All Categories

History

This section provides an overview for probers as well as their applications and principles. Also, please take a look at the list of 14 prober manufacturers and their company rankings. Here are the top-ranked prober companies as of February, 2026: 1.The Micromanipulator Company, 2.Chunglai Hung Probes Manufacturing Co., Ltd., 3.TEGAM Inc..

Table of Contents

Categories Related to Probers

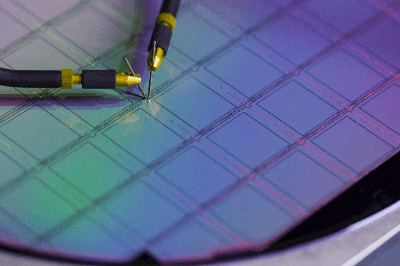

A prober is a device for fixing a probe (needle) at an arbitrary position, also called a probe station. It is a positioning device that connects the probe of the contact part of the measurement device to the correct position of the electrode of the semiconductor to measure electrical items on the semiconductor wafer in the front-end process, mainly in the semiconductor wafer manufacturing process and IC design and development.

A prober is a device for fixing a probe (needle) at an arbitrary position, also called a probe station. It is a positioning device that connects the probe of the contact part of the measurement device to the correct position of the electrode of the semiconductor to measure electrical items on the semiconductor wafer in the front-end process, mainly in the semiconductor wafer manufacturing process and IC design and development.

Since the electrode area of a semiconductor is tiny, it is necessary to apply the probe of the contact part of the inspection device to the exact position. Very precise controllability is required for the prober in positioning.

In addition to semiconductor chips, this equipment is often used to evaluate the electrical characteristics of PCB substrates, various thin-film substrates, such as sensors and filters, and ceramic substrate packages, such as LTCC.

Probers are used when inspecting the electrical characteristics of semiconductors, thin-film substrates, and package substrates. When used for research and development purposes, the probers should have functions to eliminate noise and prevent signal leakage (crosstalk), be able to measure with high accuracy and be as versatile and flexible as possible in terms of measurement methods.

For mass production, the most important feature is the ability to perform fast processing accurately and in large quantities, so a wide variety of probers models should be selected to suit the application.

The probers must also be temperature tolerant to ensure correct operation at high and low temperatures during temperature characteristic evaluation. In addition, a prober that can handle high voltage and low impedance is required when used to measure semiconductors for power devices.

The most typical prober for silicon wafer applications is described below. The prober consists of a wafer chuck for fixing a silicon wafer, a stage for moving the wafer chuck in the XY direction, a contact plate to which multiple probes for inspection are attached and which moves in the Z direction concerning the stage, and a camera for positioning. The wafer is then moved in the XY direction to the stage.

In addition to these mechanisms, a transport system for moving silicon wafers is often included in probers products. The principle of operation is that when a silicon wafer is set, the silicon wafer is transported to the wafer check position and fixed.

The stage then positions the wafer in the XY direction, and with the position of the probe for measurement and the electrode of the semiconductor on the silicon wafer adjusted, the contact plate moves in the Z direction to contact the probe and the electrode. Through this process, the electrical characteristics of the semiconductor can be inspected by the inspection system.

With the recent miniaturization of semiconductor devices, microcurrent measurement is an important indicator to evaluate the manufacturing quality of semiconductor devices. In the design and fabrication of semiconductor devices, changes in device materials, crystal growth parameters, or geometry can create unexpected current paths inside the device, which is commonly referred to as leakage current.

Increased leakage current can be caused by lattice defects, gate oxide structure, substrate selection, and other factors that can induce excessive power consumption and, in some cases, lower breakdown voltage. In recent years, the gate length of FETs and the emitter size of bipolar transistors in semiconductor devices have become very small, and while the voltage required to drive these devices is decreasing, leakage current is increasing.

Therefore, from the viewpoint of quality evaluation, highly accurate current measurements using probers are required. One measure to improve the accuracy is the development of cryogenic probes.

The contact position accuracy of the probers directly affects the measurement accuracy. If various evaluations are performed without correct probing, it is difficult to know what is being evaluated.

For example, if you want to evaluate the characteristics of a semiconductor device, but the wafer is out of position and probed on an insulator, it is not difficult to imagine that the evaluation results will be far off from the expected results.

It is necessary to understand the accuracy required for the evaluation target and then focus on improving that accuracy. It is the component called a positioner (manipulator) that determines the positioning accuracy of the probers. Positioning accuracy varies depending on the correct selection of a positioner suited to the required specifications.

