All Categories

History

This section provides an overview for epdm rubber as well as their applications and principles. Also, please take a look at the list of 10 epdm rubber manufacturers and their company rankings. Here are the top-ranked epdm rubber companies as of March, 2026: 1.Everest, 2.YT Industrial Parts, 3.Aero Rubber Company, Inc.

Table of Contents

Categories Related to EPDM Rubber

2020: Obtained a master's degree in Engineering from the Graduate School of Organometallic Complexes, Osaka University, where he conducted research on polymerization reactions using complexes as catalysts.

Currently working for a general chemical manufacturer.

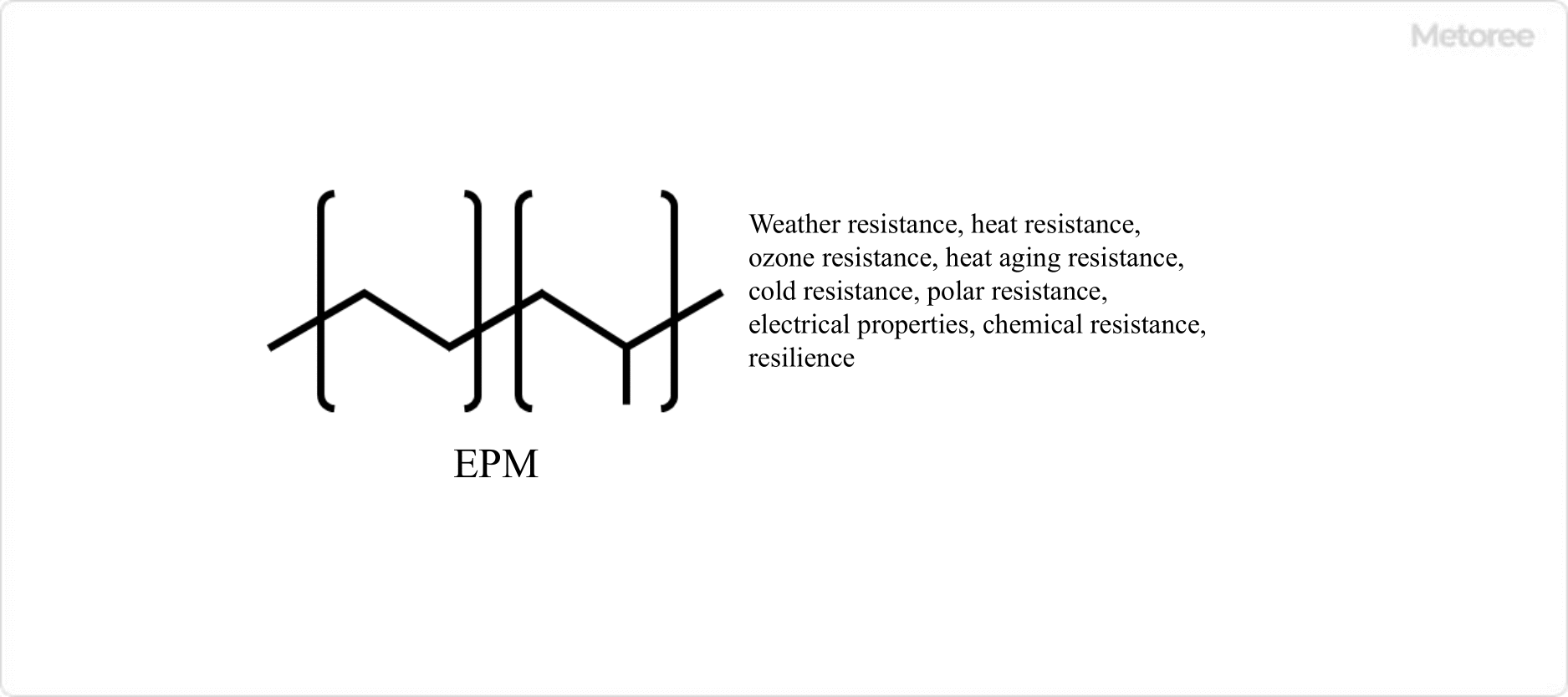

Figure 1. Structure of EPM

Ethylene Propylene Diene Monomer (EDPM) Rubber is a copolymer of ethylene and propylene.

