All Categories

History

This section provides an overview for hand operated winches as well as their applications and principles. Also, please take a look at the list of 25 hand operated winch manufacturers and their company rankings. Here are the top-ranked hand operated winch companies as of July, 2025: 1.Thern Incorporated., 2.WPT Power Corporation.

Table of Contents

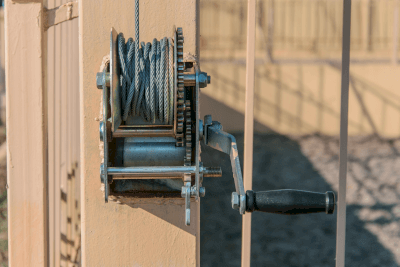

A hand-operated winch is a mechanical device used to lift heavy objects by manually winding a wire that is attached to them. Its primary advantage is its ability to be installed and used anywhere, independent of electric power, unlike an electric winch. To enhance their utility in various environments, some models are designed with improved durability features like salt resistance and rust resistance. There are even specialized large hand-operated winches capable of lifting objects weighing up to 10 tons.

Hand-operated winches find use in numerous work sites and facilities. For instance, they are employed in sports fields and driving ranges to stretch ball nets onto poles, significantly reducing the labor intensity of this task. These winches are also utilized in maritime applications, such as for raising and lowering shipboarding ramps, adjusting the height of work steps and piers, and other scenarios where heavy objects need to be safely raised, lowered, and secured in a specific position.

Hand-operated winches consist of a frame, a drum for winding the wire, and a handle to rotate the drum. The handle’s shaft is fitted with a pinion gear that engages with a drum gear on the drum’s circumference. Turning the handle causes the drum gear to rotate via the pinion gear, thereby winding up the wire. The larger size of the drum gear relative to the pinion gear allows for greater torque generation, albeit with a higher force requirement to turn the handle.

The reduction ratio, which is the ratio of the number of teeth on the pinion gear to the drum gear, is approximately 1/4 for smaller winches. However, for winches designed to lift objects as heavy as 10 tons, the reduction ratio can be about 1/300, meaning it takes 300 handle rotations to complete one drum rotation. Most hand-operated winches are equipped with an automatic brake to prevent the load from falling in case of an issue.

*Including some distributors, etc.

Sort by Features

Sort by Area

Duff-Norton is a division of Columbus McKinnon Corp and was originally founded in 1883, now headquartered in Charlotte, North Carolina. Duff-Norton is an automation machinery manufacturer for aerospace, defense, automotive, entertainment, pharmaceutical, food processing, paper, energy, rail/road, and energy supply industries. Duff-Norton manufactures standard and customer-designed screw jacks (mechanical actuators), linear actuators (electro-mechanical actuators), modulator actuators, swivel joints, electric cylinders, rotary unions (rotating joints), acme and ball screws, nuts and rail maintenance equipment to customers globally.

Thern, established in 1948 and based in Minnesota, USA, is a manufacturer of lifting, pulling & positioning equipment. The company produces a range of winches and cranes like portable and stationary davit cranes, electric and hand winches, air winches, hydraulic winches as well as custom made ropes and rigging and electric control system for winches. These equipment are used in various industries like aerospace, oil & gas, defence, mining, wastewater operations and also in the theatre and stage application. Times Square, One World Trade Centre and BC place stadium are some of the projects these equipment have been customised for.

WPT Power Corporation, established in Wichita Falls, Texas, in 1992, is a manufacturer of mechanical power transmission equipment. The company's product portfolio includes Gearboxes used for transmitting power, Shaft Couplings, sprockets and roller chains, suitable for power transmission in conveyor systems and other mechanical applications and Belt Drives. Their products are used in industries including Manufacturing and Industrial Plants, Mining and Quarrying, and Agriculture. The company provides Quality Assurance, Technical Support, national distribution, customized services and customer support.

