All Categories

History

This section provides an overview for dimensional inspection systems as well as their applications and principles. Also, please take a look at the list of 7 dimensional inspection system manufacturers and their company rankings. Here are the top-ranked dimensional inspection system companies as of February, 2026: 1.LaserLinc, 2.ViSCO Technologies USA, Inc., 3.Gardner Business Media, Inc..

Table of Contents

Categories Related to Dimensional Inspection Systems

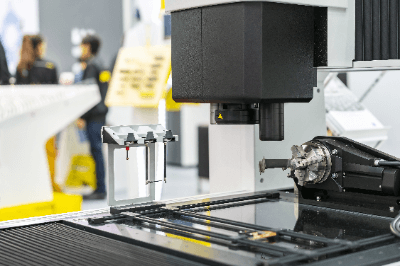

A dimensional inspection system is a highly functional visual inspection system that inspects the dimensions of mainly small electronic components such as LED substrates, CMOS sensor substrates, and ceramic substrates.

Dimensional inspection, a component of visual inspection equipment, is an inspection device that makes a pass/fail judgment as to whether a component or product is finished according to specifications. It is capable of measuring dimensions with micrometer-level precision, and by using the device for pass/fail inspections of finished products, it is possible to inspect the entire number of products.

In addition, by linking the conveyor system with image processing, an automatic dimensional inspection line can be constructed. Since image processing is equipped with a high-performance camera, it can be used to check the condition of intermediate products or for positioning during processing. They can also be used for dimensional measurement of metal parts as well as electronic parts.

Dimensional inspection systems are often used for electronic components that require micron-level accuracy. Specifically, they are used to measure the edge width, alignment, register length, and other dimensions of coated sections in intermittent coating, stripe coating, and other processes of electrode sheets. It is also used to detect defects and uncoated areas.

Other uses of dimensional inspection systems include dimensional inspection of exterior wall boards, tiles, etc., and surface checks of lumber and after-extrusion processes. 3D dimensional inspection models can also be used to check the volume of minerals, food, etc.

Also, the equipment can measure parts that cannot be measured by human operators. For example, the inner and outer diameters of O-rings, the radius and angle of the tip of a metal part, and other difficult-to-measure areas can be measured using image processing.

The dimensional inspection systems use a high-performance CCD or CMOS camera to perform inspections. Some models can scan laser beams and obtain height information to measure 3D XYZ axis dimensions.

On the production line, defective products identified as out of specification as a result of dimensional measurement using image processing is eliminated, and only the good products are automatically passed to the next process.

The work procedure for dimensional inspection systems begins by illuminating the object and capturing images with a camera through a lens. The image is then recognized by an image processor and measured.

The number of pixels is selected according to the dimensional tolerances required for the inspection of the object to be measured.

There are three types of illumination: direct reflection type, diffuse reflection type, and transmission type, which are selected according to the surface condition of the object to be measured.

Edges are the areas where color shading is often expressed in image processing. Differences in product height, material, color, and texture appear as edges. Dimensional inspection systems can measure the length and angle of areas that appear as edges, as well as the center position from the edge. Since the distance between edges is measured, the accuracy of the measurement depends on whether the edges are visible.

Appearance inspection equipment is a device that can automatically inspect the appearance of a product. The visual inspection device is equivalent to a camera or other image sensor for visual inspection, and an image processing device or software replaces the brain. Since the numerical values listed in the judgment criteria are based on past data, it is easy to create standard values.

However, visual inspection equipment is not necessarily ready for operation immediately after installation. This is because inspection equipment requires preparation, and prior adjustment and confirmation take time. In some cases, it is difficult to set the sensor and light source positions for video and other sensors, as well as the judgment values for detecting foreign objects, and in some cases, the imaging software is unable to detect the foreign objects that it originally wanted to detect.

Such problems can be solved by repeatedly changing the hardware position settings to find the proper position. Even if the software setting detects an unexpected rejection the first time, it learns the data and updates the judgment data, including the next appropriate judgment value, so that the same rejection will not occur thereafter.

Image dimensional inspection is a method that can instantly measure the height and depth of an object through images. In image sensor dimensional measurement, edges are detected by planning the object and measuring its position, width, and angle. In addition, mastery of the edge detection principle enables optimal detection to be set up.

