, whereas rotary press printing presses use rolls of paper.

Offset printing is used for low-cost, high-volume printing and is often used to print magazines, newspapers, flyers, etc. with large circulation. Also used for posters, etc. Relatively thin paper is used. Special ink dries quickly with heat, so post-processing is unnecessary, and high-speed processing is possible by dryer processing at high temperatures after printing.

A roll of paper is set in the rotary press, and printing is performed while the roll passes between the blank and pressure cylinders. The printing plate (aluminum plate) is set in a part called the plate cylinder of the rotary press. Fountain solution and ink are applied to this plate, and once the ink is transferred to the blanket cylinder (blanket, a transfer roller made of resin or rubber), it is printed on the passing take-up paper. Printing is done in double-sided multi-color printing, which enables high-speed printing. To speed up ink drying, the rotary press uses heat-set ink, which dries rapidly with heat, and the ink is passed through a dryer section to dry. The hot paper is cooled by being wound onto cooled rollers in the cooling section that adjusts the tension of the web, and then the paper is folded and cut.

In a rotary press, the ink on the blank cylinder is transferred to the paper, so the paper and the plate do not come into direct contact with each other. This printing method is called offset printing. Since the plates do not touch the paper directly, there is less wear, and the long life of the plates also makes them suitable for high-volume printing.

Both rotary presses and photocopiers can reproduce originals, but each has its own advantages and disadvantages and is used for different purposes.

Copiers are generally for home and office use, with multifunction devices that include fax, printer, and scanner functions in addition to copying. They can be conveniently linked to a computer or network. Because the functions are integrated, they have the advantage of reducing equipment management costs and saving installation space. However, because they can print in full color, they are used for a wide range of purposes, including photo printing and the preparation of presentation materials.

A rotary press is not as multifunctional as a copier and is a dedicated printing machine that can print manuscripts at high speed, with one- or two-color printing being the most common type. They can print at more than 100 sheets per minute. Although it requires some space for installation and preparation such as setting up a rewinder and adjusting the machine, once a plate is made, ink is applied and the paper is crimped to print a large number of sheets, so the more sheets printed, the lower the unit price per sheet.

Printing with a rotary press consists of the following three major steps:

1. Prepress Process

This is the process from composition, design, and editing of the manuscript to be printed to plate making. Before digitalization, printing was done by typing on a transcription machine or creating plates from scanned pictures and photos.

2. Pressing Process

This is the process of printing using the plates created in the pre-press process. Printing is started after preparations such as setting the roll paper, mounting the plate, and adjustment of the ink have been made. At the beginning of printing, printing is done slowly while checking for any abnormalities such as misprinting or density, etc. After that, printing is done at a high speed by increasing the rotation speed.

3. Post-press Process

This is the process of post-processing the printed paper. Cutting is performed according to the size of the final printed product. Depending on the application, folding such as two-fold or four-fold, laminating, foil stamping, or other processing may be applied.

*Including some distributors, etc.

Sort by Features

Sort by Area

Allied Machinery Group, Inc., established in 2006, is a manufacturer and supplier of machine tool rebuild and control retrofit in Santa Fe Springs, CA, USA. The company designs and produces small air clutch presses, punch presses, shears, and press brakes, within the limits of OSHA compliance. Their team has over 100 years of collective experience in troubleshooting and resolving complex machinery problems. Their product line includes Italian punch presses, air feeds, and stock reels. They also specialize in servicing machinery in-house or on-site.

GlobePharma, incorporated in 1993, is a manufacturer of pharmaceutical sampling equipment, laboratory and pilot scale blending systems, milling machines, cleaning validation tools and coupons, high-shear granulators, and tablet presses. The company is a supplier of particle size-reducing equipment, sundry equipment, and cGMP valves used in the pharmaceutical, nutraceutical, food, cosmetic, and automotive industries. The company in New Brunswick, New Jersey, offers services such as equipment maintenance, training, documentation services, repair, and refurbishment of equipment.

