All Categories

History

This section provides an overview for high strength bolts as well as their applications and principles. Also, please take a look at the list of 8 high strength bolt manufacturers and their company rankings. Here are the top-ranked high strength bolt companies as of February, 2026: 1.BACO Enterprises, Inc., 2.Fast-Rite International, Inc., 3.National Bolt & Nut Corp..

Table of Contents

Categories Related to High Strength Bolts

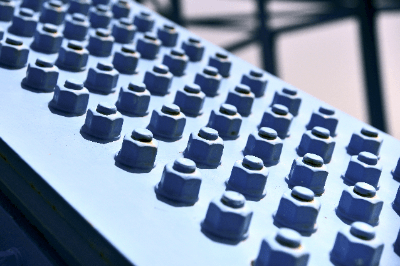

Unlike bolts used in general machinery, high-strength bolts are much more substantial.

The commonly used steel material called SS400 has a tensile strength of 400 N/mm2, but the material used for High strength bolts has a strength of 800 N/mm2 at the lowest.

Therefore, it is used in construction, not for general mechanical applications. In particular, they are widely used as bolts for fixing steel materials together in friction-jointed joints, often employed in steel construction.

These bolts are still widely used today.

Uses of high-strength bolts are mainly in the field of construction. There are many ways to build a building structure; among them, it is straightforward to construct a building structure with steel frames compared to concrete structures.

High-strength bolts are used to join steel members together.

In the case of steel construction, welding steel frames together is very time-consuming, and the quality is not stable with on-site welding, so they are joined by a method called friction welding.

High-strength bolts are used because high torque is required to generate this frictional force.

Since high-strength bolts are used in steel-frame joints, where high torque is required, chrome and molybdenum steel has been used for many years, but nowadays, low-carbon boron-added steel is widely used.

This has made it possible to prevent delayed fracture, which has been a problem with chromium and chrome molybdenum steels. High-strength bolts are divided into two types according to their shape and usage: Torsia-type high-strength bolts and high-strength hexagonal bolts.

The main difference between these two bolts is that the torusia-type high-strength bolt has a particular shape for the fastening portion and requires a dedicated tool. However, the tightening part is shaped to break if tightened with more than the specified torque, so torque management is straightforward.

On the other hand, High strength bolts can be tightened using the same wrenches and other tools as general bolts and nuts, but torque control may be neglected.

The general disadvantage of high-strength bolts is that they are more expensive than ordinary hex bolts. However, since hexagonal bolts of common materials cannot handle high torque, they are always used in construction sites.

High-strength bolt friction joining is a method of joining steel plates by frictional force generated on the contact surfaces of the steel plates by tightening them together with the strong axial force applied to the high-strength bolt. This method is used in construction fields such as road bridges and skyscrapers. Stronger fastening is required because of the additional surface bonding force between the steel plates compared to fastening with only the axial force of a normal bolt. Another advantage of this method is that it does not require firearms like rivet joints and does not require professional skills like welding.

Since the frictional force between steel plates must be high, the contact surfaces must be slip-resistant. Slip resistance is determined by the "slip coefficient" specified in the Building Standard Law, which must be 0.45 or higher. The higher the slip coefficient, the greater the resistance and frictional force, so a friction surface treatment is applied to roughen the surface of the steel plate in advance.

There are three types of friction surface treatments: "red rust treatment," "shot blasting," and "phosphate treatment.

Red Rust Generation Treatment

In the red rust-generating treatment, the contact area of the steel plate is roughened by applying a grinder, etc., and is oxidized in the atmosphere.

Shot Blast Treatment

Shot blasting treatment is a method in which fine balls (silica sand or steel balls) called media are blown together with compressed air to roughen the surface with fine irregularities. After shot blasting, the surface loses its metallic luster.

Phosphate Treatment

This simple method of applying a phosphate chemical to the bonding surface is widely used because it requires little time and effort. However, working in rainy or humid environments is strictly forbidden, as moisture will cause the bolts to fail to adhere to the surface and peel off.

High-strength and high-tensile bolts are identical, and they are no different. They are called "high-strength" and "high-tension" because they are made of high-tension steel (high-tension steel). There are different types of high-tensile steel, including those with a higher nickel content of about 3% to increase salt resistance near the coast and weather-resistant ones with increased amounts of Ni and Cu added to increase atmospheric corrosion resistance.

