All Categories

History

This section provides an overview for mangalloys as well as their applications and principles. Also, please take a look at the list of 9 mangalloy manufacturers and their company rankings. Here are the top-ranked mangalloy companies as of March, 2026: 1.Associated Steel Company, 2.Virgamet, 3.FORD STEEL.

Table of Contents

Categories Related to Mangalloys

Mangalloy is a special steel used in mining equipment and machine tools that contains 10-11% or more manganese in the steel.

Since the amount of manganese in ordinary steel is about 2% or less, it is a steel with a very high manganese content. It is also called Hadfield steel after its inventor. It is sometimes referred to as high man or high manganese steel.

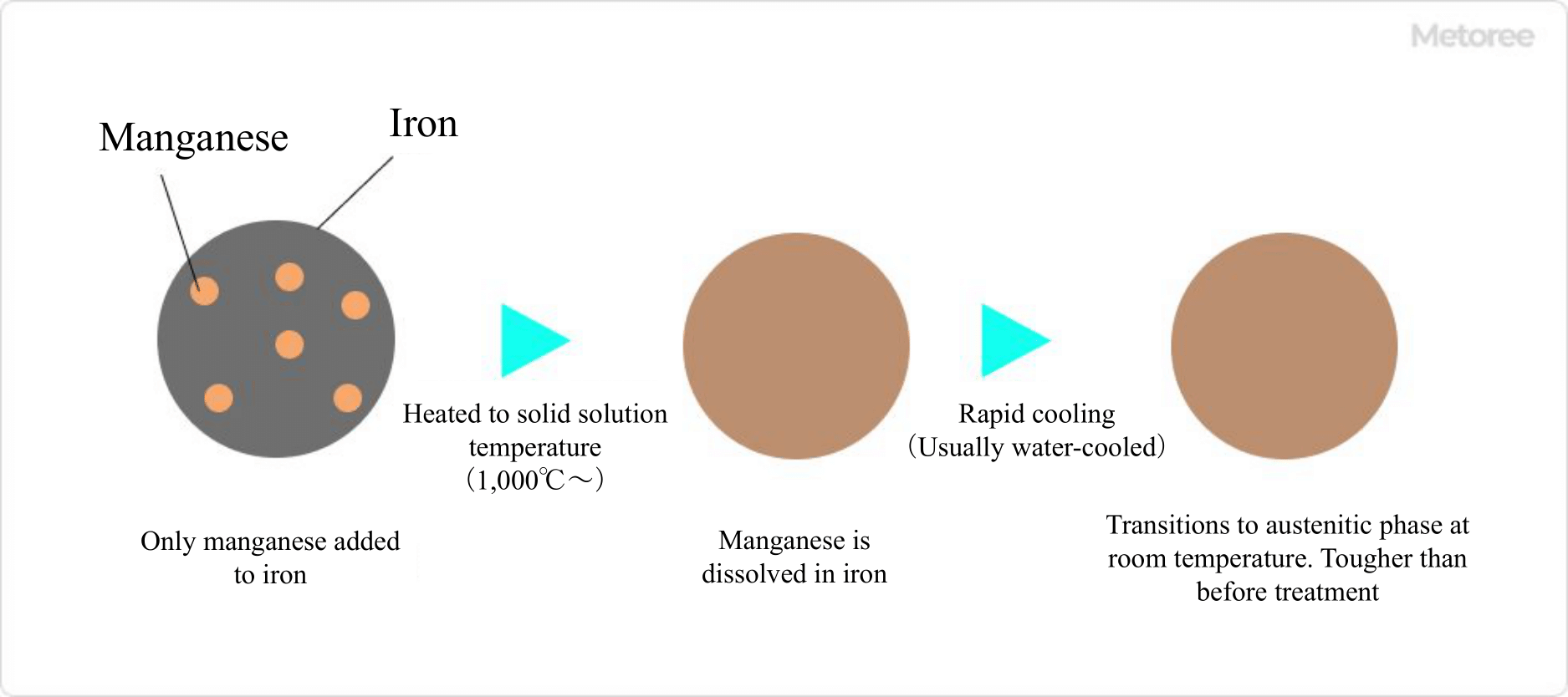

Mangalloy is fabricated using a water toughening process. Water dust treatment is a method of heating the steel to around 1,000 to 1,100°C and then quenching it to improve toughness. This process solidifies the carbides inside the steel, thereby creating a fully austenitic structure. This operation is similar to quenching, but instead of increasing hardness, this method improves toughness, which indicates tenacity.

