All Categories

History

This section provides an overview for worm gears as well as their applications and principles. Also, please take a look at the list of 36 worm gear manufacturers and their company rankings. Here are the top-ranked worm gear companies as of March, 2026: 1.Dalton Gear Company, 2.Martin Sprocket & Gear, Inc., 3.Cleveland Gear Company.

Table of Contents

Categories Related to Worm Gears

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

Worm Gear is a type of screw gear.

It consists of a worm (worm shaft), which is a threaded toothed shaft, and a worm wheel, which is a helical helical gear with its axis of rotation at 90 degrees to the worm's axis. Rotation of the worm sends the teeth of the worm wheel, which are meshed with the worm, to rotate.

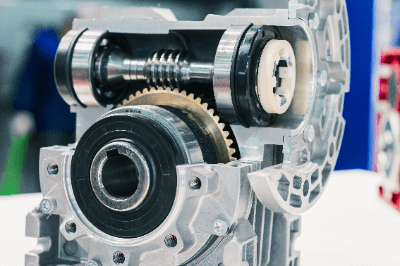

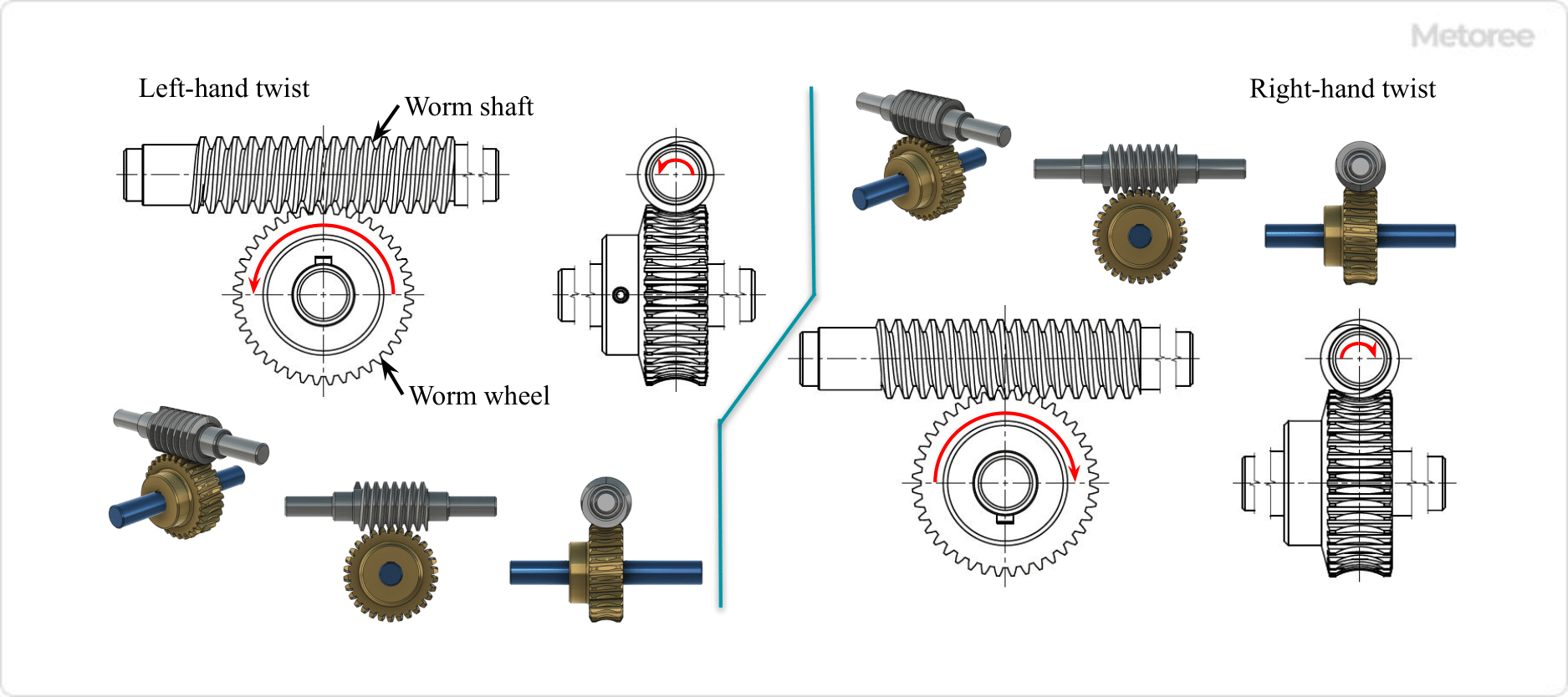

See Figure 1 for the configuration of Worm Gear.

