All Categories

History

This section provides an overview for roll coaters as well as their applications and principles. Also, please take a look at the list of 9 roll coater manufacturers and their company rankings. Here are the top-ranked roll coater companies as of February, 2026: 1.CMS Industrial Technologies, LLC, 2.C.G. Bretting Manufacturing Co. Inc., 3.Black bros. Co..

Table of Contents

Categories Related to Roll Coaters

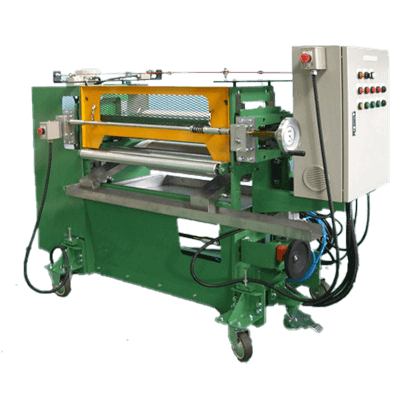

A roll coater is a machine that uses rollers to apply a coating to a flat surface, such as film.

Roll coaters apply paint, adhesives, chemicals, and other materials evenly. They are also equipped with a sputter source and plasma CVD, enabling continuous and high-speed deposition of barrier films, transparent conductive films, etc. Generally, it is limited to coating thin flat surfaces, such as sheets and films.

The applications are diverse depending on the combination of technologies, and various coating thicknesses and viscosities can be used. Therefore, the fields of application for roll coaters range from optics, liquid crystal products, and electronic components to chemicals and foodstuffs.

Roll coaters are used for functional films in optical products for tablets, smartphones, and other high-performance, low-profile devices, as well as for high-density, compact components. Film types include light control, anti-reflection, anti-glare, polarization, light diffusion, screen protection, and transparent conductivity.

They are also used in films for solar cells and secondary batteries. Types of films include reflector, light shielding, decorative, and heat dissipation. Thin film coating technology is used in automobiles, textiles, housing, electronic components, and semiconductors.

Roll coaters use multiple rollers to apply paints, adhesives, chemicals, conductive films, barrier films, and optical films to films and other materials. Rolls have various names such as "coater roll," "doctor roll," "feed roll," "knife roll," "guide roll," and "gravure roll."

Linear bearings are used to raise and lower the upper roller section to maintain high accuracy and smooth operation for a long time. The opening height can be adjusted. The rolls can be removed and reassembled in a short period for easy replacement.

The doctor roll open/close handles are integrated on both sides, enabling accurate and quick adjustment of application volume. Each roll is independently driven and can be divided into types according to the deposition process. The system is classified according to whether the coating amount is measured and selected and whether the coating liquid is before or after coating, and a combination of multiple systems can be used.

Various types of roll coaters are in practical use. The two main types are the direct roll coater and reverse roll coater. They can also be classified according to whether the coating liquid is released or sealed.

The direction of rotation of the rolls and the direction of the object to be coated are the same. Also called natural roll coater. The material to be coated is fed between the rubber-lined coating roll and the steel backup roll.

In this method, the coated object will travel in the opposite direction of the roll rotation. The coating rolls rotate in the opposite direction and roll over the coated object sent by the roller called the backup roll.

Compared to the direct roll, the reverse roll can apply a thicker coating at a time and has a cleaner surface, so it is widely used for primer coating, etc.

The post-metering coating method is a method in which extra coating liquid is applied once and then scraped off to the desired amount. It is called a knife coater or roll coater with blades, etc. The amount of scraping off and film thickness are determined by setting the shape and gap of the rolls.

Sputter Roll Coater

Sputter roll coaters use the sputtering method to deposit metal, transparent conductive, and optical films used in solar cells, touch panels, window films, and FPDs.

Plasma CVD Roll Coater

A plasma CVD roll coater uses electrical discharges generated between rollers to deposit silica films to achieve barrier properties used in organic EL, e-paper, lighting, solar cells, etc.

