All Categories

History

This section provides an overview for aluminum die castings as well as their applications and principles. Also, please take a look at the list of 72 aluminum die casting manufacturers and their company rankings. Here are the top-ranked aluminum die casting companies as of March, 2026: 1.IQE, LLC, 2.AmTech OEM, 3.Soldy Manufacturing.

Table of Contents

Categories Related to Aluminum Die Castings

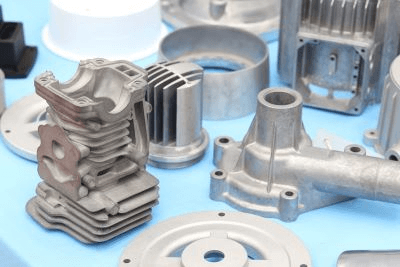

Aluminum Die Casting is a special casting method in which aluminum alloy or zinc alloy is melted and pressed into a mold. Aluminum die casting is characterized by its ability to mass-produce products of complex shapes with high dimensional accuracy and beautiful surfaces.

Aluminum Die Casting is a special casting method in which aluminum alloy or zinc alloy is melted and pressed into a mold. Aluminum die casting is characterized by its ability to mass-produce products of complex shapes with high dimensional accuracy and beautiful surfaces.

For this reason, aluminum die casting is highly regarded among metalworking methods. It is often confused with aluminum casting, however it is a different casting method from aluminum die casting because it refers to a method in which a metal such as aluminum alloy or copper is made into a liquid at a temperature higher than its melting point, poured into a mold, and cooled to harden. In addition, aluminum die casting uses metal molds, whereas sand molds are generally used for aluminum casting.

Aluminum die casting is characterized by high production costs because it requires the design and fabrication of molds from a block of metal.

Aluminum die casting is mainly used in automotive parts. Among them, steering related parts are in high demand in recent years. This is because aluminum die casting can manufacture products with complex shapes and high precision in large quantities and in a short time.

Aluminum die casting is not only used for automotive parts. It is also used in various products in our daily lives, such as personal computers, cell phones, digital cameras, refrigerators, and washing machines.

Aluminum die casting can also be used to produce small parts, thus contributing to product weight reduction.

Aluminum die casting is a casting method that uses molds. The die casting machine consists of a die clamping device that opens and closes the die, an injection device that ejects the molten metal into the die, and an extrusion device that pushes the metal out of the die.

In aluminum die casting, aluminum alloy is first melted. At this time, metals other than aluminum are also melted to produce an alloy with the desired composition, so careful adjustment and control of the composition is necessary. After the aluminum alloy is melted, the die is cleaned and the die is closed with a die clamping device. The closed mold is then filled with the molten aluminum alloy by an injection device.

Aluminum die casting is characterized by a fine surface structure because the molten metal is injected into the mold and cooled rapidly. This fine surface structure makes the surface of aluminum die casting hard and enables the production of strong products.

On the other hand, the disadvantage of aluminum die casting is that the rapid cooling process tends to create casting voids. These casting voids occur not only on the surface, but also in the center of the product where it finally solidifies. If casting cavities occur in aluminum die casting, the expected product performance will not be achieved, such as reduced strength. Therefore, aluminum die casting requires temperature control during die casting and careful consideration of the mold shape.

Aluminum die casting is formed by melting aluminum alloy or zinc alloy and press-fitting it into a die. Generally, the material is heated to approximately 500°C to 700°C to melt, poured into the mold at low speed, and then cooled under high pressure to form the mold.

Aluminum casting, on the other hand, involves melting a liquid aluminum alloy in a high-temperature furnace and pouring it into a metal or ceramic mold. Aluminum casting basically does not apply any external force, but uses the input of liquid metal by falling and subsequent flow. Aluminum die casting is sometimes referred to as gravity casting.

The advantages of aluminum die casting are its high dimensional accuracy and the ability to produce even complex shapes. This is because the molten aluminum alloy is fed into the mold under pressure, so the aluminum alloy is instantly distributed to every corner of the mold. On the other hand, aluminum casting may not achieve the desired dimensions or may cause wrinkles on the surface. This is because the high-temperature aluminum alloy has relatively low fluidity, and it takes time for it to spread to all corners of the mold by simply dropping it into the mold.

As a result, aluminum casting shrinks as it solidifies, which can result in defects such as dimensional changes and wrinkles created during flow. Aluminum die casting is also characterized by high dimensional accuracy and excellent surface roughness. Since the aluminum alloy is spread instantaneously, manufacturing time can be shortened, which has the advantage of enabling mass production of products.