Figure 1. Structure of worm gear

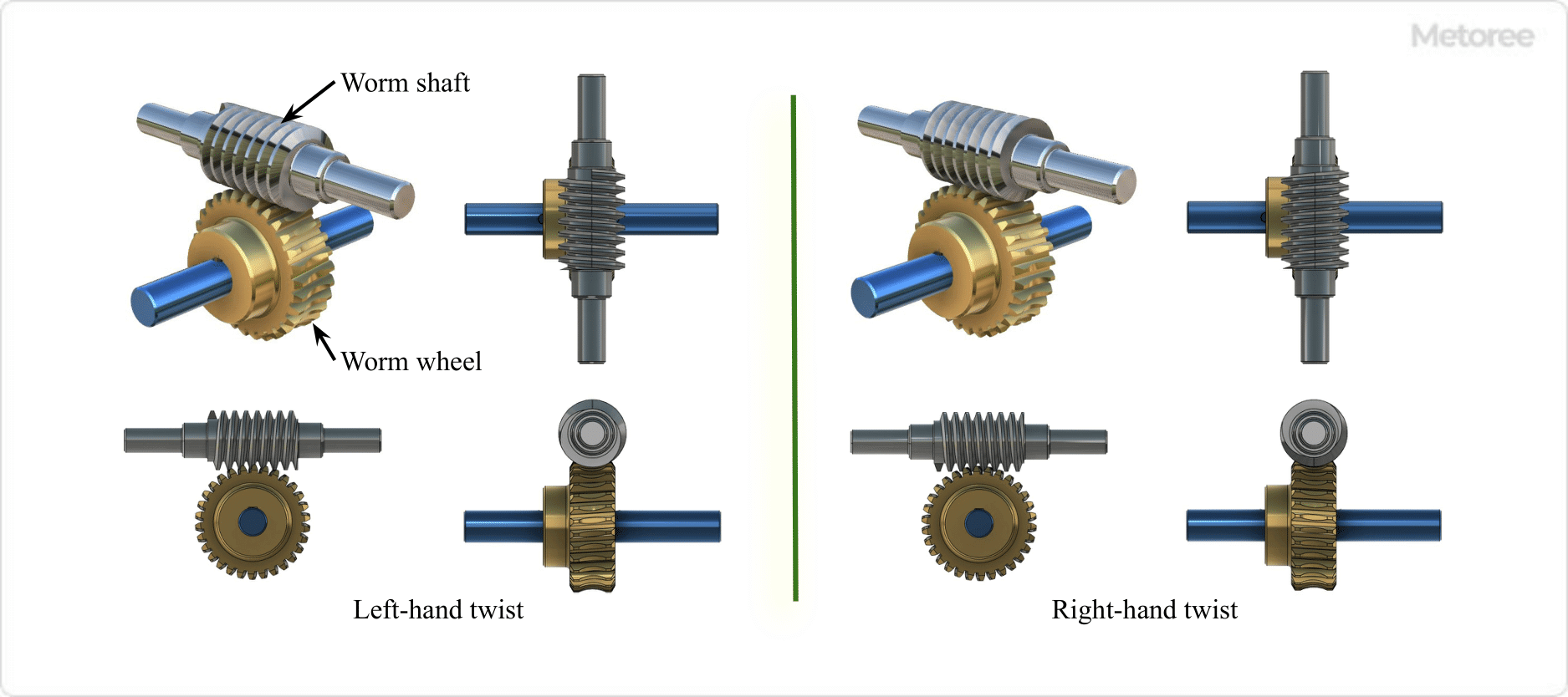

Figure 2. Example of worm gear use

Worm Gears are orthogonal shafts that can transmit power by changing the axial direction by 90 degrees, and can produce a large reduction ratio even when the gears are small. As a result, worm gears are used in a variety of fields and devices, such as conveyor belts in factory equipment, screw jacks, steering systems for automobile steering wheels, wiper drives, pivoting mechanisms for electric fans, material feeders in food and drug manufacturing equipment, music boxes, and stringed musical instrument pegs.

A familiar example is the peg around which the strings of a stringed instrument such as a guitar or bass are wound. The peg consists of a worm shaft, which is twisted by hand, and a worm wheel, which winds the strings around it. The self-locking function ensures that the wound strings are held in place without loosening.

Worm reduction gears are capable of moving large objects with little force and are incorporated into factory equipment and machinery for power transmission. For example, they are used in the drive units of presses and rolling mills, medium- and low-speed elevators, escalator lifting and lowering drives, and conveyor drives.

Worm Gears' self-locking function may be utilized in the reduction devices of elevators and escalators to serve as a safety device to prevent reverse rotation. In general, worm reduction gears are used to configure equipment in industrial applications. They can provide particularly large reduction ratios, enabling deceleration with small input torques. As a result, reduction gears can be manufactured relatively compactly.

Worm Gears are used in cases where a space-saving, large reduction ratio is required to transmit power with orthogonal input and output shafts, or when a self-locking function is used to transmit power.

