All Categories

History

This section provides an overview for mechanical valves as well as their applications and principles. Also, please take a look at the list of 14 mechanical valve manufacturers and their company rankings. Here are the top-ranked mechanical valve companies as of February, 2026: 1.Palex Medical, 2.Highlight Tech. Corporation, 3.Blain Hydraulics GmbH.

Table of Contents

Categories Related to Mechanical Valves

A mechanical valve is a control valve that changes the flow of air operated by human power or by contact with an object.

To make an actuator such as a pneumatic cylinder work, it is necessary to switch the flow of compressed air freely. In the case of a single-acting cylinder, compressed air is supplied in the forward direction when moving forward, and in the reverse direction when moving backward, the compressed air is released into the atmosphere.

The valve that controls the direction of air flow is called a directional valve. Directional valves can be controlled in three ways: electrically, pneumatically, or by human or mechanical contact. A solenoid valve is operated by an electrical signal to open and close the valve, while a pneumatically operated valve is called a (air) pilot operated valve.

A mechanical control valve is operated by hand or foot, or by mechanical contact with an object, such as a limit switch. Such a control valve operated by human power or mechanical contact is called a mechanical valve because it is operated by mechanical action.

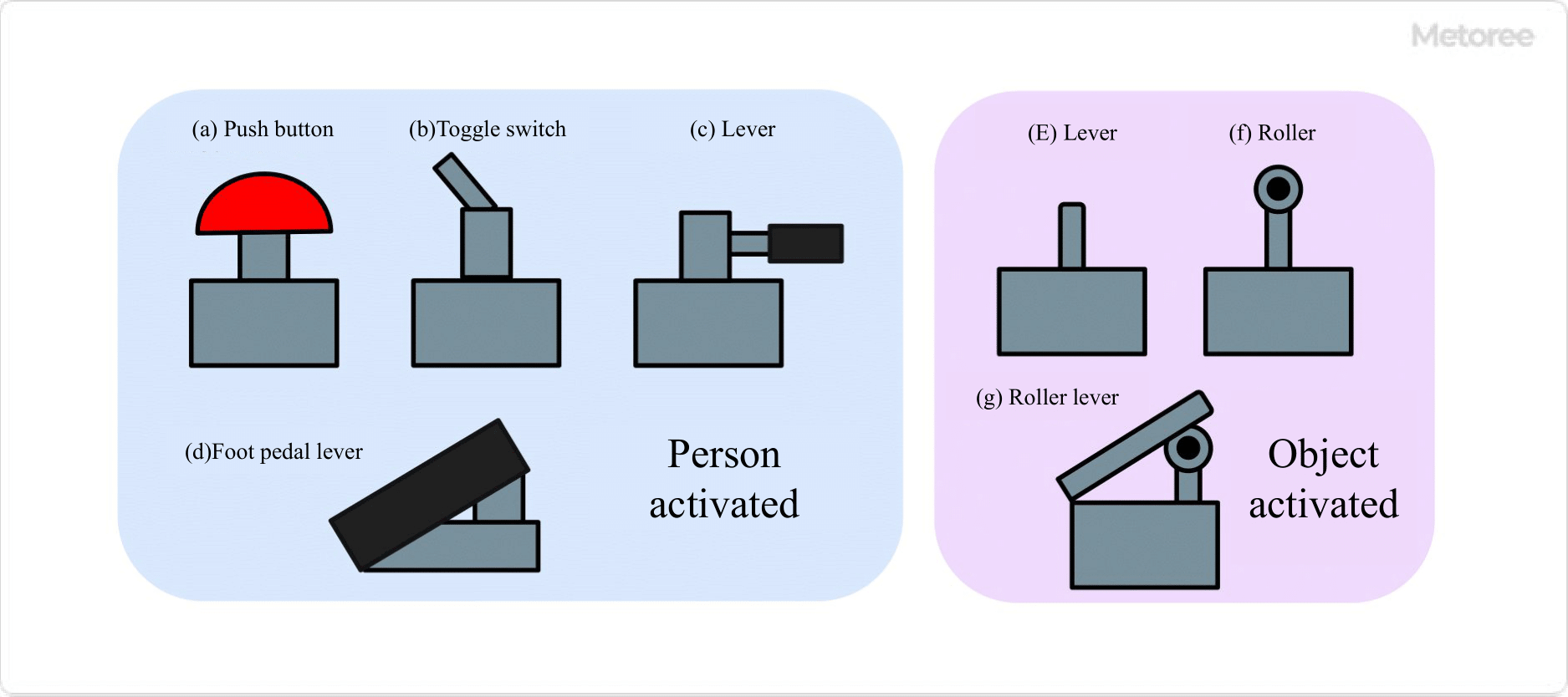

Figure 1. Classification of mechanical valves by method of operation

Mechanical valves are useful in places where fire is strictly prohibited and explosion-proof specifications are required. Since actuators such as pneumatic cylinders can be operated only with pneumatic devices without using electrical signals, there is no need to worry about leakage of electricity or electric shock.

