All Categories

History

This section provides an overview for coaters as well as their applications and principles. Also, please take a look at the list of 27 coater manufacturers and their company rankings. Here are the top-ranked coater companies as of March, 2026: 1.Walco, Inc., 2.Metal Coaters System, 3.Freund-Vector Corporation.

Table of Contents

Categories Related to Coaters

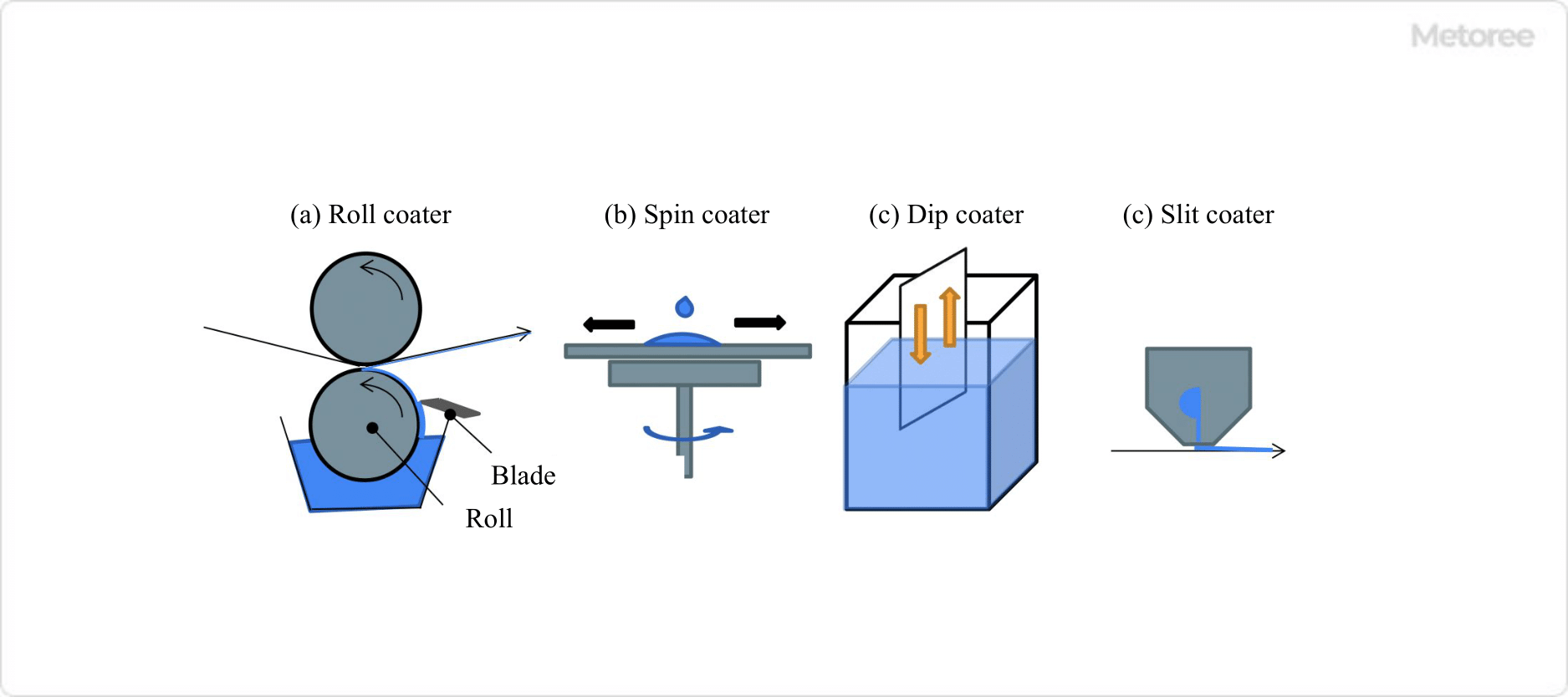

Figure 1. Types of Coaters

A coater is a device used to apply chemicals or other materials to a product or material.

General coater methods vary depending on the shape of the object to be coated, the chemical to be applied, and the purpose of the application. Therefore, roll coaters, spin coaters, dip coaters, and slit coaters are used for various applications.