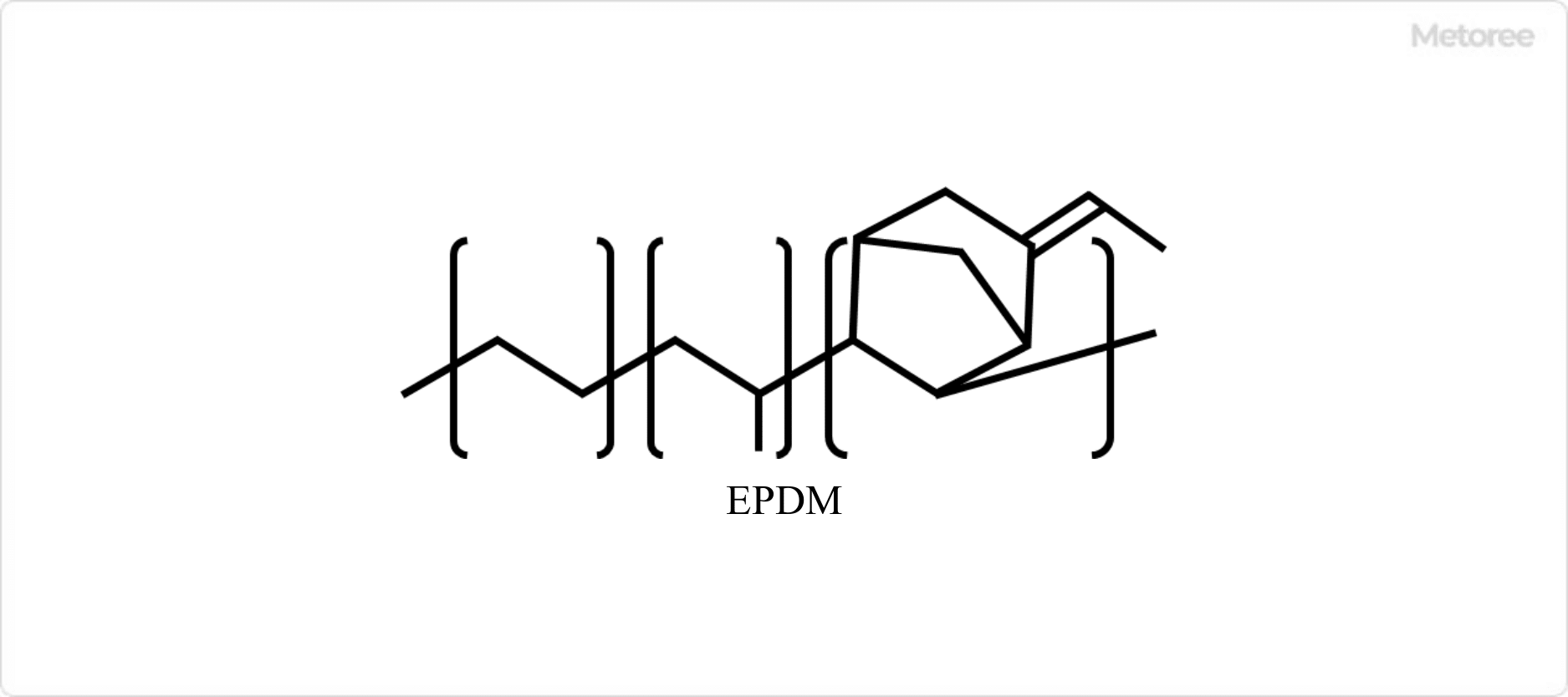

Those that do not have unsaturated bonds in the main chain and cannot be vulcanized by sulfur are called EPMs. It has various excellent properties. On the other hand, ethylene propylene diene rubber copolymerized with a small amount of monomer having unsaturated bonds to enable sulfur vulcanization is called EPDM.

