All Categories

History

This section provides an overview for worm wheels as well as their applications and principles. Also, please take a look at the list of 29 worm wheel manufacturers and their company rankings. Here are the top-ranked worm wheel companies as of March, 2026: 1.Intech Corporation, 2.PIC Design, 3.Renold Jeffrey.

Table of Contents

Categories Related to Worm Wheels

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

A worm wheel is a gear that makes up a worm gear.

A worm gear is a type of screw gear. It is a combination of a worm (worm shaft), which is a threaded toothed shaft, and a Worm Wheel, which is a helical gear with its axis of rotation at 90 degrees to the worm's axis.

Rotation of the worm feeds and rotates the teeth of the worm wheel that engage the worm.

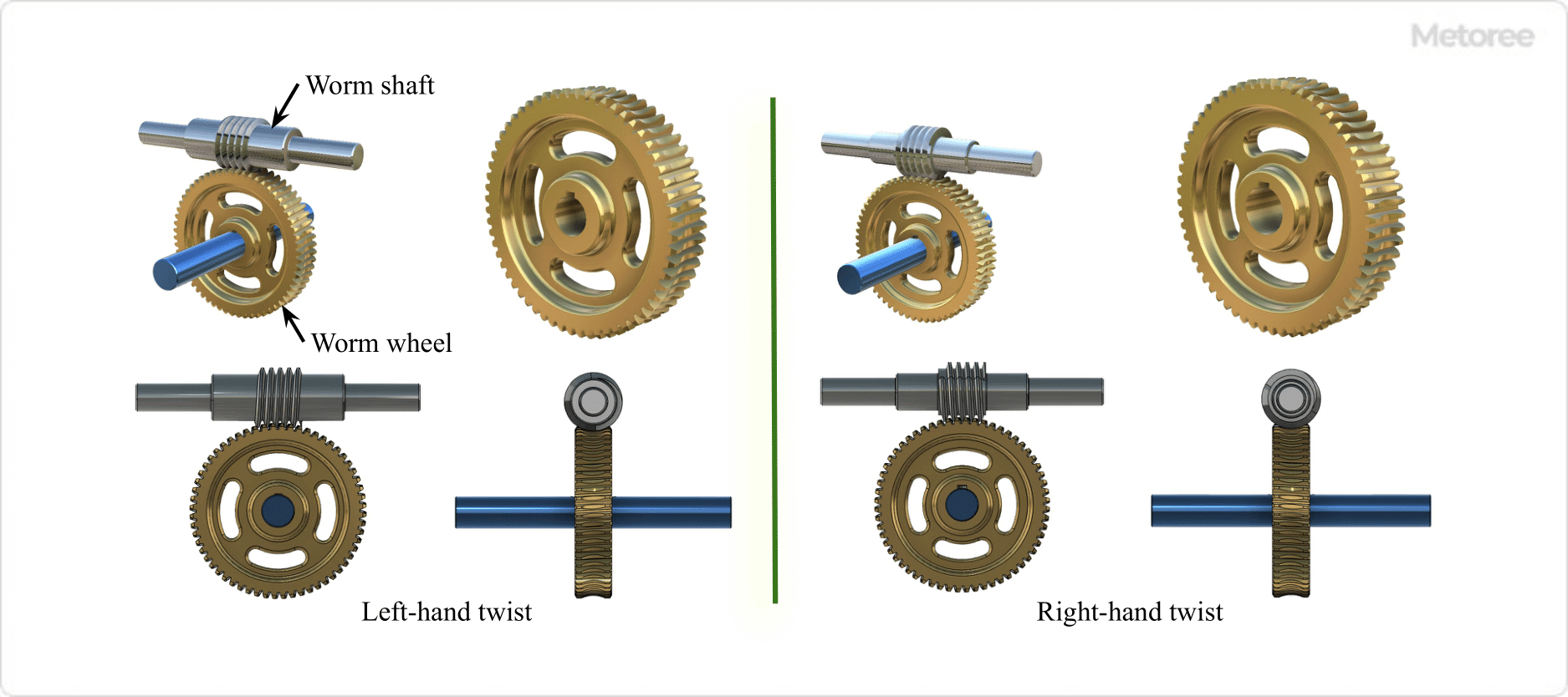

Figure 1. Structure of worm gear

Figure 2. Example of worm gear (worm wheel) use

Worm wheels are used in combination with worms (worm shafts) as worm gears.

