All Categories

History

This section provides an overview for fine u-nuts as well as their applications and principles. Also, please take a look at the list of 14 fine u-nut manufacturers and their company rankings. Here are the top-ranked fine u-nut companies as of February, 2026: 1.KSLNC & Kumsan E&C Co., Ltd, 2.Böllhoff, 3.Advance Components Inc..

Table of Contents

Fine U-Nuts are a type of locknut with a function or mechanism to prevent the loosening of a screw and are mainly used for bearings.

Locknuts are generally used in combination with lock washers to prevent loosening. In addition, there are hard locknuts that have an anti-looseness mechanism.

Fine U-nuts are used in many machines and equipment that use bearings because of their simple structure and easy tightening as lock nuts with an anti-looseness mechanism.

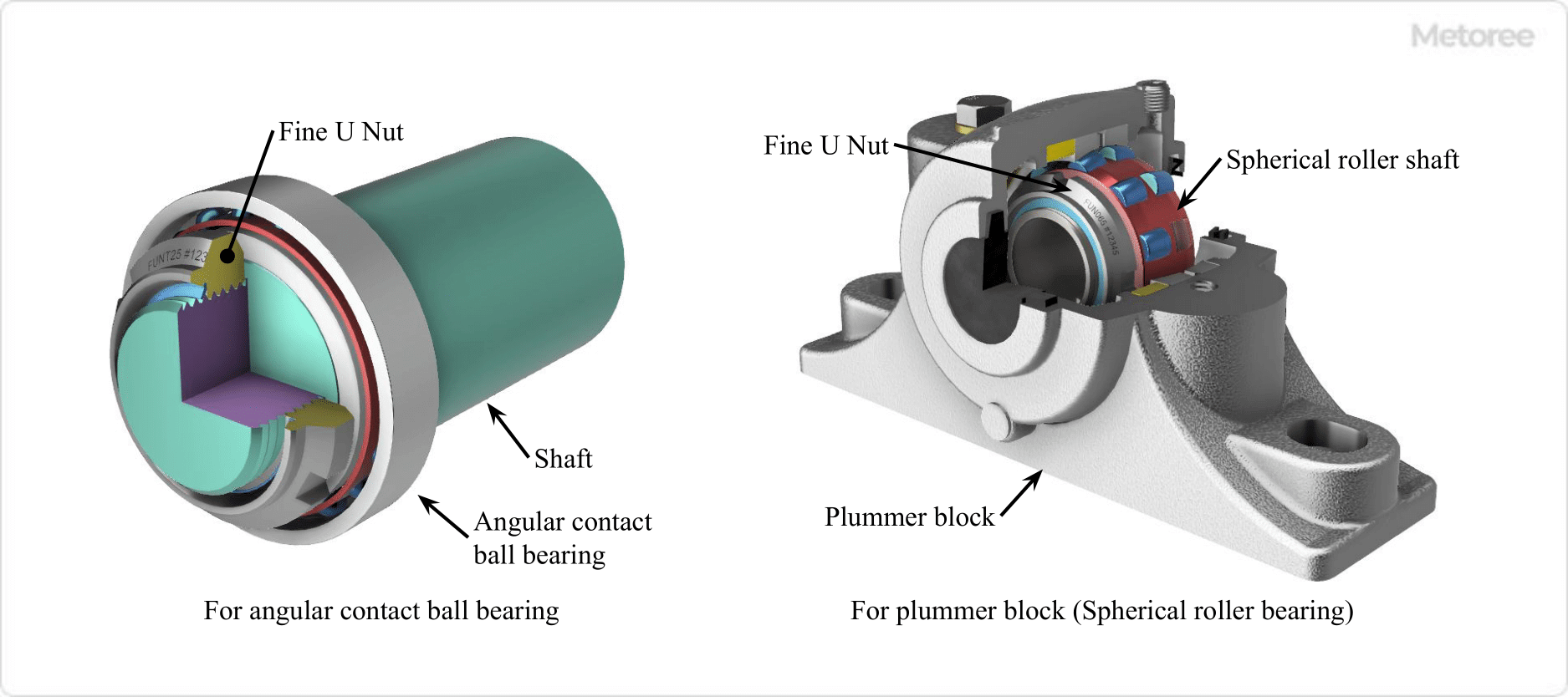

Figure 1. Example of Fine U-Nut use

Fine U-nuts can be applied when bearing locknuts are used, replacing the conventional method of securing bearings with a combination of locknut and lock washer.