Beckwood Press is an American manufacturer of press machines and hydroforming equipment that was established in 1976. Based in St. Louis, Missouri, the company offers standard and custom hydraulic presses, linear servo presses, servo-electric presses, and sheet hydroforming equipment. These have a wide range of applications including punching and blanking, compression molding, forging, and assembly. Beckwood Press also provides retrofitting, upgrading, maintenance, and press relocation services to their clients in the aerospace, defense, and automotive sectors.

Evoqua Water Technologies began in 2013 and is headquartered in Pittsburgh, Pennsylvania. The company is a manufacturer and service provider of water and wastewater treatment systems, serving commercial, industrial, and municipal water treatment customers both in the United States and globally. The company’s two operating segments are Integrated Solutions and Services, and Applied Product Technologies. The former provides water service contracts providing water cleaning services including odor and corrosion control services. The latter sells advanced filtration products including self-cleaning filters, disinfection solutions, and non-chemical disinfection products.

Hi-Tech Fasteners (HTF) was founded in 1988 and headquartered in Frederick, Maryland. HTF is a distributor of hardware components. HTF offers products in four product types: self-clinching fasteners such as studs and nuts, general fasteners & hardware, inserts, and components. HTF also offers a full line of PEM® Brand products including fasteners for metal sheets and panels, fasteners for BC boards and other non-ductile material, insert for plastics, bonding fasteners, rivet nuts, and fastener installation equipment.

GEA Group Aktiengesellschaft, founded in 1881 with headquarters in Germany, is an integrated manufacturer of process technology, machinery, and production plants. The company offers various products, including complete turnkey solutions for beverage plants, as well as beverage packaging services. The company has more than 18,000 employees working across five divisions and has facilities in over 60 countries, serving the food and beverage, chemical, marine, pharmaceutical, and energy markets, among others. GEA Group Aktiengesellschaft's service division works with clients to improve their production plant productivity, especially in the food and beverage industry.

Macrodyne Hydraulic Presses and Automation is based in Ontario, Canada. The company is a manufacturer of hydraulic presses, press lines, and die-handling equipment. Macrodyne designs and manufactures hydraulic presses of up to 30,000 tons, fully automated hydraulic press lines, and die-handling equipment for dies and molds weighing in excess of 100 tons. Their products are used for general metal forming, forging, die spotting, and rubber transfer molding among others, and can be customized to specification.

Altman Manufacturing Co., Inc. established in Lisle, IL in 1945 is a manufacturer of secondary operation machines that are used for cutting and trimming. Their product portfolio includes gang dies, air bench presses, HY Pro Trim presses, automatic finishing machines, and rotary secondary operation machines. The company's products are used for the manufacturing process in industries including electronics, automotive, plastic injection molding, and packaging. The company has a national distribution network and a customer support center.

Pankaj Industries was founded in 1984 in Maharashtra, India, as a manufacturer and supplier of Table Press Machines. The company's range of products includes Veterinary Tablet Press Machines (VTPM), Bi-Layer Machines (BLM), and Double Rotary Tablet Press Machine Bolus (DRTPMB). The products are vital in the pharmaceutical industry for medicine production but cherished for high performance, less maintenance, and easy installation. Products are popular in markets such as Bangladesh, Sri Lanka, Malaysia, and the United States.

Talleres Pradillos, S.L, established in 1988 in Tomelloso, Spain, is a manufacturer and supplier of machinery for producing indoor and outdoor terrazzo tile. The company manufactures essential machines based on client specifications, including concrete plant, rotary press, automatic horizontal take-off, roll turnover machine, vertical extractor, and feeder. It also utilizes 3D design software to produce custom-made projects, automate industrial processes, manage export procedures, provide technical assistance online, create spare parts, and repair used machines.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Talleres Pradillos, S.L. |

12.9%

|

| 2 | Allied Machinery Group, Inc. |

12.1%

|

| 3 | MORI MACHINERY CORPORATION |

11.2%

|

| 4 | GlobePharma Inc. |

10.3%

|

| 5 | Evoqua Water Technologies LLC |

8.6%

|

| 6 | GEA Group Aktiengesellschaft |

8.6%

|

| 7 | Macrodyne Technologies Inc. |

7.8%

|

| 8 | Beckwood Press |

6.9%

|

| 9 | Hi-Tech Fasteners, Inc. |

6.9%

|

| 10 | Altman Manufacturing Co., Inc. |

6.0%

|

Derivation Method

The ranking is calculated based on the click share within the rotary presse page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 50.0% |

India

India

|

2 | 20.0% |

Germany

Germany

|

1 | 10.0% |

Canada

Canada

|

1 | 10.0% |

Japan

Japan

|

1 | 10.0% |

46 products found

46 products

GTB Co., Ltd.