Worm gears are orthogonal shafts that can transmit power by changing the direction of the input and output rotary axes by 90 degrees, and can produce large reduction ratios, even with small gears. This includes devices, such as belt conveyors in factory equipment, screw jacks, steering systems for automobile steering wheels, wiper drives, and swiveling mechanisms for electric fans. It also includes material feeders in food and drug manufacturing equipment, music boxes, and stringed instrument pegs.

Worm wheels are used in machine tools such as lathes and milling machines.

High torque for moving heavy loads and smooth belt movement.

Used in hoisting devices for elevator carriages. It can provide the power needed to lift and lower heavy loads and smooth operation.

Worm wheels are used in power steering systems in cars, trucks and other vehicles. Worm gears are used in some reduction gears for power steering drives.

Worm gears are used in some winches. They output high torque and can lift heavy loads.

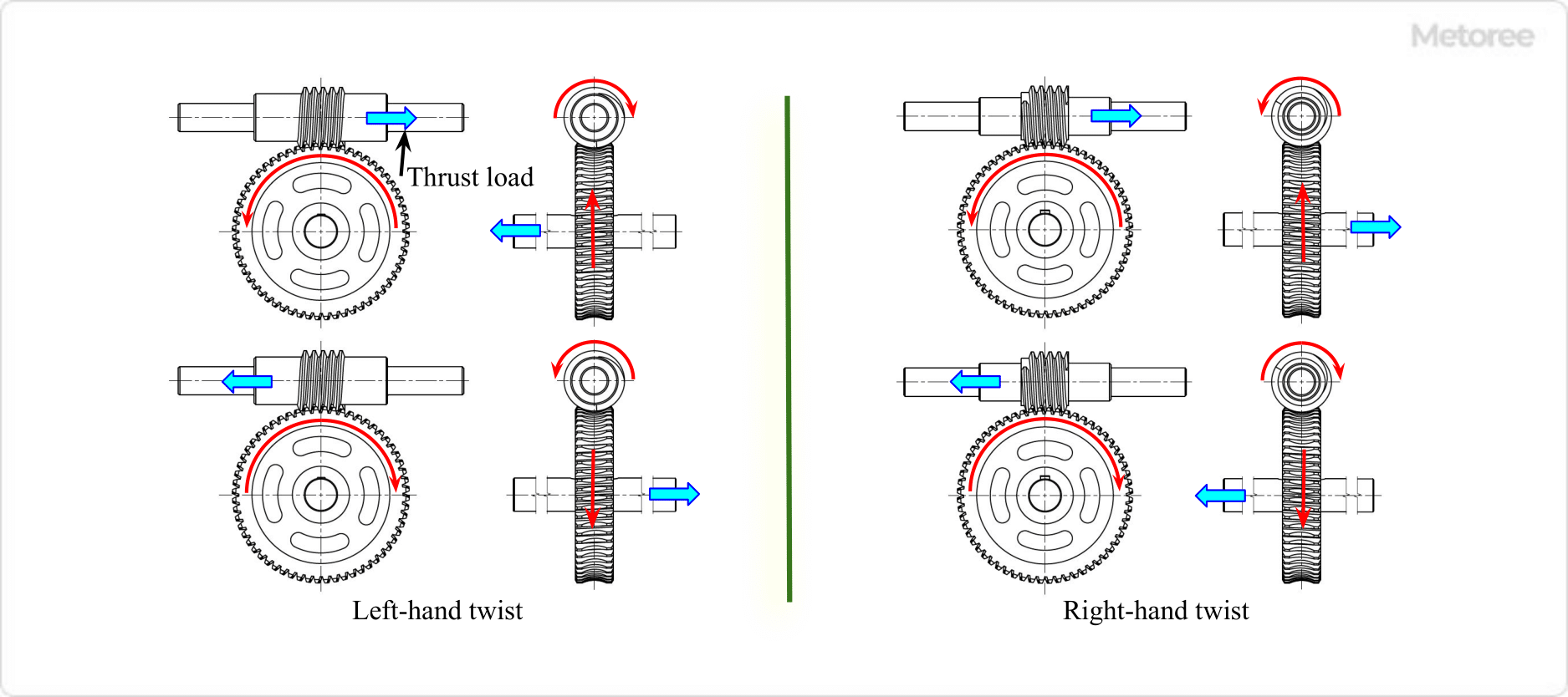

Figure 3. Direction of rotation and torsion of worm gear, direction of thrust load

