All Categories

History

This section provides an overview for windlasses as well as their applications and principles. Also, please take a look at the list of 13 windlass manufacturers and their company rankings. Here are the top-ranked windlass companies as of July, 2025: 1.Schaefer Marine, 2.Maxwell, 3.Appleton Marine.

Table of Contents

Categories Related to Windlasses

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

A windlass is a device designed for winding sheet products such as film or hoses. It’s primarily used for winding sheets and similar products, streamlining handling and storage. By coiling long products onto a core, it enables compact handling without compromising the quality of the products.

Windlasses are crucial for optimizing material winding processes and enhancing organization and storage. These devices are ubiquitous in various industrial settings and everyday life, playing a vital role in efficient material handling and management.

Windlasses have diverse applications:

Windlasses consist of several components:

Provides structural support, typically made of steel or other metals.

Powers the device, selected based on material weight and winding speed. In the case of manual winding, the motor is omitted and a handle is attached instead.

The core component where materials are wound. Its design varies based on material characteristics.

The winder is operated by a control unit. The controller adjusts the parameters of the winding process, such as winding speed and traverse control.

A constant tension must be maintained if the windlass is to wind the sheet product without wrinkling or sagging. However, since the roll diameter increases as the winding progresses, tension cannot be maintained simply by keeping the output of the motor on the take-up shaft constant.

To maintain constant tension during winding, open-loop or feedback control systems like a dancer roll are used.

Windlasses come in various forms:

*Including some distributors, etc.

Sort by Features

Sort by Area

Appleton Marine was founded in 1972 and is an employee-held manufacturer of custom marine deck machinery in East Persing Street, Appleton, Wisconsin, USA. The company’s products are cranes, winches, vertical or horizontal windlasses, and capstans used in mining, shipbuilding, government, offshore, and shipyard industries. The company offers testing, inspection, and quality services with ISO 9001:2015 certification and APoi Specification Q1. The products have certifications in ABS, CCS, DNV, USCG, and RS.

Schaefer Marine, founded in 1966, is a designer and manufacturer of rugged and durable gears and sailboat products in Duchaine Boulevard, New Bedford, MA. The company’s products include boom furler systems, tuff luffs, blocks, jib furlers, and battslide mainsail systems. It also produces horizontal or vertical windlass, water jet machines, and hardware such as cast pads, lined slides, lead blocks, Jib and shackles. The company warrants its products to be free from defects in material and workmanship for ten years.

MITSUBA MFG. CO., LTD., established in 1930 and headquartered in Tokyo, Japan, is a manufacturer in the areas of plastic and rubber extrusion and electric wire coating. The company's product lineup includes front wiper systems, rear wiper systems, windshield washer systems, power window motors, and power sliding door drives It also offers personalized production services to meet the needs of its customers. It has improved automobile safety and comfort through enhanced field of vision, convenience, comfort, and communication. The company's products are used in various industries, including the automotive industry, motorcycle industry, micro-mobility industry, and life-support goods industry.

The Japan Steel Works, LTD., founded in Tokyo, Japan, in 1907 is a manufacturer of plastic machinery products and plastic molding machines, as well as IT and defense products. The company's product portfolio includes Spinning Extruders, Film and Sheet Manufacturing Equipment, Polyolefin Pelletizers, Magnesium Injection Molding Machines and hot presses. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company has a national distribution network and a customer support center.

Quick, founded in 1982, is a designer and manufacturer of electrical systems, air conditioning, refrigeration, heating, and marine electronics, in Piangipane, Italy. Products offered by the company include handheld remote controllers, controls for proportional systems, chain counters, multipurpose capstans, and vertical axis windlasses. It also manufactures auxiliary items for anchoring, including thruster systems, hydraulic system parts, water heaters, pure sine wave inverters, and other items like connections, electronic switches, solenoid valves, and cable outlets.

