All Categories

History

This section provides an overview for slugs as well as their applications and principles. Also, please take a look at the list of 12 slug manufacturers and their company rankings. Here are the top-ranked slug companies as of February, 2026: 1.Henan Sigma Industrial Co.,Ltd, 2.Impol, 3.American Elements.

Table of Contents

Categories Related to Slugs

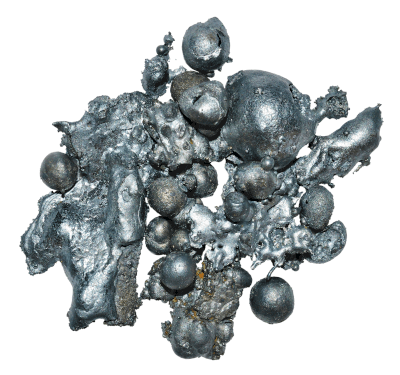

Slugs are byproducts generated during the melting and refining of metals such as iron and copper.

It is produced when impurities contained in metal ores dissolve and react with oxides such as lime and silica. In addition to metals, they are sometimes used as raw materials for cement and glass, or reused as materials for railroads and pavements. The reuse of slug is expected to make effective use of resources and reduce waste, but since it can cause environmental pollution, it must be treated appropriately in the manufacturing process.

Slugs are materials that mainly contain oxides such as silica, alumina, and iron oxide. Silica, alumina, and iron oxide are used as raw materials for cement. When heated together with lime, the main ingredient of cement, Slugs undergo a chemical reaction and become a solidified material. Slugs can be used in cement to remove oxides and improve the strength of the cement.

Silica is a compound called silicon oxide whose chemical formula is SiO2. Alumina is a compound called aluminum oxide with the chemical formula Al2O3.

It mainly contains oxides such as silica and alumina, which are used in glass production because these components are similar to silica acid and alumina, which are major components of glass.

The high density and durability of glass make it an ideal material for use in road and rail substructures. Its low permeability also allows it to drain well, making it an excellent drainage material for road and railroad construction.

Slugs contain components such as silica, alumina, iron oxide, and calcium, which are used in building materials such as limestone and cement. Being a solid, it can be used as it is when used as a building material.

Slugs are also used to stabilize roadbeds for roads and railroads. Since it is solid, it can be mixed with soil to improve the stability of roadbeds. It can also improve soil compaction due to its high density.

Due to its excellent acoustic properties, it is sometimes used for soundproofing walls, protective walls, and pavement materials.

Slugs are also used as soil conditioners in agriculture. It is used as a fertilizer in agriculture because it neutralizes soil acidity and provides nutrients. The iron and calcium content in Slugs is also used as a nutrient for crop growth.

Slag is suitable for ground improvement because it increases the density of soil and improves its compressibility. As a ground improvement material, it is also used in road and railroad construction.

The components contained in slugs are effective in adsorbing and removing pollutants. For example, it is sometimes used for water purification. Slugs contain metal ions such as iron and aluminum, and these ions are used in the treatment necessary for water purification.

Slugs are also used as a raw material for the manufacture of recycled iron powder. Recycled iron powder is an iron powder produced by reusing waste materials such as iron scale and steel scrap generated in the iron manufacturing process, and is used as a raw material for manufacturing recycled iron powder.

Slugs are produced during the process of melting metal ores at high temperatures to separate the metal from the impurities. The basic process is as follows

Melting metal ores at high temperatures initiates the dissolution process to separate metals from impurities. Impurities contained in the metal ore have a lower melting point than the ore itself, so they tend to dissolve during melting.

The molten slugs contain oxides as well as metals. When oxygen is blown in to remove these oxides along with impurities, the impurities are oxidized and become slugs, making them easier to dissolve.

After impurities are oxidized by oxygen blowing and dissolved into the molten slag, they react with additives such as lime and silica to form slugs. This reaction leaves the slugs as a liquid with properties different from those of metals.

Since slugs are lighter than metal, they float on the surface in liquid form, which makes it easier for slugs to separate from metal. After the metal and slugs are separated, the slugs are cooled and solidified, and processed as a byproduct.

Slugs come in a variety of types depending on the type of metal ore and refining method, and there are several ways to classify them. Below are some of the typical classification methods for Slugs.

Since slugs are produced from different materials depending on the type of metal ore, they may be classified based on their materials. Typical slug materials include iron slugs, copper slugs, lead slugs, zinc slugs, and aluminum Slugs.