Edge refers to the border between light and dark in an image, and edge detection is the detection of the border between these shades of gray using image processing. Edges are processed by the following processes.

(1) projection, (2) differentiation, (3) correction so that the maximum value of the differentiation is 100%, and (4) sub-pixel processing (interpolation calculation is performed on approximately three pixels centered on the maximum portion of the differential waveform from the waveform formed by those pixels to measure edge positions to the nearest 1/100th of a pixel).

One advantage of image processing is that it can automatically measure the dimensions of each part based on the captured data and save the numerical values as data. In addition, by performing dimensional inspection using image processing, the measured dimensions of each part can be saved as numerical values, and the data can be used for dimensional information management, shape analysis, and process improvement.

*Including some distributors, etc.

Sort by Features

Sort by Area

ViSCO Technologies USA, Inc. is a manufacturer of machine vision systems that was established in March 2014 and is headquartered in Minato-ku, Tokyo, Japan. The company offers a wide range of products, including machine vision cameras, image processing software, and machine vision inspection systems, used in various industries, including automotive, electronics, and food and beverage. ViSCO Technologies also provides machine vision solutions which are known for their quality, dependability, and ease of use. The company is customer-centric, and its products are backed by a comprehensive warranty and support program.

LaserLinc, based in Fairborn, Ohio, founded in 1996, is a manufacturer of non-contact measuring and control technologies. The company manufactures automated sample inspectors, surface flaw detectors, process visualizers, laser micrometers, and ultrasonic wall thickness measurements for medical devices, aerospace, communications, energy, and automotive industries. The firm provides an annual guarantee for transducers and a standard four-annum warranty for other instruments and services like spare parts replacement in the air, software products with lifetime support, interactive support over the internet, and return merchandise authorization requests.

NORMAN NOBLE , INC was established in 1946, located in Ohio, United States and it is a manufacturer of medical implants and medical devices. The company products are Nitinol implants, vascular implants, orthopedic implants, metallic implants, bioresorbable implants, medical stents, X-ray computed tomography systems and satellite components. The company products are applicable in medical field and implants, oncology, aerospace, vascular and orthopedic field and multileaf collimators. The company is FDA approved and is ISO 13485:2003 certified.

Yasunaga Corporation, founded in 1923 and based in Iga City, Mie Prefecture, Japan, is a manufacturer of engine parts, machine tools, as well as wire saws, and electronics systems. The company's core business are on precision machining of engine components, with connecting rods being a primary product. It has been serving the automotive, semiconductor, and electronic parts industries, delivering machine tools for various processes, including boring, drilling, slicing, assembly, and inspection.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Gardner Buisness Media, Inc. was established in the year 1928 in Ohio, United States and it is a publisher for manufacturing companies in North America. The company products and services are magazines, digital media, E-mail, events, lead generation and research. The company also writes manufacturing and marketer blogs, industry and media reports, economic intelligence and automotive articles. It also provides with Manufacturing Marketer Newsletter. The company also organises digital, in-person and calendar events.

Cross Company is a provider of precision measurement solutions that was established in 1954 and is headquartered in Minneapolis, Minnesota, USA. The company offers a wide range of precision measurement products, including hose and fitting equipment, automation equipment, mobile systems integration equipment, precision measurement equipment, and process equipment. Its products, such as digital micrometers, dial indicators, and laser trackers, are used by a number of industries, as diverse as manufacturing, aerospace, and medical industries. The company provides a range of services, including mobile systems integration, automation, calibration, hose and fitting, process and precision measurement services.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | LaserLinc |

21.4%

|

| 2 | ViSCO Technologies USA, Inc. |

17.1%

|

| 3 | Gardner Business Media, Inc. |

16.4%

|

| 4 | Cross Company |

15.0%

|

| 5 | NORMAN NOBLE, INC |

14.3%

|

| 6 | Omron |

11.4%

|

| 7 | YASUNAGA CORPORATION |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the dimensional inspection system page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 75.0% |

Japan

Japan

|

1 | 25.0% |

41 products found

41 products

Linkwith Co., Ltd.

640+ people viewing

Last viewed: 27 minutes ago

Achieved in-line 100% inspection by robotizing human visual inspection and jig inspection. ``The ideal would be to test everything.'' However, the ...

OptoComb Co., Ltd.