In recent years, coaters have evolved dramatically along with improvements in coating technology, as precision coating accuracy is required in the fields of semiconductor manufacturing, flat panel display (FPD) manufacturing, solar cell and rechargeable battery manufacturing.

In the semiconductor and flat panel display (FPD) manufacturing fields, where thin, high-functionality, and high-density products are required, such as PCs, LCD TVs, smartphones, and tablets, spin coaters, and slit coaters are used to apply photoresist in the photolithography process.

Roll coaters and other coaters for thin film coating are also used for functional films and sheet products used in rechargeable batteries, solar cells, automotive parts, housing construction materials, textiles, medical care, and other applications.

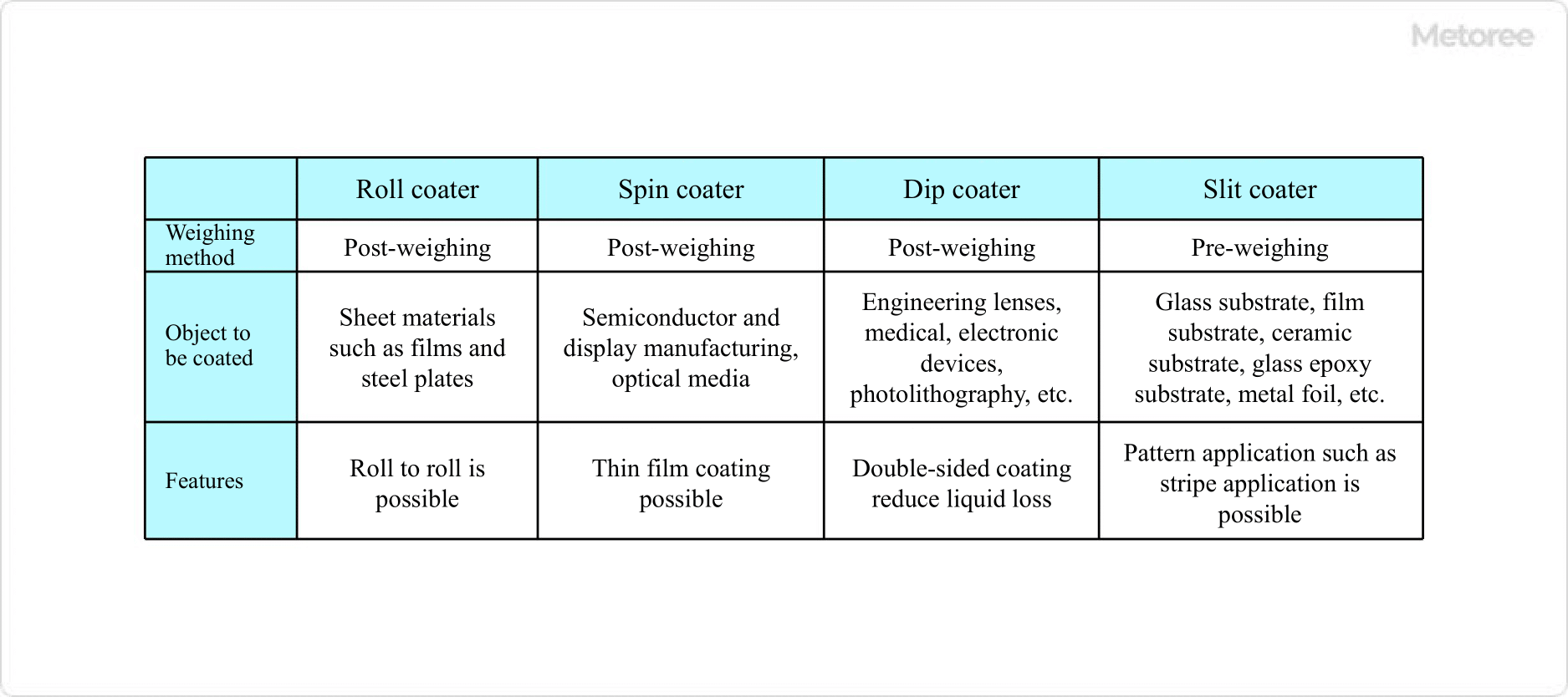

Figure 2. Characteristics by the Coater type

There are many types of coaters, but the basic principle is to apply shear force to the coating liquid to make it thinner. The way the shearing force is applied differs depending on the type of coaters.