Slugs are sometimes classified based on their chemical composition because they have different chemical compositions depending on impurities and additives in the ore. Examples include lime slugs, silica slugs, alumina slugs, and manganese slugs.

Slugs are by-products generated during the metal ore refining process and may have different properties depending on the manufacturing process. For example, blast furnace slugs are generated in the blast furnace steelmaking process, while molten slugs are generated in the melting furnace coppermaking process. Thus, Slugs may be classified based on the manufacturing process.

Typical slugs, their generation processes, and reuse methods are shown in the table below.

| Name of Slugs | Generation Process | Reuse Method |

|---|---|---|

| Iron Slugs | Produced by melting metallic ores at high temperatures and blowing oxygen into them | Used as raw material for cement and concrete, material for road and railroad substructures, and alternative material for gravel and pavement materials |

| Copper Slugs | Produced by melting ores at high temperatures and blowing oxygen into them during the copper manufacturing process | Used as cement, pavement material, abrasive, and road substructure material |

| Aluminum Slugs | Produced by melting metal ores containing aluminum at high temperatures and blowing oxygen into them | Used in cement, soil conditioners, pavement materials, and the manufacture of metal parts |

| Silicon Slugs | Generated in the process of reducing silicon ore | Used as an additive in the manufacture of cement, limestone, soil conditioners, building materials, and steel production |

| Steel Slugs | Generated in the process of steel manufacturing | Raw material for cement and concrete, material for road and rail substructures, substitute material for gravel, additive to remove impurities during steel refining, fuel for steelmaking processes |

| Zinc Slugs | Generated in the smelting process of zinc ore | Cement, soil improver, material for road substructures, metal recycling |

| Nickel Slugs | Generated in the refining process of nickel ore | Cement, soil improver, material for road substructure, metal recycling |

In addition to metal refining, slugs are used in a wide range of fields, including environmental measures, construction, and agriculture.

For example, slugs are sometimes used as a soil conditioner. Slugs contain lime, iron, and other components that adjust the pH value of the soil and increase the absorption of nutrients in the soil. Slugs also improve air permeability and drainage, which can promote the growth of crops.

Furthermore, it is effective in environmental measures. Slugs are sometimes used as adsorbents for acid rain and soil pollutants. Lime slugs are particularly effective in neutralizing acid rain and helping to protect the environment.

In the construction field, slugs are used as raw materials for road and railroad substructure materials and building materials. It is attracting attention as an environmentally friendly material with excellent durability and longevity.

JIS (Japanese Industrial Standards) related to slug aggregate includes the following slug aggregate is a type of construction material made from molten slugs generated during the smelting of ferrous and nonferrous metals.

*Including some distributors, etc.

Sort by Features

Sort by Area

American Elements was founded in 1997 in California and currently has research and production facilities in Utah, Mexico, China, and the United Kingdom. AE manufactures and distributes advanced materials from a catalog of over 30,000 products for bulk industrial use as well as small scale laboratory use. AE also provides testing and analyses services including spectroscopy along with structural, thermal, and electrical analyses. AE holds sustainable development as a core corporate value and is committed to work to protect the health of the environment.

U.S Resistor, established in 1992, and based in St. Marys, Pennsylvania, is a manufacturer and supplier of a range of resistors. Their extensive product range includes axial lead resistors, tubular resistors, rod resistors, and resistor washers. These products find applications in industries such as energy transmission, automotive, and wind power systems. U.S Resistor adheres to hold ISO 9001:2015 standards. Their products are utilized for current control, voltage division, circuit protection, and signal conditioning, enabling optimal performance in electronic devices and systems.

Sumitomo Metal Mining Co., Ltd. was established in 1952 and is a manufacturer of battery materials based in Minato, Tokyo, Japan. The company produces various products related to the battery materials in a complete in-house system, such as mineral ore, low-grade nickel oxide ore, nickel sulfate, and cathode material. The company divide different products into three business divisions, which are Mineral Resources, Smelting and Refining, and Materials business. The minerals that are being the main commodities of the company are mainly copper, nickel, cobalt, gold, and silver.

Shanghai Metal Corporation, established in 1980 as a state-owned Shanghai Metal Materials Company headquartered in Shanghai, China, is a manufacturer and supplier specializing in metal materials and products. The company's metal offerings include aluminum, copper, stainless steel, galvanized steel, and steel products. It also provides metal machines for forming, cutting, bending, and processing. Additionally, the company offers various containers, gas cylinders, fire extinguishers, mechanical products, and electrical systems. These products find applications in various industries, such as automobile, construction and decoration, electrical and transformer components, machinery, and packaging. Other applications include oil, gas, and water pipelines, as well as boilers and tanks.