Another feature that distinguishes aluminum die casting from aluminum casting is that the surface roughness remains high quality, which reduces finishing and inspection processes. One disadvantage of aluminum die casting, however, is the high cost of mold design and manufacturing. For this reason, aluminum die casting using sand molds may be more cost-effective for small-lot production.

Another disadvantage of aluminum die casting is that it is not suitable for parts that require high strength. Due to the manufacturing process, aluminum die casting involves air and evaporated mold release agent during the molding process. This creates cavities called nests, which reduce the strength of the product.

Aluminum die casting materials include casting and elongation materials, and a large number of die casting materials are available in a series headed by ADC.

The main component systems of aluminum die casting materials are Al-Si and Al-Mg, to which elements such as Cu and Mn are added. Each material is selected according to the corrosion resistance, castability, and impact resistance required for aluminum die casting.

The metallographic structure of aluminum die casting materials is a matrix phase of Al solid solution. The matrix can be a lamellar Al-Si eutectic or precipitation strengthened by fine precipitates such as Mg2Si, Al2Cu, etc., and the properties exhibited differ accordingly.

Normally, aluminum alloys are subjected to heat treatment after casting and machining to prepare crystal grains and form micro-precipitates. However, in aluminum die casting, heat treatment is often not performed to avoid air and gas entrained in the die castings from expanding and forming defects due to heat treatment.

However, vacuum die casting and non-porous die casting methods, which have recently been increasingly applied, are characterized by the fact that these defects are less likely to occur. Therefore, in recent aluminum die casting, it is possible to bring out the characteristics of materials by adding heat treatment process.

*Including some distributors, etc.

Sort by Features

Sort by Area

IQE, established in 2004 in Indianapolis, IN, is a manufacturer and supplier specializing in aluminum die casting, investment casting, steel forging and plastic injection molding. The company’s services include aluminum die casting, investment casting, iron sand casting, and more. They also offer standard products such as rigging hardware and stainless steel worm drive hose clamps. Engineering assistance such as CAD model development and stress analysis is available on request. IQE is ISO 9001-2000 certified and is backed by a production facility in China, offering optimal pricing and custom solutions to diverse industries including manufacturing, automotive, construction, and more.

Amtech Manufacturing, Inc., established in 1995 with facilities in North America, is a contract manufacturer of gear parts and drive components. The company's products include gears, shafts, castings, forgings, and screw machine parts. Amtech Manufacturing, Inc. also offers flexplate Assemblies, flywheel Assemblies, screw machining, stamping, and fineblanking. The company also offers custom manufacturing, machining, engineering, and laser cutting services. Amtech Manufacturing, Inc. services original equipment manufacturers in the automotive, construction, marine, power sports, and robotics markets.

CHICAGO WHITE METAL CASTING Inc., established in 1937 in Chicago, USA is a manufacturer of die-castings using aluminum, magnesium, and zinc. The company produces castings that require minimal or no additional processing, offering design capabilities, machining, finishing, and turnkey operations. Some of its products are electric and electronic die-castings made from magnesium and zinc under pressure, such as mesh and lattice-shaped casings, servo drives, commercial scales, PV panels, and more. All products must meet stringent criteria: must be robust and durable, lightweight for portability, waterproof, dust-resistant, and equipped with EMI protection.

Fort Recovery Industries Inc., established in 1945, is a manufacturer of die castings based in Ohio, United States. The company manufactures ISO-CERTIFIED zinc and aluminum castings used in plumbing, appliance, automotive and furniture applications. Fort Recovery also has operations in China that feature powder coating, polishing, plating and in-house casting. It conducts its production process environment-friendly by minimizing waste generation. Also, the company supports the community through the Fort Recovery Community Foundation.

Soldy Manufacturing, founded in 1982 in the USA, is a manufacturer specializing in zinc alloy and aluminum alloy die casting, serving a wide range of industries. Company employs a technologically advanced process monitoring system for consistent quality control and offers custom heat treatment options while delivering prime, cost-effective solutions to cater diverse industries; such as automotive, medical, telecommunications, and more. Whether it's zinc or aluminum die casting, Soldy ensures precision and efficiency, making it a dependable partner for manufacturing parts and components. It serves customers across the United States, Canada, Mexico, and Western Europe.

PHB Inc., established in 1984 with a history in the industry dating back as far as 1096 and headquarters in the USA, is a custom manufacturer and supplier of die cast tooling, parts, and supplies. The company's manufacturing capabilities include aluminum and zinc die casting, precision CNC machining, plastic and rubber molding, tool and die design, and production. It also provides final part finishing and product assembly. The company provides services, including engineering, product development, and prototyping. Other services include millipore testing, leak testing, impregnation, and cryogenic deflashing.