The coaters can be classified into two types: the pre-measuring method, which applies a pre-measured amount of coating liquid, and the post-measuring method, which reduces the amount of coating liquid to a predetermined level after coating.

Roll coaters are generally used for coating relatively thin and flat materials such as films and sheets. Various coating methods are used depending on the nature and viscosity of the chemical to be coated, and the film thickness to be applied, such as gravure coaters and reverse coaters, which use the rotation of rollers in contact with the liquid pool of the chemical to be coated and the winding rotation of the film or sheet material to apply the coating.

The roll-to-roll coating is possible and is the most suitable for high-speed coating. The characteristic feature of these methods is that a bead is formed between the coating liquid and the object to be coated, and the object to be coated or both the object to be coated and the roll are moved or rotated to apply a shear force to the coating liquid and apply a thin coating. Stabilizing this bead is essential for high-quality coating.

Spin coaters generally consist of a rotating table and a mechanism for applying chemicals. After the chemical is discharged onto the product or other material, a centrifugal force from the table's rotation spreads the chemical throughout the product or other material, forming a chemical film. This is the thinnest coating method, but it is not suitable for mass production because it cannot apply multiple coats and continuous production is not possible.

This is called the dip coater-dip method and is used for coating by dipping and pulling up in the dip coating solution. Regardless of the shape of the object, it is characterized by its ability to form a uniform thin film with minimal loss of coating liquid.

The slit coaters are coaters that discharge the coating liquid through a nozzle with a slit. It is also called die coaters or slot die. The object to be coated is placed on a table, and a chemical film is formed by scanning the product or other material while discharging the chemical from the chemical nozzle.

Sometimes used for roll-to-roll coating, the slit coaters dispense a constant amount of coating solution onto a film or sheet being conveyed. Since the coating fluid does not come in contact with air, it is ideal for the highest quality coatings and for complex coatings such as stripes.

