All Categories

History

This section provides an overview for worm gear speed reducers as well as their applications and principles. Also, please take a look at the list of 22 worm gear speed reducer manufacturers and their company rankings. Here are the top-ranked worm gear speed reducer companies as of March, 2026: 1.Dalton Gear Company, 2.Candy Manufacturing Co., Inc., 3.Superior Gearbox Company.

Table of Contents

Categories Related to Worm Gear Speed Reducers

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

A worm gear speed reducer is a device that utilizes a worm gear as its reduction mechanism.

A speed reducer is a device that takes the rotational output of an electric motor or another rotary power-generating device as its input and reduces its rotational speed while increasing its torque. The reduction mechanism comprises various types of gears. One of these gear types is the worm gear, which is a combination of a worm (worm shaft) and a worm wheel.

Other types of reduction gears include spur gear reduction gears, which are commonly used, bevel gear reduction gears, and miter gear reduction gears that consist of bevel gears with orthogonal gear shafts, and planetary gear reduction gears that combine three types of spur gears (sun gears, planetary gears, and internal gears).

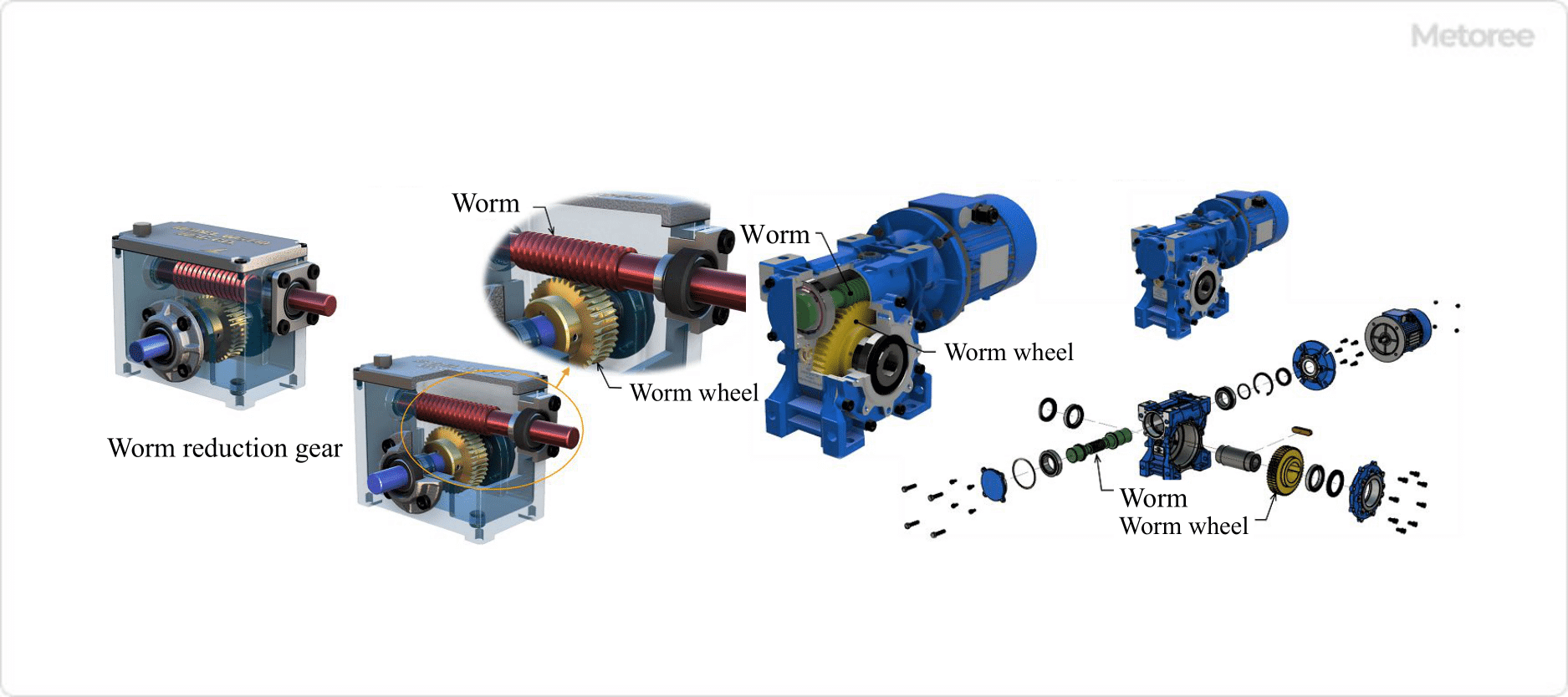

Refer to Figure 1 below for the structure of a Worm Gear Speed Reducer.

Figure 1. Structure of worm reduction gear

Worm gear speed reducers, like other reduction gears, are capable of moving large objects with minimal force. As a result, they are commonly used in factory equipment and machinery for power transmission.