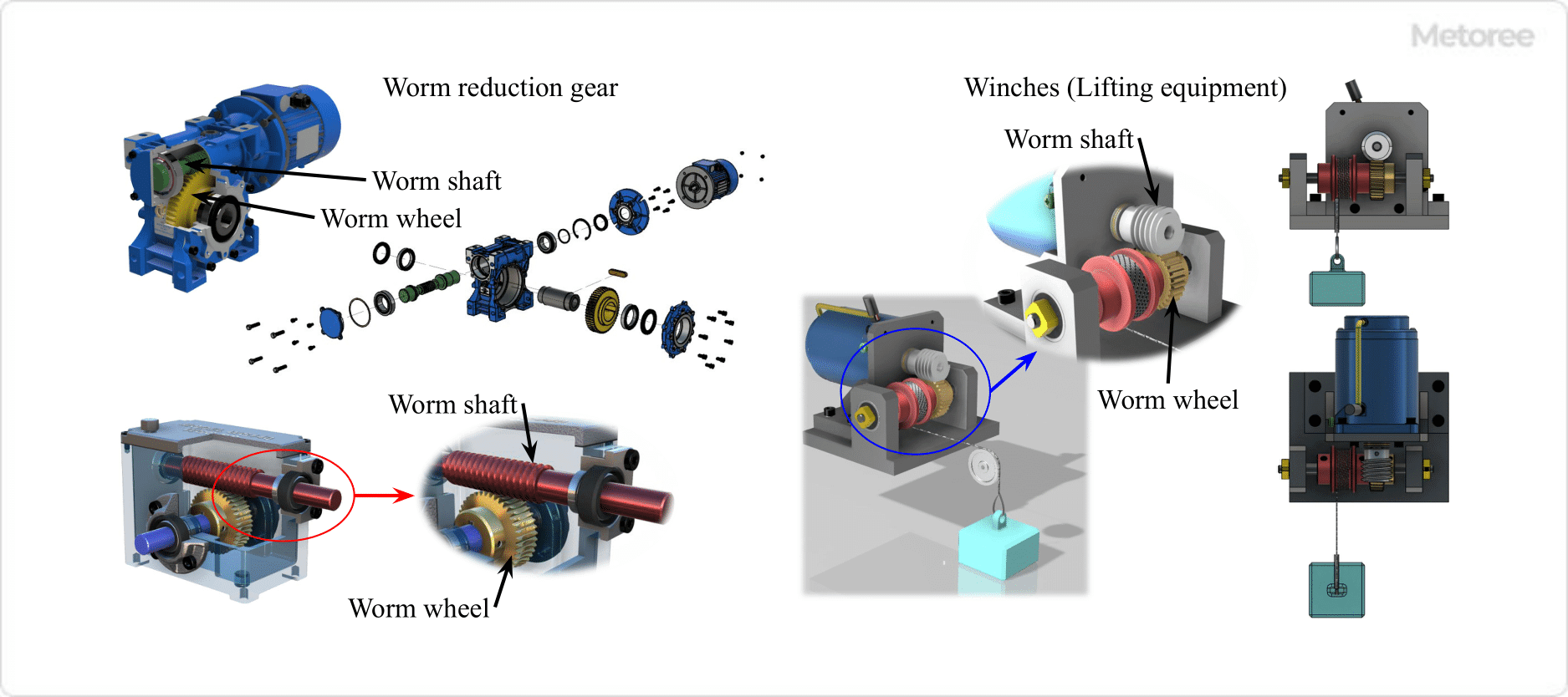

Worm wheels are helical gears that fit into a helical groove machined into the worm (worm shaft). This is called a helical gear, and is one of the cylindrical gears with a spiral tooth trace.

The obliquely cut grooves mesh with the shape of the gears, resulting in a large amount of slippage and friction when the gears mesh with each other. Also, when rotating at high speeds, the tooth flanks become hot due to frictional heat. Therefore, it is necessary to reduce the coefficient of friction by using different materials, such as a hard metal for the worm and soft metal for the worm wheel.

In worm gears, when the worm is rotated, the worm's spiral groove rotates. The teeth of the worm then press against the beveled teeth of the worm wheel, which transmit rotation to the worm wheel, causing it to rotate.