Push buttons, levers, and pedal types are available for those operated by human hands and feet. Besides being used as supply shutoff valves installed at the entrance of equipment, they are mainly used in semi-automated equipment. They may also be used as start-up switches for air sequence control.

Those with mechanical operation include plunger and roller types. Used as a switch for cylinder operation or workpiece position confirmation, it generates a signal for air sequence control.

For example, it is possible to control the cylinder to stop moving automatically when the door is opened or to operate only when the door is opened.

In mechanical valves, a button is pressed by a human, or a plunger is pressed by a door or workpiece, which releases a flow path or is blocked by a valve. This is the principle of changing the pressure of airflow.

There are three types of valve structures: poppet type, spool type, and sliding valve type. The poppet type has a simple structure but requires a large amount of force to operate. This makes the valve more sealed, making it suitable for high-purity gas lines.

The spool and sliding valve types can be operated with relatively small force, but require a longer stroke.

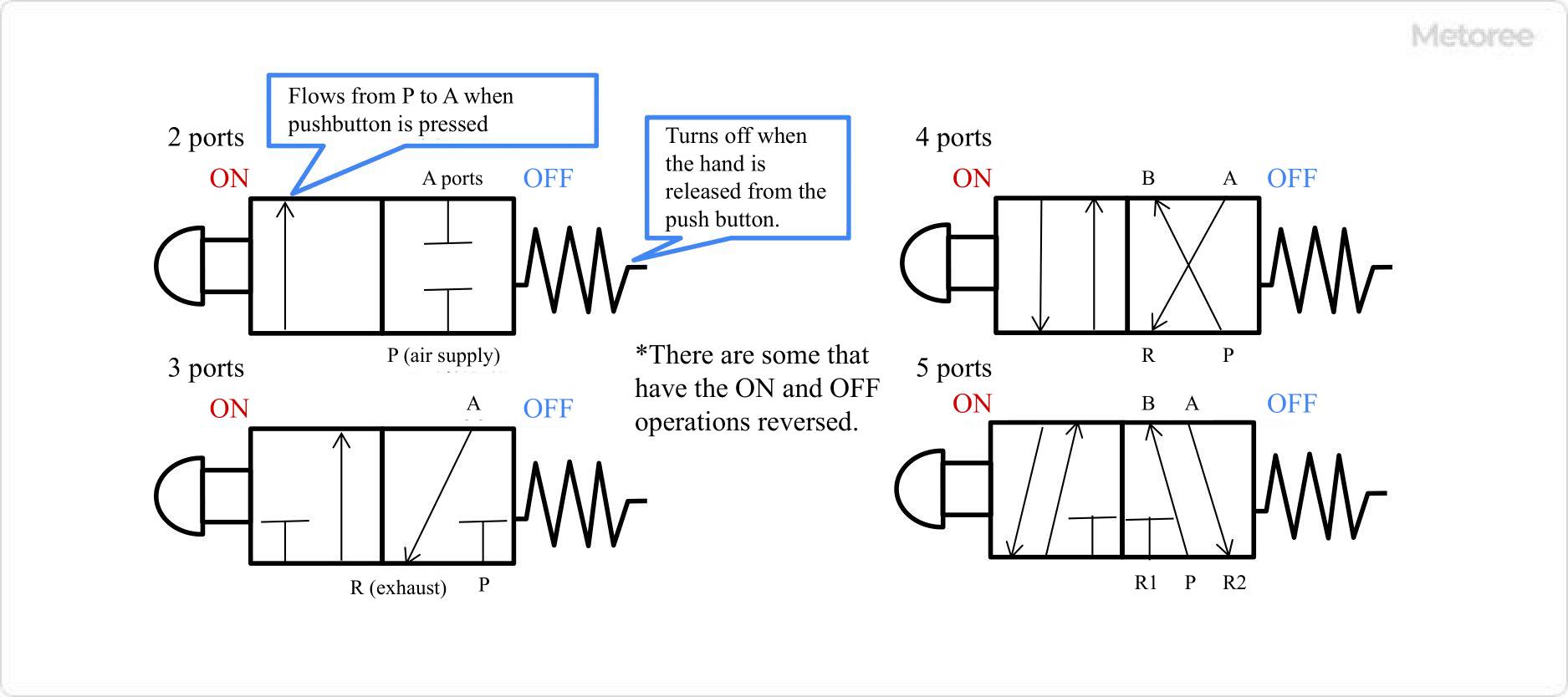

Figure 2. Difference in flow direction by port of 2-position mechanical valve (JIS symbol)

As with solenoid valves, the number of ports must be selected for mechanical valves as well.