410+ people viewing

Last viewed: 29 minutes ago

■Further evolution of industry-leading digital/analog print inspection ・Achieving faster and more accurate print inspection ・Non-contact scanne...

2 models listed

Gensuke Co., Ltd.

600+ people viewing

Specification ■Number of printed sheets Plastic plate ・Front side six colors (back side 1 color) ・Front side five colors (back side 1 color) ■Nu...

Gensuke Co., Ltd.

520+ people viewing

Features ■Equipment ・Corona processing device ・Hot melt coating equipment ・UV glue coating device ・Automatic examination device between impress...

Gensuke Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

Gensuke Co., Ltd.

710+ people viewing

Last viewed: 29 minutes ago

Features ■Equipment ・Meandering correction device ・Tension control ・Touch panel operation specification ■Detection function ・Label omission ・...

Newlong Machine Works, Ltd.

410+ people viewing

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

400+ people viewing

Last viewed: 12 hours ago

New Long's flexographic printing machine utilizes the latest electronic technology and precision mechanical technology. As a pioneer of flexo prin...

Newlong Machine Works, Ltd.

450+ people viewing

Last viewed: 1 day ago

New Long's flexographic printing machine utilizes the latest electronic technology and precision mechanical technology. As a pioneer of flexo prin...

Newlong Machine Works, Ltd.

370+ people viewing

Efficiently process printing plates and proofs using computer control This machine is a computer-controlled flexographic printing plate pasting pr...

Newlong Machine Works, Ltd.

780+ people viewing

Last viewed: 10 hours ago

Efficiently process printing plates and proofs using computer control This machine is a computer-controlled flexographic printing plate pasting pr...

Newlong Machine Works, Ltd.

470+ people viewing

Last viewed: 2 hours ago

A new weapon for efficiently operating flexo printing machines. It has excellent operability and even beginners can easily print proofs. It can be ...

Yukosha Shito Trading Co., Ltd.

510+ people viewing

■Why not replace it with a high-quality, long-life plastic doctor blade? It is a reliable product with a top class share in the world in the fields...

Newlong Machine Works, Ltd.

410+ people viewing

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Seiko Epson Corporation

400+ people viewing

Last viewed: 15 hours ago

Responding to the changing label market ■Meeting the needs of the increasingly small-lot, multi-product market. Reinvent your workflow with SurePre...

2 models listed

Gensuke Co., Ltd.

370+ people viewing

■Features This machine is a rotary printing machine with two-color printing, die-cutting, label transfer, and slitter, and is a modification of exi...

Europort Co., Ltd.

290+ people viewing

Last viewed: 23 hours ago

■Transfer paper and fabric are set as rolls. Drum-type thermal transfer machine compatible with large-volume printing This rotary press for heat tr...

Newlong Machine Works, Ltd.

380+ people viewing

Last viewed: 23 hours ago

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

390+ people viewing

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

390+ people viewing

Last viewed: 1 day ago

New Long's flexographic printing machine utilizes the latest electronic technology and precision mechanical technology. As a pioneer of flexo prin...

Newlong Machine Works, Ltd.

380+ people viewing

Last viewed: 1 day ago

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

420+ people viewing

Last viewed: 1 day ago

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

410+ people viewing

Last viewed: 1 day ago

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

340+ people viewing

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

350+ people viewing

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...

Newlong Machine Works, Ltd.

440+ people viewing

The FK series is a stack type single-sided 2-color or 3-color flexo printing machine. This printing machine is directly connected to a square-botto...