The worm gear can rotate in both directions (e.g., clockwise and counterclockwise when viewed from the input shaft side). This can be achieved by selecting the worm twist direction as a left-hand or a right hand twist. As the worm gear rotates, a thrust load is applied in the direction of the Worm Wheel and the center of the worm shaft. Therefore, the direction of the thrust load on the worm gear varies depending on the direction of rotation of the input shaft and the direction of the worm twist.

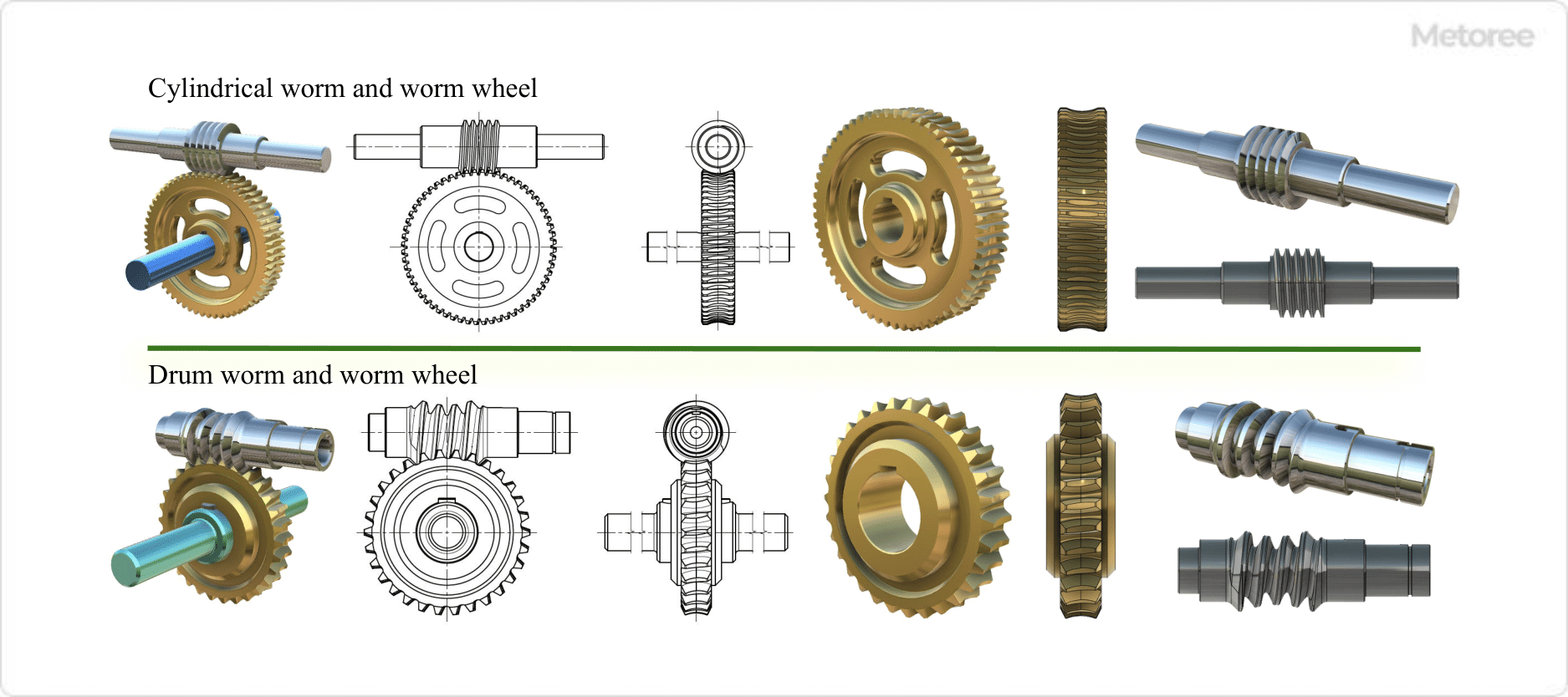

Figure 4. Shape of worm gear

Worm gears are classified into the above types according to the shape of the worm and worm wheel.

Cylindrical Worm and Worm Wheel

Used in most cases, tooth flanks are in linear contact with each other, and transmission capability is medium.

Drum-Shaped Worms and Worm Wheels

They have a special shape that requires a high degree of manufacturing precision, and their tooth flanks are in contact with each other, resulting in a high transmission capacity.