It is read as a "high-strength bolt" or "high-tension bolt." Note that they are also called high-tension bolts.

*Including some distributors, etc.

Sort by Features

Sort by Area

BACO Enterprises, Inc. located in Bronx, NY, is a manufacturer and distributor of threaded rods, anchor bolts, and fasteners, and also serves as a miscellaneous steel fabricator since 1981. The company's products include bolts, nuts, washers, custom wedges, and threaded roads. It also stocks steel products such as channels, beams, pipe & tubes, plates, and deckings. To meet the needs of its customers, the company offers services such as CNC plasma burning, custom threading & bending, saw cutting & shearing, onsite skidmore testing, and fabrication services. BACO Enterprises, Inc. is a member of the American Institute of Steel Construction.

Armour Screw Co., since 1956, has been a distributor of standard and custom fasteners such as screws, nuts, bolts, washers, and rivets made from steel, bronze, aluminum, brass, and titanium and used in appliance, construction, electrical, recreational vehicle, snowmobile, and telecom industries. The company in Elk Grove Village, IL, offers sorting machine services and hand poly bagging, providing customers with hardware kits used for assembly and repair in a product recall situation. Armour Screw Co. is ISO 9001:2000 certified and RoHS compliant.

National Bolt & Nut Corporation is based in Schaumburg, Illinois. National Bolt & Nut is a distributor of bolts, nuts, and related tools, serving the heavy equipment & construction, mining, transportation, automotive, and alternative energy industries. National Bolt & Nut is ISO 9001 certified. National Bolt & Nut product listings include standard and custom nuts, spacers, and washers with assorted head styles. Other offerings include a variety of screws, pins, and sprockets.

Associated Fastening Products, Inc. (AFP) was established in the early 1990s in Itasca, Illinois. AFP is a manufacturer and distributor of both standard and special fasteners for all uses, with many customers in the agriculture and gun manufacturing industries. Some of AFP’s product and service offerings include automatic screw machining, CNC services, brass fittings, standard fasteners, CNC machining, laser and waterjet cutting services, custom cold headed fasteners, metal stamping services, standard and special washers, cable ties, hardware kits and bagging, Swiss screw machining, inventory management, large diameter bolts, security fasteners, and wire form products.

Anyang General International Co., Ltd, founded in 1958 and headquartered in Henan, China, is a manufacturer and supplier of railway products for railroad construction. The company produces a number of rail fastening systems and related fastening parts such as rail clips, joints, bolts, tie plates and fish plates. With a large production capacity, it produces a hundred thousand rail clips a day and over 60 million tons of cast iron plate, rail shoulder and rail anchor annually. The company supplies these products to railways and the rail joints production base in East Asia as well as exports them to other countries.

TOAGOSEI CO., LTD, founded in Nagoya, Japan in 1944 is a manufacturer of commodity chemicals, adhesive materials and plastics. The company's product portfolio includes Acrylic acid used as a raw material in acrylic polymers, Synthetic hydrochloric acid, Sodium hypochlorite and Liquid chlorine, Their products find application in the disinfection of water, sewerage and pool, pulp bleaching, food industries, water and wastewater treatment, and ballast water purification. Their products are used in industries such as Food and Beverage , Pharmaceutical and Biotechnology, Chemical and Petrochemical, Environmental Testing and healthcare.

Fast-Rite was founded in 1992 and is headquartered in Glendale Heights, Illinois. The company is an ISO 9001:2015 certified manufacturer and distributor of fasteners, abrasives, tools, and accessories to manufacturing and other industries. The company has multiple distribution centers throughout the United States, as well as full-service sales, warehouse, and production facilities in both Mexico and Asia. The company offers rite-stock programs and optimization options. Rite-stock programs include customer-managed inventory, total VMI, virtual inventory, Kanban, and JIT programs. Optimization programs include assembly, automation, and robotics solutions.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | BACO Enterprises, Inc. |

21.8%

|

| 2 | Fast-Rite International, Inc. |

19.1%

|

| 3 | National Bolt & Nut Corp. |

17.3%

|

| 4 | Armour Screw Co. |

14.5%

|

| 5 | Associated Fastening Products, Inc. |

9.1%

|

| 6 | TOAGOSEI CO., LTD |

9.1%

|

| 7 | Anyang General International Co., Ltd |

6.4%

|

| 8 | Mitsubishi Electric Corporation |

2.7%

|

Derivation Method

The ranking is calculated based on the click share within the high strength bolt page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 66.7% |

Japan

Japan

|

1 | 16.7% |

China

China

|

1 | 16.7% |

126 products found

126 products

Topura Co., Ltd.