KenWalt Die Casting Company, established in 1968, is a manufacturer of die casting based in Los Angeles, United States. The company develops zinc and aluminum die castings for nuclear energy, water systems, electrical, automotive and aerospace applications. It uses automated production such as sprayers, automated ladlers and automated programmable controllers, to ensure the castings meet the proper standards. The company's castings come with a Kan-Ban inventory to help manage the stock.

J&M Precision Die Casting, Inc., a subsidiary of Rhenium Alloys, Inc., established in 1968 and headquartered in Elyria, Ohio is a manufacturer specializing in Aluminum die castings and zinc castings. The company offers various products, including Electric motor components, Security hardware, and Decorative hardware. The company also offers services such as assembly and testing, mold building, and product design, as well as building custom machines for specific requirements. It is a member of The North America Die Casting Association and some of its clients are the agricultural and automotive Industries.

G & M Die Casting, established in 1978 and located in Wood Dale Illinois, is a manufacturer of aluminum die casting. The company is built on a 70,000-square-foot facility and houses an experienced team of engineers and machinists. It is a single-source provider of cast, machined, and painted mechanical components. It is an ISO 9001:2015 certified company providing die-casting services, including design, engineering, manufacturing, and finishing. The company’s products are used in the automotive, aerospace, and medical industries.

American Precision Die Casting (APDC), founded in 2006 in Cuba, Missouri, is a manufacturer rand supplier of aluminum die-casting services. The company is built on a 40,000-square-foot facility housing designers, machinists, engineers, and customer support agents. The company offers various die-casting services, including design, engineering, manufacturing, and finishing, all of which are provided through SMED (single-minute exchange of dies) and Kanban programs. American Precision Die Casting supports automotive aftermarket, agriculture, commercial vehicles, military and defense industries, offering customer support and maintenance of business connections.

Apex Aluminum Die Casting Co. Inc. is a manufacturer of aluminum die castings and zinc die castings. Established in 1980 and located in Piqua, Ohio, the company specializes in developing and delivering die castings from concept to final product. The company offers assembly and finishing services, including machining, sanding, and painting as well as tool manufacturing, conversions, maintenance, and repair services. The company provides support in the manufacturing and design of new mold, the transfer of existing die-cast tooling, and the processing of conversions from sand and permanent mold applications.

Xometry is an American AI-driven B2B platform of custom parts and assemblies, with minor operations as a contract manufacturer that was originally established as NextLine Manufacturing Corp. before its rebrand in 2015. Based in North Bethesda, Maryland, the company connects manufacturers and buyers via a range of services including instant quoting and a web database. They also offer sheet metal fabrication, CNC machining, 3D printing, injection molding, and die casting services for rapid prototyping or high-volume production projects. Xometry chiefly serves clients in the defense, robotics, aerospace, and automotive sectors, including BMW, Bosch, and NASA.

Reliable Sourcing Solutions (RSS) is an American contract service provider and manufacturer specializing in global sourcing as well as engineering services since 2008. Based in Jonesboro, Arkansas, the company primarily provides outsourcing solutions to help clients find suppliers in China, Taiwan and India. They also maintain minor contract manufacturing operations, offering injection molding, forging, die casting, stamping, and tooling services for customer projects. RSS is a division of Southern Marketing Affiliates, which distributes agricultural parts nationwide. The company chiefly serves clients in the agricultural and industrial sectors.

Kirsan Engineering, Inc., founded in 1967, is a contract manufacturer of precision machined components such as tooling racks, bar/saw loaders, tubes, and shafts for the automotive, agriculture, transportation, medical, and military industries. The company works on specialized projects like casting, high-speed machine spindles, machine camera base housing, and machined aluminum valves. With an ISO 9001:2015 registration, the Pleasant Prairie, WI-based company provides CNC machining and secondary services. Ocenco, Inc. bought the business in 2001.

Peridot, Inc., established in 1997, and located in Hoagland, Indiana, is a custom manufacturer of metal fabrication and printing services. The company's capabilities include molded plastic parts, metal castings, CNC machining, prototyping, and 3D printing, which serves to industries such as automotive, consumer products, industrial equipment, toy, plastic molding and electronics industries. It's products are designed to enhance the functionality and performance of complex systems across industries, ensuring accurancy and precision.

Amos Industries, Inc., founded in 1999 and based in Aurora, Illinois, is a manufacturer and supplier of machine parts. It offers R&D, stamping, forgings, castings, metal injection molding, precision machining, surface treatment, product assembly, heat treatment, and more. The company provides services ranging from sample development and product optimization to an after-sale service as a e-stop-shop experience. It serves customers in the motive, agricultural, marine, sports & athletics, aerospace, healthcare and related industries.

