All Categories

History

This section provides an overview for alloy steel as well as their applications and principles. Also, please take a look at the list of 40 alloy steel manufacturers and their company rankings. Here are the top-ranked alloy steel companies as of February, 2026: 1.ATI, 2.United Equipment Accessories, Inc., 3.Heyco Metals.

Table of Contents

Categories Related to Alloy Steel

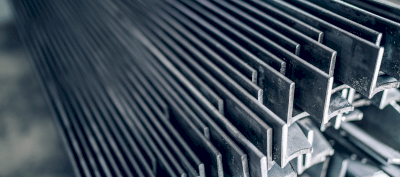

Alloy Steel is a type of steel made from combining carbon steel with one or more elements known as alloys. Physical and chemical properties vary according to their composition.

Alloy Steel is a type of steel made from combining carbon steel with one or more elements known as alloys. Physical and chemical properties vary according to their composition.

Alloy Steel generally contains elements such as carbon, chromium, nickel, molybdenum, manganese, and vanadium, which combine with iron to improve the steel's strength, corrosion resistance, wear resistance, durability, and machinability.

Alloy Steel can be produced in a variety of ways, but it is generally formed by mixing iron and the elements to be added at high temperatures and then cooling.

Post-treatment such as heat treatment and fabrication may also be required.

Alloy Steel, such as stainless steel and titanium alloys, are used because high strength and high corrosion resistance are required. Examples include jet engine parts and landing gear.

High tensile strength steels are especially used because of the high strength and hardness required. Examples include chassis and body panels.

Because strength and durability are required, steel materials with high earthquake resistance are used. Examples include high-rise buildings and bridges.

Alloy Steel with high heat and pressure resistance is used because it is required to be used in high temperature and high pressure environments. Examples include nuclear power plants and thermal power plants.

Alloy Steel such as stainless steel and titanium alloys are used. Examples include artificial joints and dental implants.

Implants are a type of medical device that are implanted inside the body and made from artificially created materials.

Alloy Steel such as high speed metal and molybdenum steel are used because of their wear and heat resistance. Examples include drills and cutting tools.

High-speed steel (HSS) is a type of high-performance steel made by adding alloying elements such as chromium, molybdenum, and vanadium to iron, and is widely used in cutting and machine tools since it can withstand high temperatures and cut and machine at high speeds.

The main properties of alloy steel are as follows:

Alloy Steel is stronger than pure iron and can withstand high loads and impacts. It is used in structures such as bridges, skyscrapers, and aircraft, as well as in automobile chassis and engine parts and tools.

Alloy steel is tough and has high hardness. It is used for high-load parts such as tools, machine parts and gears.

High abrasion resistance prevents wear due to grinding and abrasion, and is used for high-load parts such as tools, machine parts, gears, and bearings.

Corrosion resistance is increased by added alloying elements. Alloy steels such as stainless steels are used in applications such as food processing equipment and medical instruments.

Alloy Steel has high heat resistance due to the alloying elements added. They are used for parts used in high-temperature environments and in nuclear power plants.

Alloy Steel has high corrosion resistance because the alloying elements added to the steel prevent the formation of oxides and corrosion products and protect the surface. Alloy steels are used in chemical plants, etc., taking advantage of their high corrosion resistance.

There are many types of alloy steel. The following are typical examples:

Carbon Steel is an alloy steel in which carbon is the main alloying element and is composed only of iron and carbon. It is widely used because of its high strength and low-cost production.

Stainless steel is a steel to which chromium is added as a major alloying element. It has excellent corrosion resistance. It is suitable for applications such as food processing and medical equipment.

Tool steel is a steel to which carbon, chromium, vanadium, and other alloying elements are added, featuring high hardness and high durability. It is widely used for cutting tools, dies, and machine tools.

Nickel steel is a steel to which nickel is added as the main alloying element, and is characterized by high strength and heat resistance. It is used in high-temperature environments such as aircraft and nuclear power plants.