The specifications of a positioner are almost always determined by the following four factors: (1) travel distance, (2) travel resolution, (3) adjustment sensitivity, and (4) external dimensions. See below for the contents of each specification.

Probers suitable for RF evaluation are required for the evaluation of semiconductor transistors for high-frequency (RF) and device modeling.

Generally, a GSG probe (a needle with a ground (GND) on both sides of the signal pad) with a dedicated calibration board is used, but depending on the frequency to be measured, care must be taken not only with the probe but also with the RF cable to the network analyzer or various measurement devices. This is because the flexure of the cable may affect the RF measurement results.

In the millimeter wave band, which has a higher frequency than a microwave, a dedicated VNA extender is used, but the configuration of the device should be discussed in detail with the dedicated manufacturer because the probers configuration itself has a very large impact on the measurement.

*Including some distributors, etc.

Sort by Features

Sort by Area

TEGAM, established in 1979 and headquartered in Geneva, Ohio, USA, stands as a manufacturer and provider of advanced test and measurement solutions. The company serves industries such as electronics, telecommunications, and aerospace. Its product line encompasses precision measurement tools, temperature and humidity measurement devices, and RF power sensors, addressing the needs of sectors that prioritize precise measurements. TEGAM's quality is evident through its ISO 9001 certification and industry awards. American Association for Laboratory Accreditation (A2LA) has also accredited this company for its specific calibrations listed on Certificate Number 2018.01.

FormFactor, based in Elmsford, New York, is a manufacturer and supplier of IC test and measurement technologies such as probe systems, analytical probes, probe cards, metrology tools, and quantum cryogenics since 1993. Their probe systems are available in 150 mm, 200 mm, and 300 mm and are used in cryogenic, open, pressure, shielded, and vacuum environments. They offer probe cards with a minimum pitch of between 50um to 250um for DRAM, flash, logic, optical, and parametric applications. These products enable inspection, characterization, debugging, and testing in 5G & 6G communications, automotive, computing, data centers, & quantum, and aerospace & defense industries.

The Micromanipulator Company, established in 1956, with its headquarters located in Carson City, Nevada, USA, is a manufacturer of advanced probing equipment for the semiconductor, microelectronics, and materials science industries. The product range includes advanced wafer probing systems, analytical probing solutions, and accessories for precision testing and analysis. These products enable researchers and engineers to make precise measurements, facilitating the characterization and analysis of semiconductor devices and materials at the micro and nanoscales. The benefits of the products include improved accuracy, increased efficiency, and enhanced data collection for applications such as failure analysis, device characterization, and reliability testing.

E+E Elektronik Ges.m.b.H., established in 1975 in Austria, is a manufacturer and provider of cutting-edge sensor solutions for humidity, temperature, and CO2 measurement. The company’s product portfolio includes humidity sensors, temperature sensors, transmitters, and CO2 sensors. These technologies are broadly employed in industries such as HVAC, automotive, pharmaceuticals, and more. E+E Elektronik's team of experienced engineers and professionals collaborate closely with customers to understand their specific needs and deliver tailored sensor solutions. The company also plays a great role in raising measurement accuracy and enhancing improved environmental monitoring and control systems.

Tulip Company Limited was established in 1948, based in Hiroshima, Japan, and is a manufacturer of needlework-related items. The company has a rich tradition of needle-making that spans over 300 years, producing a range of quality sewing needles, crochet hooks, knitting needles, and various handicraft-related accessories. Additionally, the company is involved in the manufacturing of test probes. Test probes are essential for electronics and testing applications, enabling precise measurements and connectivity. The company's products cater to a wide range of needlework enthusiasts, from sewers to crocheters and knitters.

Hisol Inc., established in 1967 as Kan Electronics, is a manufacturer based in Tokyo, Japan, producing machines for the semiconductor manufacturing process. The company's product range includes standard and compact manual probers and probe system accessories. It also offers prober flip chip bonders, covering desktop types for small-scale or research applications, automatic types for higher volume production, and high-accuracy types for precise chip placement. The company has received numerous awards, including the "Excellent Health Management Corporations 2020" recognition from the Ministry of Economy, Trade and Industry (METI).

KAWASO ELECTRIC INDUSTRIAL Co., Ltd., established in 1957 and headquartered in Nishi-Ku, Osaka, Japan, is a manufacturer and exporter of measurement devices. The company’s diverse portfolio includes ‘Molten Metal Immersion Probe’ used for temperature & component measurement at blast furnaces & converters, Oxygen Measurement Probe used for quality control, Temperature Measurement & Sampling Probe used to collect information in steel-making process, Sublance Probe for an estimated measurement of carbon, and a calculator for chemical sensors among others. The company exports its products to markets in the US, UAE, South Africa, Vietnam, and Saudi Arabia.