M&P Manufacturing USA is a metal and plastic parts manufacturer founded in 1992 and based in Brooksville, Florida with a secondary office in Shenzhen, China. The company is an exclusively built-to-print OEM provider that does not distribute any products under its own branding. The company offers plastic injection molding, precision CNC machining, plastic and metal extrusion, tooling, and other services for the development, fabrication, and finishing of components used in aerospace, automotive, construction, and general industries.

Federal Group USA, founded in 1980, is a manufacturer of custom metal components for various industries, headquartered in Fernand, Michigan, USA. From fasteners to metal stamping and CNC machining, they provide a comprehensive range of engineering and manufacturing services. They are a Thomas Verified Supplier, Quality Systems Basics and ISO 9001:2015 certified company. The company’s capabilities include cold heading, metal fabrication, additive manufacturing, and precision CNC machining. Their product applications cater to diverse industries, from automotive and aerospace to medical and consumer goods.

Aluminum Die Casting Co. Inc., founded in Mira Loma, CA, in 1950 is a manufacturer of Die Casting & Tooling. The company's product portfolio includes Prototyping Services, precision die-cast components, tooling solutions for die casting processes, precision machining for post-casting operations, and Surface Finishing. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

P.Q.D. International, Inc. founded in 1984 in Dallas, Texas, is a manufacturer of all types of metal products used in CNC tube & pipe bending, and powder coating. The company's product portfolio includes casting foundries, secondary operations from precision machining, assembly, finishing, and packaging and CNC tube and Custom Fabrications. Their products are used in industries such as Electronics and Telecommunications, Automotive, Transportation and aerospace and Defense. The company also offers customer services that include support, custom research projects and customized services.

DyCast Specialties Corporation, founded in 1978, is an American manufacturer based in Starbuck, Minnesota, specializing in die casting solutions. The company’s capabilities include high-pressure die casting using non-ferrous metals, particularly aluminum die casting due to its conductivity, dimensional stability, mechanical properties, resistance to corrosion, and strength. Additionally, the company offers zinc die casting for castability, durability with minimal maintenance, and shielding capabilities. The company also offers die cast manufacturing services, including value-added capabilities, like designing, testing, machining, deburring, and finishing, catering to various sectors, including aerospace, automotive, medical, radar, and robotics.

Feralloy, Inc. is a manufacturer of engineered metal parts and goods based in Cleveland, Ohio. Founded in 1984, the company produces various superalloys, machined bar stock components, and custom metal fabrications for clients in oil and gas, power generation and mining. The company's product lineup includes rolled ring and closed-die forgings, sand and heat-resistant alloy castings, and custom weldments as well as assemblies for clients with niche specifications. Feralloy also offers logistics planning and coordination, distribution and scrap alloy buyback services.

Pilgrim Harp, established in 1998, and located in Avon, Ohio, is a custom manufacturer of precision machined components. Its range of custom products includes CNC machining, turning, stamping, casting, and forging which caters in industries such as aerospace, medical, fiber optics, fitness equipments, and industrial. It's products are used in engine, diagnostic equipments, ferrules, gears & bearings, and weights. Pilgrim Harp is ISO 9001:2015 and AS9120B certified, which ensures the quality and performance of the company's products.

Source International is an American-owned industrial supplier established in 1988, headquartered in Louisville, Kentucky and with offices in Xiamen, China and Ho Chi Minh, Vietnam. The company provides its customers with access to its multinational network of factories for them to source their requested items. The company’s factory network has manufacturing capabilities of plastic injection molding, CNC machining, metal forging, and product assembly, among others. They do not directly market any products of their own, offering OEM services and their custom tooling fabrication and mold making to customer specifications as their core business model.

Die Cast of America, established in 1992, is a veteran-held and family-operated manufacturer of aluminum and zinc die castings located in Walnut, CA. The company is ISO 9001:2008 and has capabilities such as spectrographic metal analysis, CNC milling & turning, multi-spindle machining,mil-spec & spares specialists, and domestic & offshore tooling. The company offers services such as surface finishing, powder coating, plating, kitting, and mechanical assemblies such as Helicoils, PEM, and custom-engineered inserts.

Amfas International Inc, founded in 2002 and based in Memphis, Tennessee, is a manufacturer and supplier of custom metal and plastic components. The metal part capabilities include CNC machinings, stamping, aluminum extrusion, and metal injections. The organization provides logistics services ranging from transportation to correct customs and duty documentation and quick prototyping. The plastic parts are rotational & blow molding, thermoforming, and 3D printing. The ISO 9001-certified company caters to the aviation, oil & gas, industrial, electronics, and medical sectors.

