All Categories

History

This section provides an overview for measuring light curtains as well as their applications and principles. Also, please take a look at the list of 16 measuring light curtain manufacturers and their company rankings. Here are the top-ranked measuring light curtain companies as of December, 2024: 1.Blum-Novotest GmbH, 2.Saddle Brook Controls, 3.dieEntwickler Elektronik GmbH.

Table of Contents

Categories Related to Measuring Light Curtains

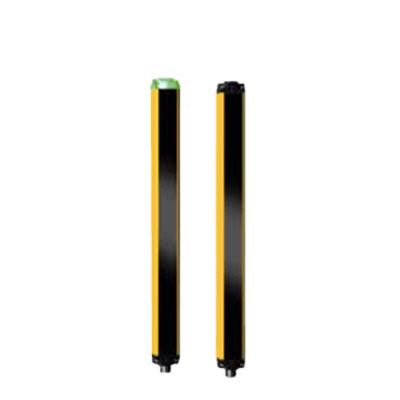

A measuring light curtain is a safety sensor that detects when a person or object enters the hazardous area of a machine or equipment.

They are sometimes also referred to as light grids. Light curtains are installed at entrances and exits of machinery without doors to provide time for the light to stop when it detects that the light beam has been interrupted. This happens at a distance where no person or object is in contact with the hazardous area.

Since the size of the smallest detectable object varies from device to device, it is crucial to select the appropriate one based on the size of the object to be blocked, the safety distance, and the installation site's height. Measuring light curtains typically use LEDs that emit infrared rays with a wavelength of about 900 nm, as the specified light source falls in the 400 nm to 1,500 nm wavelength range.

Measuring light curtains are commonly employed to enhance safety in manufacturing facilities with automated production processes, including metal processing, pharmaceuticals, food production, packaging, semiconductor manufacturing, transportation, and automotive industries.

When partitions or doors cannot be installed in hazardous operational areas, such as automated assembly machines, mounting machines, packaging equipment, printing machines, and line conveyor systems, they serve to monitor for the intrusion of workers' hands, fingers, arms, legs, other body parts, and obstructions.

Measuring light curtains consist of a floodlight and a receiver, installed as a set. The floodlight contains aligned projection elements, and the receiver also features aligned projection elements. They are positioned in parallel, allowing multiple parallel light beams emitted from the projector side to be received on the receiver side.

When the receiver side successfully receives all of the multiple beams emitted by the projector side, it is considered normal, and the machine or equipment's operation is allowed. If any part of the light path is blocked due to an intrusion, such as a worker's hand or leg, the system recognizes the situation as dangerous and halts the machine or equipment's operation.

The light curtain also includes a muting function, which differentiates between a workpiece passing through the detection area and a human body entering the detection area. It also has a blanking function, enabling the disabling of a specific portion of the detection area.

A wide variety of measuring light curtains are available from different manufacturers. To make the best selection, consider the following points:

The length of the main body of measuring light curtains should be suitable for the actual production site where they will be used. If it is too short, it may fail to detect if any part of a worker's body enters the hazardous area, potentially leading to accidents. Conversely, if it is too long, installation may become impractical.

Production sites often involve dust and other particles. If these particles adhere to the projector and receiver surfaces of measuring light curtains, the light receiver may fail to detect the projector's light properly, resulting in false danger alerts. Therefore, opting for water-resistant curtains simplifies maintenance.

Measuring light curtains rely on synchronized timing between the light emitted by the projector and the light received by the receiver to ensure safe monitoring. Two synchronization methods exist: wired synchronization, where the projector and receiver are connected by a synchronization wire, and optical synchronization, where they are connected optically by a synchronization wire.

Optical synchronization involves less wiring and is easier to manage, but generally, it is limited to a smaller number of light curtains to prevent false detection (interference) caused by light projectors from different measuring light curtains.

Measuring light curtains require the receiver to capture all the multiple lights emitted by the floodlight. This necessitates adjusting the position and angle of the projector and receiver, known as optical axis alignment. Additionally, it is important to check whether the curtain provides clear indications of which part of the receiver receives specific amounts of light and whether it is resistant to torsion, among other factors.