SemiShareProber, established in 2015 in Shenzhen, Guangdong, China, is a manufacturer and supplier of wafer probe stations. The company’s product line includes wafer probe stations, probe cards, probe tips, probe heads, and probing systems, serving industries like semiconductors, MEMS, photonics, displays, and solar cells. These products provide a diverse range of services including design, engineering, manufacturing, testing and certification, and technical support. The company also holds ISO 9001:2015 certification, making it excel in quality and service.

Chunglai Hung Probes Manufacturing Co., Ltd., established in 1986 and headquartered in Yingge District, New Taipei City, Taiwan, is a manufacturer and supplier of test probes and related equipment. The company's product range includes bare board test probes, testing machine probes, ICT/FCT test probes, and double-ended probes, catering to diverse industries such as semiconductors, electronics, and telecommunications. The company’s services entail custom design and manufacturing, technical support, and training. The company emphasizes in providing quality products and services to its customers, as reflected in its ISO 9001:2015 certification. It consistently exceeds expectations in quality and service.

Evident Corporation is a scientific research and development company in Shinjuku, Tokyo that was established in 2008. Formerly known as Olympus Scientific Solutions, the company specializes in developing cutting-edge technology and products for various industries, including aerospace, automotive, electronics, energy, and medical research. Evident Corporation has proliferated and expanded its product offerings and services to meet the needs of its customers. Their product offerings include non-destructive testing (NDT) solutions such as thickness gauges and automated inspection systems, XRF analyzers like handheld XRF analyzers, industrial microscopes, and video scopes and borescopes.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | The Micromanipulator Company |

20.3%

|

| 2 | Chunglai Hung Probes Manufacturing Co., Ltd. |

10.7%

|

| 3 | Tulip Company Limited |

10.0%

|

| 4 | TEGAM Inc. |

10.0%

|

| 5 | FormFactor, Inc. |

9.6%

|

| 6 | SEMISHARE CO., LTD. |

8.9%

|

| 7 | E+E Elektronik |

8.6%

|

| 8 | HiSOL,Inc. |

5.2%

|

| 9 | KAWASO ELECTRIC INDUSTRIAL Co., Ltd. |

4.8%

|

| 10 | SemiProbe |

3.8%

|

Derivation Method

The ranking is calculated based on the click share within the prober page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 36.4% |

United States of America

United States of America

|

3 | 27.3% |

Germany

Germany

|

1 | 9.1% |

China

China

|

1 | 9.1% |

Taiwan

Taiwan

|

1 | 9.1% |

Bulgaria

Bulgaria

|

1 | 9.1% |

96 products found

96 products

Yuzan Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Features The OYM series is a manual probing station that can be operated intuitively. We have a lineup of probers that can be equipped with stereo...

2 models listed

Yuzan Co., Ltd.

660+ people viewing

Last viewed: 23 hours ago

This is a space-saving model with excellent cost performance that is suitable for various measurement purposes. ■Features The compact shielded box...

Yuzan Co., Ltd.

740+ people viewing

Last viewed: 1 day ago

■Features This is a simple, A3 size, small manual prober that is compatible with everything from chip level to Φ50mm wafers. By closing the sliding...

Apollo Wave Co., Ltd.

560+ people viewing

Last viewed: 1 day ago

■Features ・Model compatible with temperature characteristic evaluation from -60℃ to +350℃ and microcurrent measurement. -Manual probers compatible...

Yuzan Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

Supports 1/f noise and minute current measurements without being affected by the installation environment. The unique compact shield structure pro...

Apollo Wave Co., Ltd.

680+ people viewing

Last viewed: 11 hours ago

■Features ・Standard model compatible with various wafer level measurements. - Manual prober compatible with wafer sizes up to 6, 8, and 12 inches....

Yuzan Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

This model is compatible with measurements in high temperature environments. By installing a sample stage with a heater unit inside a vacuum chamb...

Apollo Wave Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

■Features ・Small prober ideal for IV/CV measurements on up to 4-inch wafers. - Compact prober compatible with wafer sizes up to 4 inches. ・The st...

Yuzan Co., Ltd.

720+ people viewing

Last viewed: 1 day ago

This model is compatible with measurements in a deoxidized atmosphere. By creating a vacuum or inert gas atmosphere inside the vacuum chamber, sam...