RCM Industries, Inc. is a manufacturer and supplier of aluminum die casting products and was founded in 1951 as RCM Industries and is based in Franklin Park, Illinois, United States. The company's range of offerings encompasses die castings, finishing, machining, and assembly services, among other services. The company's die casting goods and accessories exhibit innovation, efficiency, precision, and user-friendliness. These products have been specifically engineered to cater to a diverse array of requirements across several sectors, including but not limited to the automotive, medical, industrial, and consumer electronics industries.

Control Plastics Inc. is a supplier of plastic and metal components, operating in the USA since 1978. Their devotion to excellence and precision has solidified their position as a partner for industries spanning aerospace, electronics, and consumer goods. Offering diverse services, including design, prototyping, and manufacturing, Control Plastics Inc. delivers tailored solutions to meet clients' unique needs. Boasting a proven track record of delivering products on time, Control Plastics Inc. excels in fostering strong client relationships and utilizing advanced manufacturing technologies.

Talbot Associates, Inc., founded in Springfield, NJ in 1994 is a supplier of Die Casting, Investment Casting, and Permanent Mold Casting services. The company's product portfolio includes aster Mold Casting, Ceramic Mold Casting and Sand Casting in all metals & alloys for all industries. Their products are used in industries such as Electronics and Telecommunications, Automotive, Transportation and aerospace and Defense. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

American Die Casting, Inc. was established in 1991 and is headquartered in Fontana, California, and the company is a supplier of a range of services, including in-house tool repair, axis machining, and tool development for clients operating in the aerospace and commercial sectors. The company considers itself on its outstanding customer service, internal tool repair capabilities, tool design expertise, and unique approach to enhancing tooling for challenging castings. Commencing the project with superior casting facilitates the subsequent stages of the process, rendering them less complicated.

Orange1 Holding, established in 1971 and based in Piazza della Repubblica, Milan, is a manufacturer specializing in single-phase and three-phase asynchronous electric motors, foundry and turning parts. Its product portfolio encompasses single-phase and three-phase asynchronous electric motors, foundry and turning components, and drives for electric motors. These products have wide-ranging applications in industries like automotive, railways, and industrial sectors. The company's manufacturing capabilities extend to asynchronous motors up to 3700 kW, synchronous motors up to 2700 kW, hydroelectric generators up to 3000 kW, and wind turbines up to 5000 kW.

Eurobalt, established in 2015 and based in Tallinn, Estonia, is a manufacturer of hydraulic cylinders, sintered parts, and die-casting products. The company uses technologies such as powder metallurgy, casting, machining, aluminium die casting, and forging to manufacture products including cemented carbides, shock absorber parts, large-size stainless steel casting, and permanent magnets. With production facilities in India and China, the company has been catering all the products to different industries, including automotive, consumer electronics, agricultural machinery, and large industrial facilities. The company performs quality checks according to the PPAP standards.

Blisk Casting, established in 1985 and headquartered in Slovenia, is a manufacturer of high-pressure aluminum die-casting components and related components. The company specializes in aluminum parts and offers tooling design, production, and mechanical and surface treatment services. It employs AlSi9Cu3 DIN 226 and AlSi12Cu3 DIN 231 alloys to meet industrial requirements in the automotive, electronics, and mechanical engineering sectors. It incorporates management systems and sustainable development practices into its operations and produces ready-to-use components using CNC machining technology delivered directly to assembly lines. The company also provides technical support, R&D services, and prototyping, utilizing die-casting mold techniques.

Junying Metal Manufacturing Co., Limited, established in 2005 in China, is a manufacturer of machining parts with over 100 employees. The company's products include carbon steel, stainless steel, aluminum, and alloys. It also offers services such as tuning, grinding, drilling, heat treatment, and assembly. Having attained ISO certifications and environmental compliance, the company prioritizes quality and production standards. As an original equipment manufacturer that uses computer numerical control precision techniques, it produces machining parts at a low cost for the medical, electronic, aerospace, mechanical and communication industries.

Sunrise Metal Technology Co., Ltd., founded in 2013, is a Chinese manufacturer based in Kunshan, Jiangsu, specializing in die casting solutions. The company provides a range of services centered around aluminum die casting manufacturing and computer numerical control (CNC) machining, specifically for aluminum materials. This includes CNC milling, drilling, tapping, and boring processes. It also offers rapid prototyping services utilizing both additive and subtractive manufacturing techniques. Optional surface finishing services are available for both the die casting and machining processes. The company serves various industries with its die casting and machining capabilities, notably catering to the automotive, marine, medical, and telecommunications sectors.