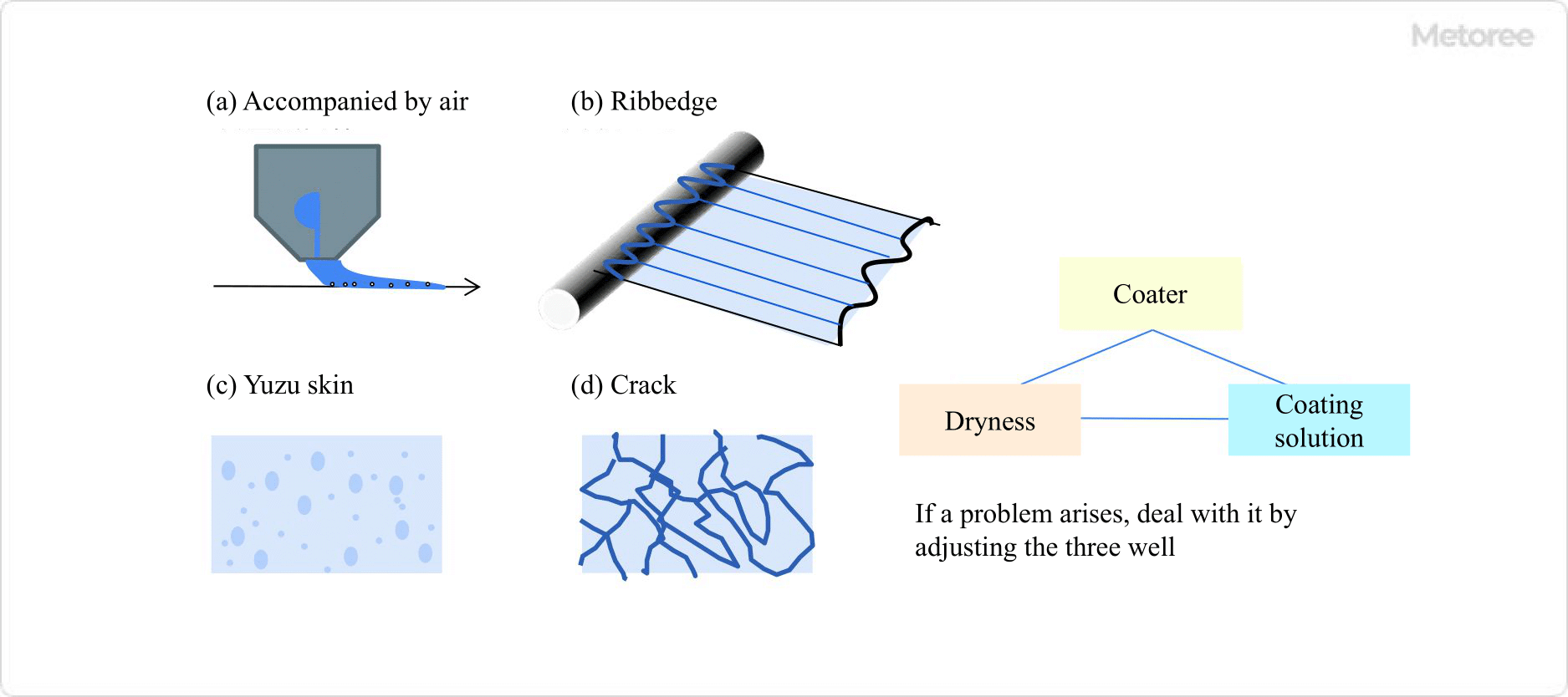

Figure 3. Typical example of Coating defects

No matter how sophisticated the coater is, depending on the coating liquid and coating conditions, it may not be possible to obtain a clean coated surface. This section briefly describes the types of coating defects and their remedies.

1. Those caused by Coating

| Type of defect | Cause | Remedy |

| Air entrainment | Air cannot escape when the coating liquid is applied to the coated object. | Reduces the coating speed. |

| Livestock | Livestock is subjected to a reverse pressure gradient in the coating section in the direction of the coating. | Reduction in viscosity of the coating liquid and coating speed. |

| Holes caused by air bubbles | Bubbles exist in the coating liquid. | Take measures to eliminate bubbles. |

| Unevenness in the shape of a horizontal dam, | mainly due to the reverse gravure method. | Suppress vibration of the coated object or change the rotational speed of the gravure. |

| Unevenness | Coating liquid flows in the coating film. | Improve the coating liquid. |

| Foreign matter | Coating liquid agglomerates or becomes gelatinous. | Introduce a filter. |

| Flickering | The surface tension of the coating liquid is too high. | Add a surfactant, etc. |

2. Defects caused by Drying

| Type of defect | Cause | Remedy |

| Orange-peel skin (The coated surface becomes uneven like orange peel.) |

This is due to an excessively fast drying rate. | Reduce the drying speed or add a surfactant. |

| Wind pattern | Hot air drying | Reduce the speed of hot air. |

| Cracking | Shrinkage of coated film | Avoid thick coating. |

Coating is a technique that is accomplished through the proper selection of coaters, dryers, and coating liquid, respectively. It is important to select the appropriate coaters, taking into consideration the conditions of the coating liquid to be used and the specifications of the drying oven.

*Including some distributors, etc.

Sort by Features

Sort by Area

Metal Coaters System, established in 1987 and based in Ohio, United States, is a manufacturer of metallic-coated painted metal coils. The company offers coating finishes and coil coatings for building, construction and consumer markets. The company uses upgraded equipment to clean, pre-treat and roll-apply organic coatings to commercial steel and aluminium substrates. The company offers coating finishes for polyesters, silicone-modified polyesters, fluorocarbons and plastisol—metal Coaters System. The company offers in-house sitting and embossing services. The company serves the construction and consumer markets in the US.