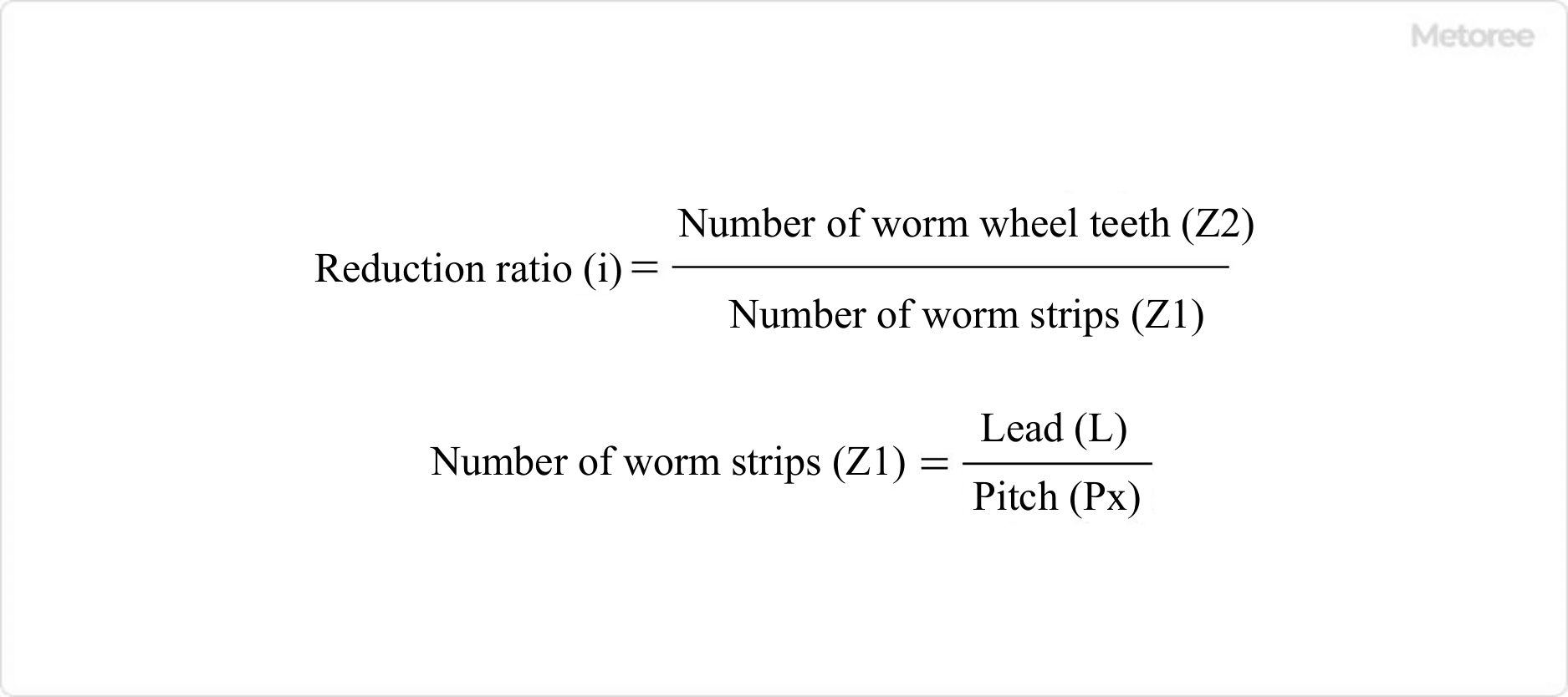

In Worm Gear, when the worm (input shaft side) makes one revolution, the worm wheel (output shaft side) rotates by one tooth. The number of teeth on the worm in this case is called the number of worm teeth, or "one worm. In the case of a worm with two worm teeth, one rotation of the worm rotates the worm wheel by two teeth.

The reduction ratio of Worm Gear can be calculated as follows.