Locknuts for bearings are mainly used when angular contact ball bearings, tapered roller bearings, spherical ball bearings, and adapter sleeves for tapered bores of spherical roller bearings are used, and the shaft (rotating shaft) thread is machined and the locknut is used to align, secure, and preload the bearing inner ring. The locknut is used to align, secure, and adjust the preload of the bearing inner ring.

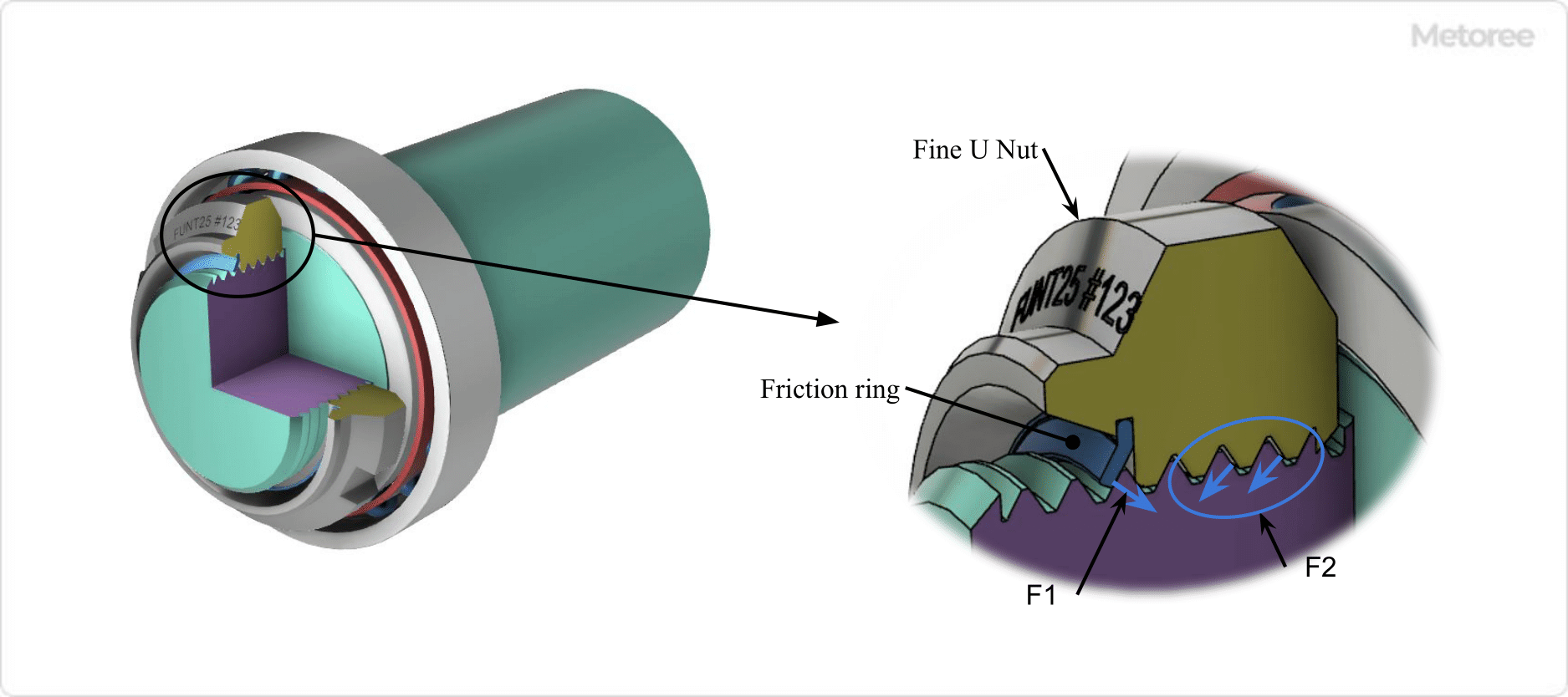

Figure 2. Principle of Fine U-Nut

The Fine U-nut's anti-looseness mechanism is a type of friction ring lock nut or preveling torque type nut. A ring called a friction ring is fitted on the side opposite the bearing of the lock nut for the bearing, and the outer circumference of the nut is fixed and integrated through a process of crimping. Crimping is a method of joining and fastening two parts by mechanically applying pressure to plastically deform the metal.

When a fine U-nut is screwed onto a shaft, a friction ring is inserted into the valley of the shaft thread. As it is further tightened, the friction ring deforms along the thread to generate a pushing force F1 against the thread and a frictional force F2 between the male and female threads.

F1 and F2 work in opposite directions to prevent the reduction of frictional force between the male and female screws, which is the cause of screw loosening.

Features of the FINE U-nut are as follows

In particular, the friction ring type anti-looseness mechanism provides an anti-looseness effect regardless of the mounting position (tightening position) of the nut, and the tightening torque can be easily controlled, eliminating the need for advanced skills in installation and removal operations.