Chromium molybdenum steel is a steel to which chromium and molybdenum are added as major alloying elements, and is characterized by high strength and durability. It is used for structural parts of automobiles, rolling stock, ships, etc., and for hydraulic equipment, etc.

Manganese steel is a steel to which manganese is added as the main alloying element, and is characterized by high wear resistance. It is used for railroad rails, construction steel, machine parts, etc.

Aluminum steel is a steel in which aluminum is added as the main alloying element, is lightweight and has excellent corrosion resistance and workability. It is used for automotive parts, aircraft parts, construction materials, etc.

Alloy Steel may become brittle due to its high hardness and strength. This is due to the fact that the blending of elements in alloy steel causes the crystal structure to become less uniform and localized crystal defects are more likely to occur. These defects can expand as stress is applied, eventually leading to fracture.

Alloy Steel is also harder and more brittle than ordinary steel, and can be easily damaged by impact.

Alloy Steel generally contains elements such as chromium, copper, phosphorus, silicon, and aluminum. These elements form an oxide film on the surface of the steel, preventing corrosion and deterioration. In particular, when chromium is added in large amounts, the oxide film is very tough and extremely resistant to corrosion.

Alloy Steel is therefore suitable for outdoor use. For example, it is used for automobile parts, building exteriors, bridges and other structures, ships, and wind power generation towers. It is also used for parts and equipment used in harsh environments such as areas with strong salt damage and tropical regions.

However, weather resistance varies depending on the environment in which it is used, so appropriate alloy steel should be selected.

Periodic maintenance and repairs are necessary because corrosion progresses when the oxide film on the surface is damaged.

*Including some distributors, etc.

Sort by Features

Sort by Area

ATI is an American custom valve automation equipment manufacturer that was established in 1995 in Houston, Texas. The company primarily produces hydraulic and pneumatic valve actuators for linear and quarter-turn linear valve models, power systems (e.g. accumulators, gas bottles), and control systems such as limit switches and solenoids. It also offers custom design, machining and production of equipment as well as retrofitting and repair services to customers requiring additional support. ATI chiefly serves clients in the oil and gas, power generation, chemical processing, and mining industries.

United Equipment Accessories, Inc. is a manufacturer of slip rings, rotary unions, and integrated slip rings and rotary unions and was founded in 1952. The company produces slip rings, precision hydraulic swivels, industrial cables, and hose reels. The company also has a product catalog of shift controls for heavy-duty and off-road equipment. Its design options vary from cable fighters, column mounts, console mounts, and customer-supplied gate patterns. The industries served by the company include wind, construction, utility, and industrial markets.

Arnold Magnetic Technologies is a manufacturer of magnets, magnetic assemblies, and precision thin metals based in New York since 1895. The company deals in permanent magnets, flexible composites, electromagnets, magnetic assemblies, and precision thin metal foils. The permanent magnets, such as L-Type Laminated ones have various applications in the aerospace, automotive, motorsport, and industrial markets. Similarly, alloy strips and foils are used in industries that need to improve the power density of motors, transformers, and batteries. The composite sheets and strips are used for X-ray and gamma-ray radiation absorption, and RFI/EMI shielding and electromagnets are vital for defense projects.

Heyco Metals is based in Reading, Pennsylvania, USA, and is a manufacturer and custom milling service provider specializing in copper as well as stainless steel products established in 1969 as a part of the Wieland Group. The company primarily produces copper and copper alloy light- and medium-gauge strips and coils. It also offers stainless steel coils, strips, and double-o gauges down to 0.0012 inches. The company mainly serves clients in the construction, metalworking, and aerospace industries.

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Loos & Co. Inc, founded in 1958 and headquartered in Pomfret, USA, is a manufacturer of wire and cable products. The company's product line includes military specification aircraft cables, cable assemblies, and wire products in various alloys. These products are applied in many industries including construction, marine and automotive industry. It also provides resources like content library and technical information to guide the customer about the product application. The company's quality standard certifications include ISO9001, ISO13485 and AS9100D.