Figure 2. Structure of EPDM

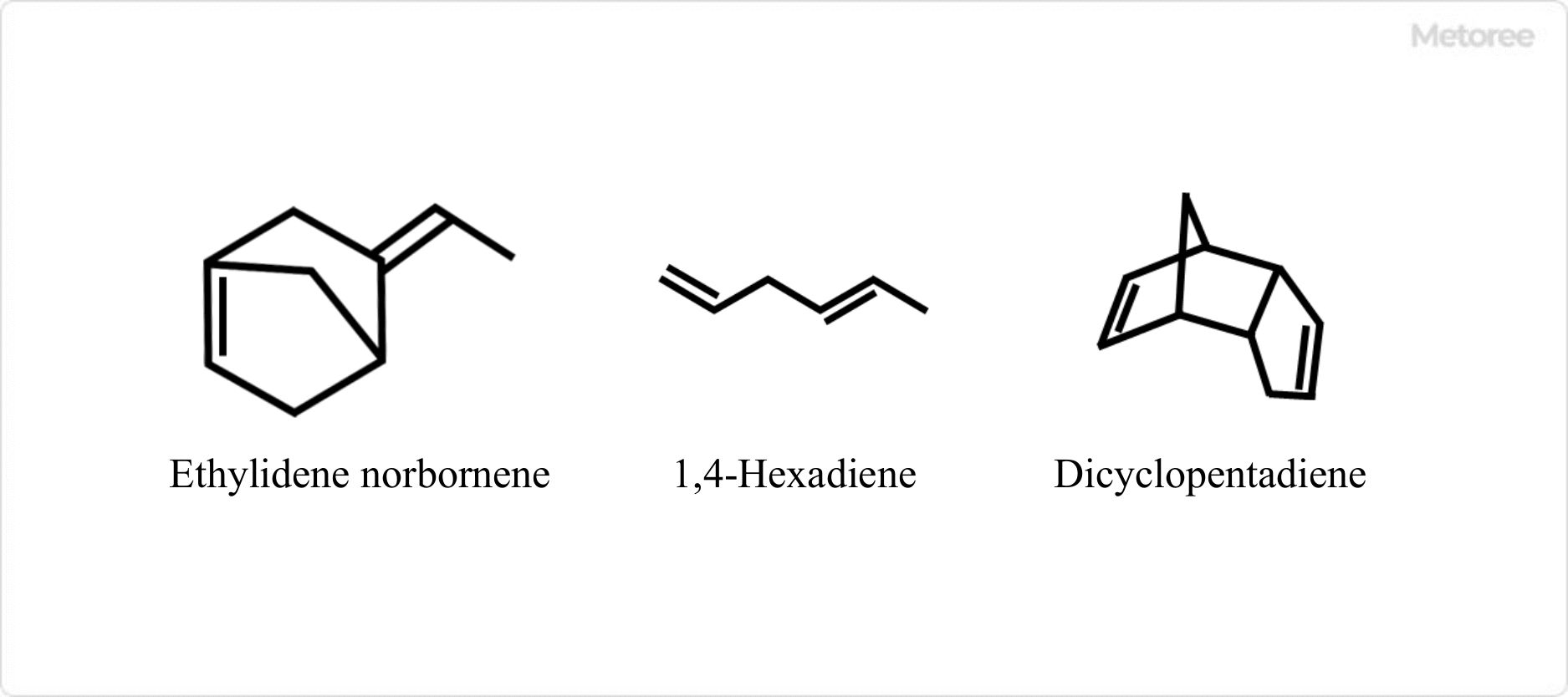

Various diene compounds have been considered as monomers with unsaturated bonds, but three types are still in industrial production worldwide: ethylidene norbornene, 1,4-hexadiene, and dicyclopentadiene. Of these, ethylidene norbornene is the most used.