Enchuang Precision Hardware Technology Co. Ltd, established in 2010, is a manufacturer of industrial machinery based in Dongguan, China. The company specializes in hardware, such as zinc die casting, connector shells, and connector housing used in manufacturing industries. It offers processing services such as surface treatment, aluminum, zinc alloy and magnesium die-castings. Its main partners include Amphenol, BYD, JONHON, IMS and TTI. The company’s products are IATF-CERTIFIED and are exported to the United States, UK, France, Germany and Italy.

PA International, a manufacturer and engineering consultancy company based in China, collaborates with known manufacturing facilities and research centers in China and Taiwan. The company produces a wide range of products for clients, including designs in consumer goods, health, and environmental sectors. It offers in-house capabilities encompassing industrial design, mechanical and electronic, as well as general engineering, and provides comprehensive project management, manufacturing, and legal counsel services on-site in China. The company facilitates successful connections between engineers and solutions available in China and maintains an ongoing partnership with each engaged company, from defining part specifications to product manufacturing and post-sales support.

KICastings, established in 1992, is a manufacturer of castings based in Los Angeles, United States. The company deals with investment casting, a technique for casting alloys. Some investment casting services offered include stainless steel, copper, aluminum, alloy steel and carbon steel casting, which serve the automotive, hardware, train and arms industries. It also manufactures using technologies like Siemens NX software, CNC Milling and in-house metal treatment and has ISO and IATF certification for standard assurance.

Mag-Tec Casting Corporation, established in 1990 and based in Jackson, Michigan, is a manufacturer specializing in die castings. The company offers a complete line of in-house services, including product inception, tooling design, short and long-term production runs, CNC machining, and finishing and coatings. It provides comprehensive services in the die casting of magnesium, aluminum, and zinc, with die casting machine sizes ranging from 600 to 1000 tons. This allows customers to obtain products ranging from a few ounces to 16 lbs.

Peerless Hardware founded in 1908 in Connecticut, USA is a manufacturer of industrial hardware such as latches, hinges, handles, locks, and other components used in various industries such as transportation, construction, and agriculture. The company's main focus is on producing custom metal components for OEM production, although they also have a diverse product line that they manufacture and keep in inventory for sale. The company's products are designed to withstand harsh environments and heavy use, making them ideal for demanding applications.

Modern Aluminum Castings Co., Inc., established in 1919, is a pattern maker and manufacturer of aluminum castings for OEMs worldwide based in Terre Haute, Indiana. The company is a one-stop source for Castings and Component Parts including Aluminum Sand Castings, Aluminum Permanent Mold Castings, Iron Castings as well as Investment Castings. Modern Aluminum Castings also offers design assistance for wood and metal patterns, including Close Tolerance Aluminum Castings. The company serves a wide range of industries including Automotive, Medical Devices, and Industrial machinery.

Wrex Products Inc. of Chico are manufacturers of custom plastic and metal die-casting parts founded in 1960 in Chico, California. The company develops complete solutions for plastic injection molding, die casting, and powder coating. The plastic injection molding includes Prototype/Production Tooling, Medical Devices & Documentation, and more. The Aluminum & Zinc Alloy Die Castings help with mechanical strength, cost-effectiveness, and plated finish of equipment. The powder coating services include Clear/Gold Conversion Coating, Sandblasting and Custom Masking & Fixturing. Wrex are also certified for manufacturing many medical devices as well.

SDC, Inc. is a manufacturer of zinc and aluminum die casts for producing shapes ranging from one gram to five pounds and the company is based in Sullivan, Missouri, and was established in 2014. The die casts and accessories offered by the company are crucial components in various industries, such as automotive, aerospace, medical, and consumer products. The products are used for creating complex and precise parts with high strength and durability. The company also provides secondary operations, such as drilling, pressing, and machining, as well as tool room services for gauges, fixtures, die and mold building and repair.

ZETWERK Manufacturing USA Inc., established in 2018, is a manufacturing services provider offering unlimited manufacturing capacities in every area of manufacturing. The company has capabilities such as high pressure & low pressure die casting, sheet metal fabrication, metal stamping & forming, metal injection molding, and CNC milling and machining. The company provides services like prototyping, mass production, warehousing, and inventory management. The company in Mesa, Arizona, AZ, is ISO 9001:2015 and AS9100D certified and serves the industrial machinery & equipment, transportation, construction & infrastructure, energy, and electronics & appliance industries.

AGC Industrial Solutions, founded in 2000 and headquartered in Namur, Belgium, is a contract manufacturer of plastic, metal, and electronic components. Its operational offices are in Shanghai and Qingdao, and it helps small and medium enterprises worldwide to manage and maintain projects in China through subcontracting and purchasing support. The company has over 70 active and audited suppliers and provides services such as casting, stamping, and precision machining. It offers four industrial solutions for manufacturing plastic components, including plastic injection, machining, and 3D printing.