Trinity Brand Industries, founded in 1989 and located in Burr Ridge, Illinois, is a supplier of tool room specialty products to the industrial market. The company offers a full line of tool room products, which include stainless steel shim, brass shim, aluminum shim stock sheets, titanium coils, and sheets. Its products come with traceability and a Material Test Report (MTR) included with all materials. Pre-cut slotted shims, feeler gage strips, and coils are also available. Its fabrication services include laser cutting, waterjet cutting, wire EDM, and 3D industrial printing.

Belmont Metals was founded in 1896 as a nonferrous dealership on Brooklyn’s Belmont Avenue where it remains to this day. The company serves many industries with individualized alloys such as those for jewelry, marine applications, countertops, and babbitt bearings. The company produces alloys based on several metals including aluminum, bismuth, copper, lead, and zinc. The company also employs several other metals such as cadmium, indium, nickel, and tin in standard grades up to 99.99% purity.

O’Hare Precision Metals is a manufacturer of fabricated metal products, engineering materials, and machining services since 1970 and is headquartered in Arlington Heights, Illinois. The company manufactures bar stocks, round stocks, and round bars made of copper, carbon, aluminum, steel, and nickel. The products are used in the automotive, aerospace, construction, mining, and medical industries. The company runs a service department offering packaging and various machining services such as milling, chamfering, saw cutting, polishing, and burnishing.

MicroGroup Inc., established in 1971 and headquartered in Medway, Massachusetts, United States, is a manufacturer and supplier of micrometal parts and medical device components. The company's products include FEP heat shrink tubing, pull wire assemblies, and metal tubing used in surgical, diagnostic, and interventional cardiovascular medical applications and devices. Its primary service is original equipment manufacture in the medical device manufacturing industry and offers full OEM services with engineering capabilities that include laser engraving, custom shaping, and tool making. It was acquired by TE Connectivity and integrated into TE’s Medical Business Unit in 2017.

Ed Fagan Inc. was established in 1965, is located in Franklin Lakes, NJ, and are supplier of specialty metals and special purpose alloys. The portfolio includes controlled expansion alloys, electronic grade nickels, refractory metals and alloys, soft magnetic alloys, and many more. Every day the company furnishes customers with special-purpose metals and alloys, competitive market pricing in conjunction with all the services the clients expect from a supply chain. The stocking program of the company provides customers the methods so that the materials can be shipped on demand, in the quantities needed.

Packline USA LLC, founded in 1994, is an American manufacturer and distributor in Rancho Cucamonga, California specializing in packing solutions and machinery. The company offers individual product packaging for various items, including dips and salsa, jellies and puddings, oatmeal and cereals, soups and dressings, and ready-to-eat or frozen meals. It also provides packing machines that seamlessly integrate with existing operations, such as modified atmosphere packaging (MAP) machines, tray fillers, bottling machines, and piston fillers. Other machine offerings include cup-sealing machines, capping machines, and pouch-packing machines. The company caters to the food, dairy, and beverage packaging industries.

Bergsen, Inc, since 1974, has been a distributor of metals such as carbon steel, aluminum, stainless steel, and saws. Metals are available in hexagonal, round, square, flat, and custom extrusion shapes and are used in the surgical, oil and gas, aerospace, electronics & sensors, automotive, and machining industries. The Santa Fe Springs, California-based company offers heat treatment furnaces, saw cutting, trepanning, centerless grinding, and lathe turning. With blind shipments, boxing, scheduling common carriers, and packing for UPS/FedEx, the company can ship same-day.

Hoover Steel, Inc., established in 1978 and based in Schwenksville, Pennsylvania, USA, is a manufacturer and steel service provider. The company offers aluminum tubing for building frames, WF beams to support loads transverse to their longitudinal axis, and galvanized sheets for constructing structures such as verandas and walkways. It also provides custom shop services for unique projects or limited production operations. Hoover Steel serves clients in the industrial manufacturing and construction sectors.

Roda Specialty Steel Inc., established in 1956 and headquartered in Buffalo Grove, Illinois, and also having additional warehouse facilities in Daytona, New Jersey, United States, is a distributor of stainless steel bars and related products manufactured by Rodacciai S.p.A., Italy. The company offers a range of steel bar products, including stainless steel wire, alloy bars, and specialty carbon bars. It also offers free-cutting carbon steel suitable for high-speed cutting tools and welding consumables.