Tytan Marine, established in 2000, is a custom manufacturer and designer of systems for anchor & mooring, ocean investigation, and lifting for offshore, government, and shipbuilding in Yubei District, Chongqing, China. The company’s range of products includes cranes, winches, windlasses, capstans, and power pack units for marine environments. It has loading test platforms, CNC, boring, loading test towers, and milling capabilities. The company offers after-sale services such as spare parts, repair, maintenance, and inspection. The company is an ISO 9001 certified company, and the products are CCS, ABS, RINA, BV, and NK certified.

PilotFits Engineering Co.,Ltd., founded in 2008 with headquarters in China, is a manufacturer of marine and offshore berthing and docking systems and equipment. The company's products include anchors, marine chains, boat fittings, marine cranes, and marine winches. PilotFits Engineering Co.,Ltd. is used on consumer boats and commercial ships, as well as on local docking facilities and large-scale infrastructure ports. The company also offers custom product production and installation services for clients that include shipowners, contractors, and shipyards.

Lofrans, founded in 1966, is a manufacturer of windlasses and anchor management solutions in Monza, Italy. The company's catalog contains vertical or horizontal windlasses, wrapping capstans, mega yacht solutions, and deck accessories such as chain counters, hand-held controls, chain stoppers & rollers, gypsies, and chains made from stainless steel marine grade metals, and electric motors for the marine environment. It also produces spare parts, finger, maintenance, and sensor kits for windlasses.

Lighthouse Mfg. Co. has been a manufacturer of marine equipment, fishing parts, and systems in Riverside, California, Since 1979. The company's catalog includes stainless steel anchor windlasses, capstans, motor extension housings, winches, and accessories comprising cockpit-mounted remote control consoles, submariner reversing circuits, handheld roving remotes, ball bearings, and hydraulic system components for marine environments. It also creates distant count stations with prewired bi-directional LCD chain counters to facilitate smooth product installation.

Muir USA has been a manufacturer and designer of anchor winches and anchoring systems in the Southern Ocean, Tasmania, Australia, since 1968. The company manufactures equipment based on their applications, such as recreational products such as capstans, drum winches, vertical or horizontal windlasses, and easyweighs for workboats, fast ferries, defense vessels, and mega yachts. It also produces industrial goods including anchoring and mooring equipment out of stainless steel, chromed bronze, manganese bronze, and aluminum bronze.

Maxwell, established in 1969, is a designer and manufacturer of anchoring solutions for pleasure craft, superyachts, and commercial vessels in Rosedale, Auckland, New Zealand. The power and sail items include vertical windlasses, drum winches, chain windlasses, bow rollers, as well as accessories such as solenoids, wired rode counters, foot switches, and auto anchor wireless. It also manufactures deck gears and retractable capstans and provides backup services. The company has distributors in South Africa, South America, the Middle East, the Gulf States, and Europe.

Westec, in North Vancouver, BC, and incorporated in 1999, is a supplier of machinery, services, and hydraulic systems and components to the marine and fishing industries. The company supplies the fishing division with power blocks, fish pumps, fishing winches, hydraulic pump drives, and bow thrusters. It also serves the marine division with anchor windlasses, mooring capstans, articulated tug barge clamp systems, and pump drives. The company offers design solutions, machining services, welding, fabrication, and equipment rebuilding for the machines.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Schaefer Marine |

15.8%

|

| 2 | Maxwell |

11.4%

|

| 3 | Appleton Marine |

11.4%

|

| 4 | Westec |

9.2%

|

| 5 | Quick S.p.A. |

8.1%

|

| 6 | Muir USA |

8.1%

|

| 7 | Lighthouse Mfg. Co. |

7.7%

|

| 8 | Tytan marine |

7.7%

|

| 9 | Lofrans |

7.4%

|

| 10 | MITSUBA MFG. CO., LTD. |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the windlass page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 22.2% |

Japan

Japan

|

2 | 22.2% |

Italy

Italy

|

2 | 22.2% |

China

China

|

2 | 22.2% |

Canada

Canada

|

1 | 11.1% |

74 products found

74 products

Nippon Sealing Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■Features ・SH-201 is not a packaging machine. - Automatically winds the film. ・It is very convenient because it has two convenient hooks and stor...