Figure 3. Reduction ratio of worm gear

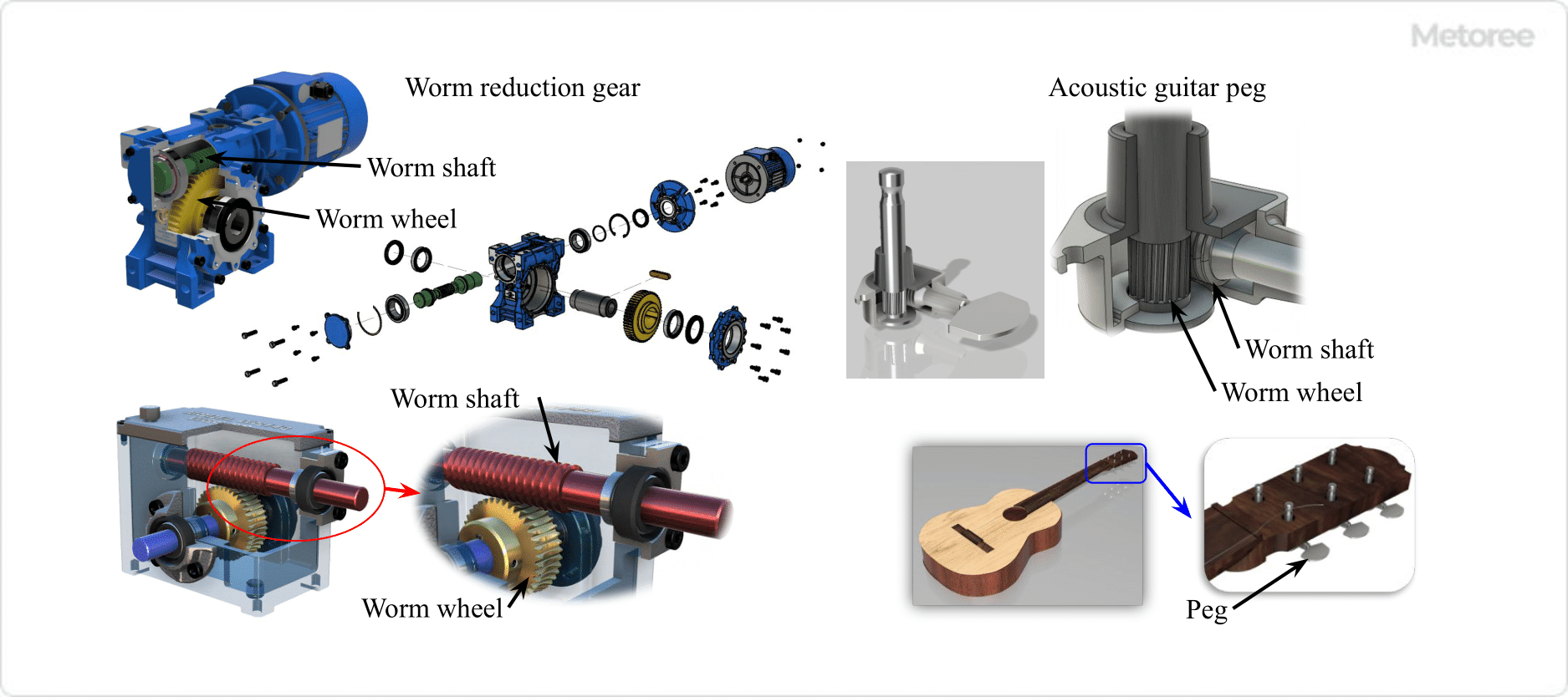

Worm Gears can rotate in both directions (e.g., clockwise and counterclockwise as viewed from the input shaft side). This can be achieved by selecting the worm torsion direction as left-hand or right-hand. See Figure 4 for Worm Gear torsion direction and shaft rotation direction.