Schneider Electric S.E. is headquartered in Rueil-Malmaison, France, and has been operating since 1836. Schneider Electric provides a number of products and services including electrical car charging, energy management software, surge protection devices, load banks, servers and HMIs, valve and valve actuators, feeder automation, grid automation, and SCADA software products, data center cooling and software, home automation and security, light switches, motion control and robotics, signaling units, solar and energy storage, RFID systems, as well as other hardware, services, and software.

Aichi Steel Corporation, established in Tokai, Aichi, in 1934, is a manufacturer engaged in special steels and materials for the Toyota Group. The company's product range includes Steel Bars and Rods, Structural Steel,Steel Pipes and Tubes. The company also manufactures materials other than steel, such as stainless steel, titanium and magnetic materials. In 2011 the company developed a magnet production technology using MAGFINE powder with 30% less alloy and established the Silicon Valley Office in the USA.

Champak Industries, established in 1997 and based in Mumbai, Maharashtra, India, is a manufacturer and exporter of a wide range of stainless steel and alloy carbon steel-based industrial pipes and plates. The company’s main product portfolio includes boilerplates, pipes, and seamless and welded tubes and fittings. The materials used include stainless steel and non-alloy carbon steel. Customized products are available by customer request. The company provides customer service to clients domestically and internationally, serving the petrochemical, chemical, oil and gas, construction, shipbuilding, and other industries.

Meidi steel, based in Shandong, China, is a manufacturer of stainless steel materials. The company handles the production and processing of carbon steel materials, as well as direct sales to customers. Its main products include stainless steel pipe, bar, plate, coil, tube and other alloys. These products are primarily utilised in railways, tunnels, highways and water conservancy engineering. The company also supplies its materials to China water resources and hydropower engineering, railway engineering and traffic engineering companies.

Jinan Tianzan Steel Co., Ltd, established in 1999, and based in Shandong, China, is a manufacturer and supplier of different types of steel materials. Their product portfolio includes a diverse range of steel such as cold rod carbon steel plates, hot rolled steel plates, galvanized steel coil, carbon structural quality steel plates, and wear-resistant steel plates. The products are used in various applications which include oil pipeline, power engineering, mechanical, ship, chemical, and automobile sectors. The company also provides quality inspection and services.

Nova Steel Corporation, established in 2005, based in Mumbai, Maharashtra, India, is a manufacturer and supplier of various forms of pipe fittings. The company’s product portfolio includes pipes and tubes, round bars, high speed steel round bars, sheet plate coil, and fasteners, among others. The materials used include stainless steel, nickel alloy, titanium, aluminum, and inconel, among other metals. The company’s manufacturing process has trained professionals dealing with all kinds of pipe fittings and other products, as well as the type of material used. Industries served include oil and gas, chemical, petrochemical, power plant, and water, among others.

Super Metal Manufacturing Co. was founded in 1965 and is based in Mumbai, India, as a manufacturer of steel bars and billets for various industrial applications. The company manufactures products according to AMS 2304 and AMS 2301 specifications and its product folio includes bright bars of different types and shapes such as peeled, turned, round, flat, and rectangular models. The company also offers mild steel, carbon steel, and, free cutting bright bars for construction, mining, machinery manufacturing, and, power production sectors. The company produces steel solids in different steel quality levels, including para premium, aircraft, bearing, electric furnace, and commercial.

AB Steel, established in 2001, is a manufacturer and supplier of stainless steel seamless and welded pipes and tubes based in Mumbai, India. The company’s product range includes stainless steel pipes, tubes, fittings, flanges, and more. They also deal in Monel, Inconel, Hastelloy metals, and copper tubes serving industries such as engineering, chemicals, pharmaceuticals, and more. With ISO 9001:2008 certification and global suppliers in countries like South Korea, China, Mexico, and the USA, AB Steel caters to diverse client requirements and needs globally.