If there is no abnormal deformation of the friction ring or the nut itself, the nut can be reused after 10 times of mounting and dismounting with only a slight decrease in axial force. In addition, the material used is metal and can be used in high-temperature atmospheres up to about 300°C.

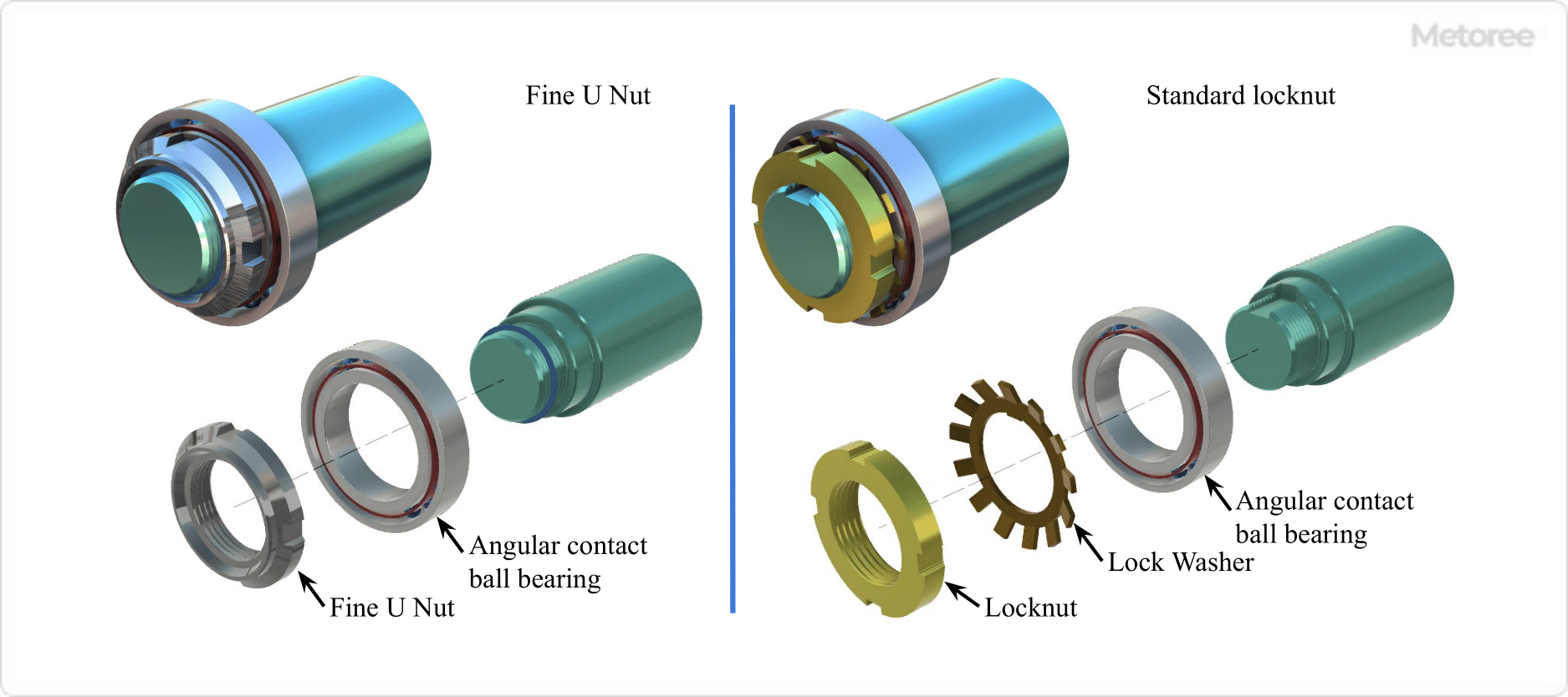

When a standard lock nut is used, a groove must be machined on the shaft where the projection on the inside of the lock washer fits to prevent the lock washer from turning.

Figure 3. Comparison of Fine U Nut and Standard Lock Nut

The general method of preventing loosening is to use a standard locknut and lock washer (washer) as specified in JIS B1554 Rolling bearings - Locknuts, washers, and retaining clip. In this case, the inner projection (jaw) of the lock washer fits into the shaft groove and the outer projection fits into the groove of the lock nut to prevent loosening.