Specific Applications of Worm Gear Speed Reducers include:

Worm gear speed reducers find use across various industries and applications, particularly in the following situations:

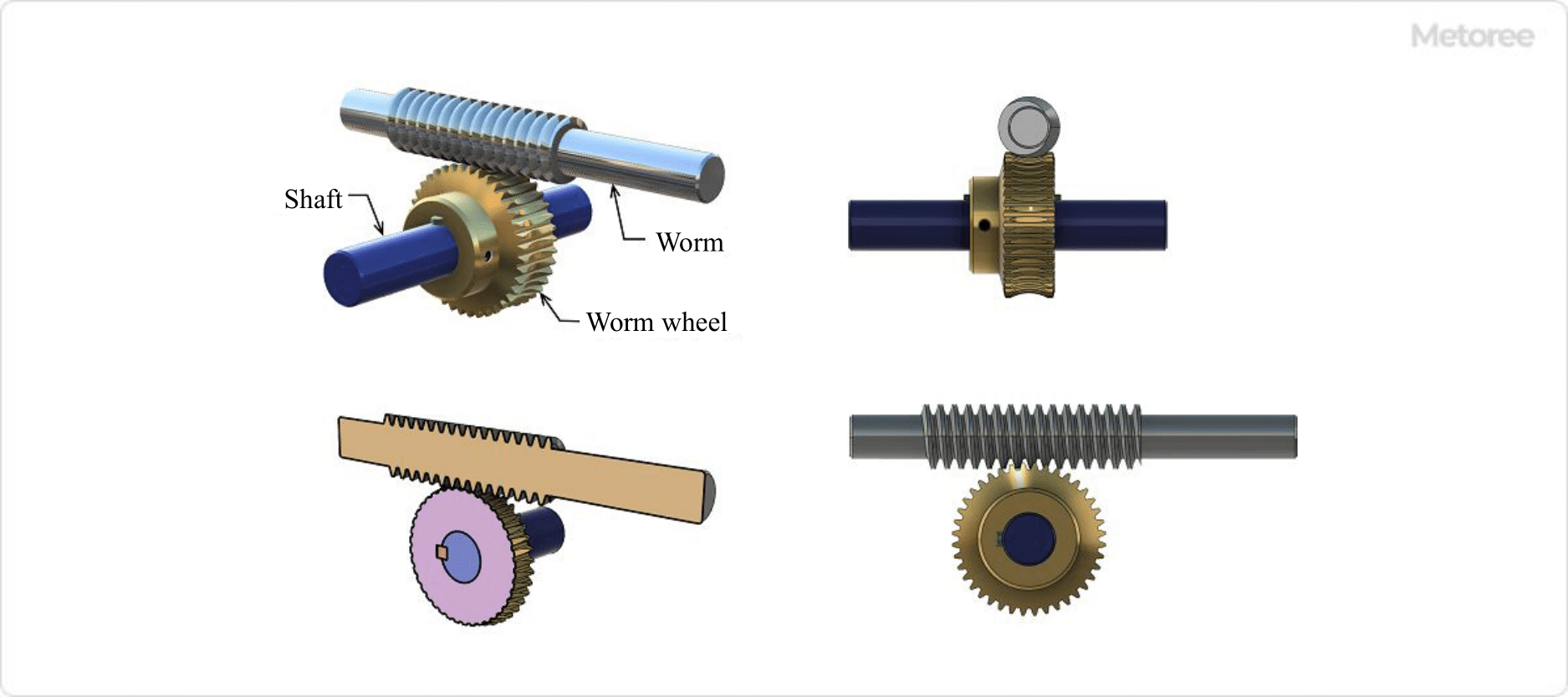

Figure 2. Principle of worm gear

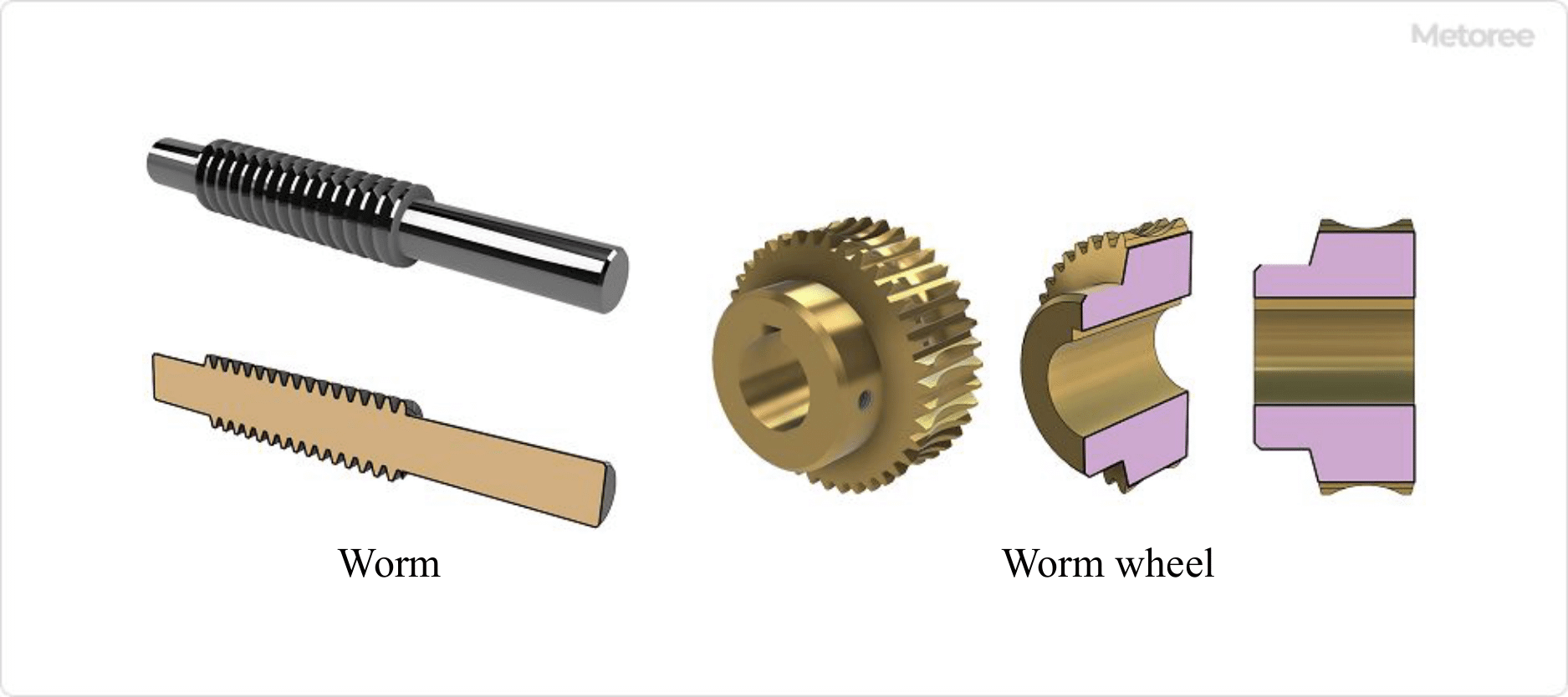

A worm gear speed reducer employs a gear mechanism consisting of a worm (worm shaft or worm axle) and two types of worm wheels.

Figure 3. Worm gear assembly

The worm, a type of screw gear, rotates to push the teeth of the worm wheel, causing it to rotate as if a wedge is being driven into it. When the worm (input side) completes one revolution, the worm wheel (output side) advances by one tooth.

In this context, one set of worm teeth equals one tooth. For example, a worm with two worm teeth means that one rotation of the worm results in a two-tooth rotation of the worm wheel.