Aesteiron Steels LLP (ASL) is an Indian manufacturer and supplier of seamless tubing and welded steel pipes that was established in Mumbai in 2007. The company primarily produces various steel pipes in various grades, including carbon, alloy, and stainless steel models, as well as aluminum and copper pipes with higher conductivity. They also offer custom fabrication of alloy pipes using different elements such as chromium or molybdenum, or with specifications for higher oxidation or corrosion resistance. ASL chiefly serves clients in the power generation, petrochemical processing, water treatment, construction, and infrastructure sectors.

Isabellenhütte USA, founded in 1989 and headquartered in Swansea, MA, United States, is a manufacturer of precision alloys and power resistor products. The company's products use precision measurement technology, such as DC current, voltage and temperature sensors, resistance alloys, and various resistors, including surface-mounted assemblies, bus-bar-mounted assemblies, and hybrid-mounted assemblies. It serves industries that include automotive, chemical processing, and medical equipment manufacturing. Isabellenhütte USA is a wholly owned subsidiary of Isabellenhütte Heusler GmbH KG, located in Dillenburg, Germany.

Ulbrich Stainless Steels and Special Metals Inc., founded in North Haven, CT, in 1924 is a manufacturer of precision metal products. The company's product portfolio includes Precision Machined Components, sheet metal fabrication, metal stamping, die casting and forging and welding and assembly services. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

High Performance Alloys, Inc. is an ISO 9001:2015-certified manufacturer and distributor of specialized alloy materials for industrial applications established in 1984 and based in Windfall, Indiana, USA. The company offers its Monel series corrosion-resistant alloy materials designed against oxidizing and reducing acids, and its HPA series wear-resistant alloy materials designed for property retention after cold working or hardening treatments. It also offers its Inconel series temperature resistant alloy materials for manufacturing fuel nozzles, heat treating fixtures, or gas turbines. The company mainly serves clients in the oil and gas, chemical processing, and aerospace industries.

JSW, established in 2018, based in two locations, Mingo Junction, Ohio, and Baytown, Texas, is a manufacturer of steel products. The company’s product portfolio includes hot rolled coil, carbon steel plates, and double submerged arc welded (DSAW) pipe. Industries served include shipyards, oilfield fabricators, heavy equipment producers, energy producers, railcar manufacturers, and storage tank manufacturers. The company’s objective is manufacturing, supplying, and providing products in a more sustainable strategic way. In 2022, the company was recognized as the Steel Sustainability Champion by the Worldsteel Association.

Alloy Steel International was founded in 1991 and is based in Perth, Western Australia, is a manufacturer of protective wear plates for various industrial applications. The company's product folio consists of acro plates, acro blocks, acro tuffs, acro bolts, and wear asset monitoring systems that are essential in medical, material handling, and, mining industries. The company is equipped with a manufacturing plant that is able to produce wear plates in thicknesses up to 20/11 and in a 1270mm width and also provides engineering, fabrication, and off-site repairing services.

TOKUSHU KINZOKU EXCEL Co. Ltd. is an ISO 9001-certified manufacturer of precision metal materials that was established in 1940 in Tokyo, Japan. The company produces various performance alloys designed for flexibility, durability, or magnetism. These include electrical heating alloys, soft magnetic iron steel, and shape memory alloys. The company also offers contract manufacturing for custom or industry-specific material orders. It primarily serves clients in the aerospace, digital consumer products, and semiconductor manufacturing sectors.

United Performance Metals, founded in 2008 and headquartered in Hamilton, Ohio, United States, is a manufacturer and supplier of high-temperature alloys and stainless steel. The company offers various specialty metal solutions, including nickel alloys, titanium alloys, and stainless steel alloys. Its services include cut-to-length, leveling, and custom re-rolling. It also offers finishing options to its laser customers by incorporating high-production deburring machines and packaging. Its specialty steel is primarily used in aviation and aerospace parts and structures.