Because mangalloy has wear resistance and toughness, is not machinable, and is mainly used for casting, it is used for relatively large items that do not require precision. In addition, since it is not magnetic, it is suitable for use in parts related to precision machinery and linear motor cars.

Examples of applications include liners for impact crushers, mill liners for grinding mills, charging shafts, cutter bars, bullrings for roller mills, railroad rail crossings, liners, and bucket teeth. It is an ideal material for use in parts subject to impact and wear, but its disadvantage is that it is difficult to machine due to severe work hardening.

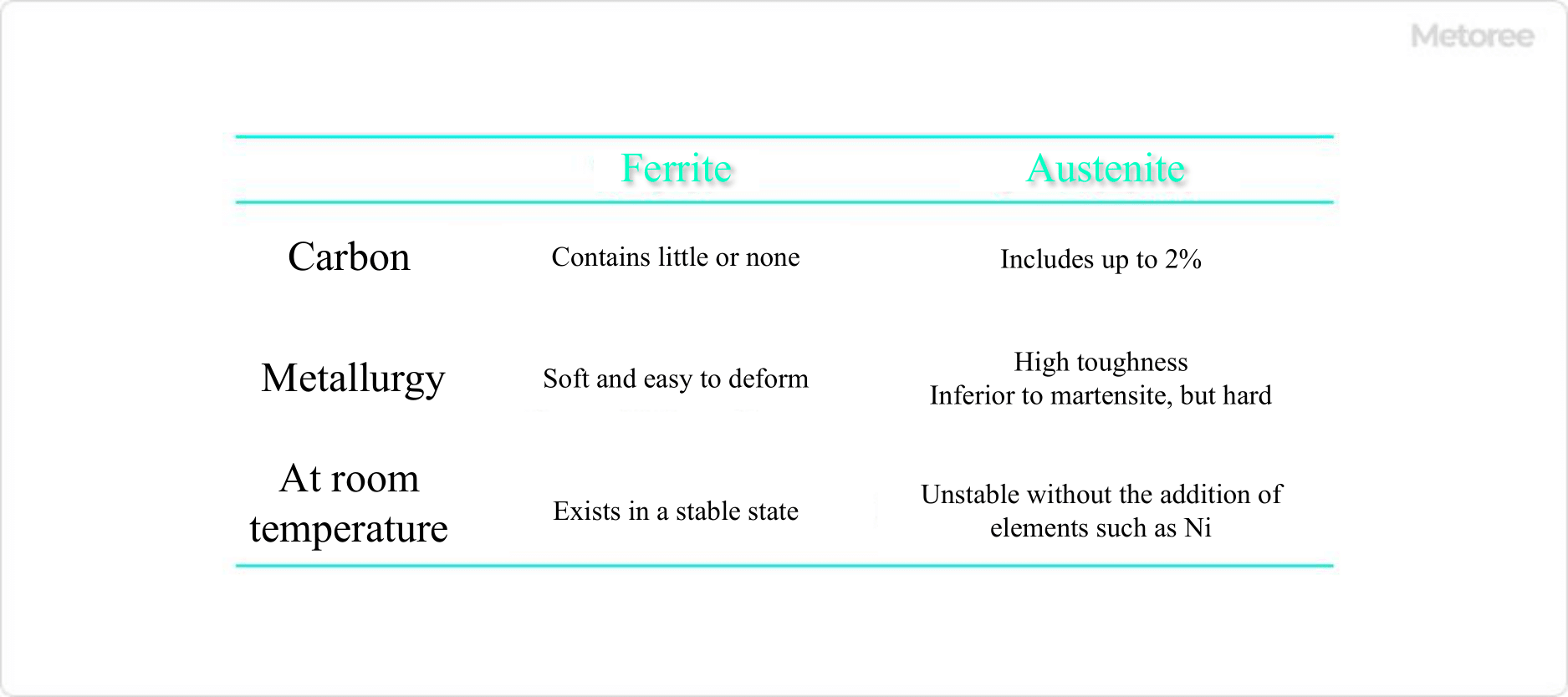

Figure 1. Differences between ferrite and austenite

In carbon steel, the austenite phase, which is a face-centered cubic lattice, is the stable phase at a high temperature of about 1,000°C. When carbon steel cools, the crystal structure will change to the ferrite phase. This is called transformation, and if a certain amount of a specific metal is added to carbon steel, the transformation phenomenon will not occur.