Figure 4. Worm gear torsional direction and shaft rotation direction

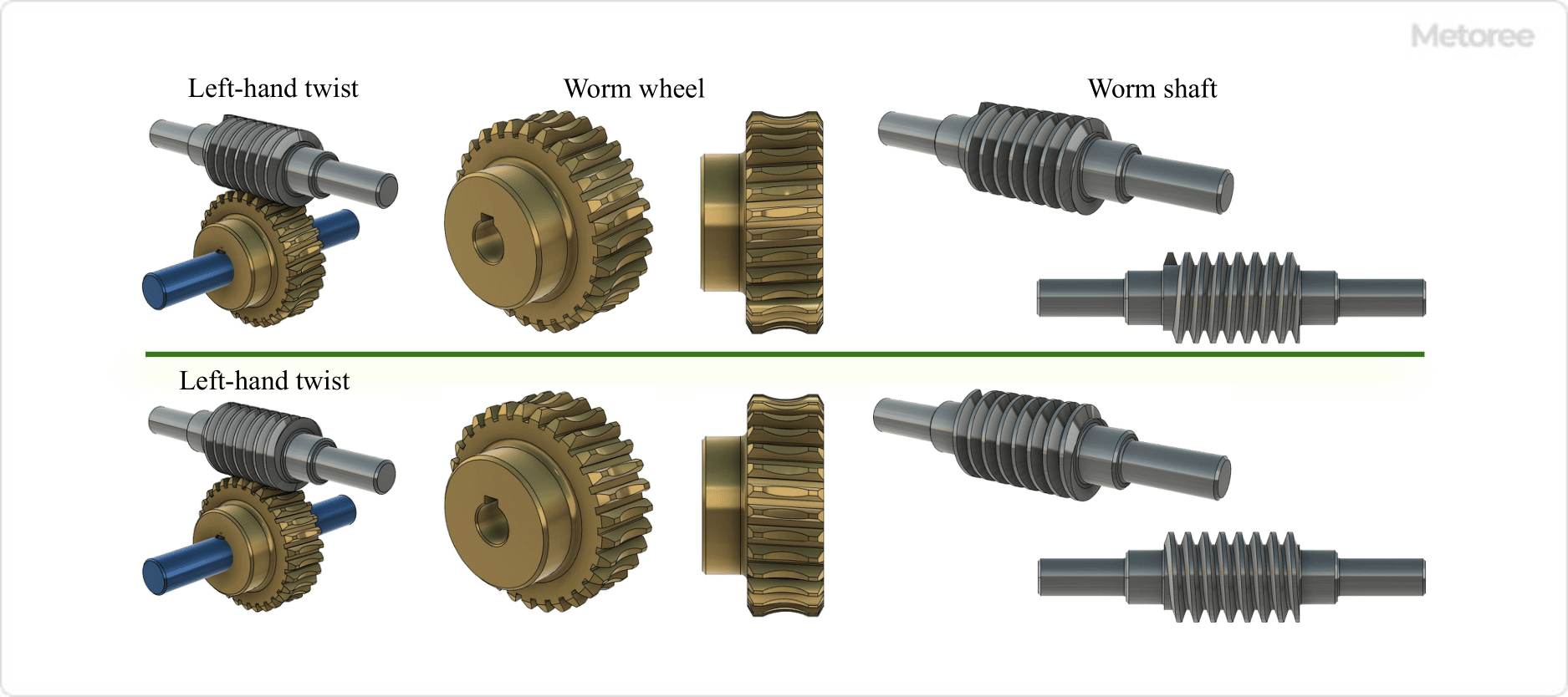

Refer to Figure 5 for the worm Gear's torsional direction and the shape of each part.

Figure 5. Worm gear torsional direction and shape of each part

Worm Gears have the following features

Therefore, the worm side is always the input shaft side, where the rotating shaft that serves as the drive or power source is mounted.

The worm wheel side is the output shaft side, where the device that transmits power is mounted. However, a separate braking mechanism must be provided to completely prevent reverse rotation. Since pitch error and other factors vary depending on the accuracy of the gear, check the required accuracy and select the appropriate accuracy for the application.

Worm Gears are not suitable for high-precision positioning because of backlash. For high-precision positioning, it may be better to re-select the gear type.

*Including some distributors, etc.

Sort by Features

Sort by Area

Dalton Gear Company was formed in 1955 and is headquartered in Minneapolis, Minnesota. The company is a manufacturer of custom and standard gears related to machined parts for domestic and international customers. The company’s standard parts include overload safety devices, worm gear reducers, and drive tensioners & idler sprockets. The company’s customized manufacturing is accomplished using CNC machining with capabilities including machine centers and CNC lathes with accuracy down to 0.0005 inches, and additional operations such as grading and honing.

Cage Gear & Machine LLC, founded in the United States, is a manufacturer of custom Gears. The company's product portfolio includes spur gears, helical gears, bevel gears, and worm gears. It also offers prototyping and customization services that allow it to work closely with clients to design gears that precisely match their requirements. The company serves industries such as automotive, aerospace, oil and gas, power generation, and various industrial machinery and equipment.

Cleveland Gear Company, Inc. was founded in 1912 and is headquartered in Cleveland, Ohio. The company is a manufacturer of gears, speed reducers, and other parts for industries such as manufacturing, mining, and packaging. The company has four product and service categories: Enclosed Drives, Open Gearing, Custom Drives, and Field Service & Rebuilds. Enclosed Drives include modular gear products, larger enclosed drive products, and helical enclosed drive products. Open Gearing includes Master Worm Systems and services such as case hardening. Custom drives are produced according to industry need such as rubber production and mineral processing.

Omni Gear & Machine Corp, since 1988, has been a manufacturer of precision-machined custom gears such as spurs, helical, clusters, worms, and sprockets out of materials such as brass, plastic, bronze, alloys, and fiber. The products have applications in graphical arts, food equipment, corrugated box and bag manufacturing, material handling, and custom machines. The Joliet, IL-based company offers customized gear fabrication, machining, shaping, gear grinding, and frequent product inspection during and after production.

KHK USA Inc., a subsidiary of Kohara Gear Industry, is based in Mineola, NY, and has been a manufacturer and supplier of metric gears since 2015. The company's products include metric spur gears, helical gears, internal ring gears, gear racks, CP racks, and pinions. These gears are used in automation, packaging, robotics, food processing, and agriculture industries. The company has more than 26,000 ROHS-compliant gear options made of alloy steel, carbon steel, stainless steel, aluminum bronze, and brass. It also offers free gear design software and hosts the "KHK Gear World" site for gear information.

Leistritz was founded by Paul Leistritz in 1905, located in Nuremberg, Germany and is a manufacturer of pumping systems. The company manufactures a wide range of products, including pumps, screw pumps, multiphase pumping systems, re-engineered pumps, IRON pumps, aero engine aerofoils, aero engine discs/blisk, titanium aluminide turbine plates, and metal leading edges. The company holds NADCAP and ISO certifications. The company products are applicable in Oil & Gas, Aerospace, Automotive, Energy, Marine, Process, and Pharmaceutical industries.

American Precision Gear Co., Inc. is a manufacturer of gears since 1956 and is based in California. The company not only manufactures precision gears but crafts many custom gears as well which include spur, ring, miniature, and helical. Splines and worms for industrial machining applications are also designed including custom machined gear racks for various linear motion applications. The company serves numerous industries that require the use of precision and custom gears for various applications, some of them being Biomedical, Aerospace, Oil & Gas, Medical devices, Technology, and lots more.