2-Port Valve

A 2-port valve simply stops or diverts airflow. If you look at the 2-port, you will see a square on the left side, which means that air flows when the pushbutton is pressed. On the right side, the A and P ports are not connected, so no air flows.

3-Port Valve

A 3-port valve has an exhaust port and functions to supply and exhaust air. They are often used to operate single-acting cylinders or to signal air pilot lines. When the button is pressed, air flows from P to A. When the button is released, the air in A is exhausted out through the R port.

4- and 5-Port Valves

The 4- and 5-port valves have a function to intake air from the P port and supply and exhaust air alternately from the A and B output ports. One or two exhaust ports are available.

When connected to a double acting air cylinder, it can slide in both directions.

Depending on the number of switching positions the directional valve has, it can have two or three positions. For example, if the valve is designed to switch between state 1 and state 2 by "pushing" or "not pushing" a switch, it has 2 positions, and if it is a lever-type manual switching valve, it has a third state 3. In the case of a lever-type manual switching valve, a valve that has a third state (state 3) is in the 3-position. In the case of mechanical valves, state 3 is a 3-position closed center, which means that both ports A and B are sealed.

A switch that returns to its original state by spring force when the button is released after being pressed is called a spring return type. A switch that retains the pressed state is called a retention type. It is also important to consider the operation after the switch is pressed when making a selection.