Freund-Vector Corporation, founded in 1972 and located in Marion, Iowa, is a manufacturer specializing in processing equipment. Its product line encompass coating pan systems designed for applying aqueous or sugar film coatings, fluid bed systems utilized for granulating, coating, and drying, high shear granulator mixers tailored for wet granulation, roll compactors for material densification and granulation, as well as spray dryers, and automated process control systems for all equipment and systems. The company has been assessed and is a registered International ISO 9001:2015 Quality Manufacturing Company.

Hitachi High Tech was established in April 1947 and operates in 26 countries with products and services ranging from semiconductor manufacturing equipment and Medical and Biosystems to Analytical Systems and Manufacturing related equipment and solutions. A unique state-of-the-art technology company with two functions as a manufacturer and a trading company with the motto of "Tackling social issues," the Hitachi High-Tech Group aspires to be a company that pursues not only economic value, such as revenue and profit, but also provides social and environmental value by contributing to resolving social issues through its business activities, including products and services. They also provide one-stop services, such as evaluations and analysis at a global level.

Sono-Tek Corporation was established in 1975 and is headquartered in Milton, New York. The company specializes in precision ultrasonic coating solutions, serving diverse industries, including electronics, medical, and industrial. Its product range encompasses ultrasonic spray nozzles, coating systems, and fluxers. Sono-Tek's pioneering technology is evident through multiple patents and global market recognition such as the acquisition of ISO 9001: 2015. The company is also found in many other countries, with seven application labs and over 50 factory-trained distributors to add to its design and manufacturing headquarters in the US.

Romaco, founded in 1886, is a supplier of machinery and integrated system solutions for the development, production and packaging of pharmaceuticals, nutraceuticals, food and chemical products. Its products include powder and liquid filling, tablet coating, capsule filling, granulation among others. The company’s aim is to help reduce carbon dioxide emissions with its technology. The company has received ASI and Green energy Certifications. Its vision is to be the provider of sustainable products and services for the pharmaceutical industry.

Zhengzhou CY Scientific Instrument Co., Ltd., established in 2013 and based in Zhengzhou, Henan, China, is a manufacturer of scientific research equipment. The company primarily offers standard laboratory furnaces along with customized furnaces and related accessories. Some of its products include diamond color change furnace, plasma cleaner, spin coater, and more. The company maintains its manufacturing base and collaborate with several subcontracting factories, enabling them to supply equipment and technologies tailored to diverse customer needs and specifications.

Xiamen Lith Machine Limited, founded in 1998 and headquartered in Xiamen, Fujian, China, is a manufacturer of battery laboratory and production equipment. Its product offerings encompass lithium battery production line machines and battery pack assembly line machines for battery manufacturing, laboratory machines for research and testing, battery materials for production, prismatic cell production machines, and cylindrical cell laboratory machines. The company has been verified on-site by SGS Group, an inspection company, and holds more than 16 patent rights.

Vac Techniche Ltd. is a designer and manufacturer of vacuum coating systems that is headquartered in Hastings, East Sussex, United Kingdom since 2012. The company designs, manufactures, and supplies multiple vacuum coating systems. Its product line include DCR- Desktop Carbon Coating System, Triple Thermal Evaporation Desktop Coating System, DST2-TGB Glovebox Sputter and Thermal Evaporation Source and DC power supplies for magnetron Sputtering and Plasma generation. Vac Techniche Ltd. products are used in many industries, including electronics, optics, and materials science. The company also offers technical support, installation, and training services to ensure efficient utilization of its products.

ASAP Co., Ltd., founded in 1999 with headquarters in Saitama, Japan, is a manufacturer of semiconductor production equipment. The company's product line includes a range of coating and developing modules and pressure-jet metal lift-off equipment with ASAP’s unique nozzles for research and development to mass production, as well as ASAP-designed mask alignment equipment. It also offers fully custom-built equipment, with clients that include UC Berkeley's Nano Lab. The company was recognized as a leading Saitama business in 2016.