Continental Alloys & Services Inc., founded in 1976 and based in Texas, USA, is a manufacturer and supplier of steel products designed for the energy sector. The company specializes in the production of steel and alloy pipe, tube, and bar products tailored to the unique demands of the energy services industry. It offers an array of valuable services, such as custom pipe coating, threading, specialty end connections, heat treating, and maintenance solutions. The company operates in seven countries, including the United States, Canada, Britain, Singapore, Malaysia, Dubai, and Mexico.

Dhand Steel Traders was founded in 1974 and is based in Punjab, India is a manufacturer and supplier of straightened and aligned bright bars, metal bars, alloy steel bright bars, and specially shaped bright bars for various industrial and commercial applications. The company offers alloy steel, square bars, hex bars, round bars, and, HHB wires that have applications in heavy engineering, construction, automobile, railways, and, machinery manufacturing sectors. The company has ISO9001:2015 certification and its steel bars are used in building frames, beams, rafters, and other structural components.

Dynamic Metals was established in 1999 and is headquartered in Leighton Buzzard, UK, and is a supplier of aerospace-grade metals for various industries and organizations. The company has AS9120B, AS9100D, ISO9001:2015, and, EN 10204 3.1 certifications and offers titanium, stainless steel, nickel alloys, cobalt alloys, and aluminum alloys that are crucial in aerospace, motorsports, and, power generation sectors. The company provides forging, rolling, cutting, testing, and, heat treatment services and is also capable of manufacturing and distributing bars and forgings, with semi-finished components in nickel-based superalloys, titanium, stainless steels, and low alloy steels.

Chonghong Industries Microwork Ltd., established in 2004 and headquartered in China, is a distributor of components made from industrial sapphire, ruby, and glass materials. The company’s products include sapphire and ruby nozzles, custom components, and silicon carbide substrates, catering to semiconductors, aeronautics, and optical sectors. It specializes in components, primarily single crystal sapphire and ruby materials, for OEMs across the fluidic, metrology, and chemical industries. The company also offers Zirconia Ceramic, Alumina Ceramic, and Carbide materials. Additionally, it provides custom services such as orifice fittings, kitting, and tubing assemblies facilitated by an on-site Class 10,000 clean room.

Leading Edge Metals & Alloys is a supplier of refractory as well as exotic metal alloys established in 2009 and located in Torrance, California, USA. The company offers tantalum for high corrosion-resistant applications or alloys, molybdenum for increasing steel alloy strength or electrical conductivity, and niobium for improving the strength of alloys at low temperatures. It also offers Nickel 200, 233, and 270 for wire manufacturing or ingot production. The company mainly serves clients in the industrial manufacturing and processing sectors.

NeoNickel was founded in 2013 and is headquartered in West Midlands, United Kingdom, as a supplier of specialty metals and nickel alloys to European industries. As a provider of performing, meticulously crafted nickel alloy and titanium alloy components, the company’s proficient sales team continually endeavors to surpass customer expectations. The extensive inventory levels and diverse range of processing capabilities reinforce this obligation. The company exhibits unique strength and other crucial attributes indispensable in applications where performance integrity and distinctive characteristics are essential.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ATI |

9.2%

|

| 2 | United Equipment Accessories, Inc. |

6.8%

|

| 3 | Heyco Metals |

5.8%

|

| 4 | Arnold Magnetic Technologies |

4.8%

|

| 5 | Stock Drive Products/Sterling Instrument - SDP/SI |

4.8%

|

| 6 | Loos & Co. Inc |

3.9%

|

| 7 | O’Hare Precision Metals, LLC. |

3.9%

|

| 8 | Belmont Metals, Inc. |

3.9%

|

| 9 | Trinity Brand Industries, Inc. |

3.4%

|

| 10 | NeoNickel |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the alloy steel page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

17 | 60.7% |

India

India

|

5 | 17.9% |

Japan

Japan

|

2 | 7.1% |

China

China

|

2 | 7.1% |

France

France

|

1 | 3.6% |

United Kingdom

United Kingdom

|

1 | 3.6% |

113 products found

113 products

TOKUSHU KINZOKU EXCEL CO.,LTD.

