14 Cap Sealing Machinery Manufacturers in 2024

This section provides an overview for cap sealing machinery as well as their applications and principles. Also, please take a look at the list of 14 cap sealing machinery manufacturers and their company rankings. Here are the top-ranked cap sealing machinery companies as of April, 2024: 1.N.K. INDUSTRIES, 2.SigmaCapseal, Electronics Devices Worldwide pvt. ltd., 3.BellatRx.

Table of Contents

What Is Cap Sealing Machinery?

Cap sealing machinery is machinery that heat-seals (thermo-compresses) a container and a film to seal the contents while sealing the film.

The purpose of heat sealing is to prevent liquid leakage from the container, to prevent foreign matter from entering the container, to improve the shelf life of food products, and to add value to the product.

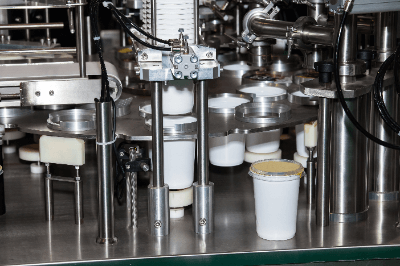

There are two types of cap sealing machines: semi-automatic and fully automatic.

Semi-automatic sealers are relatively small machines for small-lot production that require manual operation.

Fully automatic sealers are large machines that can be operated continuously for mass production.

Uses of Cap Sealing Machinery

Cap sealing machinery ranges from mass-production models that are incorporated into food production lines to portable models for small stores and mobile sales.

In particular, examples of food applications include tofu, prepared foods, seafood, meat, desserts, pickles, processed marine products, shellfish, etc., and nursing food.

In addition, it can also be used for air fresheners, cosmetics, and other industrial and medical applications.

Principle of Cap Sealing Machinery

In the cap sealing machinery, the container is first covered with a lid, and the sealing material is paper, paper plus aluminum vapor deposition, or resin film, which must adhere to the container.

Adhesion methods include heating, thermo-compression bonding, ultrasonic waves, etc. There are two types of sealing methods: one is to cover the seal that has been formed first, and the other is to cut the overflowing part after sealing.

The heat sealing method here, using thermo-compression, involves covering a plastic cap with a film and clamping it at a certain temperature, for a certain time, and under a certain pressure to weld the cap and the film material together with the intended strength.

The temperature, pressing time, and pressure of the metal heating plate can be controlled within a practical range, and sealing is possible with extremely high reliability.

It applies not only to a wide variety of foods but also to various contents and can be used not only for various types of container packaging but also for product prototyping.

Also, as long as a mold is available, it can be used for containers of various shapes as well as general shapes.

Furthermore, gas displacement can be performed at the time of sealing, and especially when used in combination with a gas mixer that supplies a certain ratio of carbon dioxide gas and nitrogen gas, etc., the spatial gas composition inside the container can also be controlled.

List of 14 Cap Sealing Machinery Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- India

- Japan

-

-

Manufacturer Overview

Filamatic, owned by the Rosen family, is a manufacturer of liquid filling machines established in 1953 and headquartered in Baltimore, Maryland. It offers semi-automatic filling machines, inline filling systems, monoblocs, hazardous product-filling machines, and capping systems. The machines are used to fill a range of sensitive containers like syringes, vials, micro-vials, tubes, and micro-tubes, as well as perform closing functions such as stoppering, plugging, crimping, and overcapping. The company, which is a member of PMMI and ISPE, offers products used in cosmetic, food & beverage, pharmaceutical, natural products, and contract manufacturing industries.

-

-

-

-

-

SigmaCapseal, Electronics Devices Worldwide pvt. ltd.

SIGMA PRO

Manufacturer Overview

Sigma CapSeal, a division of Electronics Devices Worldwide Pvt. Ltd., is a manufacturer and supplier of packaging machinery, established in 1974 and based in Gilbert, United States of America. It manufactures induction sealing machines, wad inserting machines, flip-top cap closing machines, and cap lining machines. It also produces cap assembly machines, vision inspection systems, and seal integrity testing machines. Its product applications span various industries, including health care, personal care, dairy, petrochemicals, agrochemicals, food and beverages, confectionery, and specialty chemicals. Some of its clients are Coca-Cola, Oriflame, Castrol, Lotte, GSK, Nestle, and P&G.

-

-

-

-

-

Enercon Industries Corp.

