All Categories

History

This section provides an overview for edgewise coils as well as their applications and principles. Also, please take a look at the list of 3 edgewise coil manufacturers and their company rankings. Here are the top-ranked edgewise coil companies as of February, 2026: 1.Li Tone Electronics, 2.SAN-EI ELECTRONIC INDUSTRIES, 3.URATANI ENGINEERING, Inc..

Table of Contents

Categories Related to Edgewise Coils

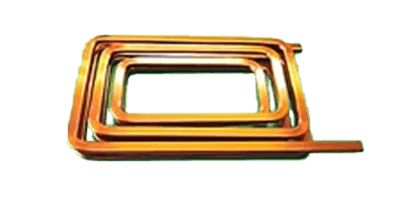

An edge-wise coil is a coil made of rectangular flat wire with a rectangular cross section of wire as the conductor.

Unlike coils in which wires with a round cross section are wound on a bobbin as usual, these coils have a structure in which thin plates that match the size and shape of the coil are processed and stacked so that the current flows in a spiral shape. As a result, it has the appearance of laminated fins.

Edge-wise coils are used in electronic circuits, for example, in DCDC converters, and as coils that temporarily store energy in switching circuits. Products include power adapter units, DCDC converter units, inverter units, battery chargers, motor driver units, generator units, and motor units.

They are used in products that handle relatively large amounts of electric power, and a variety of products are manufactured for electric power-related and automobile-related businesses. They are often used in the field of power electronics, and are used by electromagnets, such as inductors, motor units, and generator units in circuits that require large currents of over 10A.

Coils required in circuits that handle large amounts of power must carry large currents. To increase the current in the coil, the cross-sectional area of the wire in the winding must be increased.

Formula: L = (A X 4π2 X μS X A2 X N2) ÷ B (B Is the Length of the Coil)

As shown in the formula for the inductance of a solenoid coil, to obtain a high inductance, the coil length value, which is the denominator in the calculation, must be small. In other words, the shorter the total length of the coil, the higher the inductance.

Therefore, edge-wise coils use a flat wire as the winding wire to increase the cross-sectional area while reducing the length of the coil to achieve high inductance.

Edge-wise coils are made by rolling copper wire into a spiral shape. Therefore, the winding bobbin, which was essential for conventional wire wound coils, may not be necessary, and coils that could not be produced before due to restrictions imposed by the bobbin lineup may be produced.

If a coil that requires a bobbin other than a ready-made bobbin were to be made using the conventional method of using a bobbin for winding, a great deal of time and cost would be required to design a special bobbin and make a mold. However, since the bobbin itself is not required, coils can be developed without such labor and cost. In terms of freedom of development and design, edge-wise coils are very attractive devices.

Some manufacturers offer edge-wise coils as ready-made products, while others offer custom-made products. Many of the off-the-shelf product lineups support high currents and are suitable for power system product development.

We have a full lineup in the industry, including inductances for power circuits that exceed 10A. On the other hand, in the case of custom products, we may be able to respond flexibly by inquiring about electrical performance as well as size, shape, and other arbitrary requirements.

The advantage of edge-wise coils is that they allow for greater electrical design freedom in, for example, inverter circuits. Higher inductance can be obtained because the length of the solenoid shape can be reduced compared to a solenoid coil wound with a wire having a round cross section of the same cross-sectional area. Another advantage is that it can contribute to the design of generator units and motor units in terms of higher power, smaller size, and heat dissipation performance.

*Including some distributors, etc.

Sort by Features

Sort by Area

Uratani Engineering Inc., established in 1997 and headquartered in Kyoto, Japan, is a manufacturer of coils, motors, and various components to suit diverse devices. The company offers a range of coils, including edgewise coils, rectangular wire coils, and rectangular copper wire coils. These find applications in a wide array of devices such as car-mounted and vessel-mounted motors. The company accepts a broad spectrum of services from single prototypes to mass production, and also provides a comprehensive support from winding to inspection.

Li Tone Electronics, established in 1986, is a manufacturer and supplier of electronic components and power supplies, headquartered in New Taipei City, Taiwan. Their product range includes high-frequency transformers, power inductors & coils, AC/DC adapters, and LED drivers. These products can be applied in industries such as telecommunications, consumer electronics, industrial automation, and automotive. Li Tone Electronics is certified with ISO 9001 for quality management and ISO 14001 for environmental management.

San-Ei Electronic Industries Co., Ltd., founded in 1958 with headquarters in Komoro City, Japan, is a manufacturer of magnetic wire and edgewise coils. The company's main product is magnetic wire, which is thinner than human hair and is used in automobiles, communication devices, household applications, measuring equipment, and mobile devices, among others. It also produces a range of edgewise coils, including textile heating machinery, motor coils for hybrid vehicles, and components for various consumer products. The company offers design, engineering, and production for custom applications.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Li Tone Electronics |

64.3%

|

| 2 | SAN-EI ELECTRONIC INDUSTRIES |

21.4%

|

| 3 | URATANI ENGINEERING, Inc. |

14.3%

|

Derivation Method

The ranking is calculated based on the click share within the edgewise coil page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 66.7% |

Taiwan

Taiwan

|

1 | 33.3% |

43 products found

43 products

Comotechnos Co., Ltd.