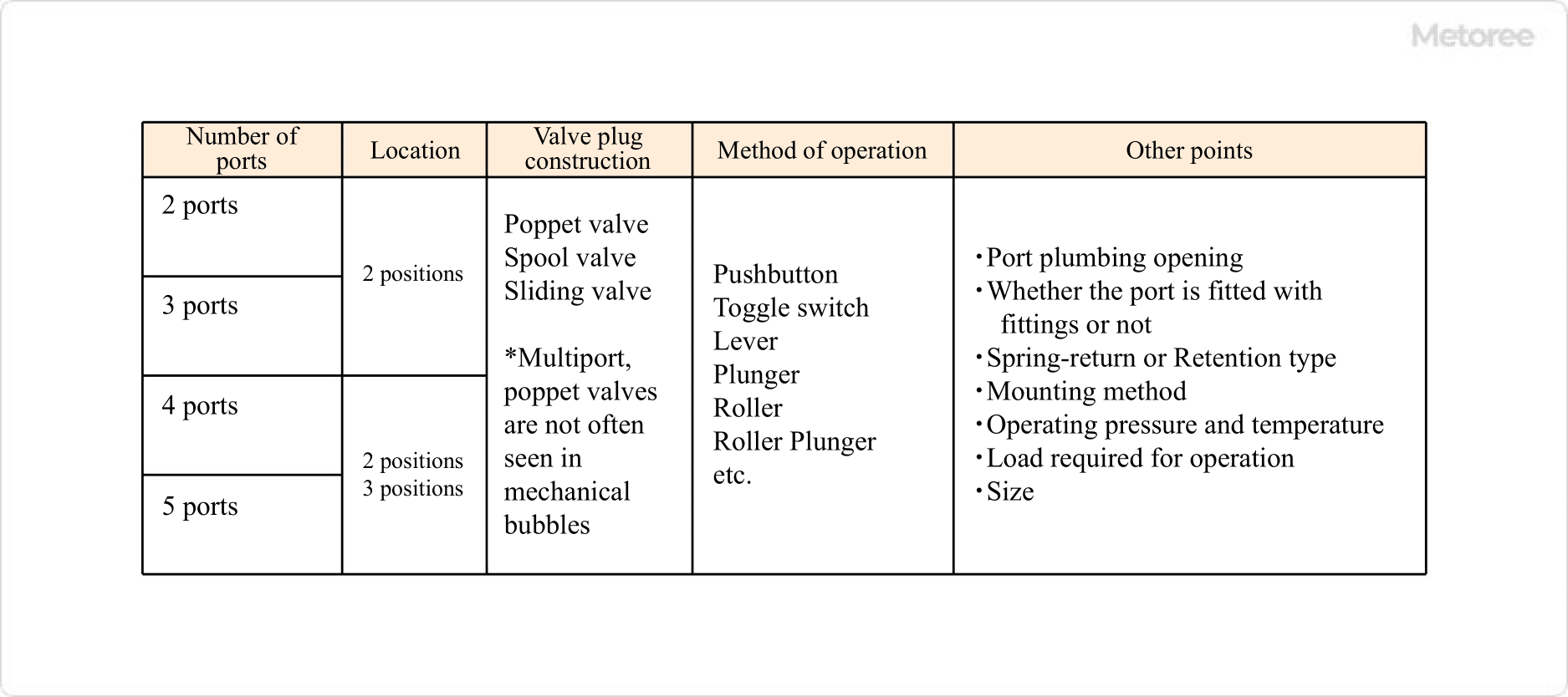

Figure 3. Classification of mechanical valves by method of operation

There are various other selection points, such as the size of the port piping opening and the operating pressure. Because of these various types, it is important to design the pneumatic circuit in advance and determine which components will be needed before purchasing.

Because the valve must be moved under pressure by compressed air, a large amount of force is required, especially for valves with poppet-type valves. For example, an object that is intended to push the plunger may be pushed back the other way. Be sure to check the catalog value, as it states how much load should be applied.

It is important to always use a filter in the compressed air supply circuit to all directional control valves to ensure that debris and condensate are removed. Select a filter with a filtering fineness of 5 µm or less.

Air pressure containing large amounts of condensate can cause malfunctions to other pneumatic equipment, so countermeasures should be taken by installing after coolers, air dryers, etc.

*Including some distributors, etc.

Sort by Features

Sort by Area

Blain Hydraulics GmbH, established in 1971 and headquartered in Baden-Württemberg, Germany, is a manufacturer that specializes in the design and manufacture of elevator control valves. The company offers a wide range of products, including lift component, pipe rupture valve, micro leveling drives, home lift, and lift valves. It also provides safety valves, rupture valves, components such as pumps and motors, accessories such as hand Pumps, and more. Its products have self-cleaning filters with a high tolerance to oil contamination. The company has achieved ISO 9001 certification for its quality management. Moreover, it serves the hydraulic elevator industry.

Highlight Tech. Corporation, established in Tainan City, in 1977 is a manufacturer engaged in vacuum valves, gate vales and vacuum components for ultra-high vacuum environment process engineers. The company's product range includes LED, Touch flat panel display, semiconductor, optoelectronics technology and film vacuum coating. The company has service locations in Taiwan, China and worldwide representatives in Europe, Asia, The USA and Australia. In 2022 the company entered the Chinese market by selling the equipment of Thin-film Photovoltaic, developed by HTC.

WENZHOU PIONEER VALVE, founded in 1993 and headquartered in China, is a manufacturer of wafer type ball valves. The company offers diverse products including flush tank bottom ball valves, direct mounting high platform ball valves, and thin-type flanged ball valves. Additionally, it offers services such as repair, maintenance, and a complete line of spare and replacement parts. These products are used across various industries, including heavy-duty ball valves, refrigerant central air conditioning units, and high-temperature jacket chemical applications.

Nihon Pisco Co. Ltd., founded in 1976 and based in Nagano, Japan, is a manufacturer and distributor of pneumatic equipment and is ISO 9001 and ISO 14001 certified. The company stocks various products like valves, actuators, and vacuum accessories used in several industries, including semiconductor, medicine, and rechargeable battery. The company started selling push-in fitting for pneumatic piping in 1977 and launched the industry’s first push-in fitting built-in type speed controller in 1981. In 1993, it launched a few products, including a quick exhaust valve, a digital pressure sensor, and a vacuum generator with a digital pressure sensor.

SHAKO Co., Ltd., established in 1980, based in Taiwan, is a manufacturer of pneumatic components. The company's product portfolio includes filter regulator-lubricator combinations, pneumatic solenoid valves, mechanical valves, pneumatic press, and other relevant valves and accessories. Their products are marketed and applied to the industrial fields of automation equipment, automotive assembly, medication, and electronic machinery. The company has a robust sales network and offers after-sale service, as well as providing well-equipped in-house design and engineering team to handle in-time customer request.