Amtech Manufacturing, Inc., established in 1995 with facilities in North America, is a contract manufacturer of gear parts and drive components. The company's products include gears, shafts, castings, forgings, and screw machine parts. Amtech Manufacturing, Inc. also offers flexplate Assemblies, flywheel Assemblies, screw machining, stamping, and fineblanking. The company also offers custom manufacturing, machining, engineering, and laser cutting services. Amtech Manufacturing, Inc. services original equipment manufacturers in the automotive, construction, marine, power sports, and robotics markets.

Gear Motions is a custom gear manufacturer for global OEMs. Founded in 1960 and headquartered in Syracuse, New York, with additional locations in Buffalo and Oliver Springs, Gear Motions has grown significantly since its founding. Initially a ten-man company serving primarily in the New England Area, they have since expanded through acquisitions of companies such as Nixon Gear, Gear Supply and Broaching, and Pro-Gear Co Inc. The company provides custom gear solutions for various custom and precision applications, offering products such as ground helical gears, spur gears, pump gears, timing pulleys, shafts and splines.

QTC METRIC GEARS is a reputable manufacturer and supplier of quality metric gears, located in the United States since 1964. QTC METRIC GEARS has a rich history of providing a wide range of precision gears that cater to various industries, including automotive, aerospace, robotics, and manufacturing. Their devotion to quality and precision ensures that their gears meet rigorous standards and offer dependable performance. With a aim to deliver products and exceed customer expectations, QTC METRIC GEARS prioritizes customization, timely delivery, and excellent customer service.

Martin Sprocket & Gear, Inc. (MSG) is an Arlington, Texas-based manufacturer and supplier of power transmission products, material handlers, and industrial hand tools. Founded in 1951, the company primarily serves clients in the pulp and paper, petrochemical, automotive, and agriculture industries. The company produces various products including conveyors, sprockets, sheaves, bushings, and custom products for client companies like John Deere and General Electric. MSG has over thirty operating plants across the United States, with retail locations and storage facilities on three continents.

Delroyd Worm Gear, located in Niagara Falls, New York, has been a manufacturer of worm gear drives and custom-engineered worm gear products since 1923. Besides offering single, double, triple, and helical worm speed reducers, the company also provides standard and special gear sets. These products are ideal for propulsion-related systems, grinding and logging machines, and crane applications. Industries the company serves are power generation, pulp & paper, material handling, mining, etc. The company provides installation assistance, troubleshooting, preventive maintenance, and other services.

Boston Gear is a North Carolina-based manufacturer and supplier of power transmission components including bearings, clutches, enclosed gear drives, and AC/DC motors. Founded in 1877, the company offers more than 30,000 standard products, as well as the option to create custom-engineered solutions. The company is ISO 9001 certified, with clients in the mining and aggregate, energy, aerospace, defense, construction, and agricultural industries. Boston Gear components are also used in packaging and robotics operations by companies such as Disney and Coca-Cola.

Circle Gear & Machine Co., Inc., established in 1951 and based in Illinois, USA, is a manufacturer of gears and gearboxes. The company manufactures a range of gears including bevel, helical and worm gear for automotive, construction, chemical and other industries. It provides reverse engineering for gear and gear boxes, from worn samples, prints or sketches, along with rebuild, repair and emergency services. The company has a quality management system in compliance with ISO 9001:2015, and has a complete inspection lab with CMM(Coordinate Measuring Machine).

The Adams Company was established in 1883 and is located in Dubuque, Iowa, United States is a manufacturer of custom gears, shafts, and power transmission parts for various industrial and commercial applications. The company produces straight bevel, helical, spur & worm gears along with power transmission parts including sprockets, couplings, clutches & shafts that have applications in agriculture&construction machinery manufacturing industry, oil recovery equipment, winches, and industrial pumps. They also offer services including CNC blanking, hobbing, shaping, vertical machining, and gear shaving that are needed in the thread grinding, broaching, milling, tapping, and deburring systems.

Mädler North America was founded in 2020 as the US-based subsidiary of Mädler which was founded in Berlin, Germany in 1882. Mädler specializes in manufacturing precision-made machine parts. Product lines include linear guides, bearings, bushes, bevel gears, worm wheels, castors and wheel systems, couplings, fastening elements, clutches, gear boxes, idlers, linear bearings, locking assemblies, machine mounts, elements for pneumatic machines various joints, rubber padding and dampers, splined shafts and hubs, sprockets, timing belts, spindles, adhesives, sealants, and other assorted accessories.

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

Atlanta Drive Systems, founded in 1943 and located in Farmingdale, New Jersey, is a supplier of drive systems. The company’s broad range of products includes gear racks, pinion ears, servo reducers, linear actuators, and washdown gearboxes. These products play a fundamental role in automation and robotics for precise and controlled movement, industrial machinery for applications like material handling and manufacturing, motion control for regulating speed and torque, linear motion systems for accurate positioning, and the food and beverage industry. The company’s products are used to enable precise movement, control, and efficiency in mechanical and automated systems across diverse sectors.