Cap Sealing

Manufacturer Overview

Enercon Industries Corporation was founded in 1974 and is headquartered in Menomonee Falls, Wisconsin. The company is a global manufacturer of surface treating systems and induction cap sealers. The company’s 3 product segments are Induction Sealing, Web Treating, and Object Treating. Induction Sealing provides induction sealing machines that range in size from handheld sealers to its Super Seal Max industrial sealer. Web Treating machines provide Corona and flame treatment for conversion, extrusion, and treatment of the film. Object Treating applications include adhesives, printing, and plasma treatment for plastic, metal, and glass applications.

-

-

-

-

-

Packline USA

Packaging Machine

Company Overview

Packline USA LLC, founded in 1994, is an American manufacturer and distributor in Rancho Cucamonga, California specializing in packing solutions and machinery. The company offers individual product packaging for various items, including dips and salsa, jellies and puddings, oatmeal and cereals, soups and dressings, and ready-to-eat or frozen meals. It also provides packing machines that seamlessly integrate with existing operations, such as modified atmosphere packaging (MAP) machines, tray fillers, bottling machines, and piston fillers. Other machine offerings include cup-sealing machines, capping machines, and pouch-packing machines. The company caters to the food, dairy, and beverage packaging industries.

-

-

-

-

-

TurboFil Packaging Machines, LLC

Capping & Crimping

Company Overview

TurboFill Packaging Machines, LLC, founded in 1999 and headquartered in New York, is a manufacturer and distributor of liquid filling and assembly machines. It manufactures automatic filling machines, benchtop filling machines, automatic crimpers, benchtop crimping machines, and benchtop syringe labelers. It also produces unscrambling and accumulating tables, conveyors, syringe and cartridge filling machines, automatic chunk cappers, and benchtop flat surface labelers. Its products find applications in the medical, cosmetic, and personal care industries.

-

-

-

-

-

HydraCheck

CLEAN SEAL SYSTEM

Distributor Overview

HydraCheck was established in 1990 and headquartered in West Valley City, Utah. The company is a distributor of diagnostic testing and maintenance for hydraulic systems across North America. The company provides support services for end customers as well as mechanics and technicians. The company’s product lines include testing products, diagnostic kits, and safety devices. Testing products include flanges, gauges, and thermometers while kits include identification kits and test kits. The company's safety devices include goggles, models, and guides.

-

-

-

-

-

SHIBUYA CORPORATION

Cup and Tray Sealer

Manufacturer Overview

Shibuya Corporation, founded in 1931, is a Japan-based manufacturer and retailer of industrial systems and equipment. Their product portfolio is available in various categories, including packaging plant business, mechatronics, agricultural and regenerative medicine. The packaging plant segment includes various equipment and systems used in the bottling, packaging, food processing and pharmaceutical industries. The agricultural division includes grading & analyzing systems such as fruit, welsh onion, and flowering plant grading systems. The mechatronics system segment includes medical equipment such as dialysis systems, medical lasers, and UV Light treatment systems. The division also includes semiconductor manufacturing and cutting processing systems.

-

-

-

-

-

Punit Industrial Premises Co-op. Society Ltd.

The Manufacture Of Perfect Induction Cap Sealing Machine

Manufacturer Overview

Punit Industrial Premises Co-op. Society Ltd. is an induction cap sealing and Corona treater machines manufacturer, headquartered in Navi Mumbai, India and established in 2003. It manufactures induction cap-sealing machines, semi-automatic manual induction cap-sealing machines, and manual induction cap-sealing machines. It also produces mini sealing machines, water-cooled induction cap sealing machines, and Corona treaters. These products can be used in various industrial segments such as food & beverages, dairy products, pharmaceuticals & health care, petrochemicals, chemicals, agrochemicals & pesticides.

-

-

-

-

-

Mahalaxmi Machines

Fully Automatic Screw Cap Sealing Machin

Manufacturer Overview

Mahalaxmi Machines, established in 2004 and based in Jaipur, India, is a manufacturer of packaging solutions like filling machines, sealing machines, and weighing machines. It manufactures automatic pouch packing machines, granule and powder filling machines, batch coding machines, cap sealing machines, and liquid filling machines. It also produces can seaming machines, semi-automatic pouch packing machines, and top sealing machines. The application for the packaging machines is to complete the process of packing the materials.