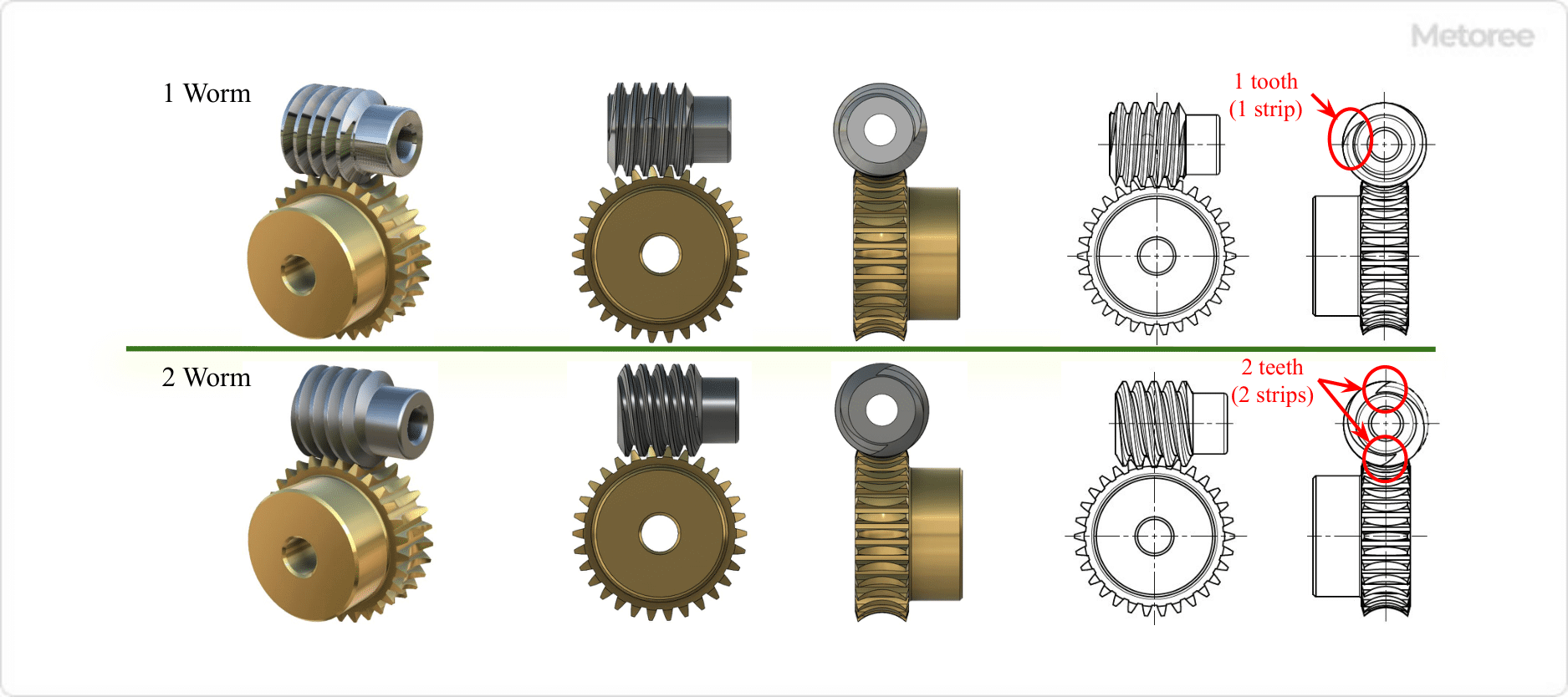

Figure 5. 1- and 2-strip worm gear

The number of worm gear teeth indicates the number of teeth on the worm (worm shaft), which can be confirmed by looking at the worm end face and checking the number of teeth per circumference of the shaft.

The number of worm teeth and their characteristics are as follows:

Single-Start

The worm has one tooth, and the worm wheel has the same number of teeth. The worm wheel rotates by one tooth per worm revolution. Reduction ratio is relatively low and torque transmission is stable.

Multi-Start

The worm has multiple teeth, and the worm wheel has the same number of teeth. The worm wheel rotates two teeth per worm revolution. The reduction ratio is greater than that of a single worm, allowing for greater torque transmission, but reducing the possibility of self-locking.

*Including some distributors, etc.

Sort by Features

Sort by Area

Renold Jeffrey, founded in 1887 and based in Morristown, Tennessee, is a chain designer and manufacturer and the oldest chain company in the U.S. In 1987, the company became the first chain company to obtain BS:5750, which later became ISO:9002. Later, in 2000, Renold acquired Jeffrey Chain Corp, broadening its line of chains. Some of its products include tooth chains, asphalt chains, dairy case chains, chain pin extractors, and sprockets. The company’s chains can serve various industries, including transportation, mining, material handling, manufactured products, and construction machinery.