Acme Gear Co., Inc. established in 1929 and based in Englewood, NJ, USA, is an ISO 9001:2008 certified manufacturer and supplier of precision ground or cut gears. The company's product lineup includes helical gears, spur gears, worm gears, bull gears, and bevel gears. serving industries such as Aeronautics, Renewable Energy, Industrial Air Conditioning, and Mining, these gears play a fundamental role in machinery operations ranging from transit to aerospace applications. Its services include prototype development, mass production, and rigorous quality assurance, ensuring clients get the required precision-crafted gear solutions.

Commercial Gear & Sprocket Company Inc. is located 20 miles southeast of Boston in East Walpole, Massachusetts, and is a manufacturer of machine tool builders, construction equipment, mining, power hand tools, medical equipment, defense suppliers, mass transit, rail cars & track equipment, and many more. The portfolio of the company consists of machining gears, splines, sprockets, and other related products for over 70 years. The products also include Bevel and Mitre Gears, Helical Gears, Rack and Pinion, Ratchets and Jaw Clutches, Splines, and more.

The Robertson Manufacturing Company, Incorporated, is situated in the state of Utah, in the United States, and was established in 1986, and is a producer of customized canvas and industrial fabric goods. Robertson Gears encompass a diverse array of gear types, such as spur, helical, internal, worm, worm gears, and racks, all of which are tailored to meet customers' unique requirements. In addition, the company manufactures a diverse range of power-transfer components, encompassing synchronous belt pulleys, specialized sprockets, and ratchets.

Metro Sprocket & Gear, Inc. was established in 1985 and headquartered in Midlothian, Texas. The company manufactures custom gears, sprockets, and prototype parts used in agricultural machinery, construction equipment, power transmission equipment, machine tools, and other applications. The company’s product segments include splines and custom, helical, plastic, and worm gears. The company’s custom servicing options include several CNC and milling. Heat treating, milling, surface grinding, and other alteration options are also available.

Renold, established in 1947, and based in Manchester, UK, is a manufacturer and supplier of industrial chains, gearboxes, and couplings. Their product portfolio includes tooth chains, transmission drive chains, gear and gearboxes, couplings, conveyor chains, leaf chains, sprockets, and accessories. The company offers the latest innovation with high precision-engineered power transmission products. The products are used in various industries which include agriculture, construction, energy, environment, food and drink, transportation, and machinery.

Framo Morat, headquartered in Eisenbach, with subsidiaries in the United States, Turkey, and Poland, has been a gear and drive engineering product manufacturer since 1912. The company products include spur gears, ring gears, pinion shafts, worm gear sets, etc., with material selection including steel, bronze, fabric laminate, or plastic. The company produces 1 million gear sets in a 26,500 m2 production area. The company serves automation, material handling, automotive, and medical industries. In medical industries, worm gear sets are utilized to adjust operating tables and stair lifts. In energy industries, gear sets are ideal for rotary heads for solar trackers.

Kohara Gear Industry Co., Ltd. (KHK), established in 1935, is a Japanese manufacturer headquartered in Kawaguchi, Saitama, specializing in the production of stock gears. The company’s product portfolio includes bevel, helical, internal, miter, and plastic gears. Additionally, it offers other types of stock gears such as screw, spur, and worm gears. The company also provides standard and circular pitch (CP) gear racks, gear couplings, as well as pre-lubricated bevel gear boxes designed to be freely mountable in any direction. Furthermore, the company offers customization options, allowing customers to choose specific gear tooth pitches, sizes, grades, and materials, such as metal and plastic.

W M Berg, founded in 1967 and based in Cudahy, Wisconsin, is a manufacturer and supplier of precision industrial parts. The company delivers ISO 9001:2015 certified products and services, including assemblies, bearings, belts & chains, couplings & shafts, gears, fasteners & hardware, pulleys & sprockets and more. W M Berg provides designing, developing, manufacturing and testing facilities to its clients in the aerospace, medical and motion control industries. Its distributors include Applied Industrial Technology and Motion Industries.

igus GmbH, established in 1964 and based in Cologne, Germany, is a manufacturer and distributor of technical products made using polymers for movement. Its products include injection molding frames, motor control systems, and plain bearings, and it has over 240,000 products in over 1,000,000 variations. It serves 188,000 companies from over 80 countries worldwide in 50 different industries, including packaging, automotive, and renewable energy. The company is ISO 9001, ISO 14001, and ISO 50001 certified, and in 2023, it recorded €1.115 billion in sales. Since 2021, the company has purchased 380 new injection-molding machines and has replaced 275 old ones.

