13 Photoelectric Switch Manufacturers in 2024

This section provides an overview for photoelectric switches as well as their applications and principles. Also, please take a look at the list of 13 photoelectric switch manufacturers and their company rankings. Here are the top-ranked photoelectric switch companies as of April, 2024: 1.Shenzhen EPT Tech co., LTD, 2.Omron Microscan, 3.Banner Engineering Corporation.

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

What Is a Photoelectric Switch?

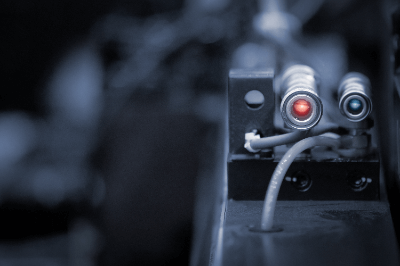

A Photoelectric Switch is a device that uses light to detect the presence or absence of an object or its surface shape. Although sometimes called photoelectric sensors, photoelectric switches are especially used for contact output products.

A Photoelectric Switch is a device that uses light to detect the presence or absence of an object or its surface shape. Although sometimes called photoelectric sensors, photoelectric switches are especially used for contact output products.

The majority of light used is in the visible range or infrared light. They are characterized by long detection distances and few restrictions on the substances to be detected.

Uses of Photoelectric Switches

Photoelectric Switches are used in industrial applications. Because they can control electrical signals according to the intensity of light, they are used in a wide variety of fields, such as sensors and fiber-optic communications.

They can detect a wide range of substances, including liquids and metals, and are used to provide a contact output for their presence or absence.

They can also detect substances with low reflectance and detect differences in color.

The following are examples of applications for photoelectric switches:

- Detection of bottles and cans in beverage factories

- Edge detection of printed circuit boards

- Detection of the presence or absence of pills, such as medicine

- Detection of postcards at post offices

- Detection of workpieces in processing plants

Principle of Photoelectric Switches

Photoelectric Switches are available in a variety of detection methods, such as light transmission, retro-reflection, and diffuse-reflection types.

1. Transmission Type

In the transmission type, the light from the projector is always detected by the receiver, and the light is interrupted when an object crosses the detector. The sensor detects a decrease in the amount of light received when the light is interrupted, and the receiver outputs a contact. The features of this type of sensor are the separation of the light emitting and light receiving parts and the long detection distance.

2. Retro-Reflective Type

The retro-reflective type is a photoelectric switch in which the light emitter and receiver are combined into a single unit. The light from the projector is reflected by the reflector, detected by the light-receiving part in the projector unit, and output at the contact point. This switch is characterized by the fact that it does not require optical axis alignment.

3. Diffuse-Reflective Type

Unlike the retro-reflective type, the diffuse-reflective type has no reflector. The light emitted from the projector is reflected by the material and detected by the light-receiving part. The advantage of this type is that it has only one unit and does not require a reflector.

Types of Photoelectric Switches

There are the following types of photoelectric switches:

1. Transparent Type

The projector and receiver are combined into a separate component. They are installed opposite each other, separated only by the distance required for detection.

When installing, it is necessary to adjust the optical axis so that the projection axis of the transmitter and the receiver axis of the receiver are perfectly aligned. The maximum installation distance for the transmissive type varies depending on the product, so the specifications must be checked.

2. Groove Type/U-Shaped Type

A light emitting source and a light receiving element are housed in a case with their optical axes aligned. The light path inside the groove in the case serves as the detection range.

3. Integrated Type

This is a product in which the light emitter and receiver are integrated into a single unit. As described in the Principle section, there are two types: retro-reflective and diffuse-reflective. The retro-reflective type requires a reflector, while the diffuse-reflective type does not.

However, the diffuse reflection type can be used only when the object to be detected reflects light. It can be used for metal plates, etc., but is not suitable for detecting round or small objects. The retro-reflection type is also superior in detection accuracy.

4. Optical Fiber Type

This product uses an optical fiber for the detection part. Since it can detect any location where an optical fiber can be inserted, it can be installed in a narrow space. Since signals are transmitted and received via optical fiber, this type is suitable for use in environments that require waterproofing and explosion-proofing.