Toughness can be improved by water toughening, which dissolves the carbides that cause toughness degradation and cools them in water before they regenerate. Water toughening of general carbon steels causes a quenching effect, resulting in the formation of martensite, which makes the steel hard and brittle.

Figure 2. Water toughness treatment

Since no quenching occurs, the higher carbon content grades have more carbon in solid solution, which has the effect of increasing hardness. The carbon content of general carbon steel is about 0.3%, while mangalloy steel contains about 1% carbon.

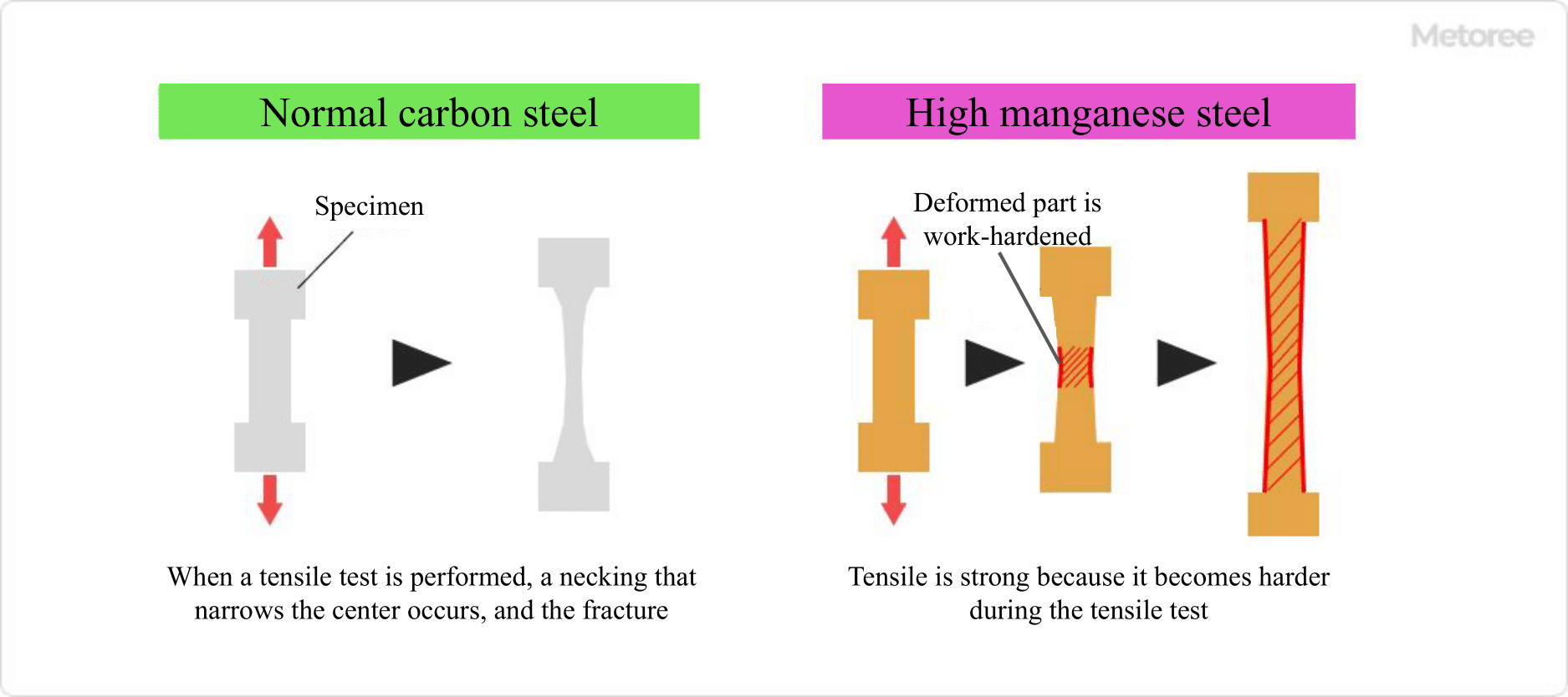

Figure 3. Strong work hardening of high manganese steel

The surface of mangalloy becomes harder as it is subjected to load, and its wear resistance also improves. When tensile tests are performed on mangalloys, the deformed areas are progressively work-hardened, and the undeformed areas are preferentially deformed. For this reason, it has a very good elongation performance.