-

-

-

-

-

LODHA International LLP

Cap Sealing Machine

Manufacturer Overview

Lodha International LLP, founded in 2008 with headquarters in India, is a manufacturer of pharmaceutical packaging and process equipment. The company's products include sterile washing machines, powder filling machines, sticker labeling machines, mixing and kneading machines, and various packaging machines. Lodha International LLP also offers custom turn-key solutions for biotechnological, API, pharmaceutical, and radiopharmaceutical manufacturing facilities. Examples include HVAC and clean rooms, automatic eye drop filling and capping machines, and custom packing conveyors for pharmaceutical products.

-

-

-

-

-

BellatRx

CAPPING MACHINES

Manufacturer Overview

BellatRx, established in 2002 and based in Montreal, Canada, is a manufacturer and supplier of primary packaging lines and packaging equipment. It manufactures liquid filling machines, table counting and bottle filling machines, powder filling machines, capping machines with torque control, and labeling machines. It also produces bottle unscrambling machines, tamper-evident bands and sleeve applicators, conveyor belts & accumulation tables, and complete turn-key lines. it serves pharmaceutical, biotechnology and diagnostics, nutraceutical, food and beverage, and cosmetics and personal care industries.

-

-

-

-

-

Shree Bhagwati Machtech India Pvt. Ltd.

Semi Automatic ROPP Cap Sealing Machine

Company Overview

Shree Bhagwati Machtech India Pvt. Ltd., established in 2000 and based in Ankleshwar, India, is a manufacturer and distributor of process and packaging machines. It manufactures laboratory & pilot scale equipment, fluid bed equipment, and pellet extruder spherodizers. It also produces CIP - WIP bunker washing systems, semi-solid cream paste gel processing, and mixers for solids – dry and wet. Its product range serves industries such as pharmaceuticals, cosmetics, foods, chemicals, paint and more. It has passed ISO 9001:2008 and Conformité Européenne (CE) certifications.

-

-

-

-

-

WNA Packaging Technologies LLC

Cup and Tray Filling and Sealing Technology

Company Overview

Waldner North America, established in 1908 and based in Boston, United States of America, is a manufacturer and distributor of packaging machinery. It manufactures Waldner’s DOSOMAT rotary and inline pouch systems and Waldner’s DOSOMAT spouted pouch filling systems. It also produces WALDNER filling and sealing equipment and retort packaging solutions. Rotary and inline pouch systems offer solutions for low output pouch filling and high-productivity, high-volume pouch-filling applications. Spouted pouch-filling systems provide solutions for filling and sealing pre-made pouches with spouts, caps, and other fitments.

-

-

-

-

-

N.K. INDUSTRIES

Vial Cap Sealing Machine

Company Overview

NK Industries Ltd., established in 1978, is a machinery manufacturer based in Ahmedabad, Gujarat, India. The company’s solutions include automatic washing, filling, and sealing machines for various materials. It also produces manual and automatic vial ampoule or bottle inspection machines and sterilization tunnels. In addition, the company offers capping, labeling, and packaging machines for complete production lines. The company is certified with ISO 9001:2008 and serves various industries, including the food, pharmaceutical, and cosmetic sectors.

-

-

Cap Sealing Machinery Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | N.K. INDUSTRIES |

16.7%

|

| 2 | SigmaCapseal, Electronics Devices Worldwide pvt. ltd. |

16.7%

|

| 3 | BellatRx |

16.7%

|

| 4 | Filamatic |

8.3%

|

| 5 | Punit Industrial Premises Co-op. Society Ltd. |

8.3%

|

| 6 | Shree Bhagwati Machtech India Pvt. Ltd. |

8.3%

|

| 7 | WNA Packaging Technologies LLC |

8.3%

|

| 8 | Mahalaxmi Machines |

8.3%

|

| 9 | Enercon Industries Corp. |

8.3%

|

Derivation Method

The ranking is calculated based on the click share within the cap sealing machinery page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- SHIBUYA CORPORATION: 3,635

Newly Established Company

- LODHA International LLP: 2008 (16 years ago)

- Mahalaxmi Machines: 2004 (20 years ago)

- Punit Industrial Premises Co-op. Society Ltd.: 2003 (21 years ago)

Company with a History

- SHIBUYA CORPORATION: 1931 (93 years ago)

- HydraCheck: 1990 (34 years ago)

- BellatRx: 2002 (22 years ago)

Cap Sealing Machinery Manufacturers in United States

*Including some distributors, etc.

- Filamatic

- SigmaCapseal, Electronics Devices Worldwide pvt. ltd.

- Enercon Industries Corp.

- Packline USA

- TurboFil Packaging Machines, LLC

- HydraCheck

Global Distribution of Cap Sealing Machinery Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 46.2% |

India

India

|

5 | 38.5% |

Japan

Japan

|

1 | 7.7% |

Canada

Canada

|

1 | 7.7% |

List of Cap Sealing Machinery Products

23 products are listed.