990+ people viewing

Last viewed: 4 hours ago

■Three types of optical comb sensors that achieve high precision and high speed inspection XTIA's optical comb 3D sensor is the world's first indus...

New Pulsa Co., Ltd.

690+ people viewing

Last viewed: 28 minutes ago

This device is an automatic visual inspection machine that inspects O-rings supplied by a belt conveyor for chips, scratches, foreign objects, dime...

Linkwith Co., Ltd.

570+ people viewing

Last viewed: 27 minutes ago

Automatically controls the robot according to the shape of the workpiece. ``Ideally, the robot line should not be stopped,'' but the current situat...

OptoComb Co., Ltd.

660+ people viewing

Last viewed: 27 minutes ago

■Desktop 3D scanner Anyone can easily obtain 3D images with a height accuracy of ±1 µm. This is a base model of a 3D inspection device that utilize...

Yutaka Co., Ltd.

710+ people viewing

Last viewed: 27 minutes ago

We are a manufacturer of inspection equipment for precision parts such as roller outer diameter sorters, laser sorters, CCD optical sorters, etc., ...

Yuki Giken Co., Ltd.

620+ people viewing

Last viewed: 27 minutes ago

Yuki Giken designs and manufactures automatic machines and inspection machines controlled by computers. It allows complex control and advanced calc...

OptoComb Co., Ltd.

720+ people viewing

Last viewed: 27 minutes ago

■3D 360° full circumference scan of measurement target Inline inspection of manufactured parts exhibiting rotational symmetry and micrometer tolera...

OptoComb Co., Ltd.

680+ people viewing

Last viewed: 27 minutes ago

■Measure bore dimensions in seconds Many medium and large components have deep and complex structures and must meet high quality requirements and d...

OptoComb Co., Ltd.

680+ people viewing

Last viewed: 27 minutes ago

■Improving efficiency by combining optical comb laser and image inspection Automating inspection is extremely difficult because there are a wide va...

Nihon Kohki Seisakusho Co., Ltd.

790+ people viewing

Last viewed: 27 minutes ago

This is an inexpensive and easy-to-use microscope that allows you to observe the surface of an object. Widely used in industry as a factory measure...

OptoComb Co., Ltd.

780+ people viewing

Last viewed: 27 minutes ago

This model is equipped with OptoComb SA (top surface inspection device), an image camera, and AI. Imaging is performed using an image camera, defec...

True Sortech

1030+ people viewing

Last viewed: 27 minutes ago

Examine the total high accuracy of the terminals performed with inline, measure dimensions, and detect scratches and deformation! ◆ Controller (TS...

CHUO ELECTRIC WORKS L.T.D

780+ people viewing

Last viewed: 17 minutes ago

This system is a three-dimensional image inspection system for three-dimensional structures. Using the sensor mounted on the robot arm, it is possi...

YASUNAGA CORPORATION

290+ people viewing

Last viewed: 27 minutes ago

■We propose optimal solutions for automation and labor saving. Yasunaga's machinery equipment business began with processing machines for sewing ma...

2 models listed

YASUNAGA CORPORATION

540+ people viewing

Last viewed: 3 minutes ago

■We propose optimal solutions for automation and labor saving. Yasunaga's machinery equipment business began with processing machines for sewing ma...

Photonic Instruments Co., Ltd.

600+ people viewing

Last viewed: 27 minutes ago

This is a device that automatically inspects the seal line width used in the liquid crystal dropping (ODF) process of the liquid crystal panel prod...

Nidek Power Train Systems

1160+ people viewing

Last viewed: 27 minutes ago

3D scanner technology in -line inspection Inline non -contact 3D scanners using light cutting methods using line lasers. Automatically tested inli...

NT Tools Co., Ltd.

740+ people viewing

Last viewed: 1 minute ago

■A presetter used to measure the protrusion length and radial dimension of NT taper holders such as BT shanks. The lightweight and compact design a...

NT Tools Co., Ltd.

860+ people viewing

Last viewed: 33 seconds ago

■This is a presetter used to measure the protrusion length and radial dimension of the holder. There are two types, NTP400 and NTP300A, depending o...

NT Tools Co., Ltd.

740+ people viewing

Last viewed: 27 minutes ago

■Customer usability comes first. Introduced the ``Aegis Eye'' optical tool presetter series, completely developed in-house. Because it is completel...