SIGMA Aluminum was established in 2008 and is based in Henan, China, is a manufacturer of aluminum fabrication products for various industries. The company's product line includes aluminum plates, coils, foils, aluminum alloys, and sheets for versatile applications in the aerospace, shipping, printing, automobile, and, construction industries. The company has an annual production capacity of 200,000 tons and its products have applications in domestic appliances, decorating, packaging, and pharmaceutical sectors. The company is equipped with hot rolling, cold rolling, and foil processing production lines and also manufactures aluminum slugs for cosmetic and medical packaging requirements.

AWW-Aluminum Werke Wutöschingen was established in 1914 and is headquartered in Wutöschingen, Germany is a manufacturer of aluminum products for various industrial and commercial applications. The company has DIN ISO 9001:2015 and IATF 16949:2019 certifications and provides aluminum alloys, slugs, and, extruded aluminum profiles and discs for applications in construction & architecture, automotive, and mobility & transport industries. The company also offers cold forming using the extrusion process, foundry processes, forming and machining processes, and, surface finishing along with technical advice and logistic solutions.

Haomei, located in Zhengzhou, Henan, China is a manufacturer of Aluminium slugs and discs for various industrial and commercial applications. The company's product folio consists of aluminum alloy plates and strips, hot-rolled thick plates, aluminum discs, tapes, and aluminum plastic tubes, for air-conditioners, cosmetics, packaging, building decoration, and telecommunication industries. The company is equipped with 4 hot tandem rolling line machines, cold mill production machines, and, fishing equipment and has an annual production capacity of 200,000 metric tons.

Ball Corp., established in 1880 and headquartered in Westminster, Colorado, is a manufacturer and supplier of sustainable aluminum packaging solutions for beverage, personal care, and household products. The company's strength lies in its ability to offer not only sustainable packaging but also a wide array of aerospace technologies and services to both commercial and governmental customers. It offers instruments and sensors, spacecraft and space science, electronic warfare, aerospace technology and components, and more. Its product portfolio extends to manufacturing metal packaging products, including steel, aluminum, general, and aerosol containers.

Cupro Alloys Corporation was founded in 1976 and is based in Uttar Pradesh, India, as a manufacturer and supplier of Brazing Alloys for various industrial and commercial applications. The company's product chart consists of Silver Brazing Alloys Cadmium Free, Silver Copper Phosphorus Brazing Alloys, Brazing Rods, Brazing Strips, and Rings that are used for the manufacturing of several products such as bicycle frames, diamond cutting tools, chemical plants, compressors carbide tips, and, diamond segments.

Impol was established in 1825 and is headquartered in Partizánska, northern Slovakia, and is a manufacturer and supplier of aluminum products for various industrial and commercial applications. The company has ISO9001, EN 1508, and, IATF 16949 certifications, and its product chart includes extruded and rolled aluminum products, blanks, motorcycle components, and machined tubes that have applications in food processing, pharmaceutical, renewable resources, consumer goods, and electrical sectors. The company also offers slugs of various dimensions and shapes for the transport, automotive, and, aerospace industries.

Nippon Steel Corporation is based in Tokyo, Japan, and is an ISO 9001-certified manufacturer of steel production materials and steel products established in 1970 following the merger of Yawata Iron & Steel and Fuji Iron & Steel. The company produces steel parts for industrial projects, flat or wire steel products, and steel plates. It also offers chemicals used for metal treatment, including carbon materials, coal tar, and coke. The company also provides plant construction and engineering services for its clients in the energy distribution, shipbuilding, and railway sectors.