AIP Roll Coater

An AIP roll coater deposits metallic compound films by evaporating target materials using vacuum arc discharge.

The problem with roll coaters is that the equipment is large due to the large area of the target material, and the setup and changeover are extensive. In recent years, roller cassettes have been introduced for coaters that can easily accommodate changes in coating conditions.

Coater equipment has become more sophisticated and complex, and it is desirable to have coaters that can measure, monitor, and record the condition of the coating surface, equipment, and workpiece using laser displacement gauges, cameras, and sensors.

*Including some distributors, etc.

Sort by Features

Sort by Area

C.G. Bretting Manufacturing Co. Inc., founded in 1890 and headquartered in Ashland, Wisconsin, USA, is a manufacturer and supplier of converting equipment. The company offers a range of product offerings, from integrating specialty modules into existing production lines to providing complete turnkey installations. Their equipment includes napkin folders, interfolders, and rewinders, available in various features and specifications. Bretting also provides comprehensive machine audits to identify potential equipment upgrades and safety enhancements, offering cost-effective solutions that deliver long-term benefits to our clients.

Filtration Technology Systems, founded in New Albany, IN in 1990, is a manufacturer of Filtration Manufacturing Equipment. The company's product portfolio includes pleating equipment, filter and filtration equipment, rotary pleaters, air filter production equipment and laminating equipment, as well as customers consulting services, post production support, technical service and training. The company serves industries including Chemical Manufacturing, Pharmaceutical, Food and Beverage Processing, Power Generation and Aerospace. The company operates in 23 countries.

TRC Inc is in Wisconsin Rapids, Wisconsin. TRC provides metal stamping solutions, systems, consulting, repair and inspection services, and upgrades to existing systems. Their primary customers are the metal-forming equipment industries. The products offered by TRC include Coil Handling and Feed Lines; Automated Equipment and Transfer Systems; Press Controls and Safety Guarding Systems; Mechanical, Servo, and Hydraulic Presses; Die Change and Handling; and Dexco Coil Racking Systems and Equipment. T TRC Inc. is a member of the Precision Metal Forming Association.

Yasui Seiki Inc., established in 1979 and headquartered in Kanagawa, Japan, is a manufacturer that builds custom coaters and offers R&D coating services. The company manufactures roll-to-roll, precision custom coating machines, including MICROGRAVURE and slot die coaters. It also offers R&D coating services including roll-to-roll coating feasibility tests, new flexible material development, coating consultation, and new product contracts. Its products and services are adaptable and can participate in many industries that require sub-micron coatings with its MICROGRAVURE and Slot Die. It serves a wide range of industries, such as Medical devices, Energy, Optics, Packaging, and Textiles.

Kumagai Riki Kogyo Co. Ltd., established in 1944 and headquartered in Tokyo, Japan, is a manufacturer of testing machines for the pulp and paper industry. The company specializes in designing and producing equipment ranging from pulp processors to printing testers. It holds a 70% share of the domestic market and 30% internationally. The company's primary offerings include testing machines for paper/board physical properties, coating/printing/processing, and pulp/chip processing. Its auto scan automatic paper properties testing machine epitomizes the company's efficiency and technological advancement. Its clientele spans major paper manufacturers, the National Printing Bureau, and various research institutions.

BLACK BROS. Co, founded in 1882 in the USA, is a manufacturer of coating and laminating equipment, serving various industries from woodworking to plastics and metals. The company offers machinery for the construction industry, aerospace industry (including durable machines and complex transport systems), automotive industry (for interior components), and more. Its product range extends to embossed decorative metal machines, machinery and web handling systems for packaging and converting, and consumer products like the 22D adhesive spreader and AIR POD PRESS, catering to residential, contract, healthcare, education, and government markets.

Independent Machine Co. (IMC) is an American manufacturer of conversion and web-processing machinery that was established in 1968. Based in Fairfield, New Jersey, the company offers various traverse winders, laminators, slitter rewinds, and auxiliary equipment such as heat sealers or splicers. These are mainly used by medical device and pharmaceutical manufacturers, as well as by clients in the aerospace, energy, and packaging sectors. IMC also provides design and consultation for custom spooling or winding equipment, blade sharpening, and conversion services.