The David Round Company, Inc. was founded in 1869 and is based in Streetsboro, Ohio. The company is one of the world’s oldest hoist manufacturers. The company’s customers include Pfizer, General Mills, Ford, and Exxon Mobile, representing pharmaceutical, food processing, automotive, and oil & gas industries. The company’s custom-engineered hoists and related products include jib cranes, winches, and tractor drives. The company custom engineers machines and replacement parts to fit individual customer needs for projects both large and small.

Suncor Stainless, Inc. is based in Plymouth, Massachusetts. Suncor Stainless serves the industrial, marine, architectural, commercial, government, and OEM markets as a manufacturer of stainless steel hardware and components. Suncor Stainless is ISO 9001:2015 certified. Suncor Stainless’s services include custom stainless steel manufacturing, product testing and quality assurance, strength testing, metal content testing, custom webbing, custom stainless steal chain assemblies, custom threading, machine swaging, corrosion resistance testing, and retail packaging. Suncor Stainless also supplies numerous components such as sheaves, hooks, and clips.

Stanspec, founded in 1976 as Stanspec Wht Corporation Inc., is a division of American Crane and Hoist Corporation (ACH), an American manufacturer headquartered in Boston, Massachusetts, specializing in overhead bridge and jib cranes, as well as winches, hoists, and car pullers. This business unit manufactures both standard and custom single and double overhead bridge cranes, whereas the motorized jib cranes are engineered for either general-purpose and maintenance activities or heavy-duty and high-cycle production tasks. The product lineup also includes electric and air-powered winches, hoists, and car pullers under the Rightway brand, tailored to handle lifting and pulling operations in industrial settings

Samco Sales Inc was founded in 1981 and is headquartered in Houston, Texas. The company is a manufacturer and distributor of industrial equipment, serving metal casting, forging, manufacturing, marine, and trucking markets. The company’s product lines also include standard and galvanized wire rope, fencing material, farming tools, and steel lock keys. The company’s metal forging services include small to medium components of steel and other alloys with several surface finishing options available.

Advanced Industrial Solutions has been a provider of material handling and fall protection solutions since 2001 in Irvine, USA. The main services provided by the company includes Crane systems, Fall protection, Access, and loading solutions. The company has a customer-centric approach to build partnerships through attentive service and responsive customized solutions. Their services aim to improve safety, efficiency, and profitability for companies worldwide. AIS has earned awards and long-standing partnerships with companies like Tesla, Rolled Alloys, Brenntag, and IMI Critical Engineering among others.

Orr & Orr, Inc. has been offering wholesale distribution services since 1934 out of Bedford Park, IL. Orr & Orr emphasizes speed of order processing, shipping, and both customer and distributor satisfaction. Product categories that Orr & Orr offers include air conditioners, brake controls, cargo restraint equipment, door tracks, lighting equipment, fans, gas springs, heating equipment, hinges, plumbing supplies, seat belts, steps, toolboxes, hitch and towing products, various truck hardware, cables, battery products, safety equipment, and spring latches.

J. Herbert Corp., established in 1978, is a distributor of hoists & trolleys, cranes & monorails, lifting & storage solutions, winches, and accessories such as cable reels, radio remote controls, and electrifications used in boat manufacturing, concrete pole casting, vehicle manufacturing & maintenance, veterinary facilities, and wastewater facilities. The Kissimmee, Florida-based company provides load testing, filed and in-shop repair, preventative maintenance & inspection, crane refurbishment, and system relocations among other services. Abell-Howe, Caldwell, Little Mule, Harrington, Coffing, and Shawbox are among the brands represented by the company.

Hassel Materials Handling Co. was established in 1968 and is a distributer for material handling solutions. Hassel Materials Handling product lines include “carts & trucks” such as picking carts and shelf trucks, “cranes, hoists & crane accessories” such as jib cranes and chain hoists, “ergonomic products” such as industrial seating and antifatigue matting, “gravity & power conveyors” such as gravity conveyors and plastic belt conveyors, “loading dock equipment” such as dock lights and hoppers, “security & wall systems” including guard rails and post protectors, “shop equipment” such as workstations and welding reels, and “storage products” such as workbenches.