SCM Group was established in 1952 and is headquartered in Rimini, Emilia-Romagna, Italy, as a manufacturer of industrial equipment for the non-ferrous metals, plastics, and wood processing sectors. Their products comprise band saws, radial saws, universal combination machines, throughfeed moulders, thicknessing planers, sliding table saws, and semi-automatic boring machines, among others. These tools are utilized in woodworking shops, construction, manufacturing, carpentry, art, and DIY projects for tasks such as cutting, shaping, and joining wood materials accurately and efficiently. The products are extensively employed in the furniture, automotive, construction, plastic processing, shipbuilding, and aerospace industries.

Yasui Seiki Inc., established in 1979 and headquartered in Kanagawa, Japan, is a manufacturer that builds custom coaters and offers R&D coating services. The company manufactures roll-to-roll, precision custom coating machines, including MICROGRAVURE and slot die coaters. It also offers R&D coating services including roll-to-roll coating feasibility tests, new flexible material development, coating consultation, and new product contracts. Its products and services are adaptable and can participate in many industries that require sub-micron coatings with its MICROGRAVURE and Slot Die. It serves a wide range of industries, such as Medical devices, Energy, Optics, Packaging, and Textiles.

FUJI KIKAI KOGYO Co., Ltd., established in 1951 and based in Hiroshima Pref, Japan, is a manufacturer of printing trades machinery. The company manufactures products such as Rotogravure printing presses, dry laminators, coating machines, metal printing machines, small bore excavating machines and precision electronic-related equipment. The companies to which the products are supplied are food, beverage and candy cans. The other products manufactured by the company are laminators that coat films with adhesives for lithium-ion batteries.

Gebrüder Lödige Maschinenbau GmbH, established in 1938 and headquartered in North Rhine-Westphalia, Germany, is a manufacturer of mixing, coating, and granulating equipment. The company specializes in mechanical engineering and provides machines, filters, and support structures. As the inventor of the ploughshare mixer, it is known for its expertise in process technology, catering to pharmaceuticals, food, and chemicals industries. It provides partial systems and services encompassing process development, engineering, and maintenance. The company also offers expertise in sealing systems, pressure vessel construction, and electrical engineering support for control systems and documentation.

BLACK BROS. Co, founded in 1882 in the USA, is a manufacturer of coating and laminating equipment, serving various industries from woodworking to plastics and metals. The company offers machinery for the construction industry, aerospace industry (including durable machines and complex transport systems), automotive industry (for interior components), and more. Its product range extends to embossed decorative metal machines, machinery and web handling systems for packaging and converting, and consumer products like the 22D adhesive spreader and AIR POD PRESS, catering to residential, contract, healthcare, education, and government markets.

Dubois Equipment Company, LLC., a company founded in 1876, based in Jasper, Indiana United States is a manufacturer of scuff sanders, conveyors, and finished equipment. The company's products include flat-line, UV, spray, wood, metal and specialty finished systems, as well as vacuum coat, roll coat, cured ovens, scuff sand, profile sander, spray machines and other finished equipment for applications. The products are used to handle equipment flawless finishes, run after run to complement systems.

THANK-METAL CO. LTD., established in 1973 and based in Hyogo, Japan, is a manufacturer of battery prototype equipment. The company's expertise lies particularly in equipment for lithium-ion batteries. It offers three main types of products: direct, die head, and gravure head types, essential for making lithium-ion batteries from scratch. It provides all the necessary hardware, from high-precision coaters and roll presses to assembly machines like winders and welders. Moreover, it supports clients beyond the sale with a one-year device guarantee, a rental lab for hands-on trials, and a trade-in option for used equipment.

Structure Probe Inc, founded in the year 1970, based in Pennsylvania, United States is a manufacturer and supplier of high quality silicon AFM probes. Their product portfolio includes tweezers, small tools, vacuum pumps and tools, SEM mounts, instruments, TEM grids, chemicals, cleaning supplies, microscopic calibration, specimen storage, substrates, filtration, maintenance, nanomaterials, paint, and adhesives. The products are used in multiple applications which include SEM and TEM supplies, SPM and APM supplies, light microscopic related products, material science, and life science sample preparations.