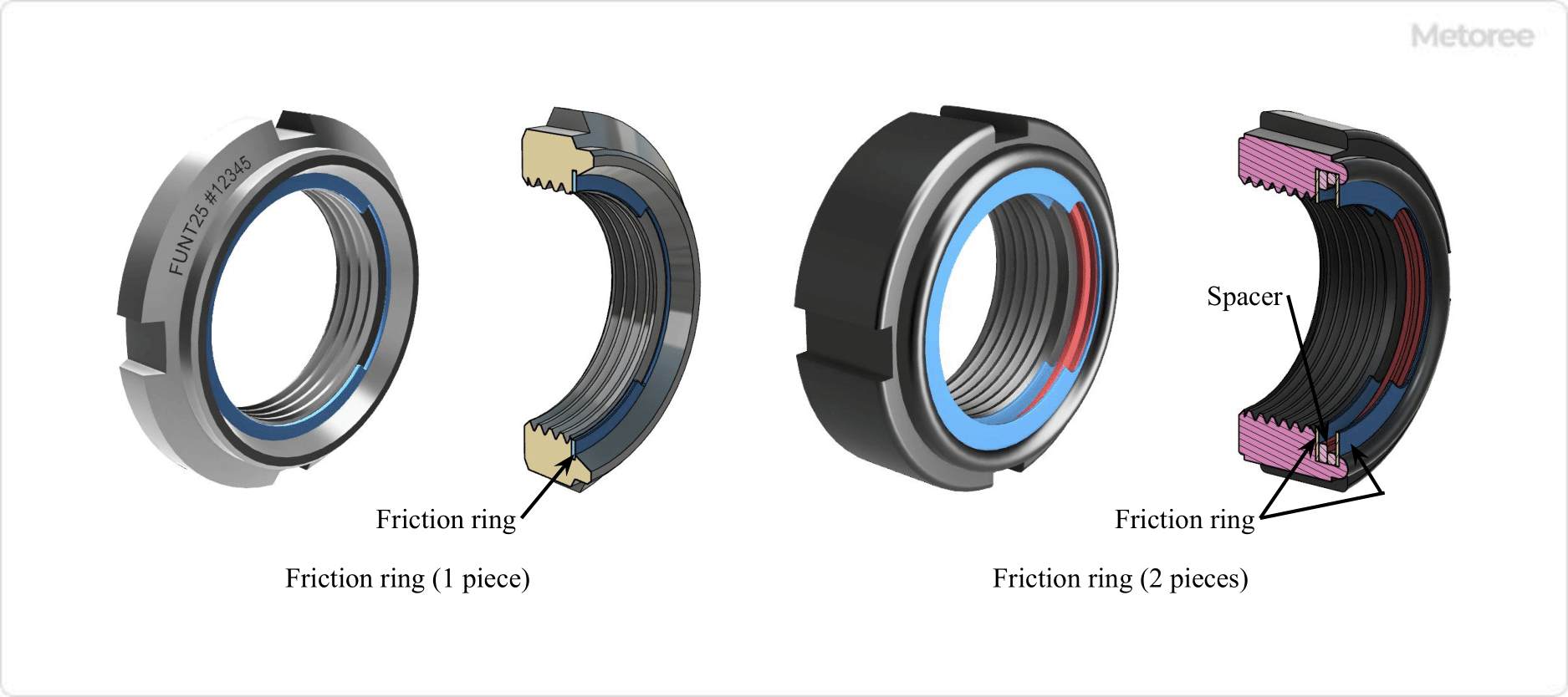

Figure 4. Number of Friction Rings

General fine U-nuts have a single friction ring, but special specifications are available with two friction rings for improved loosening prevention.

*Including some distributors, etc.

Sort by Features

Sort by Area

Die Co., located in Eastlake, Ohio, USA, has been a manufacturer of spring steel fasteners and metal stampings since 1963. The company has a large product line of metal clips, clamps, nuts, and other fasteners. Some of its products include cage nuts, nut retainers, U-nuts, tube clips and clamps, and stud receivers. Its quality management system is ISO 9001:2015 certified, and its production is monitored using statistical process control (SPC) techniques.

Advance Components Inc., established in 1972 and based in Carrollton, Texas, is a distributor of specialty industrial fasteners. The company collaborates with well-established manufacturers like A Raymond/Tinnerman and AVK Industrial and specializes in fastening products for aerospace, electronics, automotive, solar, and construction markets. Its featured items are gage bilt power tools, cage nuts/captive nuts, CLIC hose clamps, and duplex screws. As a women-operated entity affiliated with the Women’s Business Enterprise National Council, it provides enhanced services such as custom bagging labeling and bespoke inventory management solutions tailored to customer needs.

