All Categories

History

This section provides an overview for electromagnetic chucks as well as their applications and principles. Also, please take a look at the list of 11 electromagnetic chuck manufacturers and their company rankings. Here are the top-ranked electromagnetic chuck companies as of March, 2026: 1.Magnetool, Inc., 2.Eisen Machinery Inc., 3.International Machine Tools and Equipment Inc..

Table of Contents

Categories Related to Electromagnetic Chucks

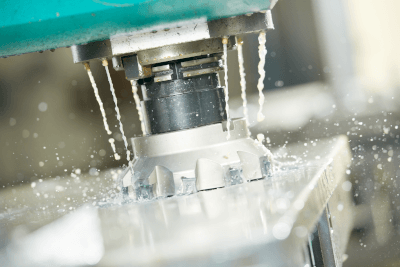

An electromagnetic chuck is a device that uses an electromagnet to clamp workpieces in machine tools.

Requiring an external power supply for operation, electromagnetic chucks generate heat when energized. They are best suited for machining large materials where high precision is not the primary concern. Their size can be easily adjusted to accommodate a wide range of material sizes.

The chucking force is adjustable via an external switch, simplifying the automation of the chucking process alongside machinery. A variant, the permanent electromagnetic chuck, utilizes a magnet that is energized only during attachment and detachment, conserving energy when not in use.

Electromagnetic chucks are integral to various machine tools, including milling machines, drilling machines, grinding machines, and more. They are invaluable for securely holding workpieces during both cutting and non-cutting processes, such as electrical discharge machining. Their ability to switch the magnetic force on and off facilitates easy handling of ferrous work materials.

This type of chuck consists of an iron core and a coil, with a faceplate designed to prevent ingress of water. Energizing the electromagnet generates magnetic field lines that attract and hold the workpiece firmly. De-energizing the electromagnet releases the workpiece instantly.

Employing a permanent magnet, this chuck type is energized only during the attachment and detachment of materials, maintaining magnetic force without continuous power, thus being energy efficient. It features rod-shaped electrodes and brass separators for pulse voltage application, enabling high-precision machining without thermal displacement.

The ability to switch the electromagnet on and off simplifies the process of attaching and detaching workpieces, facilitating automation.

The chuck's suction force is adjustable, making it versatile for different types and intensities of machining.

Electromagnetic chucks can be easily scaled up, with models available that offer clamping forces around 300 kg.

Electromagnetic chucks come in round and square shapes, catering to various work materials and machining processes. They can be categorized by cooling method: non-cooled, water-cooled, and air-cooled, with cooling essential for maintaining workpiece temperature and machining accuracy. Tiltable models allow for precise angle adjustments, crucial for grinding mold parts, featuring high-precision components and temperature control to ensure accuracy.

The permanent electromagnetic chuck combines permanent magnets and electromagnets for energy-efficient operation during attachment and detachment processes.

*Including some distributors, etc.

Sort by Features

Sort by Area

Suburban Tool, Inc., situated at AuBum Hills, Michigan, is a manufacturer and supplier of workholding products and inspection equipment. The company’s products include but aren’t limited to gage pin sets, angle blocks, index fixtures, lapping plates, and height gages. They also provide customized products for clients tailormade for the client’s specific needs. The Company is registered with CCR and is a supplier to military bases and government organizations under government contracts..

Walker Magnetics is a designer and manufacturer of magnetic products including permanent, electromagnetic, and electro-permanent magnetic products and systems established in 1896 and headquartered in Boyne City, Michigan. The company offers demagnetizers, magnetic sweepers, lift controls, and heavy lift, separation, scrap, self-contained lift magnets used for work holding, lifting, material handling, scrap magnets, and separation applications. The magnets are used in various industries including metal fabrication, scrap/recycling, mining, industrial services, and steel manufacturing & distribution.