These monomers are selected based on their reactivity ratio during polymerization, their effect on polymerization speed and catalyst life, ease of recovery in the polymerization process, ease of vulcanization, and their effect on the physical properties of the product. For example, ethylidene norbornene is excellent because its reactivity ratio to the polymerization reactivity of propylene is very large and the double bonds in the ring are highly selective during polymerization.

Figure 3. Structure of diene monomer used in EPDM

EP stands for ethylene propylene, EPD for ethylene propylene diene, and M for polymethylene-type rubber with a saturated main chain.

EPM cannot be cross-linked by sulfur, so it is vulcanized by peroxide and used in the same way as other rubber products such as tires and hoses. EPM is also used as an impact modifier added to general-purpose olefin resins such as polypropylene.

EPDM can also be modified with maleic anhydride, etc., and used as a modifier for polyamide, polyester, etc.

While other rubber products are easily degraded by direct sunlight and cold, EPDM Rubber is suitable for outdoor use due to its excellent weather and cold resistance. Familiar applications include wire sheathing covers, rubber for window frames, and automotive rubber products.

Polyethylene, which is polymerized only from ethylene, is difficult to handle due to its high crystallinity. EPDM Rubber is a polymer made by copolymerizing propylene with a methyl group on the side chain, which reduces the crystallinity by weakening the intermolecular interaction between polymer chains, making it easier to handle.

EPDM Rubber has no double bonds in its main chain, which makes it excellent in weather resistance and heat resistance. It also has excellent ozone resistance, heat aging resistance, cold resistance, polar resistance, electrical properties, chemical resistance, and repulsive elasticity, and is widely used second to styrene-butadiene rubber (SBR, BR).

EPDM is often produced by solution polymerization using metallocene or vanadium catalysts. EPDM with different characteristics can be synthesized by selecting catalysts and polymerization conditions. One of the characteristics of EPDM is that it can be produced in various types depending on the purpose.

Synthesis with metallocene catalyst

EPDM with a narrow molecular weight distribution can be obtained using a metallocene catalyst, which acts while the catalyst is dissolved in the reaction solution (homogeneous catalyst). The narrow molecular weight distribution is advantageous in terms of physical properties such as tensile strength, but its inflexibility and poor processability are disadvantages.

Synthesis with vanadium catalyst

On the other hand, vanadium catalysts have lower catalytic activity than metallocene catalyst and the polymerization process is more complicated, but the resulting EPDM has excellent processability and shows high rubber elasticity even under low temperature conditions.

Vulcanization methods include sulfur vulcanization, peroxide vulcanization, oxime vulcanization, and radiation vulcanization, but the two most commonly used are sulfur vulcanization and peroxide vulcanization.

Sulfur vulcanization

This is the most commonly used vulcanization method for EPDM. The reaction proceeds at a high temperature of 150°C or higher during vulcanization. The higher the reaction temperature, the less likely it is to cause reversion (return of vulcanization) and the higher the productivity.

Peroxide Vulcanization

This is the vulcanization method used when EPM is used for wires and cables that require flexibility.

*Including some distributors, etc.

Sort by Features

Sort by Area

WARCO (West American Rubber Company, LLC.), founded in 1910 and located in Orange, California, is a manufacturer of rubber compounds. WARCO is a fully vertically integrated, ISO 9001-registered by NSF-ISR rubber manufacturer located in Orange, California. Established in 1910, WARCO has drastically expanded its capabilities to meet all your rubber needs under one roof. The WARCO Advantage is comprised of 5 aspects. 1) Onsite Compounding Lab staffed with experts in rubber material design who can design elastomers with properties such as high durability or resistance to environmental factors. 2) In-house mixing, allowing efficient production of compounds without needing a 3rd party mixer. 3) Vertical Integration of traditionally 5 different operations: lab, mixing, sheet rubber, extruded rubber, and molded rubber manufacturing. 4) Over 110 years of expertise and thousands of products/unique applications. 5) 100% USA Domestic manufacturer, higher quality products, protection against the risk of supply chain disruptions, and opportunities to satisfy demand for American-made requirements.