PIC Design is a manufacturer and supplier of mechanical components and precision gears, established in 1954 and headquartered in Middlebury, Connecticut. The company’s product portfolio includes washers, threaded stocks & studs, knurled thumb screws & nuts, gear assemblies/reducers, and bearing & bushings used in various applications including medical, robotics, optical systems, lab instrumentation, and industrial controls. The company has achieved various registrations and certifications including DFARS, R.E.A.C.H, RoHS, DDTC/ITAR, and ISO 9001:2015.

Boston Gear is a North Carolina-based manufacturer and supplier of power transmission components including bearings, clutches, enclosed gear drives, and AC/DC motors. Founded in 1877, the company offers more than 30,000 standard products, as well as the option to create custom-engineered solutions. The company is ISO 9001 certified, with clients in the mining and aggregate, energy, aerospace, defense, construction, and agricultural industries. Boston Gear components are also used in packaging and robotics operations by companies such as Disney and Coca-Cola.

Setco Inc. is a manufacturer specializing in precision industrial components founded in 1912 and based in the United States. It works in designing, producing, and servicing precision spindles, milling heads, slides, and spindle/slide combinations. With a wide range of offerings, including belt-driven, geared, motorized, high-speed, and high-frequency spindles, it serves industries such as automotive, aerospace, construction, plastics, woodworking, and more. Notably, its precision linear slides come in various models, catering to diverse applications. Its expertise extends to special products like Spark Erosion Grinding systems, AirShield Bearing Seals, and RotoShield Coolant Unions.

Intech Power-Core, founded in 1983 and headquartered in Closter, New Jersey, is a manufacturer of self-lubricating, lightweight machine components. Its products include precision-machined plastic components, gears, rollers, cam followers, pulleys, and sprockets designed for various applications where vibration, inertia, moisture absorption, or corrosion pose problems with metal or traditional plastic materials. All finished parts undergo inspection to ensure compliance with specifications, and the company's plastics engineers utilize PRO-E for component design.

Ondrives US, founded in Freeport, NY, in 2011 is a manufacturer of standard, modified, and custom precision gears, gearboxes, pulleys and mechanical components. The company's product portfolio includes gear hobblers, gear shapers, CNC vertical mills, bar fed CNC lathes and laser engraving. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company also provides services including two dimensional drawings of 3D CAD models, product selection, national distribution and customer support.

Avon Gear & Engineering, founded in La Grange, Illinois, in 1974 is a manufacturer of Custom Gears in different materials and sizes. The company's product portfolio includes spur gears, helical gears, bevel gears, worm gears, and surface coatings to enhance wear resistance and reduce friction. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

Amtech Manufacturing, Inc., established in 1995 with facilities in North America, is a contract manufacturer of gear parts and drive components. The company's products include gears, shafts, castings, forgings, and screw machine parts. Amtech Manufacturing, Inc. also offers flexplate Assemblies, flywheel Assemblies, screw machining, stamping, and fineblanking. The company also offers custom manufacturing, machining, engineering, and laser cutting services. Amtech Manufacturing, Inc. services original equipment manufacturers in the automotive, construction, marine, power sports, and robotics markets.

Gear Motions is a custom gear manufacturer for global OEMs. Founded in 1960 and headquartered in Syracuse, New York, with additional locations in Buffalo and Oliver Springs, Gear Motions has grown significantly since its founding. Initially a ten-man company serving primarily in the New England Area, they have since expanded through acquisitions of companies such as Nixon Gear, Gear Supply and Broaching, and Pro-Gear Co Inc. The company provides custom gear solutions for various custom and precision applications, offering products such as ground helical gears, spur gears, pump gears, timing pulleys, shafts and splines.

The Adams Company was established in 1883 and is located in Dubuque, Iowa, United States is a manufacturer of custom gears, shafts, and power transmission parts for various industrial and commercial applications. The company produces straight bevel, helical, spur & worm gears along with power transmission parts including sprockets, couplings, clutches & shafts that have applications in agriculture&construction machinery manufacturing industry, oil recovery equipment, winches, and industrial pumps. They also offer services including CNC blanking, hobbing, shaping, vertical machining, and gear shaving that are needed in the thread grinding, broaching, milling, tapping, and deburring systems.