Thermal Engineering Corp., TEC Infrared, established in 1961, is a manufacturer of paint-finishing systems, spray booth/Pint allocation equipment, powder systems, air houses, and incineration & electric controls for the transportation, aircraft, motor, electric, and furniture industries. The company in Columbia, SC, provides specialty equipment such as a pneumatic air-knife coater, flame treater, two-level oven with dual elevators and conveyors, wicket oven, and vertical roll coaters humidified to reduce distortion and soaked with chemicals to prevent rot.

CMS Industrial Technologies, LLC is a manufacturer of industrial equipment and converting solutions based in Georgia since 1991. The company provides Hydrophilic Coating systems that help with full-coat or spot-coat applications and Moisturizer systems that are used for precise moisture application, as for other units there are Slitter/Rewind systems, with rod, blade, spray, and coil coaters. Overall these solutions cater to paper consumables, film and foil converting, carpet and textiles, and steel/aluminum coil coating along with many other industries.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CMS Industrial Technologies, LLC |

22.3%

|

| 2 | C.G. Bretting Manufacturing Co. Inc. |

13.5%

|

| 3 | Black bros. Co. |

12.2%

|

| 4 | Filtration Technology Systems, LLC. |

12.2%

|

| 5 | TCR Inc. |

10.8%

|

| 6 | Thermal Engineering Corp., TEC Infrared |

9.5%

|

| 7 | IMC (Independent Machine Co.) |

9.5%

|

| 8 | KUMAGAI RIKI KOGYO Co., Ltd. |

5.4%

|

| 9 | Yasui Seiki Inc. |

4.7%

|

Derivation Method

The ranking is calculated based on the click share within the roll coater page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 60.0% |

Japan

Japan

|

2 | 40.0% |

35 products found

35 products

THANK METAL

380+ people viewing

Last viewed: 7 hours ago

■Standard specifications ・With digital clearance display device ・Outfeed (nip roll) implementation ■Options ・Roll width expansion (in 50mm incr...

THANK METAL

530+ people viewing

Last viewed: 9 hours ago

Coater [Prototype equipment for power storage devices] ■Plenty of options available. Select the necessary options and provide the appropriate coat...

Sugi Macinary

1060+ people viewing

Last viewed: 3 hours ago

PUR/Hot melt roll coater Coater roll: φ250×L1,150 Doctor roll: φ175×L1,150 Feed roll: φ250×L1,050 Oil temperature: max140℃ The roll temperature i...

C&V Technics Co., Ltd.

510+ people viewing

Last viewed: 10 hours ago

■What is C&V Technics' film deposition equipment roll coater? Roll coater is a general term for equipment that continuously applies surface treatme...

Labo Co., Ltd.

510+ people viewing

Last viewed: 9 hours ago

Low price model for research and development. Unique features. ■Driving performance It is possible to create uniform coating samples that are diff...

THANK METAL

580+ people viewing

Last viewed: 9 hours ago

Coating equipment/precision coater Chibi coater Ultra-compact introductory machine ■Standard specifications ・With digital clearance display devic...

Sugi Macinary

520+ people viewing

Last viewed: 9 hours ago

This is a gluing machine for PUR/hot melt adhesives. The roll temperature is raised to the set value by circulating warm oil within the roll.

THANK METAL

620+ people viewing

Last viewed: 9 hours ago

Coating equipment/precision coater Small precision coating machine 2-roll coater Standard type of direct coater ■Standard specifications ・With di...

Phi Corporation Co., Ltd.

710+ people viewing

Last viewed: 4 hours ago

■Features ・High film thickness uniformity ・Simultaneous application on both sides ・Improved coating efficiency ・Can be applied to thin substrates

EARS Co., Ltd.