DIOSNA Dierks & Söhne GmbH, established in 1885 and based in Osnabrück, Germany, is a manufacturer of dough preparation machines for the baking industry. The company offers products such as fermenters, elevator tippers, scrap dough and leftover bread processing, fluid-bed processors and beating machines. The company also supplies equipment for the processing of liquids to pharmaceutical, feed & fine chemical, and cosmetics industries. The company offers services to maintain the laboratory machines and production systems and repairs the spare parts.

Hirata Corporation is a manufacturer and distributor of industrial robotic and logistics equipment based in Kumamoto, Japan. Established in 1951, the company first dabbled in manufacturing and marketing industrial vehicles. In 1958, they turned to manufacturing agricultural-related products. By 1959, they started their first conveyor belt line, and in May 1964, their television assembly line was launched. In 1977, they developed their first robot-controlled machine, and from there, they shifted towards robotic logistical equipment. The company is present in eight countries, namely Japan, Taiwan, the United States, Mexico, China, Singapore, Malaysia, and Thailand.

Quorum Technologies, established in 2001 and based in East Sussex, England, is a manufacturer and supplier specializing in sample preparation equipment. The company's product portfolio includes cryo-preparation systems, critical point dryers, and sputter coaters. These products find application in various sectors, including electronics manufacturing, nanotechnology, and forensics and criminal investigations. The company provides services including spare parts supply, product catalogs, and warranty support, while being ISO 9001 certified. Some of the company's customers include microscope manufacturers such as Zeiss, Hitachi, and Tescan.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Walco, Inc. |

10.5%

|

| 2 | Metal Coaters System |

7.6%

|

| 3 | Freund-Vector Corporation |

7.6%

|

| 4 | Vac Techniche Ltd. |

6.7%

|

| 5 | SM Coating GmbH |

5.7%

|

| 6 | Romaco Holding GmbH |

5.7%

|

| 7 | Black bros. Co. |

4.8%

|

| 8 | ASAP Co., Ltd. |

4.8%

|

| 9 | Zhengzhou CY Scientific Instrument Co., Ltd. |

3.8%

|

| 10 | Xiamen Lith Machine Limited |

3.8%

|

Derivation Method

The ranking is calculated based on the click share within the coater page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 27.8% |

Japan

Japan

|

5 | 27.8% |

China

China

|

4 | 22.2% |

Germany

Germany

|

2 | 11.1% |

United Kingdom

United Kingdom

|

1 | 5.6% |

Italy

Italy

|

1 | 5.6% |

178 products found

178 products

STARTECHNO COMPANY LIMITED

600+ people viewing

■Summary ・High-precision hot melt X-Y table coater applies hot melt to flat materials such as plastics, laminated materials, rubber, and paper wit...

Mitsui Electric Seiki Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

■Single-wafer coater This is a test coater that can uniformly perform blade, wire bar, application, and short dwell coatings on small samples in a ...

EARS Co., Ltd.

490+ people viewing

This device is an "ultra-compact to compact test coater specifically designed for new material development" that has the functionality, performance...

SMT Co., Ltd.

270+ people viewing

■Single-wafer coating. Uniform coating possible in a short time with a small amount of sample The single-wafer coating method enables uniform coati...

Labo Co., Ltd.

520+ people viewing

Low price model for research and development. Unique features. ■Driving performance It is possible to create uniform coating samples that are diff...

SANDO TECH Co., Ltd.

290+ people viewing

Last viewed: 4 hours ago

Coaters can be manufactured using various methods such as impregnation, gravure, and die. ■With our products, we can make the following suggestion...

SCREEN Febax Co., Ltd.

400+ people viewing

Last viewed: 3 hours ago

A compact slit-type coating device that flexibly accommodates all coating conditions and materials and achieves highly accurate coating uniformity....

2 models listed

SANDO TECH Co., Ltd.

340+ people viewing

Last viewed: 9 hours ago

Coaters can be manufactured using various methods such as impregnation, gravure, and die. ■With our products, we can make the following suggestion...

Aiden Co., Ltd.