Magnetool, Inc. was established in 1951 and located in Troy, Michigan. Magnetool is a designer and manufacturer of permanent magnet and elegromagnetic devices used for material handling, holding, lifting, demagnetizing, and filtering. Magnetool also offers custom applications. Magnetool product categories include magnetic tools such as multi-lifts and various lifting magnets, electromagnets such as bipolar electromagnets and low profile electromagnets, demagnetizers, rectifier controllers, chuck & sine plates, magnetic filters, and magnetic sweepers. Magnetool also offers repair facilities for permanent chucks and electromagnetic chucks.

Eisen Machinery Inc. is an importer and distributor of precision industrial machinery and machine components headquartered in Ontario, California. Established in 2002, their distribution includes machine tools such as grinders, milling machines, and engine lathes, as well as machine parts like forward reverse switches and power feeds. The company primarily serves machinery and equipment manufacturers as well as wholesalers in the energy, automation, and security industries. With partners in over three continents, Eisen Machinery Inc. can supply machinery and parts from Germany, Taiwan, and Japan, as well as accommodate custom orders for items not currently available.

HVR Magnetics Co., Ltd., established in 2003 and headquartered in Zhuzhou, China, is a manufacturer and supplier of magnetic lifting equipment. The company’s core products encompass an extensive array of lifting magnets, magnetic separators, and magnetic components, crucial for efficient material handling and separation across industries. HVR Magnetics plays a pivotal role in augmenting operational efficiency and safety in industries such as metalworking, recycling, and mining sectors. As a forward-looking manufacturer, they heavily invest in modernizing material handling processes and assuring sustainable solutions for industrial applications.

Uptech Engineering is an Indian ISO 9001 certified manufacturer of magnetic products, machine shop aids, and inspection instruments that was established in 1999. Based in Pune, Maharashtra, the company produces various magnetic products including lifters, chucks, tool setting gauges, and bases. It also offers a selection of non-magnetic precision vices and sine tables. Uptech Engineering provides additional contract manufacturing services to its clients in the engineering, medical device manufacturing, automotive, and defense industries.

Kanetec CO. LTD., founded in 1949 and headquartered in Nagano, Japan, is a designer, manufacturer, and supplier of magnet application equipment. Some of its products include permanent magnetic chucks, electro-magnetic chucks, tesla meters, magnetic holders, and lifting magnets. The magnet products have various uses in several areas, including milling, grinding operations, refrigerators, conveyors, and food processing. All of the motors of 0.75kW or more used in the company’s products are IE3 motors that comply with the Energy Conservation Act in Japan, and the company can also issue a calibration certificate for its measuring instruments upon request.

Relemac Technologies Private Limited is an Indian enterprise that manufactures and supplies an extensive assortment of cables and wires since 1993. Relemac Technologies produces cables that are widely used in Solar, Railways, Real Estate, Oil and Gas, and related industries. Some of the industrial cables include Submersible cables, Coaxial cables, Network Cables, PTFE, and XLPE cables. Whereas categorical wires include Telecommunications cables, Rubber cables, PVC cables, Fiber Optical cables, and Instrumentation cables. Fire survival cables are specially designed to remain operative for a certain time period in case they are exposed to fire.

International Machine Tools and Equipment Inc., located in Richmond Hill, ON, since 1999, has been a supplier of self-brand and OEM VDI, CNC milling, and other tool holders, as well as work holding equipment, and of machine tools, ranging from traditional lathes and mills to high-speed CNC machining centers. The tool holders are utilized for CNC milling applications, boring bars, collets and collet chucks, vises, and other tool-holding and work-holding equipment following the stringent requirements of HSK, DIN, ANSI, and BT standards.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Magnetool, Inc. |