260+ people viewing

Last viewed: 2 hours ago

We will create a "low cost / high quality" edge -wide coil at its own factory in its own factory in -house, a flat -angle wire and edge wise automa...

8 models listed

Pulse Electronics Co., Ltd.

560+ people viewing

Last viewed: 21 hours ago

■Coil/choke/transformer using edgewise, flat wire Achieves high performance and miniaturization. By using a ferrite core with excellent frequency c...

Kitamoto Tech Co., Ltd.

450+ people viewing

Last viewed: 3 hours ago

■Features A reactor is a type of inductance made by winding a conducting wire (copper wire) into a coil. In electrical circuits, they are used for ...

Actus Co., Ltd.

140+ people viewing

Last viewed: 1 day ago

Coils, which are related to magnets, are coils of conductive wire that perform various functions by interacting with electricity and magnetism. Als...

5 models listed

Sanmori Gen Electronics Co., Ltd.

320+ people viewing

Last viewed: 18 hours ago

■Product features ・Fully automatic winding possible ・Closed magnetic core, small magnetic leakage ・The core is not subjected to stress from the ...

6 models listed

Sky Electronics Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

Compatible with flat wire coils (lead-free solder). Utilizing our winding technology to provide detailed support for each coil, we use the latest e...

Ozeki Co., Ltd.

370+ people viewing

Last viewed: 3 hours ago

■Features ・Edgewise toroidal coil ・A rectangular edgewise winding is applied to a toroidal-shaped low-loss powder core. ・Effective for downsizin...

Ozeki Co., Ltd.

340+ people viewing

Last viewed: 4 hours ago

■Features ・Edgewise winding is applied to PQ and EER cores. ・By using a bobbin-less structure and edgewise winding, it is possible to downsize co...

Actus Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

Coils, which are related to magnets, are coils of conductive wire that perform various functions by interacting electricity and magnetism. Also cal...

Ipec Co., Ltd.

230+ people viewing

Last viewed: 22 minutes ago

By adopting an original powder core, it achieves characteristics comparable to high flux. Compatible with circuits with high load fluctuations. The...

Ipec Co., Ltd.

230+ people viewing

Last viewed: 2 hours ago

This is a product in which the HG series reactor is placed in an aluminum case and filled with resin. By dissipating the heat generated internally ...

Ipec Co., Ltd.

280+ people viewing

Last viewed: 20 minutes ago

This is a product in which the HA series reactor is placed in an aluminum case and then filled with resin. By dissipating the heat generated intern...

Ipec Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

This is a product in which the HN series reactor is placed in an aluminum case and filled with resin. By dissipating the heat generated internally ...

Ipec Co., Ltd.

230+ people viewing

Last viewed: 2 hours ago

Adopts a "figure 8" coil with high coupling and low stray capacitance. The "figure 8" coil + High-μ ferrite core makes it difficult to saturate eve...

Ipec Co., Ltd.

270+ people viewing

Last viewed: 16 hours ago

■Features ・Air core coil that leaks magnetic flux but does not saturate the magnetic flux ■Features ・Air core coil ・No magnetic flux saturation...

Ipec Co., Ltd.

300+ people viewing

Last viewed: 16 hours ago

This is a toroidal-shaped air-core coil with no external magnetic flux. ■Toroidal coil Because the magnetic flux passes through the inside of the ...

Ipec Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

Patent No. 3814288 This is a product in which the HB/BB series is placed in an aluminum case and filled with resin. By dissipating the heat genera...

Ipec Co., Ltd.

270+ people viewing

Last viewed: 22 minutes ago

Eddy current loss reduced by multi-segmented ferrite core. A power inductor ideal for high ripple power supplies. There is a wide variety of mounti...

Ipec Co., Ltd.

250+ people viewing

Last viewed: 22 minutes ago

This is a low-cost type that uses silicon steel plate, which is ideal for low frequency applications. Products compatible with large currents can b...

Ipec Co., Ltd.

360+ people viewing

Last viewed: 22 minutes ago

Achieved approximately 1/2 the volume compared to the conventional structure. The device can be made smaller and lighter. Since losses are small, i...

Ipec Co., Ltd.

240+ people viewing

Last viewed: 22 minutes ago

Adoption of JFE Steel Super Core reduces noise by approximately 20dB. Products compatible with large currents can be connected with copper bars. ■...

Ipec Co., Ltd.

240+ people viewing

Last viewed: 22 minutes ago

Eddy current loss reduced by multi-segmented ferrite core. A power inductor ideal for high ripple power supplies. There is a wide variety of mounti...