Dongguan Zhengchen Hardware Co., Ltd., situated in Dongguan City, China, is a manufacturer of a large array of engineering parts, tools, and equipment. The company makes ball plungers, spring plungers, ball rollers, special fasteners, and nylon tip set screws. It also manufactures adjusting screws, ball clamping screws, ball lock pins, shaft collars, and hinges. Its ball plungers, which consist of cylindrical bodies with threaded ends, are used to secure two or more pieces of material together.

SKF UK is the British division of SKF, originally founded in 1907 and headquartered in Gothenburg, Sweden. SKF designs, develops, and manufacturers bearings, seals, lubrication systems, and services worldwide, with industrial and automotive segments, providing solutions for industries including aerospace, agriculture, transportation, food and beverage, general machinery, material handling, mining, energy, paper, and wind energy. SKF UK offers rolling bearings, mounted bearings, automotive seals, lubrication management, vehicle aftermarket services, waste electric products, and electronic equipment products as well as services including maintenance, remanufacturing, customization, and training.

CHIN SING PRECISION INDUSTRY CO., LTD. is a Taiwanese manufacturer of precision metal stampings and machining parts. The company was founded in 1990 and is headquartered in Taipei. Chin Sing's main activity is the design, development, and manufacturing of precision metal stampings and machining parts including bearing adapter sleeves, hydraulic adapter sleeves, withdrawal sleeves, hydraulic withdrawal sleeves, and GUK self-lock nuts, among others. The company also offers a wide range of services, such as prototyping, testing, and assembly. Chin Sing's products are used by many customers, including the automotive, electronics, and medical industries.

Chin Hsing Precision Industry Co., Ltd, established in 1990 and located in Minxiong, Taiwan, is a manufacturer of bearing adapter sleeves, hydraulic adapter sleeves, and the like. The company crafts adapter sleeves and hydraulic adapter sleeves, withdrawal and hydraulic withdrawal sleeves, and lock nuts and prevailing torque bearing nuts with metal inserts. It also produces lock washers, brass self-lubricating bushings and ceramic ball bearings, and linear guides and ball screws. Its adapter sleeves have good self-locking properties and are also used in heavy-duty transmission or shock vibration applications.

Generica GmbH, founded in Germany in 1977, is a manufacturer of spare parts for strapping heads and strapping tools. The company offers a wide selection of spare parts for strapping tools, a range of spare parts for strapping heads including a range of spare parts for strapping heads, and customized solutions for clients with unique requirements. Its generic parts are manufactured by ISO 9001-certified companies and are subject to long-term testing under tough, everyday conditions.

Böllhoff is a manufacturer and distributor of fasteners and connection systems that was founded in 1877 in Bielefeld, Germany. The company’s products include blind rivet nuts, washers, and screws. It also offers custom engineering, product testing, and personnel training services for clients needing additional support. The company maintains several internationally recognized certifications, including ISO 9001, 14001, and 45001 operation standards. It mainly serves the aerospace, automotive and metal fabrication markets. Some of its notable client companies include Siemens, John Deere, and Airbus.

Kouei Japan Trading Co. LTD., founded in 2016 and based in Tokyo, Japan, is a supplier of a wide range of steel materials, tools, and equipment. Its product range includes hand, lifting, hydraulic, safety, and cutting tools. It has branches in Vietnam, Myanmar, and Bangladesh, and it sources products from several manufacturers, including Tachibana Eletech Co. Ltd, Fuji Tool Co. Ltd., Skil Corporation, 3M Japan Group, and Koki Holdings Co. Ltd. The company mainly serves those in the construction industries like bridge, port, and plant construction, and even those working in steel factories.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | KSLNC & Kumsan E&C Co., Ltd |

34.4%

|

| 2 | Böllhoff |

18.8%

|

| 3 | Advance Components Inc. |

12.5%

|

| 4 | XANDOR Canning Brett |

9.4%

|

| 5 | Die Co. |

9.4%

|

| 6 | SKF |

6.3%

|

| 7 | Dongguan Zhengchen Hardware Co., Ltd. |

3.1%

|

| 8 | Generica GmbH |

3.1%

|

| 9 | Kouei Japan Trading Co., Ltd. |

3.1%

|

Derivation Method

The ranking is calculated based on the click share within the fine u-nut page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Germany

Germany

|

3 | 21.4% |

United States of America

United States of America

|

2 | 14.3% |

Japan

Japan

|

2 | 14.3% |

Taiwan

Taiwan

|

2 | 14.3% |

China

China

|

1 | 7.1% |

Sweden

Sweden

|

1 | 7.1% |

Republic of Korea

Republic of Korea

|

1 | 7.1% |

Switzerland

Switzerland

|

1 | 7.1% |

United Kingdom

United Kingdom

|

1 | 7.1% |