Aero Rubber Company began in 1973 and is a family-run business based in Tinley Park, Illinois. Aero Rubbery Company is a custom manufacturer of rubber components such as tubing, sheeting, seals, and gaskets. Aero also offers fabrication services including die cutting, water-jet and lathe cutting, slitting, and vulcanized splicing. Aero Rubber is an ISO 9001:2015 certified company. Aero Rubber manufacturers use materials such as Viton, Neoprene, EPDM, silicone, and rubber materials. Aero Rubber manufacturing includes molded parts such as gaskets, extruded parts, sheeting, fabricated parts, and mandrel-made parts. Value-added capabilities are also offered.

BRP Manufacturing, Inc. is an American manufacturer of sheet rubber and extruded rubber products established in 1914 in Lima, Ohio. The company produces various rubber products including cork and uncured rubber tape, cloth inserted nitrile sheets for conveyor belts, elastomeric bearing pads for vibration and noise reduction in buildings, and mallets. These are primarily used by clients in the aerospace, automotive, industrial manufacturing, and transportation sectors. BRP also offers rubber molding, fabrication, and extrusion services, as well as product testing for customer projects or commission orders.

Trim-Lok, Inc, founded in Buena Park, CA, in 1977 is a manufacturer of f PVC push on edge trim, trim seals and EPDM rubber seals. The company's product portfolio includes Rubber Extrusion, Plastic Extrusion, Edge Trims, Plastic Profiles and Rubber Profiles. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Chemical and Petrochemicals. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

YT Industrial Part, established in 2010 and located in Jiangsu, China, is a manufacturer of custom metal, plastic, and rubber industrial parts. The company offers a range of products such as PVC profiles, water glass silicon sol shells, sand casting, and shell mold casting. It also provides special requirements, such as box color printing. Its PVC is resistant to weathering, chemical rotting, corrosion, shock, and abrasion, making it suitable for long-life and outdoor products. The company has achieved ISO 9001:2000 certification for its quality management systems. It serves industries such as construction, logistics, sanitary, automotive, and electrical.

ARLANXEO is a manufacturer and distributor of synthetic rubber materials, established in 2016 and headquartered in The Hague, Netherlands. The company’s products include Baymod L ethylene-vinyl acetate (EVM) rubber powder for PVC modification, Buna butadiene rubber for use in plastic and tire manufacturing, and Keltan ethylene propylene diene monomer (EPDM) rubber for construction or automotive maintenance applications. The company’s products are primarily used by clients in the industrial manufacturing and engineering sectors.

RADO Gummi GmbH, established in 1959 and based in Radevormwald, Germany, is a manufacturer and supplier of specialized rubber compounds. The company's product range includes FPM fluoro rubber, FVMQ fluorosilicone rubber, VMQ silicone rubber, pigment masterbatches, and HNBR hydrogenated NBR elastomer. These compounds find applications in various items such as profiles, seals, hoses, and coatings for protective clothing. The primary sectors that utilize these products are the automotive, industrial, aerospace, and energy and oil industries. The company's services include laboratory tests, certification validation, and detailing the advantages of its products.

Founded in 1989, with Head Quarter in Newmarket, Ontario, Canada AirBoss Rubber Solutions manufactures rubber-based formulations that are used by the automotive sector, heavy industry, construction industry, oil & gas industry, and defense sector. The company offers waterworks, conduit seals, and elastomeric bridge-bearing parts that are used in the building and construction industry. They produce car tires, conveyor belt products for mining applications, forklift tires, and automotive parts along with rubber polymer products for the oil&gas industry.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Everest |