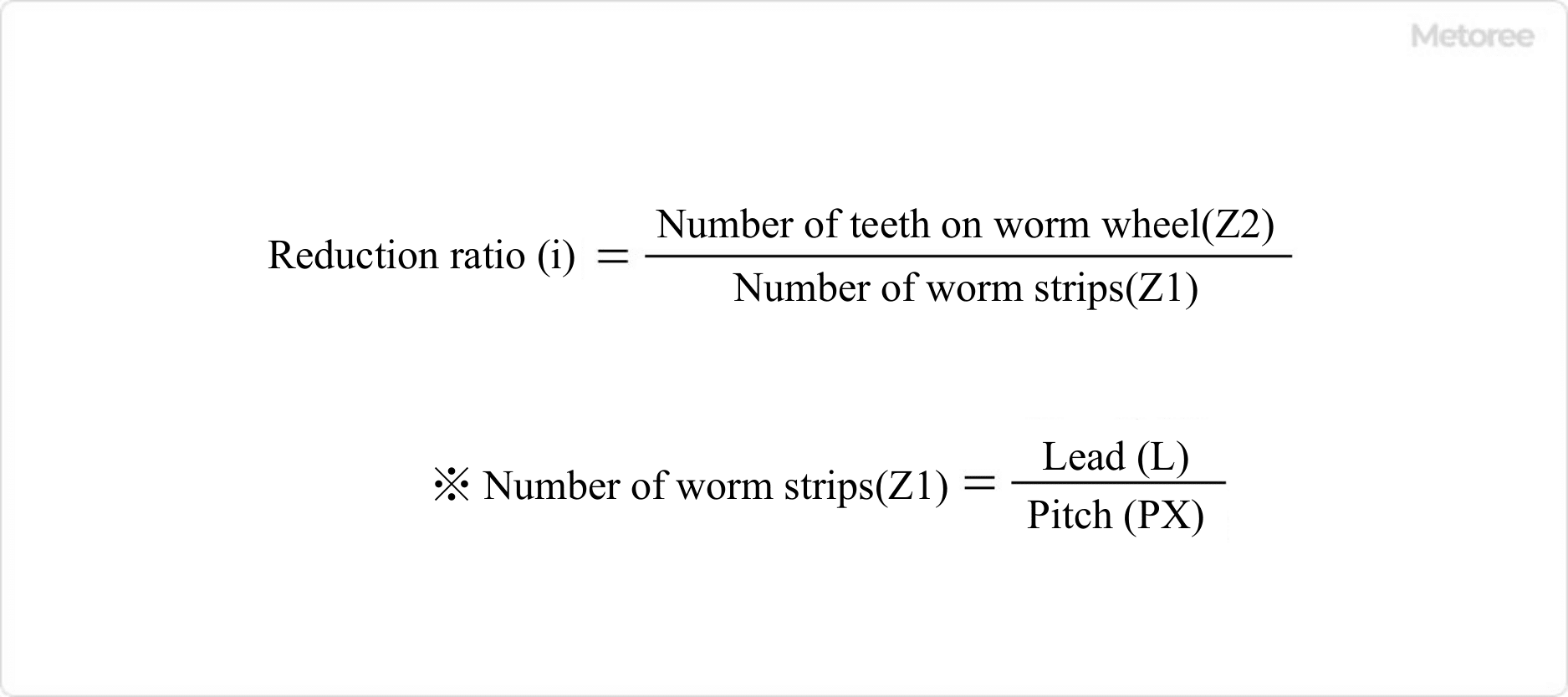

The reduction ratio of a worm gear can be calculated as follows:

Figure 4. Reduction ratio of worm gear

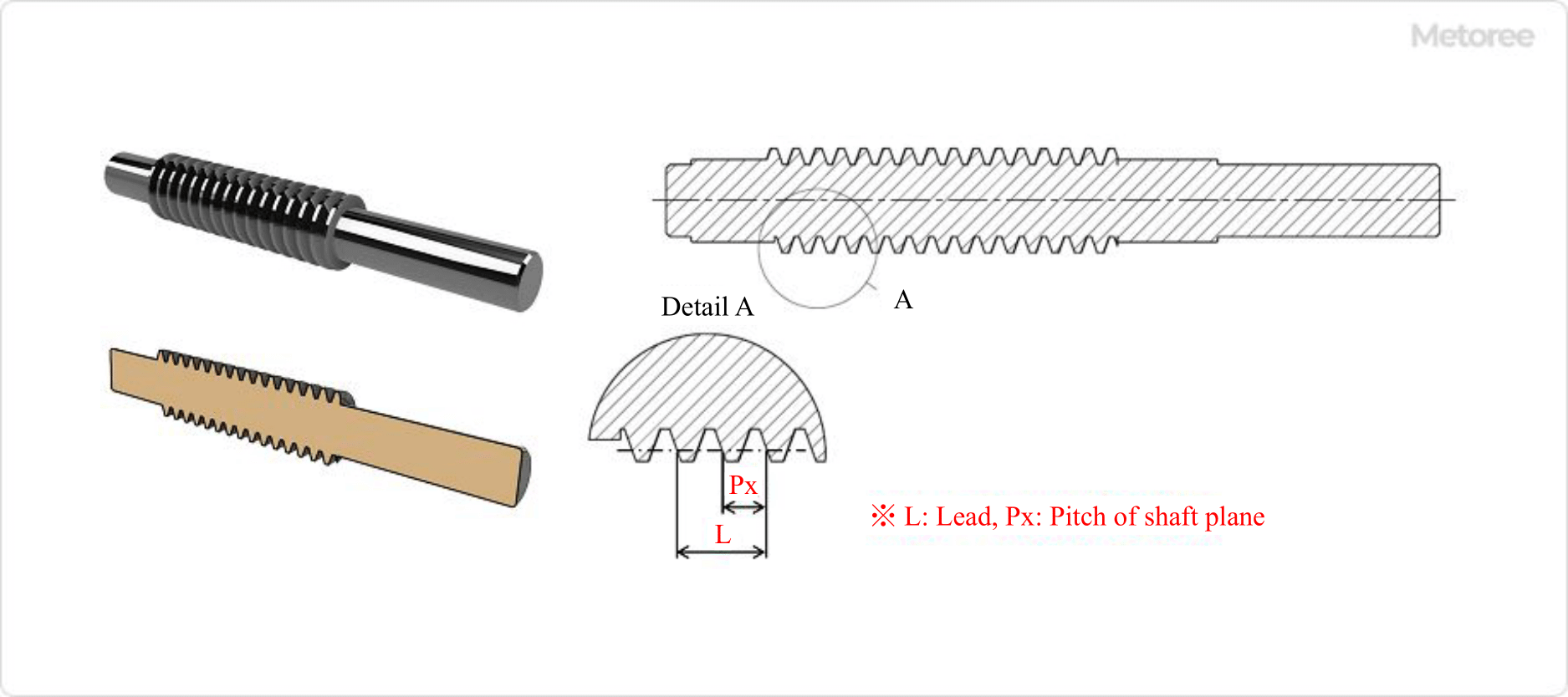

Refer to Figure 5 below for worm dimensions.