Apollo Wave Co., Ltd.

600+ people viewing

Last viewed: 1 day ago

■Features - Compact prober ideal for chip-level IV/CV measurements. -Prober compatible with sample sizes up to 50mm. ・It is an integrated type equ...

Yuzan Co., Ltd.

500+ people viewing

Last viewed: 21 hours ago

This model is compatible with measurements at low temperatures. The refrigeration section uses a pulse tube refrigerator with no moving parts, mak...

Apollo Wave Co., Ltd.

480+ people viewing

Last viewed: 11 hours ago

■Features ・Temperature characteristic evaluation from -60℃ to +350℃, micro current measurement. ・Supports power device measurement of 20kV or mor...

Yuzan Co., Ltd.

630+ people viewing

Last viewed: 13 hours ago

This model is compatible with measurements in extremely low temperature regions. The refrigeration method is a continuous flow type of liquid heli...

Apollo Wave Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Features ・Temperature characteristic evaluation at extremely low to ultra-high temperatures, vacuum environment, gas environment measurement. ・I...

Yuzan Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

This prober is ideal for use in environments where outside air is blocked, such as in glove boxes. The sample stage and positioner are placed on a...

Apollo Wave Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

■Features ・For automatic measurement of extremely low and high temperatures in vacuum and gas environments, organic devices, and power devices. - ...

Yuzan Co., Ltd.

270+ people viewing

Last viewed: 18 hours ago

This is a CV/IV measurement system using a mercury probe method with excellent reproducibility and safety. ■Features Various types of wafer proper...

6 models listed

HiSOL,Inc.

790+ people viewing

Last viewed: 1 day ago

The HSP-200SC/HSP-300SC semi-automatic prober is a semi-automatic probe system compatible with next-generation semiconductor devices that pursues l...

HiSOL,Inc.

720+ people viewing

Last viewed: 1 day ago

The HSP-200SC/HSP-300SC semi-automatic prober is a semi-automatic probe system compatible with next-generation semiconductor devices that pursues l...

HiSOL,Inc.

740+ people viewing

Last viewed: 8 hours ago

The HSP-100 and HSP-150 semi-automatic probe systems are standard semi-automatic probe systems that can measure small diameter wafers up to 4 inche...

HiSOL,Inc.

640+ people viewing

Last viewed: 21 hours ago

The HSP-100 and HSP-150 semi-automatic probe systems are standard semi-automatic probe systems that can measure small diameter wafers up to 4 inche...

HiSOL,Inc.

500+ people viewing

Last viewed: 1 day ago

The HSP-100SC/HSP-150SC semi-automatic prober is a semi-automatic probe system with a sealed chamber that can measure up to 4 inches (100mm) or up ...

HiSOL,Inc.

570+ people viewing

Last viewed: 1 day ago

The HSP-100SC/HSP-150SC semi-automatic prober is a semi-automatic probe system with a sealed chamber that can measure up to 4 inches (100mm) or up ...

HiSOL,Inc.

440+ people viewing

Last viewed: 1 day ago

We offer custom double-sided semi-automatic probe systems that allow access to both the front and back sides of the wafer. It can be used for evalu...

HiSOL,Inc.

500+ people viewing

Last viewed: 1 day ago

We offer custom double-sided semi-automatic probe systems that allow access to both the front and back sides of the wafer. It can be used for evalu...

HiSOL,Inc.

680+ people viewing

Last viewed: 1 day ago

The HSP-200 semi-automatic prober is a standard type semi-automatic probe system that can measure up to 8 inches (200 mm) wafers. It features a mec...

HiSOL,Inc.

740+ people viewing

Last viewed: 1 day ago

The HSP-300 semi-automatic prober is a standard semi-automatic probe system that can measure up to 12 inches (300mm) wafers. It features a mechanic...

Unisoku Co., Ltd.

590+ people viewing

Last viewed: 12 hours ago

This stage is ideal for nano/micromanipulation probing under scanning electron microscopy (SEM). UMP-1000-4P is a manipulator/prober that can opera...

Unisoku Co., Ltd.

670+ people viewing

Last viewed: 16 hours ago

Ideal for nano/micromanipulation probing under SEM, FIB, and optical microscopy. UMP1000 is a manipulator/prober that can operate in XYZ3 axes and ...

Unisoku Co., Ltd.

420+ people viewing

Last viewed: 12 hours ago

Supports rotational movement and angle fine adjustment of samples and probes in air, vacuum, and low-temperature environments. The UMP1000R nano/mi...