700+ people viewing

■Simple spin coater SPIN COATER Model: SC8002 ・Easy setting, small size, 2-stage rotation speed MAX 8000RPM. ・Since it has a double structure, th...

Yukos Co., Ltd.

510+ people viewing

Last viewed: 23 hours ago

Gloss processing machine exclusively for POD. Gloss coating and foil processing are available for small lots. ■Foil transfer processing without a ...

THANK METAL

560+ people viewing

Last viewed: 5 hours ago

Coating equipment/precision coater Small precision coating machine 3-roll coater 3-roll coater with a choice of coating methods ■Standard specific...

Techno Roll Co., Ltd.

480+ people viewing

Last viewed: 12 hours ago

It is an "attachment system" that allows customers to select ancillary equipment that suits their intended use and budget. Specifically, it is conf...

Mitsui Electric Seiki Co., Ltd.

470+ people viewing

■Single-wafer coater This is a test coater that can uniformly perform blade, wire bar, application, and short dwell coatings on small samples in a ...

THANK METAL

640+ people viewing

Last viewed: 1 day ago

Coating equipment/precision coater Small precision coating machine 2-roll coater Standard type of direct coater ■Standard specifications ・With di...

Sanmei Co., Ltd.

590+ people viewing

Last viewed: 1 hour ago

■Application on three-dimensional/curved structures Using a spray nozzle that can produce fine particles, it is possible to form a uniform film eve...

EARS Co., Ltd.

350+ people viewing

This device is an "ultra-compact to compact test coater specifically designed for new material development" that has the functionality, performance...

3 models listed

SMT Co., Ltd.

340+ people viewing

Paint, etc. can be applied automatically at a constant speed. This machine uses a wire bar, doctor blade, and applicator to automatically apply ink...

THANK METAL

450+ people viewing

Coating equipment/precision coater TH-C type coater Precision type 3-roll coater ■Standard specifications ・With digital clearance display device ...

Yukos Co., Ltd.

550+ people viewing

Last viewed: 23 hours ago

In addition to image coating and gold and silver color foil, lamination processing is also available. ■Product features ・Introduced as an upgrade...

Techno Roll Co., Ltd.

420+ people viewing

Dust removal roll for high-speed off-wheels. The performance of Hickey Sweeper remains the same, and it is durable against high speed rotation. Con...

Sugi Macinary

600+ people viewing

Last viewed: 4 hours ago

Flow coater/curtain coater Effective width: 700mm 【Features】 A flow coater with belt conveyors at the front and rear. The belt conveyor can be ad...

Sanmei Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■Features ・Low cost and compact ・For research, prototype development, and small lot production ・All stainless steel exterior with excellent chem...

Phi Corporation Co., Ltd.

770+ people viewing

■Features ・Device overview This device clamps a workpiece vertically on a movable hanger arm with X, Y, Z, and θ axes, and has spray nozzle units ...

SANDO TECH Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

Coaters can be manufactured using various methods such as impregnation, gravure, and die. ■With our products, we can make the following suggestion...

Mitsui Electric Seiki Co., Ltd.

600+ people viewing

Last viewed: 5 hours ago

■Tabletop coater TC-1S type (made to order) The tabletop coater TC-1SG type is an automatic film applicator that is made to order and is capable of...

Sugi Macinary

700+ people viewing

This is a side coater, a machine that coats the side of the base material.

THANK METAL

540+ people viewing

Last viewed: 5 hours ago

Coater [Prototype equipment for power storage devices] ■Plenty of options available. Select the necessary options and provide the appropriate coat...

Mitsui Electric Seiki Co., Ltd.

710+ people viewing

Last viewed: 3 hours ago

■Tabletop coater TC-3S type (automatic film applicator) The tabletop coater TC-3S is an automatic film applicator that is equipped with a touch pan...

Engineering Lab Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Product overview The resin paste coater is a fully automatic coating device developed for the semiconductor industry. The WL is equipped with a t...

Techno Roll Co., Ltd.

490+ people viewing

Last viewed: 12 hours ago

Dust removal roll exclusively for waterless printing. In addition to dust removal and ghost reduction, it also has a static electricity suppression...