Croix Gear & Machining, founded in 1966, is a manufacturer and supplier specializing in precision machining and gear manufacturing. Headquartered in Wisconsin, United States, the company offers a wide range of products and services, including precision gear manufacturing, CNC machining, and custom component production. It caters to various industries, including automotive, aerospace, and medical devices, which utilize its expertise in precision machining and gear production to ensure the performance and functionality of components and processes.

Logan Actuator Co., founded in 1939 and based in Harvard, IL, USA, is a manufacturer and supplier of parts and accessories for metalworking lathes. The company's product range includes 3-jaw chucks, double gears, flat belts, toolpost sets, and drive plates. These products are used for various operations in metalworking and lathe machining. Industries such as metalworking, manufacturing, machining, and industrial production rely on its offerings. The company also offers services like direct customer sales, shipment handling, return processing, and provision of detailed instruction manuals.

Marples Gears Inc., established in 1942 and based in San Gabriel, California, USA, is a manufacturer and supplier of high-precision fine-pitch gears. The company's product range includes spur gears, helical gears, worm gears, planetary gears, and internal gears. These gears are utilized in various applications to ensure accurate transmission of power and motion, particularly in sectors like aerospace, defense, optical, and medical. Alongside its primary manufacturing capabilities, the company provides additional services such as CNC turning and milling, grinding, honing, and specialized gear cutting techniques.

Air Parts Inc., established in 1992 in Niagara Falls, NY, Niagara serves as the direct distributor for Canadian Aero Manufacturing in the USA. Specializing in aviation parts, the company offers starter adapter units, overhaul kits, and various aircraft engine components while maintaining a well-stocked inventory. It also provides a service to resize Shafts and Worm Wheels to the next serviceable size, supplying the necessary spring and overhaul kit for reassembly. Customers send its parts for resizing; the modified components, along with additional required parts, are returned for self-reassembly. This service facilitates component adjustments and self-repair for aviation needs.

Ketterer Inc., established in 1832, is headquartered in Furtwangen, Germany, and stands as a manufacturer specializing in drive solutions. The company specializes in crafting a diverse range of drive systems, offering a product line encompassing precision gears, drive motors, and related components. Its adherence to rigorous quality standards is exemplified by its ISO 9001 certification. Its drive solutions find applications across various sectors, including automotive, aerospace, electronics, medical devices, and more.

Sovereign Gears Ltd. is a manufacturer of gears and gear drives. It is headquartered in Leicester, United Kingdom since 1997. The company designs, manufactures, and supplies multiple types of gears and gear drives, including spiral bevels, worm and wheel, spur gears, helical gears and splines. Its products are used in various industries, including automotive, aerospace, and power generation. The company also offers services such as turning and milling, wire EDM, design, grinding and lapping.

Huco Engineering Industries Ltd., founded in BL – England, in 1965 is a manufacturer of Couplings, Air motors, Shaft Collars, and Universal Joints. The company's product portfolio includes Planetary Gearboxes, Dynatork Service Kits, Geared Motors, Aluminium Motors and Acetal Motors. Their products ae used in markets including food processing, energy, textiles, medical, packaging, metals, machine tools, and material handling on applications such as stepper & servo drives, dynamometers, scanners, pumps, fans & blowers, mixers, conveyors and compressors.

Normelemente KG, established in 1958 and based in Markgroningen, Baden-Wuerttemberg, is a German manufacturer and supplier that specializes in standard parts and machine components. Norelem offers an extensive catalog of more than 70,000 products, catering to the needs of engineers and designers in various projects. Their product range includes clamping technology, measuring and testing components, electromechanics, systems and components for machine and plant construction, and material handling and transport solutions. These products find applications in diverse engineering fields, such as automotive, aerospace, machinery, and robotics sectors.

Kohara Gear Industry Co., Ltd. (KHK), established in 1935, is a Japanese manufacturer headquartered in Kawaguchi, Saitama, specializing in the production of stock gears. The company’s product portfolio includes bevel, helical, internal, miter, and plastic gears. Additionally, it offers other types of stock gears such as screw, spur, and worm gears. The company also provides standard and circular pitch (CP) gear racks, gear couplings, as well as pre-lubricated bevel gear boxes designed to be freely mountable in any direction. Furthermore, the company offers customization options, allowing customers to choose specific gear tooth pitches, sizes, grades, and materials, such as metal and plastic.