Dongguan PowerWinx Metal Industries Co., Ltd., established in 2009 and located in Guangdong, China, is a manufacturer and supplier specializing in precision metal, plastic, and assemblies. The company's product portfolio includes CNC milling, CNC turning, aluminum die castings, magnesium die castings, and plastic injections. These products are utilized in various sectors, including medical, semiconductor manufacturing, automation, telecommunications, and renewable energy. The company also provides services including delivery and technical support. The company is ISO9001, IATF 16949, and ISO14001 certified, and it exports its products to North America, South America, Europe, the Middle East, and Australia.

ZheJiang Dongrun Casting Industry Co Ltd, established in 1995 and based in Zhejiang Province, is a manufacturer and supplier of CNC machinery products. Its product portfolio includes sand casting, gravity die casting, aluminum sand casting, high pressure, and low-pressure die casting. The company’s products are used in multiple industries including automotive, medical, fuel, gas, electric, lighting, and furniture. They also offers design solutions, processing systems, and equipments with different specifications.

JC Casting Supplier, founded in 1997, is a manufacturer and supplier of investment casting, machine technique and sand casting for countries like Australia, Japan, Canada, American and the United Kingdom. The company uses carbon steel, non-ferrous alloy, stainless steel, alloy steel and carbon to make castings for these industries: oil and gas fluid equipment, fluid power castings, kitchenware, medical equipment, and construction. It tests all products using tools like vernier calipers, height gauge, coordinates measuring machine and thread gauge.

CFS Machinery Co Ltd, established in 2001 and based in Ningbo, China, is a manufacturer and supplier of industrial casting metals. Its product portfolio includes a range of steel-casting products, iron-casting products, aluminum-casting products, and nickel-based alloy-casting products. The company also offers casting processes, casting tolerances, quality control with assurance, and customer services. They are used in multiple industries such as agriculture, railway, glass fittings, container castings, and valve castings.

Nanjing Power-Est Industry & Trade Co.,established in 2015, is a manufacturer and supplier of industrial components based in Nanjing, China. The company's product portfolio includes iron, steel and brass castings, machining parts and plastic parts. The products are used in the automobile, agricultural, medical and electronics industries to create engine blocks, switchgear and circuit breakers. The company has two manufacturing sites, an in injection molding facility and an aluminum die-casting factory which are ISO 9001-certified.

China Casting Synergy Group, a manufacturer, operates with a team of over one hundred manufacturing experts in China. Specializing in Aluminum, Zinc, Magnesium, and Copper die-casting products, alongside CNC machining and turning products, the company has thrived since its inception in 2003. Collaborating with numerous Chinese manufacturing suppliers, it employs more than 40 professionals, including client managers, project engineers, project QC specialists, and logistics managers. As a member of the China Casting Industry Federation, it tailors products primarily to European and American markets, showcasing rich experience in meeting client requirements in these regions.

Reliance Foundry Co. Ltd. is a manufacturer of superb custom and stock cast metal products. Established in 1925 and located in USA. The company is a long-recognized supplier of outdoor site furnishings, bike storage systems, hardscape products, and traffic management supplies. Reliance also draws on its long history to provide excellence in the manufacture of steel wheels as well as superior custom casting services. Reliance Foundry has built upon a long tradition of metal casting expertise to become an award-winning supplier for high-profile and everyday needs across North America.

Gensun Precision Machining Co., Ltd, established in 2006 and headquartered in Dongguan, China, is a manufacturer, distributor, and supplier of custom precision machined parts. Their custom machined products cater to industries such as aerospace, medical devices, electronics, telecommunications, and consumer products. Gensun holds ISO 9001:2015 and ISO 14001:2015 certifications, highlighting their adherence to quality. The company helps technical developments and industrial applications by providing the precision components that are crucial for assuring dependability, and efficiency.

ZS Industries Co., LTD, founded in 2003 and headquartered in Shanghai, China, is a manufacturer and distributor of mechanical and engineering metal parts. The company provides a range of products, including plastic parts, sheet metal welding, and precision machining. Additionally, it offers services such as computer-aided design, material analysis of the chemical and mechanical properties, and defining and selecting prototyping processes. These products and services are applied across various industries, including environmental protection, new energy fields, and hydraulic cylinders.

American Aluminum Extrusions, established in 2001 and based in Roscoe, Illinois, USA, is a manufacturer and supplier of aluminum extrusions and fabrications. The company’s product lineup includes quality aluminum extrusions and fabrications, pivotal for the Transportation, Distribution, Building and Construction, and Electrical industries. The company's services include the provision of standard, individualized customer service, design, and tolerance specifications, ensuring that clients obtain great quality and tailored aluminum solutions meant for various needs.