Figure 5. Worm dimensions

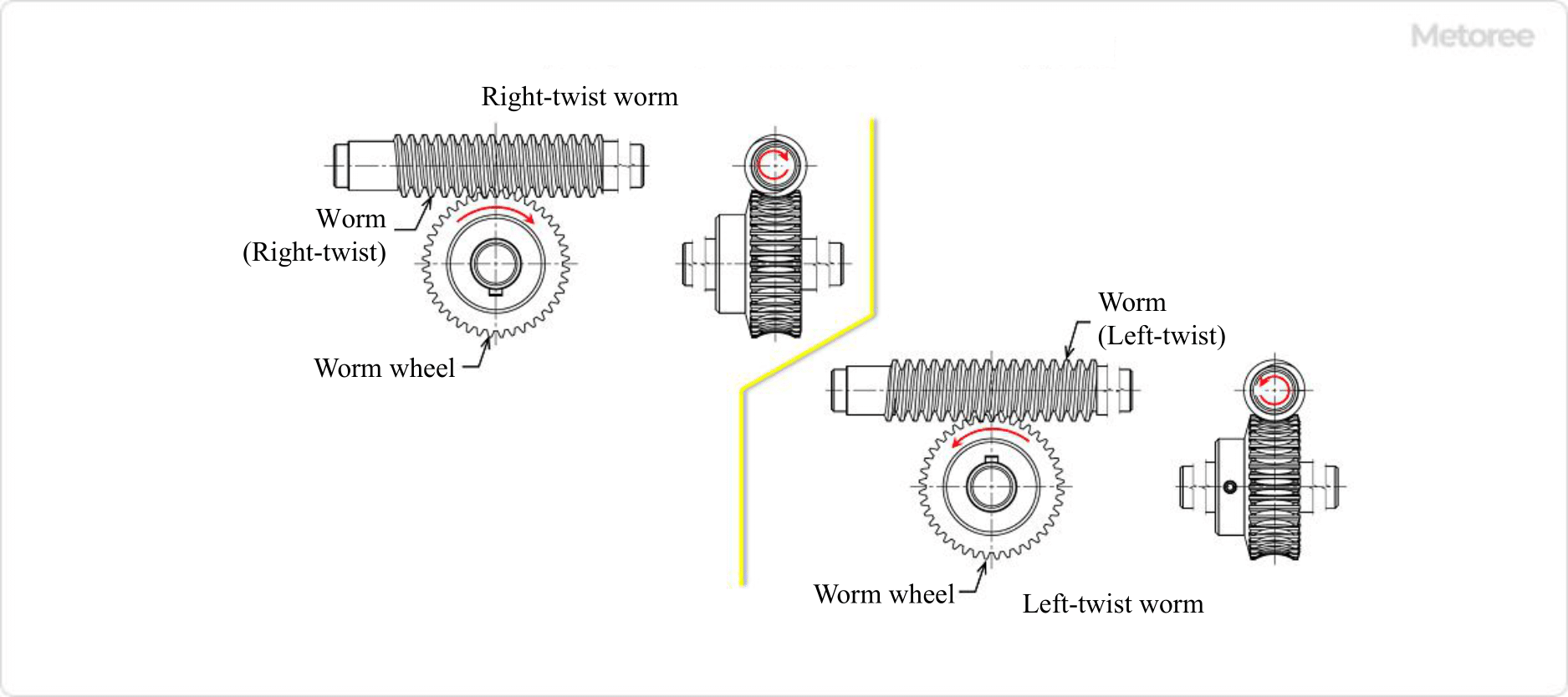

The worm gear can rotate in both directions (clockwise and counterclockwise when viewed from the input shaft side). This direction can be determined by selecting the right-hand or left-hand twist direction for the worm. The same rotation of the worm will result in the opposite rotation direction of the worm wheel. Refer to Figure 6 below for the worm twist direction and worm wheel rotation direction.

Figure 6. Direction of worm twist and worm wheel rotation

A worm gear speed reducer possesses six significant features:

Single-stage gears (comprising one worm and one worm wheel) can achieve high reduction ratios, reaching 1/60 or even 1/120 for specialized gears.

The input and output shafts are orthogonal to each other, meaning they lack a coaxial direction.

The direction of rotation for the output shaft, connected to the worm wheel, can be altered by selecting either the left or right worm twist direction.

Input and output shafts can be installed in four directions on one or both sides.

The worm side (input shaft side) can rotate the worm wheel side (output shaft side), but the reverse is not true, thanks to the self-locking effect.

The meshing of the worm and worm wheel provides greater slippage due to linear contact, resulting in lower noise and vibration compared to spur gears, bevel gears, or other rolling transmissions.

One drawback of worm gear speed reducers is their large contact surface on the meshing tooth flanks, which can lead to seizing. To mitigate this, the worm is typically made of alloy steel or other hard materials that undergo heat treatment, while the worm wheel is crafted from copper alloy, cast iron, or other low-hardness materials to reduce friction.

*Including some distributors, etc.

Sort by Features

Sort by Area

Lexar Industrial, established in 1996 and headquartered in Pennsylvania, USA, is a manufacturer of industrial fasteners and tools. The company specializes in manufacturing speed reducers, driver bits, machine couplings, and industrial-grade fasteners. It has obtained ISO 9001:2015 certification for the precision and durability of its products. The benefits of its products include enhanced machinery performance, increased operational efficiency, and long-lasting durability. These products find applications across various industries, including manufacturing, automation, construction, and agriculture. It also makes electrical, woodworking and constructional fasteners of Grade 5 and Grade 8.