16.7%

|

| 2 | Eisen Machinery Inc. |

14.7%

|

| 3 | International Machine Tools and Equipment Inc. |

12.7%

|

| 4 | Walker Magnetics |

11.8%

|

| 5 | Suburban Tool, Inc. |

10.8%

|

| 6 | HVR Magnetics Co.,Ltd. |

8.8%

|

| 7 | Ferro Electromagnetic Systems |

6.9%

|

| 8 | Uptech Engineering |

6.9%

|

| 9 | KANETEC CO.,LTD. |

5.9%

|

| 10 | Magtech Associates |

3.9%

|

Derivation Method

The ranking is calculated based on the click share within the electromagnetic chuck page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 50.0% |

India

India

|

2 | 25.0% |

Japan

Japan

|

1 | 12.5% |

China

China

|

1 | 12.5% |

121 products found

121 products

Sunk Japan Co., Ltd.

270+ people viewing

Last viewed: 11 hours ago

High retention force permanent electromagnetic module specialized for EDM applications Advantages and Benefits ■Innovative “fine” and “active” pol...

2 models listed

Hishiko Co., Ltd.

280+ people viewing

Last viewed: 22 hours ago

■Applications A chuck for heavy cutting such as milling cutters, plano mirrors, saper/planers, etc. ■Features ・It is an electromagnetic chuck wit...

Shimonishi Giken Co., Ltd.

700+ people viewing

Last viewed: 14 hours ago

■Features of switching mug holder ・It is about half as thin as conventional products and generates great suction power. ・It can be switched ON/OF...

4 models listed

Sunk Japan Co., Ltd.

270+ people viewing

Last viewed: 1 hour ago

Magnetic chuck with very high lateral holding force for milling applications. The ideal clamping solution for powerful metal cutting processes on n...

7 models listed

Sunk Japan Co., Ltd.

520+ people viewing

Last viewed: 22 hours ago

Magnetic clamping plate with a circular design, specially designed for milling workpieces on circular workbenches. The high holding forces of the m...

8 models listed

Hishiko Co., Ltd.

360+ people viewing

Last viewed: 22 hours ago

■Applications Used for heavy cutting such as milling cutters, plano mirrors, saper planers, etc. ■Features ・It is an electromagnetic chuck with s...

Sunk Japan Co., Ltd.

450+ people viewing

Last viewed: 22 hours ago

An ideal clamping solution for powerful machining processes, with an extremely high holding force magnetic chuck suitable for milling applications,...

10 models listed

Hishiko Co., Ltd.

450+ people viewing

Last viewed: 22 hours ago

■Applications Ideal for high precision grinding and slicing. ■Features - There is no self-heating caused by the chuck, making it difficult for pre...

Hishiko Co., Ltd.

460+ people viewing

Last viewed: 22 hours ago

■Applications We have large specifications, strong types, for cutting/grinding, star pole types, etc.

Hishiko Co., Ltd.

430+ people viewing

Last viewed: 22 hours ago

■Applications Used for heavy cutting machining centers, plano mirrors, milling machines, and boring machines. ■Features The strong adsorption prop...

Hishiko Co., Ltd.

440+ people viewing

Last viewed: 13 hours ago

■Applications ・Used for heavy cutting machining centers, plano mirrors, milling machines, and boring machines. ■Features ・Strong adsorption is a...

Hishiko Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

■Applications Used for heavy cutting machining centers, plano mirrors, milling machines, and boring machines. ■Features The strong adsorption prop...

Sunk Japan Co., Ltd.

240+ people viewing

Last viewed: 22 hours ago

Manual permanent magnetic chuck with parallel pole pitch suitable for clamping small and thin workpieces, ideal for precise polishing work on polis...

10 models listed

Sunk Japan Co., Ltd.

230+ people viewing

Last viewed: 22 hours ago

Permanent electromagnetic chuck with precision parallel pole spacing suitable for clamping small and thin workpieces, ideal for accurate polishing ...

8 models listed

Sunk Japan Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

Manual magnetic chuck with radial pole spacing for machining rings and discs on cylindrical grinding machines Advantages and Benefits ■Even perman...

7 models listed