Founded in Mumbai, India in 2006, Otto Chemie Pvt. Ltd. is an ISO 9001:2015 & GMP certified chemical manufacturing company and distributor. Otto Chemie serves customers in many industries including agriculture and food processing, pharmaceuticals, oil & gas, cement, as well as educational and R&D industries. Product offerings include antibiotics, amino acids, vitamins, detergents, ionic liquids, materials science compounds, labware, oil, metal & ceramic science compounds and tools, oils, reagents, solvents.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Henan Sigma Industrial Co.,Ltd |

19.3%

|

| 2 | Impol |

12.7%

|

| 3 | American Elements |

12.7%

|

| 4 | Otto Chemie Pvt. Ltd |

10.7%

|

| 5 | U.S. Resistor, Inc. |

10.0%

|

| 6 | AWW |

8.0%

|

| 7 | Ball Corp. |

6.0%

|

| 8 | Shanghai Metal Corporation |

6.0%

|

| 9 | Haomei aluminium |

5.3%

|

| 10 | Sumitomo Metal Mining Co., Ltd. |

4.0%

|

Derivation Method

The ranking is calculated based on the click share within the slug page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

3 | 30.0% |

United States of America

United States of America

|

2 | 20.0% |

India

India

|

2 | 20.0% |

Japan

Japan

|

1 | 10.0% |

Germany

Germany

|

1 | 10.0% |

Slovenia

Slovenia

|

1 | 10.0% |

17 products found

17 products

Kotobuki Giken Kogyo Co., Ltd.

430+ people viewing

Last viewed: 7 hours ago

■Producing high quality aggregates from slag raw materials. Compatible with all types of molten granulated slag. Our overwhelming track record of d...

Kotobuki Giken Kogyo Co., Ltd.

340+ people viewing

Last viewed: 7 hours ago

■Ideal for tertiary crushing and crushing sand as it is effective in improving grain shape. ・Rotary centrifugal crushing device ・High crushing ef...

Kotobuki Giken Kogyo Co., Ltd.

460+ people viewing

Last viewed: 6 hours ago

■Ideal for tertiary crushing and crushing sand as it is effective in improving grain shape. ・Rotary centrifugal crushing device ・High crushing ef...

Kotobuki Giken Kogyo Co., Ltd.

360+ people viewing

Last viewed: 7 hours ago

■Ideal for tertiary crushing and crushing sand as it is effective in improving grain shape. ・Rotary centrifugal crushing device ・High crushing ef...

Kotobuki Giken Kogyo Co., Ltd.

340+ people viewing

Last viewed: 5 hours ago

■Ideal for tertiary crushing and crushing sand as it is effective in improving grain shape. ・Rotary centrifugal crushing device ・High crushing ef...

Kotobuki Giken Kogyo Co., Ltd.

360+ people viewing

Last viewed: 7 hours ago

■No. 6 crushing machine based on Hustler The newly developed 5-port impact rotor (patent pending) achieves larger crushing power than the conventio...

Kotobuki Giken Kogyo Co., Ltd.

370+ people viewing

Last viewed: 7 hours ago

■No. 6 crushing machine based on Hustler The newly developed 5-port impact rotor (patent pending) achieves larger crushing power than the conventio...

Kotobuki Giken Kogyo Co., Ltd.

330+ people viewing

Last viewed: 7 hours ago

■No. 6 crushing machine based on Hustler The newly developed 5-port impact rotor (patent pending) achieves larger crushing power than the conventio...

Kotobuki Giken Kogyo Co., Ltd.

300+ people viewing

Last viewed: 7 hours ago

■No. 6 crushing machine based on Hustler The newly developed 5-port impact rotor (patent pending) achieves larger crushing power than the conventio...

Kotobuki Giken Kogyo Co., Ltd.

350+ people viewing

Last viewed: 6 hours ago

■ Long-term operation is possible even with highly water-containing raw materials due to the anti-adhesion function. Compatible with all types of m...

Kotobuki Giken Kogyo Co., Ltd.

320+ people viewing

Last viewed: 7 hours ago

■ Long-term operation is possible even with highly water-containing raw materials due to the anti-adhesion function. Compatible with all types of m...

Kotobuki Giken Kogyo Co., Ltd.

300+ people viewing

Last viewed: 7 hours ago

■ Long-term operation is possible even with highly water-containing raw materials due to the anti-adhesion function. Compatible with all types of m...

Kotobuki Giken Kogyo Co., Ltd.

440+ people viewing

Last viewed: 7 hours ago

■Producing high quality aggregates from slag raw materials. Compatible with all types of molten granulated slag. Our overwhelming track record of d...

Kotobuki Giken Kogyo Co., Ltd.

500+ people viewing

Last viewed: 7 hours ago

■Producing high quality aggregates from slag raw materials. Compatible with all types of molten granulated slag. Our overwhelming track record of d...

Kotobuki Giken Kogyo Co., Ltd.

420+ people viewing

Last viewed: 7 hours ago

■Producing high quality aggregates from slag raw materials. Compatible with all types of molten granulated slag. Our overwhelming track record of d...