Wellman, based in Jiangsu, China, is a manufacturer of winch equipment and other material handling equipment. The company's main products include a range of electric and hand winches like industrial, construction, mining and ATV winch as well as brake and heavy duty hand winch and wire rope pullers. Besides that, the company also provides electric rope and chain hoists, manual hoist, lifting table, pallet truck and pallet stacker. The company supplies its products internationally and provides 35% of their production to South America.

Galaxy Electric, established in 1987 and based in Xinxiang City, China, is a manufacturer of conductors and power cables. The company produces a range of aluminium and aluminium alloy conductors as well as aerial bundled cable up to 35KV, PVC insulated wire, low and medium voltage power cable, welding, mining and control cable, rubber insulated cable and cable accessories. These products are applied in various transmission line projects in China, Peru, Indonesia and Nigeria. The company has obtained various domestic and international certifications including CE and it offers to customise its products according to other standards including GB, JB, IEC, and DIN.

Zhejiang Wuyi Changxin Tools Co., Ltd., established in 2008 and based in Zhejiang, China, is a manufacturer of trailer parts & marine accessories. The company's product portfolio includes hand winches, trailer jacks, balls & mounts, couplers, safety chains and marine accessories like fishing rod holders, boat seat hardwares, kayak hoist system and various clamps. These products are used in the agricultural, marine, livestock and construction industry and are also applied in utility trailers, trucks, cargo management, lifting cranes and portable generators & compressors. The company exports its products to the USA, Canada, Australia and some European and Southeast Asian countries.

Toho Group, established in 1932, based in Chongqing, China, is a manufacturer and supplier of lift tools, equipment, and rig systems. Their product portfolio includes lift tools, electric hoists, rig hardware, chain series, steel wire rope, safety protection materials, and marine products. The company also offers advanced test equipment under strict quality control, material inspection, and quality examination. The company products are ISO certified. The products are mainly used in two industries which include construction and transportation.

Amratlal Chhaganlal and Co., established in 1896 and based in Mumbai, India, is a manufacturer and supplier of industrial accessories like wires, ropes, pulleys and cables. Some of the company's main products include open and closed socket, ratchet lever hoist, manila rope, chain pulley blocks as well as various chain slings and lifting clamps. The company also offers material handling equipment like electric chain and wire hoists, electric trolley, electric and hand operated cranes, pulling lifting machine and various pallet trucks. The company exports its products to many countries in Africa.

MAXPULL MACHINERY & ENGINEERING Co.,LTD., established in 1976 and based in Chiba, Japan, is a manufacturer of types of industrial winches. The company produces a range of industrial electric winches for lifting and lowering heavy loads, to wind and unwind a wire rope and dual direction pulling. It also provides manual winches, stainless winch for harsh environments, winches designed for raising and lowering golf driving range and radio tower and custom made special winches for various other fields. The company offers to customise according to the use, capacity, method, size and quantity.

Speed Winch, established in 1978 and based in Shropshire, UK, is a manufacturer of commercial hand winches for transport trailers. The company offers 2 to 3 tons capacity winches, which are designed for either horizontal or vertical mounting, and can be installed with a polyester strap or a galvanised steel rope. These winches are primarily designed for transport trailers and boat trailers, but can also be adapted for agricultural and industrial applications. The company provides mounting kits for the winches and services old winch parts and custom built winches in large quantities.

Material Handling Systems, Inc., established in 1975, is a manufacturer of crane kits, end trucks, winches, trolleys, and accessories such as movement control pendants, variable frequency, and regulations safety enclosures used in aviation, marble & granite, manufacturing, marine, and nuclear industries. The company in Pompano Beach, IL, offers services such as crane repairs & modernization, hoist repairs, safety training, and crane runway alignment. More services include load testing, OSHA inspections, manufacturing, and engineering. The company is a member of the Crane Manufacturer Association of America and MHI.