Le Seur Incorporated, established in 1946, is a manufacturer and supplier of aluminum castings based in Minnesota, United States. The company uses production methods like permanent mold, die casting, plastic injection molding, sand casting and precision machining. The castings are ISO-CERTIFIED and go through casting X-ray and metallurgical labs for testing to meet quality standards. These products are used in medical, agricultural, military, recreational and transportation applications by 130 customers worldwide.

Pace Industries, Inc. established in 1970 and headquartered in Novi, Michigan, USA, is a manufacturer and supplier of die-cast products. The company's product range includes aluminum die casting, machining, magnesium die casting, zinc die casting, and tool and die. These products are essential for various applications like thin wall, test/validation, assembly, and prototyping. Serving industries such as appliance, aerospace and defense, automotive, and lighting and electrical, it ensures the delivery of quality solutions. Its integrated services further include production capabilities, product development, and materials expertise.

Fast-Rite was founded in 1992 and is headquartered in Glendale Heights, Illinois. The company is an ISO 9001:2015 certified manufacturer and distributor of fasteners, abrasives, tools, and accessories to manufacturing and other industries. The company has multiple distribution centers throughout the United States, as well as full-service sales, warehouse, and production facilities in both Mexico and Asia. The company offers rite-stock programs and optimization options. Rite-stock programs include customer-managed inventory, total VMI, virtual inventory, Kanban, and JIT programs. Optimization programs include assembly, automation, and robotics solutions.

Advanced Prototype Molding, founded in 1980 and based in Wauconda, IL, is a manufacturer and supplier of prototypes of plastics, metals and urethanes. The company provides ISO 9001-2015 certified products and services such as plastic injection molding services, RTV molding, 3D printing, tool and die, and rubber and silicone parts. It delivers goods in both low and large quantities. Advanced Prototype Molding's international partner includes China, where it extends manufacturing options at even more competitive prices.

VPIC Group, established in 1994 and headquartered in Dong Nai, Vietnam, is a supplier that offers a range of manufacturing services. The company offers a range of manufacturing services such as aluminum die casting, hot forging, tooling, CNC and assembly, and more. It also provides secondary manufacturing processes such as bicycle frame manufacturing and investment casting. Its services can help businesses achieve their desired product specifications and quality standards. The company has received ISO 9001, ISO TS/16949, and ISO 14001 certifications. It serves various industries such as power sports, automotive, agriculture, construction, healthcare, and more.

Qingdao Brilliant Machinery is a supplier of extrusion products and aluminum/magnesium casting components based in Qingdao, China. The company's supply portfolio includes aluminum and magnesium alloys used in communication electronics, rail transit and automobile industries. The products are tested using technologies like electronic Brinell hardness tester, X-ray detection, salt spray tester and metallurgical microscope. The company supplies its products to Alstom, CAF, Bombardier, BMW and Harley-Davidson. It also has ISO and BV accreditations of standard assurance.

JB Metalcraft, which changed from Janssen Boas Company to JB Metalcraft in 2015, is a Brooklyn, New York-based supplier of industrial-grade metal components built to exact requirements. The company serves the automotive, hydraulics & pneumatics, construction, agriculture, and energy industries as a Tier 1 and 2 supplier of castings, machined parts, forgings, and fabrications. The business can use various coordinate measurement devices, projectors, air gauges, Charpy impact, and profilometers. The business has TS 16949 and ISO 9001 certifications.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | IQE, LLC |

4.2%

|

| 2 | AmTech OEM |

3.3%

|

| 3 | Soldy Manufacturing |

2.7%

|

| 4 | Chicago White Metal Casting, Inc. |

2.7%

|

| 5 | Fort Recovery Industries, Inc. |

2.5%

|

| 6 | PHB Inc |

2.3%

|

| 7 | Die Cast of America |

2.3%

|

| 8 | Empire Casting Co. |

2.2%

|

| 9 | J&M Precision Die Casting, Inc. |

2.2%

|

| 10 | KenWalt Die Casting Company |

2.0%

|

Derivation Method

The ranking is calculated based on the click share within the aluminum die casting page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

34 | 60.7% |

China

China

|

14 | 25.0% |

Canada

Canada

|

2 | 3.6% |

Italy

Italy

|

1 | 1.8% |

| Estonia | 1 | 1.8% |

Slovenia

Slovenia

|

1 | 1.8% |

Belgium

Belgium

|

1 | 1.8% |

Taiwan

Taiwan

|

1 | 1.8% |

Vietnam

Vietnam

|

1 | 1.8% |