*Including some distributors, etc.

Sort by Features

Sort by Area

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

Wenglor Sensoric LLC is a supplier and manufacturer of smart sensor and image processing technologies and solutions. Established in 1983, the company is headquartered in Tettnang, Germany. The company's main activities encompass the design, manufacturing, and distribution of sensor solutions for automation and industrial applications such as Sensors, Machine Vision, Connection and Network Technology and Accessories. Wenglor Sensoric specializes in sensors for position, distance, color, and image recognition, catering to industries like automotive, packaging, and logistics. The company offers a range of services including technical support and consultation.

Applied Power Solutions is located in Addison, Illinois and serves the metal processing, metal service center, paper mills & paper converting, canning, grinding mills, commercial laundry, marine drives oil & gas, power take off clutches, and material handling markets as a parts distributor and service provider. Some of Applied Power Solutions’s product offerings include clutches & brakes such as centrifugal clutches and water cooled brakes, hydraulics such as accumulators and manifold systems, pneumatics such as actuators and valves, and power transmission parts such as bearings and safety mats.

Blum-Novotest GmbH, founded in 1968, is a manufacturer of high-precision measuring and testing equipment, headquartered in Grünkraut, Germany. The company's product line includes laser controls, probes, gauges, receivers, and measurement software. They also provide services such as retrofitting and repair. Additionally, they have partnered with TMAC, AutoComp, and Komflex to offer more systems and software. Blum-Novotest GmbH serves various industries, such as automotive and aerospace, through its measuring and testing technology. They ensure the accuracy and precision of machines and tools used in these industries, which is essential for the quality of the final products.

Die Entwickler Elektronik GmbH, established in 2013 and headquartered in Bad Zell, Germany, is a manufacturer of electronic components and automation programming. The company specializes in the development and manufacturing of electronic components and systems, offering a broad range of products including customized electronic controls, sensor solutions, and embedded systems. These unique solutions provide enhanced efficiency, precision, and automation capabilities for various industries. The products are equipped with stability and advanced features, making them ideal for applications in automotive, industrial automation, medical devices, and consumer electronics.

di-soric, founded in Urbach, Germany, in 1982 is a manufacturer of sensors that are used in industrial automation—primarily in assembly and handling technology, in the automotive, electronics and pharmaceutical industries. The company's product portfolio includes Temperature Sensors, Pressure Sensors, Proximity Sensors, Level Sensors and Motion Sensors. Their products are used in industrial automation, Consumer Electronics, medical devices and patient monitoring systems and the energy sector for monitoring and optimizing energy consumption. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

Dongguan Dadi Electronic Technology Co., Ltd., established in 2006, based in Dongguan, China, is a manufacturer and supplier of infrared sensors and safety light curtains. The safety light curtains include measurement & automation light curtains, multi-area safety light curtains, and accessories such as support columns, deflection mirrors, curtain controllers, adjustable brackets, and customizable cables. The sensors are ultrasonic sensors, color sensors, laser displacement sensors, photoelectric sensors, and slot-type sensors. The company also offers vehicle separators, safety laser scanners, mechanical bolts for safety switches, as well as safety relays. The company is certified by CE, TUC, RoHS, and ISO 9001.

Shenzhen Xaori Technology Co., Ltd., founded in 2008 and located in Guandong, China, is a manufacturer of safety light curtain sensors, laser sensors, flow sensors, human body detection sensors and various other industrial sensors. The product line features advanced safety technology designed to enhance workplace safety and productivity. The safety light curtain sensors provide real-time monitoring, detecting and preventing unauthorized access to hazardous areas in industrial settings. Laser sensors offer precision and accuracy in measurement applications, ensuring optimal-quality output. These sensors find applications across diverse industries, including manufacturing, automotive, robotics, and pharmaceuticals, where worker safety and process efficiency are paramount.