CKD Corporation, established in 1943 under the name of Japan Aircraft Electric Co., Ltd., is a Japanese manufacturer of automation machinery and manufacturing components, headquartered in Komaki, Aichi. Their diverse portfolio includes pneumatic and fluid control components, fine system components, drive components, and labor-saving components. The company has also developed various types of automation machinery, such as transparent object inspection systems, pharmaceutical products packaging machines, and more. These products find applications in various industries, for example their automated food packaging systems are designed for maintaining food quality and hygienic conditions. Their fluid control components are used in the solar cell manufacturing process.

SMC corporation was founded in 1959 and is headquartered in Tokyo, Japan. SMC Corporation manufactures and sells automatic control equipment and filtration equipment. SMC has production facilities in 30 countries, technical development centers in Japan, the United States, Europe, and China, and sales offices, globally. SMC product lines divided by them include filter replacements, condensation prevention, heat resistance, thermos-chilling, and others. SMC provides a video library as well as product selection guide to assist customers in finding solutions and optimizing product efficiency.

Humphrey Products is an American manufacturer of pneumatic and liquid control products originally established in 1901 as General Gas Light Company before rebranding in 1990. Based in Kalamazoo, Michigan, the company produces various items including actuators, solenoid and mechanical valves, pressure regulators, and total air control (TAC) miniature fittings. They also offer design, engineering, and prototyping services for custom projects. Humphrey Products primarily serves clients in the medical, commercial, industrial, and aerospace sectors.

Waircom MBS Corporation Inc. established in 1957 and based in Vizzolo Predabissi, Italy, is a manufacturer and supplier of pneumatic components for industrial automation. The company's product range includes pneumatic cylinders, valves and solenoid valves, mechanical valves, air treatment, and fittings and tubes. These products are essential for various applications in the machinery and equipment operation. The products serve industries such as industrial machinery manufacturing, automation, processing, and assembly lines. The company also offers technical information services, product customization, maintenance support, and consultation services.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Palex Medical |

17.5%

|

| 2 | Highlight Tech. Corporation |

12.5%

|

| 3 | Blain Hydraulics GmbH |

10.0%

|

| 4 | Mindman Industrial Co. Ltd. |

10.0%

|

| 5 | Hemmingford Aerospace Inc. |

7.5%

|

| 6 | Keraflo Ltd. |

7.5%

|

| 7 | SHAKO Co., Ltd. |

7.5%

|

| 8 | Wenzhou Pioneer Valve Co., Ltd. |

5.0%

|

| 9 | Airefrig Australia |

5.0%

|

| 10 | Humphrey Products |

5.0%

|

Derivation Method

The ranking is calculated based on the click share within the mechanical valve page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Taiwan

Taiwan

|

3 | 25.0% |

Japan

Japan

|

3 | 25.0% |

Germany

Germany

|

1 | 8.3% |

China

China

|

1 | 8.3% |

Italy

Italy

|

1 | 8.3% |

Canada

Canada

|

1 | 8.3% |

Australia

Australia

|

1 | 8.3% |

United Kingdom

United Kingdom

|

1 | 8.3% |

53 products found

53 products

Miyata Industries Co., Ltd.

790+ people viewing

Last viewed: 5 hours ago

The adjustable air valve is a valve that allows air to pass through, close, and adjust by rotating the handle 180 degrees. It is suitable for use n...

Miyata Industries Co., Ltd.

610+ people viewing

Last viewed: 5 hours ago

The adjustable air valve is a valve that allows air to pass through, close, and adjust by rotating the handle 180 degrees. It is suitable for use n...

Miyata Industries Co., Ltd.

540+ people viewing

Last viewed: 5 hours ago

An adjustable air valve is a valve that allows air to pass through, close, and adjust by rotating a round handle. It can be used not only for fully...

Miyata Industries Co., Ltd.

560+ people viewing

Last viewed: 5 hours ago

An adjustable air valve is a valve that allows air to pass through, close, and adjust by rotating a round handle. It can be used not only for fully...

Miyata Industries Co., Ltd.

390+ people viewing

Last viewed: 5 hours ago

A small airflow valve is a valve that can be adjusted at low airflow. You can adjust the air volume even lower than the low air volume type of conv...

Miyata Industries Co., Ltd.

450+ people viewing

Last viewed: 5 hours ago

A low airflow valve is a valve that can be adjusted at low airflow. You can adjust the air volume even lower than the low air volume type of conven...

Miyata Industries Co., Ltd.