25.7%

|

| 2 | YT Industrial Parts |

10.1%

|

| 3 | Aero Rubber Company, Inc |

9.4%

|

| 4 | BRP Manufacturing Company |

8.9%

|

| 5 | REDCO |

8.1%

|

| 6 | West American Rubber Company, LLC. |

8.1%

|

| 7 | RADO Gummi GmbH |

7.8%

|

| 8 | ARLANXEO |

7.2%

|

| 9 | AirBoss Rubber Solutions. |

7.1%

|

| 10 | Trim-Lok, Inc |

6.9%

|

Derivation Method

The ranking is calculated based on the click share within the epdm rubber page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 62.5% |

China

China

|

1 | 12.5% |

Germany

Germany

|

1 | 12.5% |

Canada

Canada

|

1 | 12.5% |

49 products found

49 products

Joe Prince Takeshita Co., Ltd.

170+ people viewing

■Product features - Can be installed by simply fitting it into the panel cut. ・Hardness 50°±5° ・Order unit: 10 pieces There are other model numb...

10 models listed

Mikawa Rubber Manufacturing Co., Ltd.

440+ people viewing

In PMMA resin molding, EPDM rubber gasket material is used as the mold gasket material. Utilizing our compounding technology, we have developed an ...

DAIDOH TOKUSHU KOGYO CO.,LTD.

440+ people viewing

Last viewed: 8 hours ago

Overview ■Specifications ・Wetted parts material: Ethylene propylene rubber ・Supplementary material: Reinforced braided fiber + wire ・Exterior su...

Ozak Seiko Co., Ltd.

220+ people viewing

Last viewed: 23 hours ago

Made of strong aluminum die -cast, it is ideal for compact design with a minimum of core height, compact combination as a shaft block for CH, CHW, ...

9 models listed

Mikawa Rubber Manufacturing Co., Ltd.

670+ people viewing

Last viewed: 5 hours ago

This is a highly resilient EPDM rubber sponge with compression set as close to 0% as possible while maintaining softness, conformability, water res...

Kimoto Rubber Industries Co., Ltd.

680+ people viewing

Last viewed: 1 day ago

It is a sheet-shaped rubber made by mixing raw rubber and chemicals and vulcanizing it. We select the material according to the application, cut it...

Murota Rubber Industries Co., Ltd.

350+ people viewing

Last viewed: 23 hours ago

It has the best ozone resistance and weather resistance.

Osaka Rubber Co., Ltd.

360+ people viewing

Last viewed: 23 hours ago

Rubber sheets are a typical rubber product that is widely used as packing materials, cushioning materials, carpets, etc. in architecture, civil eng...

3 models listed

Sugatsune Industries Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■Features - Can be installed by simply pushing it in. - Because the rubber is thinner, it can be installed with less force than the T-14582 type.

Hiraizumi Yoko Co., Ltd.

370+ people viewing

Ethylene propylene diene rubber (EPDM) is a polymer with excellent heat resistance, weather resistance, and ozone resistance. Additionally, its low...

Hiraizumi Yoko Co., Ltd.

320+ people viewing

Last viewed: 11 hours ago

Ethylene propylene diene rubber (EPDM) is a polymer with excellent heat resistance, weather resistance, and ozone resistance. Additionally, its low...

Hiraizumi Yoko Co., Ltd.

360+ people viewing

Ethylene propylene diene rubber (EPDM) is a polymer with excellent heat resistance, weather resistance, and ozone resistance. Additionally, its low...

Hiraizumi Yoko Co., Ltd.

330+ people viewing

Last viewed: 1 day ago

Ethylene propylene diene rubber (EPDM) is a polymer with excellent heat resistance, weather resistance, and ozone resistance. Additionally, its low...

Hiraizumi Yoko Co., Ltd.

280+ people viewing

Ethylene propylene diene rubber (EPDM) is a polymer with excellent heat resistance, weather resistance, and ozone resistance. Additionally, its low...

Yagyu Shokai Co., Ltd.

370+ people viewing

Last viewed: 5 hours ago

■Features - Standard ultra-thin EPDM sheet with excellent waterproof and insulation properties. - Contains no siloxane, oil, cross-linking agents, ...