ReeR S.p.A., founded in 1959 in Turin, Italy, is a manufacturer of optoelectronic sensors and controllers for industrial safety. Its products, including laser scanners, contactless interlocks, and photocells, are essential in manufacturing, robotics, automotive, and packaging industries. The company's innovation culture and adherence to ISO9001 specifications lead to the highest level of protection for workers and equipment and make products appealing to global clients. ReeR S.p.A provides technical support and know-how for clients to select, install, and maintain safety solutions.

Leuze was founded in Owen/Teck in Southern Germany in 1963 as a manufacturer of sensors. The company's product range encompasses switching and measuring sensors, identification systems, data transmission, and image processing solutions which are further classified as optical sensors, inductive switches, area scanners, IP cameras, and various cables and connectors. They serve a broad spectrum of industries including machine tools, packaging, automotive, intralogistics, and laboratory automation where they provide sensor solutions for various processes

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

TR Electronic, established in 1984 in Trossingen, Germany, is a manufacturer of encoders and industrial automation equipment. The company specializes in absolute encoders, sensors, measuring technology, monitoring, and control systems, as well as machine lighting solutions. The product range includes several optimal-precision encoders and sensors for accurate position and measurement data. These devices offer stability, durability, and optimum-resolution output, making them essential components in manufacturing, automation, robotics, and automotive. The monitoring and control systems result in process optimization and efficiency.

Saddle Brook Controls is a division of Ribble Engineering, which was founded in 1933 in Saddle Brook, New Jersey. Saddle Brook Controls is a manufacture as well as a designer, distributor, and support service provider of automation solutions for factory automation. Product groups include PLCs, controllers, Remote IO devices, HMIs, industrial computers, machine vision and inspection machines, motion devices, drives, motor controls, enclosures, circuit breakers, safety products, sensing and control products, power supplies, and UPS.

Advanced Fluid Systems was founded in 1985 and is based in York, Pennsylvania. The company is a distributor of fluid systems and provides planning, designing, engineering, and manufacturing services for customers. The company serves power generation facilities, industrial and manufacturing, and marine and mobile markets. The company has 7 product lines, ranging from simple motion controls to integrated manifolds, all the way up to hydraulic systems and power units, and power generation solutions. The company’s field services include installation, preventative maintenance, and repair.

GZ Cyndar Co., Ltd., a multinational corporation headquartered in Guangzhou, China, was founded a decade ago and specializes in offering advanced smart sensors and industrial automation technology solutions on a global scale. GZ Cyndar Co., Ltd. is an internationally recognized company that provides advanced smart sensor and industrial automation technology solutions worldwide. Cyndar emphasizes providing professional smart sensor solutions with a solid devotion to delivering quality products, tailored system integration, and effective cost management.

Ranking as of December 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Blum-Novotest GmbH |

15.6%

|

| 2 | Saddle Brook Controls |

12.5%

|

| 3 | dieEntwickler Elektronik GmbH |

9.4%

|

| 4 | Applied Power Solutions |

9.4%

|

| 5 | Banner Engineering Corporation |

9.4%

|

| 6 | Omron |

9.4%

|

| 7 | wenglor sensoric LLC |

6.3%

|

| 8 | Advanced Fluid Systems, Inc. |

6.3%

|

| 9 | Leuze electronic GmbH + Co. KG |

6.3%

|

| 10 | Shenzhen Xaori Technology Co., Ltd. |

3.1%

|

Derivation Method

The ranking is calculated based on the click share within the measuring light curtain page as of December 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

4 | 33.3% |

United States of America

United States of America

|

3 | 25.0% |

Germany

Germany

|

3 | 25.0% |

Austria

Austria

|

1 | 8.3% |

Italy

Italy

|

1 | 8.3% |

430 products found - Page 2

430 products - Page 2

Komori Safety Device Lab Co.,Ltd

30+ people viewing

Last viewed: 24 minutes ago

■Safe and easy-to-understand functions Equipped with an LED indicator that allows you to see at a glance whether light is passing through or blocki...