GearKing Inc, located in Lake Forest, CA, which was established in 1960, is a manufacturer of speed reducers and power solutions. The company's product line has categories for gearboxes, gear motors, and aerators & pumps. The gearboxes/reducers are made of aluminum and stainless steel. The products have an annual limited warranty, low noise, and long-lasting services. The paddle wheel aerators are used in shrimp farms, fisheries, livestock fields, commercial ponds, and water treatment centers.

goBILDA is a manufacturer and supplier based in Winfield, Kansas, United States, specializing in robot building systems and components. The company develops a grid-based building system for engineers, artists, and students. It also operates an online store offering products to participate in FIRST Tech Challenge (FTC), a robotics competition for students from grades 7 to 12. These offerings are categorized into structural elements for foundational frameworks, motion elements such as motors and wheels, as well as electronic elements. Other product categories are hardware elements such as screws and springs, various kits like FTC and linear motion kits, as well as merchandise.

American Gear, Inc., since 1990, has been a manufacturer of fine and medium pitch gears and accessories such as worms, timing pulleys, involute splines, segments, and ratchets. The gear types are spur, helical, straight bevel, and miniature gears serving the aviation, commercial, film, office, and hobbyist industries. The company Prophetstown, IL, offers machining services such as CNC milling & turning, screw machining, heat hobbing & shaping, heat resting, and finishing services. The company produces products with ISO 9000 standards and is an American Gear Manufacturers Association member.

Alsico High Tech based in Ronse, Belgium and was established in 1990 is a manufacturer and integrator of garments for cleanrooms, clean areas, ESD environments and operating theatres. The company develops, produces and supplies quality cleanroom garments, clean area garments and ESD garments to rental companies, end-users and specialized distributors. The products are used to shield workers from workplace hazards such as dust, dirt, grime, chemicals, sparks, flames, and infectious diseases. A dependable partnership with both suppliers and customers enables it to ensure that all delivered goods meet the critical standards and norms.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Martin Sprocket & Gear, Inc. |

5.5%

|

| 2 | Dalton Gear Company |

5.5%

|

| 3 | Cleveland Gear Company |

4.9%

|

| 4 | Delroyd Worm Gear |

4.7%

|

| 5 | Boston Gear |

4.3%

|

| 6 | Maedler North America |

4.3%

|

| 7 | Ascent Precision Gear Corporation |

3.8%

|

| 8 | Omni Gear & Machine Corp. |

3.8%

|

| 9 | Butler Gear Enterprises, LLC |

3.7%

|

| 10 | Atlanta Drive Systems |

3.4%

|

Derivation Method

The ranking is calculated based on the click share within the worm gear page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

23 | 79.3% |

United Kingdom

United Kingdom

|

1 | 3.4% |

Germany

Germany

|

1 | 3.4% |

Japan

Japan

|

1 | 3.4% |

Belgium

Belgium

|

1 | 3.4% |

China

China

|

1 | 3.4% |

India

India

|

1 | 3.4% |

58 products found

58 products

Tescom Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■FSA series FS (A) series helical worm gears are developed to achieve high torque, low energy and low surface heating. High efficiency reduces ener...

4 models listed

Tescom Co., Ltd.

340+ people viewing

Last viewed: 22 hours ago

■FV series FV series stainless steel worm gearbox is a standard worm gear. Designed to meet the latest standards in the food industry. The design f...

4 models listed

Cored Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■Features ・High-efficiency orthogonal shaft reducer: Compared to worm gears, slippage is smaller and efficiency is approximately 20% higher; reduc...

Saito Koki Co., Ltd.

960+ people viewing

Last viewed: 6 hours ago

■What is worm gear? A cylindrical ``worm'' with screw-like spiral teeth and a ``worm wheel'' which is a helical gear (helical gear) are meshed at r...

Global Parts Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

GLO-LIGU spinning holder has better holding power and anti-vibration damping system than the general ER collet type, side lock type, hydraulic type...

4 models listed

Wittenstein

1000+ people viewing

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....

Wittenstein

900+ people viewing

Last viewed: 17 hours ago

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....

Global Parts Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

GLO-LIGU spinning holder has better holding power and anti-vibration damping system than the general ER collet type, side lock type, hydraulic type...

3 models listed

Robotena Co., Ltd.

280+ people viewing

Last viewed: 13 hours ago

module 0.5.

4 models listed

Wittenstein

820+ people viewing

Last viewed: 1 day ago

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....

Global Parts Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

GLO-LIGU spinning holder has better holding power and anti-vibration damping system than the general ER collet type, side lock type, hydraulic type...

10 models listed

Wittenstein

660+ people viewing

Last viewed: 1 day ago

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....

Robotena Co., Ltd.

640+ people viewing

Last viewed: 1 day ago

Contains 2 24T flat gears, 2 worm gears, and 2 shafts.

Wittenstein

750+ people viewing

Last viewed: 1 day ago

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....

Wittenstein

590+ people viewing

Last viewed: 1 day ago

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....

Wittenstein

590+ people viewing

Last viewed: 10 hours ago

■ In order to actually apply a reliable servo deceleration machine, the highest accuracy, dynamics, and average density over average are essential....