Candy Manufacturing Co., Inc., headquartered in Niles, Illinois, has been a manufacturer and supplier specializing in automation and rotary motion control components since 1960. The company offers a diverse range of products, including planetary gearheads for applications requiring high torque, zero-backlash couplings that connect shafts without backlash, spiral bevel gearboxes for power transmission at right angles, and foot and shaft-mounted differentials used in vehicles to enable differential wheel speeds. Additionally, the company, which is ISO 9001:2015 QMS Certified, provides phase-adjusting couplings for modifying the phase relationship between rotating shafts.

Control Concepts, Inc. was established in 1951 and is a manufacturer of material flow aids headquartered in Brookly, Connecticut. The company offers four main products: AirSweep, AcoustiClean, DAZIC, and RotoGuard. AirSweep ensures on-demand flow, AcoustiClean Sonic Horns replaces manual cleaning, and DAZIC and RotoGuard Speed Switches prevent expensive equipment pileups. The products have been served to food, cement, and mined materials industries. The company has tens of thousands of systems installed worldwide, and clients that include both S&P companies and SMEs.

Superior Gearbox Company, founded in 1975 and based in Stockton, Missouri, is a manufacturer of gearboxes and gear drives for power transmission systems. Its range of drives includes bevel, worm gear, right angle, and spindle for various applications in diverse industries such as agriculture, heavy trucks, construction, marine, and sports equipment. The company’s quality control and customer-intensive service are strengths that ensure every product is of a high standard and can deliver excellent service. Additionally, the company’s ability and willingness to custom engineer products enables it to serve customers with specific needs.

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Harmonic Drive LLC, established in 1960, is a manufacturer of precision servo actuators, gearheads, and gear component sets, headquartered in Massachusetts. They offer customized motion control solutions for companies of all sizes, with a strong emphasis on engineering and production. Their strain wave gears and Harmonic Planetary gears are known for their high precision and zero backlash, playing critical roles in applications like robotics, aerospace, medical equipment, and more. With over 60 years of experience, Harmonic Drive has ISO 9001 and AS9100 certifications. They have manufacturing facilities in the US, Japan, and Germany.

Dalton Gear Company was formed in 1955 and is headquartered in Minneapolis, Minnesota. The company is a manufacturer of custom and standard gears related to machined parts for domestic and international customers. The company’s standard parts include overload safety devices, worm gear reducers, and drive tensioners & idler sprockets. The company’s customized manufacturing is accomplished using CNC machining with capabilities including machine centers and CNC lathes with accuracy down to 0.0005 inches, and additional operations such as grading and honing.

Cleveland Gear Company, Inc. was founded in 1912 and is headquartered in Cleveland, Ohio. The company is a manufacturer of gears, speed reducers, and other parts for industries such as manufacturing, mining, and packaging. The company has four product and service categories: Enclosed Drives, Open Gearing, Custom Drives, and Field Service & Rebuilds. Enclosed Drives include modular gear products, larger enclosed drive products, and helical enclosed drive products. Open Gearing includes Master Worm Systems and services such as case hardening. Custom drives are produced according to industry need such as rubber production and mineral processing.

Circle Gear & Machine Co., Inc., established in 1951 and based in Illinois, USA, is a manufacturer of gears and gearboxes. The company manufactures a range of gears including bevel, helical and worm gear for automotive, construction, chemical and other industries. It provides reverse engineering for gear and gear boxes, from worn samples, prints or sketches, along with rebuild, repair and emergency services. The company has a quality management system in compliance with ISO 9001:2015, and has a complete inspection lab with CMM(Coordinate Measuring Machine).

B&H Machine Sales was founded in 1939 and is headquartered in Detroit, Michigan. The company is a machine designer that assists manufacturers with fabrication, repair, and machining services for many industries. The company has a selection of many new, used, and remanufactured power transmission components such as bushings, variable speed drives, and gear heads from brands such as Winsmith, Sumitomo, Cleveland, Dodge, and ABB. The company can repair, rebuild, and redesign new and existing customer products to meet customer’s changing needs.

MRO Supply was established in 1898 in Los Angeles as a supplier and distributor specializing in general mill products like hose, packing materials, industrial lubricants, and various rubber goods. The company is an online extension of Mechanical Drives & Belting that carries forward this legacy providing customers with a convenient e-commerce platform to access a wide range of industrial products, tools, and equipment including motors, bearings, gears, sprockets, and many more.

Worldwide Electric Corporation, established in 1998 in the United States, is a manufacturer and distributor specializing in electric motors and related products. The company offers an extensive range of industrial-grade motors and controls, serving diverse sectors. With a rich history of innovation, Worldwide Electric Corporation has been a pioneer in electric motor technology. Their priority is to provide efficient solutions for a wide range of industrial applications, from manufacturing to agriculture. Worldwide Electric Corporation's unique selling point lies in their devotion to quality and customer satisfaction. For example, their premium efficient motors optimize energy usage, reducing operational costs while maintaining high performance.