380+ people viewing

Last viewed: 11 hours ago

■Product overview ・High strength-ductility balance (Ys×EI balance) ・A material that achieves both excellent workability and high strength and hig...

2 models listed

MTA Alloy Co., Ltd.

560+ people viewing

Last viewed: 9 hours ago

■What is MTA alloy? MTA Alloy has developed a completely new melting method using the know-how cultivated over many years. We succeeded in alloying...

MTA Alloy Co., Ltd.

910+ people viewing

Last viewed: 1 hour ago

■What is MTA alloy? Utilizing the know-how cultivated over many years, MTA Alloy has developed a completely new melting method. We succeeded in all...

MTA Alloy Co., Ltd.

610+ people viewing

Last viewed: 18 hours ago

■What is MTA alloy? Utilizing the know-how cultivated over many years, MTA Alloy has developed a completely new melting method. We succeeded in all...

Matsuse Steel Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Features ・Hardness 40HRC ・Emphasis on specularity ・High-grade plastic steel - Heat treated to 37~43HRC (surface guaranteed) under optimal condi...

Toyominato Co., Ltd.

170+ people viewing

Last viewed: 17 hours ago

Cultivate originality, strive for continuous improvement, and pursue perfection.

17 models listed

Toyominato Co., Ltd.

180+ people viewing

Last viewed: 18 hours ago

Cultivate originality, strive for continuous improvement, and pursue perfection.

11 models listed

Matsuse Steel Co., Ltd.

390+ people viewing

■Features ・Hardness 40HRC ・Emphasis on workability ・High-grade plastic steel - Heat treated to 37~43HRC (surface guaranteed) under optimal condi...

M.WATANABE & CO.,LTD.

330+ people viewing

Last viewed: 18 hours ago

Alloy tubes have higher functionality such as higher strength, higher corrosion resistance, and polishability compared to copper tubes and brass tu...

Matsuse Steel Co., Ltd.

540+ people viewing

Last viewed: 1 day ago

■Features PXA30 (PX Ace 30) is a general-purpose plastic mold steel that is based on the conventional AISI P20 improved steel and has improved spec...

Toyo Polishing Industry Co., Ltd.

400+ people viewing

Last viewed: 14 hours ago

■Steel material We handle a wide range of materials including carbon steel (S-C material), alloy steel, tool steel, and stainless steel.

Matsuse Steel Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

■Features ・Hardness 30HRC ・General-purpose plastic steel

Matsuse Steel Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■Features GHX is a high-grade steel for plastic molds that combines excellent specularity and high corrosion resistance. ■Excellent specularity Th...

Matsuse Steel Co., Ltd.

580+ people viewing

Last viewed: 23 hours ago

■Features KPM30 is a P20 improved steel type steel for general-purpose plastic molds that has excellent total balance from mold manufacturing to mo...

Matsuse Steel Co., Ltd.

500+ people viewing

Last viewed: 20 hours ago

■Features S50C forged steel

Matsuse Steel Co., Ltd.

440+ people viewing

StavaxESR is a high-grade stainless steel and plastic mold steel suitable for inserts and cores. It combines corrosion resistance and wear resistan...

Matsuse Steel Co., Ltd.

580+ people viewing

This is a new generation cold die steel that supports Japanese manufacturing. Features ■KD11MAX with excellent surface treatment characteristics A...

Matsuse Steel Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Features frame hard steel ■Hardness Possible up to 60HRC

Matsuse Steel Co., Ltd.

350+ people viewing

Features ■Improved galling resistance ・Achieved a steel structure that is ideal for PVD treatment. ・Since the surface treatment film is difficult...

Matsuse Steel Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Features ・SKD61 ・Heat crack improved steel ・Die-casting material

Matsuse Steel Co., Ltd.

500+ people viewing

Last viewed: 19 hours ago

■Features - Already tempered to 37~41HRC (surface hardness) and does not require heat treatment, making it suitable for manufacturing complex and p...

Toyo Polishing Industry Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Cemented carbide ・It is made by mixing powders of rare metals tungsten (WC) and cobalt (Co) and sintering them at a high temperature of approxima...