Vestil Manufacturing Corp. is a manufacturer and distributor of material handling equipment, based in Michigan since 1957. The company produces equipment for various industries such as they make floor markers, speed bumps and car stops, etc. for Facilities Maintenance. Their hoists and trollies, drum handling equipment, carts, and dollies, and industrial ladders have applications in the agricultural, manufacturing, construction, and general marketing industries. Other than that scales, casters, wheels, packaging equipment, and similar items have uses in the postal services, hospitals, restaurants, and food production companies. Overall Vestil provides a solution to manage material handling in any department.

Nantong Allman Industry Co., Ltd. is a supplier of material handling equipment and lifting solutions. Established in 2012, the company is based in Nantong, Jiangsu, China. The company specializes in offering a range of material-handling equipment and lifting solutions. Its product range includes cranes, electric hoist, manual hoists, beam trolleys, and lifting magnets, serving industries such as construction, manufacturing, railway and logistics. Nantong Allman provides services like equipment customization, quality control, pre-sales and after-sales technical, and technical consultation.

Murphy Industrial Products, Inc. is a wholesale supplier of tie down, hauling, and lifting equipment that was established in Houston, Texas, USA, in 1968. The company offers cable or wire rope, block and pulley sets, and beam clamps for suspending or securing fixtures. It also offers load binders, lifting straps, and tie down chains for securing cargo onto heavy duty vehicles. The company’s products are used mainly by clients in the construction, transportation, and oil and gas industries.

Shupper-Brickle Equipment Co. (SBE) is an American supplier and distributor of material handling and lifting equipment that was established in 1969. Based in Clarksburg, New Jersey, the company stocks various hoists, winches, cranes, and fall protection systems. They offer products from more than 25 different brands including Harrington and Yale Hoists. SBE provides additional installation, inspection, and repair services, as well as engineering for products used in clean rooms or hazardous locations. They primarily serve clients in the marine, food service, mining, and pharmaceutical industries.

Meyer Material Handling was founded in 1974 and is headquartered in Indianapolis, Indiana. The company is a full-service material handling products and systems distributor, serving manufacturing, packing, and material handling industries. The company’s product categories include product moving equipment such as carts and shelf trucks, lifting and docking equipment, safety equipment, modular office and storage spaces, and more. The company also produces custom design equipment, assistance with integration and layout, CAD drawing preparation, and installation services.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Thern Incorporated. |

50.0%

|

| 2 | WPT Power Corporation |

50.0%

|

Derivation Method

The ranking is calculated based on the click share within the hand operated winch page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

12 | 66.7% |

China

China

|

5 | 27.8% |

India

India

|

1 | 5.6% |

36 products found

36 products

Shoji gear engineering

1200+ people viewing

Last viewed: 1 hour ago

A lineup of models compatible with 50-100kg load. Feature ・ Winding up/Return, holding the load when the steering wheel is stopped ・ Restart witho...

6 models listed

Maxpull Industries Co., Ltd.

230+ people viewing

Last viewed: 8 hours ago

■Features of rotary manual winch GM series Base grade of Maxpull manual winch. With a built-in mechanical brake, the load can be hoisted by turning...

Maxpull Industries Co., Ltd.

220+ people viewing

Last viewed: 15 hours ago

■Features of hot-dip galvanized manual winch GS series The surface of the steel body is hot-dip galvanized, and the bolts and nuts are made of SUS-...

Best Answer Co., Ltd.

190+ people viewing

With hook at the end. A movable hook at the tip makes it even easier to use. ■ Active in all situations It can be pulled in any direction: vertica...

Maxpull Industries Co., Ltd.

230+ people viewing

Last viewed: 13 hours ago

■Features of ratchet type manual winch MR series Since it has a ratchet type handle, it can be hoisted up and down by reciprocating movement from s...

Maxpull Industries Co., Ltd.

220+ people viewing

Last viewed: 16 hours ago

■Features of capstan type manual winch MC series This is a winch exclusively for horizontal pulling that can tow workpieces back and forth. It is n...

Maxpull Industries Co., Ltd.