Midwest Power Products, founded in 1992 and headquartered in Miami, Florida, USA, is a distributor of gear reducers, gear drives, electric motors, and power transmission equipment. The company offers a broad range of optimal-quality products designed to enhance the efficiency and performance of industrial machinery and systems. It has earned ISO 9001, CE, and RoHS certifications to ensure the optimum quality of the products from certified manufacturers. These products help increase productivity, reduce maintenance costs, and improve overall operational efficiency across diverse industries such as manufacturing sectors, agriculture industry, construction, automotive and several more.

Bearings Industrial Supply Company, Inc (BIS) was founded in 1982 in Addison, Illinois. The company is a supplier and distributor of bearings, seals, belts, power transmission parts, and a variety of other industrial supplies to small and large customers such as Boeing and Toyota. The company isources from manufactureres such as Emerson, KOYO, Tsubaki, NTN, and Timken. The company's offerings include numerous types of bearings, many varieties of seals, several different belts, AC and DC motors, and power transmission components.

Gainesville Industrial Electric Co. (GIE) was founded in 1959 in Gainesville, Georgia, where it remains today. GIE is an independent, EASA-approved, motor repairer and distributor. GIE offers electric motors from Marathon and GE, FPS Pumps, Barlow Pumps, Gould Pumps, gearboxes from Hub City Gearboxes and Bearings and Motovario Gearboxes and Motors, and variable frequency drives and inverters from Mitsubishi Inverters and TECO Westinghouse. GIE also offers repair services and is a factory authorized warranty center.

Dietz Electric was founded in 1974 and is based in Milwaukee, Wisconsin. Dietz Electric is a broad-line stocking distributor offering electric motors, drives, and power transmission products. Dietz Electric also offers customization options to test, manufacture, modify, and repair all product offerings. Product offerings include electric motors, hazardous locations motors, custom electric motors, variable frequency drives, motor controls, power transmission solutions, and specialty items such as purge systems, Uras vibrators, disc brakes, transformers, and AC line reactors.

EED is a researcher, manufacturer and supplier of speed reducers that was established in 1984 and is headquartered in Hangzhou, China. The company designs, manufactures, and supplies various electric motors and generators, including AC motors, DC motors, and generators. Its products are used in many industries, including aerospace, photovoltaic, logistics and warehousing, solar power, lifting sector and commercial. The company boasts 3 certifications, CE, ISO, SGS, and 19 intellectual property rights as well as more than 20 production lines The company also offers technical support, installation, and training services to ensure efficient utilization of its products.

Saddle Brook Controls is a division of Ribble Engineering, which was founded in 1933 in Saddle Brook, New Jersey. Saddle Brook Controls is a manufacture as well as a designer, distributor, and support service provider of automation solutions for factory automation. Product groups include PLCs, controllers, Remote IO devices, HMIs, industrial computers, machine vision and inspection machines, motion devices, drives, motor controls, enclosures, circuit breakers, safety products, sensing and control products, power supplies, and UPS.

Jamieson Equipment Company (JEC) was founded in 1982 and located in the state of Georgia. JEC serves infrastructure-related industries including pavement with concrete, aggregate, and asphalt, chemicals, sewage and waste management, and agriculture and food. JEC sells, installs, retrofits, repairs, and offers training and troubleshooting for a range of components and tools from simple fittings to motion sensors to electronics to valves to actuators, cranes, mixers, silos, hoppers, and plants.

Tri-State Bearing Company was founded in 1950 and is headquartered in Evansville, Indiana. The company is an independently owned and operated distributor of a full line of bearings, mechanical power transmission, and motion control products to customers across North America in the agricultural, automotive, manufacturing, and pharmaceutical industries. The company has several product lines such as chains & sprockets, clutches & breaks, and couplings in addition to its namesake of bearings. The company also offers services such as custom-length modifications of certain components such as roller chains, electronic repair of drivers and controllers, and on-site gearbox assembly.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Dalton Gear Company |

14.5%

|

| 2 | Candy Manufacturing Co., Inc. |

11.1%

|

| 3 | Superior Gearbox Company |

9.4%

|

| 4 | Stock Drive Products/Sterling Instrument - SDP/SI |

7.7%

|

| 5 | Lexar Industrial |

6.8%

|

| 6 | Harmonic Drive LLC |

5.1%

|

| 7 | Circle Gear & Machine Co., Inc. |

5.1%

|

| 8 | Cleveland Gear Company |

5.1%

|

| 9 | MRO Supply |

4.3%

|

| 10 | Control Concepts, Inc. |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the worm gear speed reducer page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

16 | 88.9% |

Japan

Japan

|

1 | 5.6% |

China

China

|

1 | 5.6% |

116 products found

116 products

MIKI PULLEY CO., LTD.