True Sortech

680+ people viewing

Last viewed: 1 hour ago

Space -saving design that allows you to multilize existing production lines. Enriched functions such as program management of production conditions...

Yutaka Manufacturing Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

It cuts raw materials such as film, paper, filters, etc. into specified dimensions while winding them into a roll. We also manufacture custom-made ...

MITSUBA MFG. CO., LTD.

400+ people viewing

Last viewed: 22 hours ago

This facility is a line that produces hoses made of a combination of synthetic rubber and fluororesin. Taking advantage of our strength in manufact...

4 models listed

Okawa Sanki Co., Ltd.

330+ people viewing

Last viewed: 8 hours ago

■Interlocking winder ・This machine is a device that works in conjunction with SA series machines to wind up electric wires into bundles. - The siz...

Okawa Sanki Co., Ltd.

390+ people viewing

Last viewed: 10 hours ago

■Simple drum winding machine ・This machine is a simple machine for winding electric wire onto a drum. - Place the drum on the roller and use the f...

Okawa Sanki Co., Ltd.

340+ people viewing

Last viewed: 1 hour ago

■Wire winding machine ・This machine is a device for winding electric wires onto a drum, and is intended for work such as collecting temporary wire...

Okawa Sanki Co., Ltd.

290+ people viewing

Last viewed: 10 hours ago

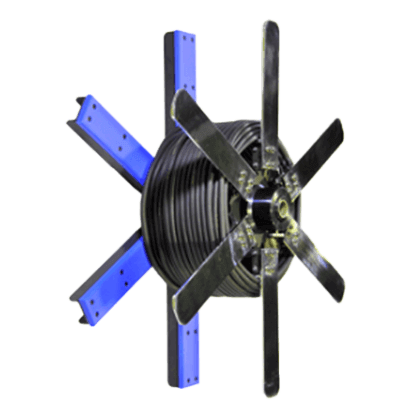

■Simple winder OSTA Model KRE ・This machine is a simple machine for winding electric wires into bundles. - The size of the winding parasol varies ...

Okawa Sanki Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

■Summary ・A device that winds up electric wire by horizontally rotating a winding parasol. -In addition to rotation speed and rotation direction, ...

Okawa Sanki Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

■Simple measuring winder ・This machine is used to measure wires and wind them into bundles. - Winding work is performed using a foot switch. - Equ...

Okawa Sanki Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Manual winder ・This machine is a manual winder for winding wires into bundles. ・Used in conjunction with PR type winding parasol. ・The winding ...

Okawa Sanki Co., Ltd.

440+ people viewing

Last viewed: 16 hours ago

■Bobbin feeder - A feeding device that pulls out the wire from the bobbin and feeds it to a cutting machine, etc. ・The electric wire is paid out i...

Okawa Sanki Co., Ltd.

270+ people viewing

Last viewed: 17 hours ago

■Interlocking flat cable winding machine ・This machine is a device that works in conjunction with SA series machines to wind flat cable records. ...

Okawa Sanki Co., Ltd.

720+ people viewing

Last viewed: 16 hours ago

■Rewinding parasol ・It is attached to devices such as KRE type, PRS type, ERS-850 type, etc. and used when winding electric wire. - The brim is op...

10 models listed

Okawa Sanki Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

■Rewinding parasol ・It is attached to devices such as KRE type, PRS type, ERS-850 type, etc. and used when winding electric wire. - The brim is op...

6 models listed

Okawa Sanki Co., Ltd.

450+ people viewing

Last viewed: 10 hours ago

■Rewinding parasol ・It is attached to devices such as KRE type, PRS type, ERS-850 type, etc. and used when winding electric wire. - The brim is op...

5 models listed

MITSUBA MFG. CO., LTD.

510+ people viewing

Last viewed: 17 hours ago

For sheathed cable lines, by selecting equipment from a wide range of products such as extruders and auxiliary equipment, we can produce power cabl...

6 models listed

MITSUBA MFG. CO., LTD.

330+ people viewing

Fluororesin tubes have characteristics such as chemical resistance, non-adhesiveness, purity, and weather resistance, so they are mainly used in se...

4 models listed