Corporation Yamatsuji

Semi-automatic cup sealer elementary and middle lot Rot ET-69SS-J jelly (disconnection type)

10+ people viewing

■ A new model that can be detachable due to surface tension 2 stickers, trolley long hole processing Ex) Jelly, pudding, watery ... etc. ■ The bog...

Daiichi Pack Machinery

STANDARD continuous high-speed cup (tray) Sealer air box motion/mechanical rotary type SR-2500TR type

10+ people viewing

■ Characteristics ・ By using mechanism and air, the reliability and high -speed of unprecedented seals are now possible. ・ Because the movement i...

Daiichi Pack Machinery

Space-saving compatible rotary cup sealer R-PM800 type (medium-sized aircraft)

10+ people viewing

■ Characteristics ・ Rotary method for space -saving. ·trimming ・ Matching light electronics papers ・ Standard equipment for one -touch replacement.

Daiichi Pack Machinery

Space-saving compatible rotary cup sealer R-PM600 type (small machine)

10+ people viewing

■ Characteristics ・ Rotary method for space -saving. ·trimming ・ Matching light electronics papers ・ Standard equipment for one -touch replacement.

Daiichi Pack Machinery

High-speed continuous cup seal machine for "Mozuku" and "Mekabu" SR-7500-WW type

10+ people viewing

■ performance ・ All three absolute three conditions required for the seal are completely satisfied, and it has outstanding performance for retort ...

Daiichi Pack Machinery

Small auto cup seal machine PACKMAN series PM-500AS type air pressurized type

10+ people viewing

■ Simple It is very simple because it is the latest mechanism with a seal heater and trimming blade integrated. ■ Easy operation Just put the cup ...

Daiichi Pack Machinery

Small auto cup seal machine PACKMAN series S-500AS type air pressure system

10+ people viewing

■ Simple It is very simple because it is the latest mechanism with a seal heater and trimming blade integrated. ■ Easy operation Just put the cup ...

Daiichi Pack Machinery

Small auto cup seal machine PACKMAN series PM-300 type hand type

■ Simple It is very simple because it is the latest mechanism with a seal heater and trimming blade integrated. ■ Easy operation Just put the cup ...

Daiichi Pack Machinery

Small auto cup seal machine PACKMAN series S-700AS type air pressure system

10+ people viewing

■ Simple It is very simple because it is the latest mechanism with a seal heater and trimming blade integrated. ■ Easy operation Just put the cup ...

Daiichi Pack Machinery

Small auto cup seal machine PACKMAN series PM-300HS type hand type

10+ people viewing

■ Simple It is very simple because it is the latest mechanism with a seal heater and trimming blade integrated. ■ Easy operation Just put the cup ...

Daiichi Pack Machinery

"Cup Ice" for "Cup ice" Cup seal machine S-5500TR 2WW (4 consecutive x 2) type

10+ people viewing

■ It is a cup seal machine of one -touch replacement method ・ You can use various cups with one of this machine. ・ Because the operation is very ...

Corporation Yamatsuji

Half-automatic cup sealer elementary and middle lot ET-98S

10+ people viewing

■ Foreigns in stores, lab machines, and this production in various scenes ■ High performance with compact design ■ Automatic driving just by plac...

Corporation Yamatsuji

Semi-automatic cup sealer elementary and middle lot ET-69L for lunch

10+ people viewing

Last viewed: 1 hour ago

■ Ideal for multiple kinds and small lot production Full automatic driving with high -performance compact design * Operation with only 100V power s...

Corporation Yamatsuji

Desktop type cup seal machine N2 ET-900SF/LF

10+ people viewing

■ Ideal for food storage and industrial parts ■ Removal from 20.9%to 0.2%oxygen Suitable for oxidation prevention. * The measured value is the sta...

Corporation Yamatsuji

Rotation type fully automatic cup sealer ET-80

40+ people viewing

Last viewed: 8 hours ago

■ Ideal for multiple kinds and medium -lot production Compact design / mass production in space saving (Machine size 950 x 950mm) ■ Equipped with...

F Picotupa Co., Ltd.

Sliperiming Simultaneous semi-automatic packaging type seal machine TK-600AS type

■ Product overview ・ Cup sealer (air cylinder method) corresponding to the CN series top seal (MJ200 top film) ·Small lot ・ Compatible with multi...