This work-hardening property is responsible for the hardening and high wear resistance of manganese steel when impact is applied. Work hardening can make the material several times harder than its initial state. This steel is more advantageous in situations where large impacts are applied, such as in mining, than in situations where small impacts are applied intermittently.

Although it is a steel, it is not magnetic. This is because, like austenitic stainless steel, it retains its austenitic phase.

Austenitic stainless steels can be slightly magnetic when processed, but mangalloy steels are basically non-magnetic. It should be noted that handling with magnets is not possible.

In addition to mangalloys, there are manganese steels with relatively small amounts (1 to a few percent) of manganese added (low manganese steels). This material has enhanced toughness and quenching properties that are different from those of mangalloys, which use the austenite phase.

Since the mechanical properties and workability are different, it is important to select the right manganese steel for the application.

*Including some distributors, etc.

Sort by Features

Sort by Area

Associated Steel Corp., established in 1938 in Cleveland, Ohio, USA, is a manufacturer of stainless steel materials for industrial uses. The company specializes in manufacturing a wide category of steel products, including specialty steels, wear-resistant alloys, abrasion resistant stainless steel, and optimal-strength steel materials. The products are equipped with robust durability, superior performance in abrasive environments, and resistance to wear and impact. These qualities make the products indispensable in industries such as mining, construction, manufacturing, and agriculture. With state-of-the-art technology, it offers advanced materials for multiple industries, is ISO 9001:2015, ANSI, ASQ certified and BBB member.

Multi Metals was founded in 1962 and headquartered in Rajasthan, India, as a seamless extruded copper alloy product manufacturer. The company has significantly added to the expansion and development of the oil and energy sector by providing quality piping materials to EPC Contractors and Promoting Companies. The company aims to establish itself as a preferred manufacturer of Industrial Piping goods by providing technically proficient solutions and fostering mutually beneficial client relationships.

Virgamet is a manufacturer of engineering materials that was founded in 1995 and is headquartered in Toruńska, Koło, Poland. Its main activity is the production of steel, including carbon steel, stainless steel, and alloy steel. The company also offers a wide range of services, such as cutting, bending, and welding. Other areas of specialization include the supply of materials that require special mechanical and physical properties, resistance to difficult working conditions, abrasion, critical temperatures and a corrosive environment. Virgamet's products are used by many customers, including the automotive, construction, and machinery industries.

Champak Steel & Engg. Co, founded in Maharashtra, India, in 1978 is a manufacturer of metal and alloy pipes. The company's product portfolio includes metal pipes crafted from various materials, including stainless steel, carbon steel, aluminum, and copper. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also offer custom packaging, warehousing customer and technical support, and national distribution services.

Eckhardt Steel was founded in 2004 and is headquartered in Mumbai, India, as a manufacturer, exporter, and supplier of various steel products, including Stainless Steel and Carbon Steel, following business standards. The company's products are manufactured by skilled specialists who utilize quality raw materials and advanced technology. Furthermore, a rigorous examination of the entire collection is conducted before its final distribution to maintain consistency and efficiency for the benefit of its clients. The items offered are highly esteemed and praised for the impeccable finish, aligning with the market's standards of superiority and ideals.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Associated Steel Company |

22.5%

|

| 2 | FORD STEEL |

12.5%

|

| 3 | Virgamet |

12.5%

|

| 4 | Aakash Steel |

10.0%

|

| 5 | Multi Metals |

10.0%

|

| 6 | Champak Steel & Engg. Co |

10.0%

|

| 7 | Eckhardt steel |

8.8%

|

| 8 | H2 Repair Alloys |

7.5%

|

| 9 | Conquest Steel & Alloys |

6.3%

|

Derivation Method

The ranking is calculated based on the click share within the mangalloy page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

4 | 66.7% |

United States of America

United States of America

|

1 | 16.7% |

Poland

Poland

|

1 | 16.7% |