How to Select a Photoelectric Switch

It is important to select the appropriate type of photoelectric switch according to the purpose of use and environmental conditions.

Transmissive photoelectric switches, in which the light source and the light-receiving element are separated, can detect the presence of an object within a certain distance, making them suitable for object detection in factories, warehouses, and the like.

On the other hand, fiber-optic photoelectric switches are useful when waterproof and explosion-proof properties are required.

The performance of photoelectric switches is also important. It is important to compare signal accuracy, speed, and durability, and select the best switch for your purpose. In addition, the method of supplying power and wiring must also be considered in the selection process.

In addition to product selection, proper handling and maintenance are also important for long-term use.

List of 13 Photoelectric Switch Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Japan

-

-

-

SICK AG

Photoelectric Sensors

Manufacturer Overview

Sick AG, founded in 1946 and headquartered in Waldkirch, Germany, is a manufacturer of sensor and sensor solutions that aid in in production, logistics, and processes automation. The company’s expansive product portfolio includes industrial sensors, encoders, and analyzers. It has over 50 subsidiaries and equity investments as well as several agencies worldwide, and in the 2022 fiscal year, it generated around €2.2 billion. The company established the first subsidiary in France in 1972 and opened another subsidiary in USA in 1975. It changed to a joint stock company in 1996 and the first employee shares were issued in 1999.

-

-

-

-

-

Omron Microscan

Photoelectric Sensors

Manufacturer Overview

Omron Automation was originally established in 1933. Omron Automation is a producer and manufacturer for industrial automation solutions including robotics, sensing, motion, logic, and safety. Industries include automotive automation, electric vehicle manufacturing, food and beverage packaging, semiconductor and manufacturing electronics, life sciences automation, logistics & warehouse automation, machine tool, oil and gas, water and wastewater, entertainment, security and detention, and other industries. Some of Omron Automation’s product categories include machine automated controllers, RFID solutions, safety laser scanners, safety outputs, smart cameras, vision sensors, machine vision software, servo systems, articulated robots, parallel robots, SCARA robots, photoelectric sensors, and rotary encoders along with many software-based solutions.

-

-

-

-

-

Banner Engineering Corporation

Photoelectric Sensors

Manufacturer Overview

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

-

-

-

-

-

Hamamatsu Photonics K.K.

S10053

Manufacturer Overview

Hamamatsu Photonics K.K., established in 1953 and headquartered in Hamamatsu, Japan, is a manufacturer of sensors and emitters for both visible and invisible light. It stocks products like LEDs, lamps, and photodiodes used in several industries, including consumer electronics, dental imaging, and environmental monitoring. The sensor and light source components are also available as modules and units that can be incorporated into systems the company develops, like optical measurement systems or imaging systems. The ISO 9001-certified company stocks over 15,000 devices, units, and systems that ship to over 100 destinations worldwide, and it has ten research and production bases.

-

-

-

-

-

Azbil Corporation

Photoelectric Switches (Photoelectric Sensors)

Manufacturer Overview

The Azbil Corporation (formerly the Yamatak Corporation) aims to realize safety, comfort, and fulfillment in people's lives and contribute to global environmental preservation through "human-centered" automation. They provide their customers with timely solutions via an integrated structure that extends from planning and development to maintenance and service, capable of responding rapidly to customer needs.

-

-

-

-

-

Shenzhen EPT Tech co., LTD

Photoelectric Sensors

Manufacturer Overview

Shenzhen EPT Technology Co., Ltd., was founded in 2003, is a manufacturer of optical water level detection sensor, capacitance level sensor, flow sensor and tilt sensor’s, based in China. The company has set up offices in Sichuan, Shanghai and Yuyao, which are responsibles for its new product development and global market expansion and services. It has strong technical strength with more than 20 patent product certificates, and has been designated as a professional manufacturer by the Ministry of Electrical and Mechanical Services.