470+ people viewing

Last viewed: 3 hours ago

The distribution adjustment air valve is a valve that distributes air to two-way pipes, A and B. It is suitable for adjusting the balance when dist...

Miyata Industries Co., Ltd.

520+ people viewing

Last viewed: 5 hours ago

A three-way adjustment valve is a valve that switches the direction of air flow. Suitable for switching the flow direction of air piping in various...

Miyata Industries Co., Ltd.

430+ people viewing

Last viewed: 5 hours ago

A compact valve is a valve that allows air to pass through and close it off. Suitable for fully closed and fully open use, it can be switched to op...

Miyata Industries Co., Ltd.

530+ people viewing

Last viewed: 4 hours ago

A compact valve is a valve that allows air to pass through and close it off. Suitable for fully closed and fully open use, it can be switched to op...

Consus Co., Ltd.

480+ people viewing

Last viewed: 5 hours ago

■Features ・Chemical-resistant plastic hand (CIP/SIP possible, autoclave compatible) ・The patented seal adjuster (US-Pat.5 377 956) allows the val...

Consus Co., Ltd.

480+ people viewing

Last viewed: 5 hours ago

■Features ・Chemical-resistant plastic hand (CIP/SIP possible, autoclave compatible) ・The patented seal adjuster (US-Pat.5 377 956) allows the val...

Consus Co., Ltd.

480+ people viewing

Last viewed: 1 hour ago

■Features - Three-piece body, full port structure. -Standard lock handle ensures safety. -Connection shape can be changed by replacing the end cap....

Consus Co., Ltd.

530+ people viewing

Last viewed: 5 hours ago

■Features - Three-piece body, full port structure, butt welding type. -Connection shape can be changed by replacing the end cap. -Standard lock han...

Consus Co., Ltd.

480+ people viewing

Last viewed: 5 hours ago

■Features - A type with an integrated arm lock coupling adapter on the exit side. ・Full port structure with low pressure loss. - A SUS handle is a...

Miyata Industries Co., Ltd.

380+ people viewing

Last viewed: 5 hours ago

A compact valve with a flexible union is a valve that can be attached to and detached from the main body by turning the cap nut of the flexible uni...

Miyata Industries Co., Ltd.

360+ people viewing

Last viewed: 5 hours ago

The adjustable air valve with a flexible union is a valve that can be attached to and detached from the main body by turning the cap nut of the fle...

Miyata Industries Co., Ltd.

450+ people viewing

Last viewed: 5 hours ago

The adjustable air valve with a flexible union is a valve that can be attached to and detached from the main body by turning the cap nut of the fle...

Miyata Industries Co., Ltd.

360+ people viewing

Last viewed: 5 hours ago

A compact valve with a flexible union is a valve that can be attached to and detached from the main body by turning the cap nut of the flexible uni...

Nihon Pisco Co., Ltd.

460+ people viewing

Last viewed: 5 hours ago

■Features - Opens and closes air pressure input to equipment. ・A 2-way valve and a 3-way valve that can exhaust residual pressure are available. -...

MEIJI AIR COMPRESSOR MFG.CO.,LTD.

360+ people viewing

Last viewed: 1 hour ago

■Features - A foot valve that allows you to switch the air circuit ON/OFF by stepping on the pedal. ・Ideal for incorporating air circuits.

MEIJI AIR COMPRESSOR MFG.CO.,LTD.

230+ people viewing

Last viewed: 5 hours ago

■Features It is possible to reduce the paint pressure to a pressure suitable for the painting conditions and keep it constant.

4 models listed

Nakajima Koki Co., Ltd.

170+ people viewing

Last viewed: 5 hours ago

■Features ・Can be used with G series F.R.L combination (bracket installation) ・Can be used as a manual 3 port valve. ・Improved visibility of ope...

7 models listed

Mizutani Iron Works Co., Ltd.

310+ people viewing

Last viewed: 5 hours ago

We manufacture rotary valves that use mechanical seals for applications where the operating line pressure exceeds 0.1 MPa, and use double mechanica...

Tokupi Manufacturing Co., Ltd.

520+ people viewing

Last viewed: 5 hours ago

■Features The body material is made of stainless steel, and the spool is made of SUS (heat-treated product) or ceramic (custom-made product), provi...

Izumi Corporation Co., Ltd.

240+ people viewing

Last viewed: 5 hours ago

■Hand-type manual type Uses manual hand valve. The system is set in a special bracket and can be easily attached to the vise side, and the extremel...

Hosho Seisakusho Co., Ltd.

280+ people viewing

Last viewed: 5 hours ago