330+ people viewing

Last viewed: 12 hours ago

This device is an "ultra-compact to compact test coater specifically designed for new material development" that has the functionality, performance...

3 models listed

C&V Technics Co., Ltd.

390+ people viewing

Last viewed: 10 hours ago

■What is C&V Technics' film deposition equipment roll coater? Roll coater is a general term for equipment that continuously applies surface treatme...

THANK METAL

440+ people viewing

Last viewed: 9 hours ago

Coating equipment/precision coater TH-C type coater Precision type 3-roll coater ■Standard specifications ・With digital clearance display device ...

C&V Technics Co., Ltd.

360+ people viewing

Last viewed: 10 hours ago

■What is C&V Technics' film deposition equipment roll coater? Roll coater is a general term for equipment that continuously applies surface treatme...

Sugi Macinary

350+ people viewing

Last viewed: 9 hours ago

Painting machine with brush roll Coater roll: φ190×L250 Doctor roll: φ123×L250 Brush roll: φ190×L250 Belt conveyor: width 200mm Effective plate thi...

2 models listed

C&V Technics Co., Ltd.

380+ people viewing

Last viewed: 25 minutes ago

■What is C&V Technics' film deposition equipment roll coater? Roll coater is a general term for equipment that continuously applies surface treatme...

C&V Technics Co., Ltd.

390+ people viewing

Last viewed: 10 hours ago

■What is C&V Technics' film deposition equipment roll coater? Roll coater is a general term for equipment that continuously applies surface treatme...

C&V Technics Co., Ltd.

380+ people viewing

Last viewed: 10 hours ago

■What is C&V Technics' film deposition equipment roll coater? Roll coater is a general term for equipment that continuously applies surface treatme...

Irie Co., Ltd.

360+ people viewing

Last viewed: 9 hours ago

A small, high-performance roll coater suitable for research and development and small-lot production. We have plasma processing, sputtering and eva...

Media Institute Co., Ltd.

390+ people viewing

Last viewed: 9 hours ago

■Summary ・FRC-100V is a small, high-performance magnetron sputter roll coater suitable for research and development and small-lot production. - De...

Sugi Macinary

630+ people viewing

Last viewed: 9 hours ago

A roll coater for flooring materials. A standard surface coating machine for housing construction materials, automobile interior materials, etc.

Sugi Macinary

690+ people viewing

Last viewed: 9 hours ago

Laminating machine for hot melt Apply hot melt with a roll coater that can heat up to 140℃

Sugi Macinary

660+ people viewing

Last viewed: 9 hours ago

Roll coater Roll width: 1,400 (compatible with 4 shaku width base materials) 【Features】 ・A linear guide is used to raise and lower the upper ro...

Sugi Macinary

760+ people viewing

Last viewed: 9 hours ago

Gluing machine specializing in safety Coater roll: φ190×L1,050mm Doctor roll: φ125×L1,050mm Feed roll: φ188×L1,000mm Effective plate thickness: 0-5...

Sugi Macinary

530+ people viewing

Last viewed: 1 hour ago

Printing machine using rolls

Sugi Macinary

500+ people viewing

Last viewed: 9 hours ago

Precision gluing machine for laminating Roll width: 1,400mm Can handle substrates up to 4 shaku wide. 【Features】 ・A linear guide is used to rai...

Sugi Macinary

510+ people viewing

Last viewed: 9 hours ago

Large double-sided glue machine Roll width: 2,350mm Large gluing machine for producing veneer plywood

Sugi Macinary

1030+ people viewing

Last viewed: 9 hours ago

Painting machine (roll coater) A standard surface coating machine for housing construction materials, automobile interior materials, etc. Using th...

Asianeotech

280+ people viewing

Last viewed: 9 hours ago

■Summary Inner layer liquid photoresist coating

Yukos Co., Ltd.

490+ people viewing

Last viewed: 4 hours ago

Gloss processing machine exclusively for POD. Gloss coating and foil processing are available for small lots. ■Foil transfer processing without a ...