240+ people viewing

Last viewed: 31 minutes ago

■Features of the reciprocating traction endless manual winch ME series This is the world's first reciprocating manual winch that uses a double drum...

Maxpull Industries Co., Ltd.

190+ people viewing

■Features of Mini Max Pull Winch A lightweight and compact mini winch developed for light work for personal use. Not suitable for heavy industrial ...

Maxpull Industries Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■Features of the small rotary manual winch 1LH series Important parts such as mechanical brakes are made to be robust using common parts with the G...

Toyo koken k.k.

240+ people viewing

Last viewed: 4 hours ago

■Summary Easily lift and lower 100 kg to 500 kg manually. Hand Mighty, with its compact design, is useful for lifting small loads such as departmen...

Maxpull Industries Co., Ltd.

190+ people viewing

Last viewed: 2 hours ago

■Features of industrial large manual winch series A large industrial manual winch unlike any other in the world. Two models are available with a te...

Maxpull Industries Co., Ltd.

200+ people viewing

Last viewed: 7 hours ago

■Features of the manual winch with built-in stopper (SI type) series Select this for use in places where there is a risk of incorrect operation if ...

Maxpull Industries Co., Ltd.

170+ people viewing

■Features of special electric winch series 35% of Max Pull Winch's total production is special winches. Special electric winches that are unique an...

Maxpull Industries Co., Ltd.

160+ people viewing

Last viewed: 31 minutes ago

■Features of the dust-proof and drip-proof manual winch (SIC type) series Like the SI type, the stopper arm that allows the drum to idle by releasi...

Maxpull Industries Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■Features of the stainless steel ratchet type manual winch (buffing) series Based on the stainless steel winch SB type (buffed) with a ratchet func...

Maxpull Industries Co., Ltd.

170+ people viewing

Last viewed: 5 hours ago

■Features of special manual winch series 40% of Max Pull Winch's total production is special winches. Special manual winches that are unique and ta...

Maxpull Industries Co., Ltd.

190+ people viewing

Last viewed: 3 hours ago

■Features of the stainless steel ratchet type manual winch (metallic paint) series Based on the stainless steel winch ST type (metallic paint), a r...

Maxpull Industries Co., Ltd.

160+ people viewing

Last viewed: 17 hours ago

■Features of special manual winch series 40% of Max Pull Winch's total production is special winches. Special manual winches that are unique and ta...

Maxpull Industries Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

■Features of the stainless steel ratchet type manual winch (electrolytic polishing) series Based on the stainless steel winch ESB type (electrolyti...

Maxpull Industries Co., Ltd.

190+ people viewing

Last viewed: 3 hours ago

■Features of special manual winch series 40% of Max Pull Winch's total production is special winches. Special manual winches that are unique and ta...

Maxpull Industries Co., Ltd.

200+ people viewing

Last viewed: 16 hours ago

■Features of stainless steel manual winch (buffing) series The unique beauty of stainless steel is the result of pursuing high performance, which h...

Maxpull Industries Co., Ltd.

140+ people viewing

Last viewed: 17 hours ago

■Features of special manual winch series 40% of Max Pull Winch's total production is special winches. Special manual winches that are unique and ta...

Maxpull Industries Co., Ltd.

170+ people viewing

■Features of the stainless steel manual winch (metallic paint) series Environments that look beautiful to the eye, such as oceans and marinas, are ...

Maxpull Industries Co., Ltd.

140+ people viewing

■Features of special manual winch series 40% of Max Pull Winch's total production is special winches. Special manual winches that are unique and ta...

Maxpull Industries Co., Ltd.

190+ people viewing

Last viewed: 10 hours ago

■Features of stainless steel manual winch (electrolytic polishing) series Highly controlled clean room equipment and research facilities. In such a...

weiwei Holdings Co., Ltd.

260+ people viewing

Last viewed: 3 hours ago

■Product details A versatile winch that can be used for a wide variety of purposes and can be operated freely from any angle, vertically, horizonta...