240+ people viewing

Last viewed: 23 hours ago

Induction motors, which are generally used as power sources for industrial machinery, rotate at relatively high speeds, so a reduction mechanism is...

10 models listed

Soritz Co., Ltd.

320+ people viewing

A compact, low-cost worm gear reducer used in a variety of fields. ■Summary With more than 20 years of experience in gearbox design and manufactur...

Maxinco Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

NIPPON GEAR CO., LTD.

450+ people viewing

Last viewed: 1 day ago

■Summary The H-type valve actuator is a 90 degree rotation worm reducer designed to be attached to large butterfly valves, etc. A helical gear atta...

Auma Japan Co., Ltd.

330+ people viewing

In addition to being used for manual valves, we also have multi-turn and part-turn types that can be easily installed on valves that require large ...

5 models listed

MIKI PULLEY CO., LTD.

300+ people viewing

Induction motors, which are generally used as power sources for industrial machinery, rotate at relatively high speeds, so a reduction mechanism is...

10 models listed

ISL Products International.

260+ people viewing

Last viewed: 20 hours ago

■High Torque in Small Packages Products’ Worm Gear Motors are designed to generate high torque in a small package size. Worm Gear Motors consist o...

Maxinco Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

Maxinco Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

NIPPON GEAR CO., LTD.

480+ people viewing

Last viewed: 15 hours ago

■Summary The HB type valve actuator is a 90 degree rotation (or less) worm reducer designed to be attached to butterfly valves, plug valves, etc. ...

Maxinco Co., Ltd.

310+ people viewing

Last viewed: 14 hours ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

Nidek Drive Technology Co., Ltd.

660+ people viewing

Last viewed: 5 hours ago

■Precision orthogonal reducer for servo Manufactured by Nidec Graessner (Germany) ■Features Orthogonal, high capacity, thin and compact, high outp...

NIPPON GEAR CO., LTD.

470+ people viewing

Last viewed: 15 hours ago

■Summary The W-type valve actuator is a multi-rotation type worm gear reducer. Used as an operating device for lifting stem valves and gates that r...

Maxinco Co., Ltd.

310+ people viewing

Last viewed: 21 hours ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

MIKI PULLEY CO., LTD.

270+ people viewing

This is a series that combines a highly efficient and compact solid-shaft worm reducer as the central module with a motor and a belt-type continuou...

2 models listed

Maxinco Co., Ltd.

360+ people viewing

Last viewed: 10 hours ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

Maxinco Co., Ltd.

310+ people viewing

Last viewed: 11 hours ago

Worm reducer ■Next-generation worm reducer required by the times With the technology and know-how accumulated over many years and a wealth of exper...

Nidek Drive Technology Co., Ltd.

430+ people viewing

■Precision orthogonal reducer Manufactured by Nidec Graessner (Germany) ■Features A small type of POWER GEAR. Orthogonal, compact, low reduction r...

Nidek Drive Technology Co., Ltd.

430+ people viewing

■Orthogonal reducer for high-speed input Manufactured by Nidec Graessner (Germany) ■Features Orthogonal, high-speed input, low reduction ratio, hi...

Soritz Co., Ltd.

350+ people viewing

This is a compact, low-cost, low-noise NEW series motorized speed reducer that is used in a wide range of fields.

Nidek Drive Technology Co., Ltd.

520+ people viewing

Last viewed: 13 hours ago

■Precision orthogonal reducer for servo Manufactured by Nidec Graessner (Germany) ■Features Orthogonal, high capacity, low reduction ratio, high o...

Nidek Drive Technology Co., Ltd.

480+ people viewing

Last viewed: 4 hours ago

■Precision orthogonal reducer for servo Manufactured by Nidec Graessner (Germany) ■Features Orthogonal, lightweight, low cost model of DYNAGEAR ■...

MIKI PULLEY CO., LTD.

420+ people viewing

Last viewed: 1 day ago

This is a series that combines a highly efficient and compact hollow-shaft worm reducer as the central module with a motor and a belt-type continuo...

4 models listed

Maxinco Co., Ltd.

530+ people viewing

Last viewed: 8 minutes ago

Differential gear box Differential gear type phase adjustment device DFA series ■Differential gear type phase adjustment device that controls timin...

NIPPON GEAR CO., LTD.

440+ people viewing

■Summary The CWG series is an economical and compact worm gear reducer for general industries such as water supply, sewerage, and steel, developed ...

Coretech Co., Ltd.

310+ people viewing

Last viewed: 4 hours ago

■Features ・In-line type self-locking reducer. - Built-in newly developed bidirectional self-locking mechanism that is resistant to vibration. ・Co...

4 models listed

Nidek Drive Technology Co., Ltd.

510+ people viewing

Last viewed: 13 hours ago

■Precision orthogonal reducer for servo Manufactured by Nidec Graessner (Germany) ■Features Orthogonal, thin and compact, high output, high rigidi...

Nidek Drive Technology Co., Ltd.

670+ people viewing

■Precision orthogonal reducer for servo Manufactured by Nidec Graessner (Germany) ■Features Orthogonal, high precision, thin and compact, high out...