Jiaxing Dexun Co., Ltd, founded in Taiwan in 1997, is a manufacturer of OEM and ODM casting, stamping, plastic injection molding, and CNC machining parts. The company's product portfolio includes OEM and ODM auto parts and machine parts as well as other standard auto parts and fasteners. It has a mould workshop with advanced equipment to develop molds for customers and have experience in manufacturing custom made parts according to customer’s drawing.

Koro Industries Inc., established in 1965 with headquarters in Maple Grove, Minnesota, USA, is a manufacturer of fine and medium-pitch gears and components. The company's product line includes helical gears, spur gears, worm wheel gears, gear shafts, and differentials made of various materials, including stainless steel, alloys, and plastics. These products are used in various applications, from electromechanical toys and vehicle power windows and mirrors to aircraft instrumentation, among many others. Historical hero projects include the manufacture of replacement parts for NASA’s Skylab in 1973. The company custom-manufactures prototypes as well as fabricates high-volume components and assemblies from customer-supplied blanks.

igus GmbH, established in 1964 and based in Cologne, Germany, is a manufacturer and distributor of technical products made using polymers for movement. Its products include injection molding frames, motor control systems, and plain bearings, and it has over 240,000 products in over 1,000,000 variations. It serves 188,000 companies from over 80 countries worldwide in 50 different industries, including packaging, automotive, and renewable energy. The company is ISO 9001, ISO 14001, and ISO 50001 certified, and in 2023, it recorded €1.115 billion in sales. Since 2021, the company has purchased 380 new injection-molding machines and has replaced 275 old ones.

Perry Technology Corporation was founded in 1938 and is based in New Hartford, Connecticut, USA, as a manufacturer of aviation and aerospace components. The product list of the company includes bevel gears, helicals, racks, sectors, and splines. The products are integral to critical aircraft systems like flap actuators, fuel controls, landing gear, pilot controls, and air turbines and are also employed in various applications within the US military defense systems. The company serves various industries, such as commercial aviation, military, defense, engineering, and inspection services.

W M Berg, founded in 1967 and based in Cudahy, Wisconsin, is a manufacturer and supplier of precision industrial parts. The company delivers ISO 9001:2015 certified products and services, including assemblies, bearings, belts & chains, couplings & shafts, gears, fasteners & hardware, pulleys & sprockets and more. W M Berg provides designing, developing, manufacturing and testing facilities to its clients in the aerospace, medical and motion control industries. Its distributors include Applied Industrial Technology and Motion Industries.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Intech Corporation |

10.8%

|

| 2 | PIC Design |

8.4%

|

| 3 | Renold Jeffrey |

6.0%

|

| 4 | Maedler North America |

6.0%

|

| 5 | Avon Gear & Engineering |

4.8%

|

| 6 | ondrives us |

4.8%

|

| 7 | The Adams Company |

4.8%

|

| 8 | Logan Actuator Co. |

3.6%

|

| 9 | Croix Gear & Machining |

3.6%

|

| 10 | AmTech OEM |

3.6%

|

Derivation Method

The ranking is calculated based on the click share within the worm wheel page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

14 | 58.3% |

Germany

Germany

|

4 | 16.7% |

United Kingdom

United Kingdom

|

3 | 12.5% |

Japan

Japan

|

1 | 4.2% |

China

China

|

1 | 4.2% |

India

India

|

1 | 4.2% |

35 products found

35 products

Saito Koki Co., Ltd.

960+ people viewing

Last viewed: 8 hours ago

■What is worm gear? A cylindrical ``worm'' with screw-like spiral teeth and a ``worm wheel'' which is a helical gear (helical gear) are meshed at r...

Yamaichi Special Alloy Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

Material: CAC703 φ133xφ45x47.5 Approx. 3.4kg

Global Parts Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

GLO-LIGU spinning holder has better holding power and anti-vibration damping system than the general ER collet type, side lock type, hydraulic type...

4 models listed

Global Parts Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

GLO-LIGU spinning holder has better holding power and anti-vibration damping system than the general ER collet type, side lock type, hydraulic type...

3 models listed

Robotena Co., Ltd.

280+ people viewing

Last viewed: 15 hours ago

module 0.5.

4 models listed

Global Parts Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

GLO-LIGU spinning holder has better holding power and anti-vibration damping system than the general ER collet type, side lock type, hydraulic type...

10 models listed

Robotena Co., Ltd.

640+ people viewing

Last viewed: 1 day ago

Contains 2 24T flat gears, 2 worm gears, and 2 shafts.