-

-

-

-

-

YUEQING YUMO ELECTRIC CO.,LTD

Photoelectric Sensors

Manufacturer Overview

YUEQING YUMO ELECTRIC CO.,LTD, founded in Zhejiang, China, in 2004 is a manufacturer of industrial automation control products. The company's product portfolio includes Programmable Logic Controller, Human Machine Interface, Photoelectric Switch, Proximity Switch, and Switching power supply. Their products find application in textile machinery Machinery, packaging machinery, wind power generation, and industrial assembly automation control field. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

-

-

-

-

-

Omron

Photoelectric Sensors

Manufacturer Overview

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

-

-

-

-

-

Cyndar

photoelectric switch

Manufacturer Overview

Cyndar, founded in 2010, is a manufacturer of smart sensor safety products, and a supplier of smart sensors and automation solutions. The company offers sensor intelligence and industrial application solutions that help ensure the safety and effectiveness of industrial processing, protecting people from accidents and curbing environmental degradation. Its metal detection and safety inspection products include safety laser scanner series products, safety light sensor series products, pressure sensitive series products, safety edge sensor series products, and safety relay series products. This ISO 9001- certified company has a diverse customer base in electrical, manufacturing, telecommunications, construction, and building technologies markets.

-

-

-

-

-

Connect2India

Photoelectric Switch

Manufacturer Overview

Connect2India, established in 2015 and headquartered in Faridabad, India, is a manufacturer that developed an integrated trading platform of the same name. Launched as a full platform in 2016, Connect2India facilitates connections between Indian micro, small, and medium enterprises (MSMEs) and overseas individuals and enterprises to foster partnerships. The company also provides assistance to these businesses in entering international markets through insights, expert resources, predictive analytics, and business tools. Additionally, Connect2India offers services such as helping with business setup in India, conducting inspections of Indian companies, and hiring import and export agents. To counter international trade frauds, Connect2India leverages technologies like Blockchain.

-

-

-

-

-

Fuji Electric Equipment Control

Photoelectric switches

Company Overview

Fuji Electric Equipment Control was established in 2008 in Saitama-ken, Japan is a manufacturer of power distribution and control equipment. The company boasts an extensive and diversified product portfolio including motor controls, MV distributors, energy control equipment, LV distributors, and industrial control relays. These products find applications in construction as magnetic contactors, automotive as manual motor starters, home appliances as air circuit breakers, health care devices as sensors and switches, and in environmental management for quality assurance and protection of high-voltage electric power and management of low-voltage consumption rate.

-

-

-

-

-

-

-

Fargo Controls, Inc.

Photoelectric Switches

Distributor Overview

Fargo Controls, Inc. was founded in 1983 and is headquartered in Eatontown, New Jersey. The company is a distributor of proximity sensors and other industrial controls for both consumer and industrial customers. The company categorizes proximity sensors by four principles: inductive for detecting metallic objects, capacitive for detecting both metallic and non-metallic objects, photoelectric for detecting light, and magnetic for detecting the presence of permanent magnets. Other product offerings include counters, rate meters, timers, and controls.

-

-

Photoelectric Switch Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | LANBAO HONOR |

20.0%

|

| 2 | Shenzhen EPT Tech co., LTD |

12.0%

|

| 3 | SICK AG |

12.0%

|

| 4 | YUEQING YUMO ELECTRIC CO.,LTD |

8.0%

|

| 5 | Fargo Controls, Inc. |

8.0%

|

| 6 | Banner Engineering Corporation |

8.0%

|

| 7 | Azbil Corporation |

8.0%

|

| 8 | Cyndar |

4.0%

|

| 9 | Connect2India |

4.0%

|

| 10 | Omron Microscan |

4.0%

|

Derivation Method

The ranking is calculated based on the click share within the photoelectric switch page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Azbil Corporation: 10,063

- Hamamatsu Photonics K.K.: 3,766

Newly Established Company

- Shenzhen EPT Tech co., LTD: 2003 (21 years ago)

- LANBAO HONOR: 1998 (26 years ago)

- Hamamatsu Photonics K.K.: 1953 (71 years ago)

Company with a History

- SICK AG: 1946 (78 years ago)

- Hamamatsu Photonics K.K.: 1953 (71 years ago)

- LANBAO HONOR: 1998 (26 years ago)

Photoelectric Switch Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Photoelectric Switch Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 37.5% |

China

China

|

3 | 37.5% |

Japan

Japan

|

2 | 25.0% |