580+ people viewing

Last viewed: 6 hours ago

■ Characteristics It is a stainless steel bolt with high strength and high corrosion resistance of SUS304 or higher. ■ Advantages No regular repla...

Topura Co., Ltd.

690+ people viewing

Last viewed: 6 hours ago

■ Characteristics Bolt with a tapping function at the tip of the screw. ■ Advantages By eliminating the screw tap processing, you can reduce man -...

Tsukimori Industrial Co., Ltd.

530+ people viewing

Last viewed: 6 hours ago

■Exhibits high corrosion resistance, high heat resistance, and excellent rust prevention ability. Dacro treatment involves coating high-strength bo...

3 models listed

NIPPON POP RIVETS AND FASTENERS LTD.

530+ people viewing

Last viewed: 6 hours ago

High-strength hexagonal bolt for friction bonding that can be installed on one side Ideal for patch plate repair work from the bottom of steel dec...

Tsukimori Industrial Co., Ltd.

510+ people viewing

Last viewed: 6 hours ago

The issue of corrosion resistance for steel structures is rapidly progressing, not only in buildings and bridges, but also in steel in general. Dem...

4 models listed

Tsukimori Industrial Co., Ltd.

420+ people viewing

Last viewed: 1 hour ago

Certified by the Minister of Land, Infrastructure, Transport and Tourism

4 models listed

Tsukimori Industrial Co., Ltd.

300+ people viewing

Last viewed: 6 hours ago

Japanese Industrial Standard certified factory certified product JIS B 1180

5 models listed

Taihei Kogyo Co., Ltd.

410+ people viewing

Last viewed: 6 hours ago

■Product usage hexagonal high strength nut ■Product Concept Using high tension bolts and caps with washers has the effect of suppressing rust on t...

Teikoku Seizai Co., Ltd.

450+ people viewing

Last viewed: 6 hours ago

Manufacturing drift pins requires advanced heat treatment technology. If heat treatment is not properly managed, problems such as pins becoming chi...

Tokyo Jizai Kogyo Co., Ltd.

340+ people viewing

Last viewed: 6 hours ago

Teikoku Seizai Co., Ltd.

640+ people viewing

Last viewed: 6 hours ago

We manufacture high-strength hexagonal bolts that are compatible with all environments. High-strength hexagonal bolts (M12 to M30), which are now u...

Teikoku Seizai Co., Ltd.

500+ people viewing

Last viewed: 6 hours ago

Headed studs are used in steel and concrete structures in civil engineering construction to prevent concrete from slipping and as anchors. Currentl...

Teikoku Seizai Co., Ltd.

400+ people viewing

Last viewed: 6 hours ago

TM truss bolts are used in the spherical joints of the TM three-dimensional truss (Taiyo Kogyo Co., Ltd.), which creates an ideal column-free space...

Yamashina Co., Ltd.

320+ people viewing

Last viewed: 6 hours ago

Gigafit is a self-tapping screw technology that can be used for ultra-high tensile strength materials of 1,180Mpa. It uses a material with low risk...

Cains Co., Ltd.

240+ people viewing

Last viewed: 6 hours ago

■Features High-strength bolt special eraser pen ■Applications Can be erased with pinpoint precision

Cains Co., Ltd.

250+ people viewing

Last viewed: 6 hours ago

For marking high-strength bolted connections ■Features Perfect fit to the bolt corner thanks to special pen tip processing ■Applications Place th...

Tsukimori Industrial Co., Ltd.

320+ people viewing

Last viewed: 6 hours ago

Tsukimori Industrial Co., Ltd.

340+ people viewing

Last viewed: 6 hours ago