All Categories

History

This section provides an overview for polyethylene pipes as well as their applications and principles. Also, please take a look at the list of 10 polyethylene pipe manufacturers and their company rankings. Here are the top-ranked polyethylene pipe companies as of March, 2026: 1.Nelson Plastics, Inc., 2.Inline Plastics, Inc., 3.Speed Field Services.

Table of Contents

Categories Related to Polyethylene Pipes

Okayama University Graduate School, Ph.D. (Agriculture). After working as a specially appointed Assistant Professor at Tokyo Medical and Dental University, a fluid researcher at the Okayama Prefectural Institute of Biological Sciences, and a special researcher (JSPS PD) at the Japan Society for the Promotion of Japan Science, he became independent as a freelancer.

Specializes in natural product chemistry, protein engineering, fermentation engineering, and instrumental analysis of chemicals (especially mass spectrometry chemistry).

Thesis: https://pubmed.ncbi.nlm.nih.gov/?term=HIROKAZU+USUKI

linkedin: https://www.linkedin.com/in/%E5%8D%9A%E4%B8%80-%E8%87%BC%E6%9C%A8-b83827228/

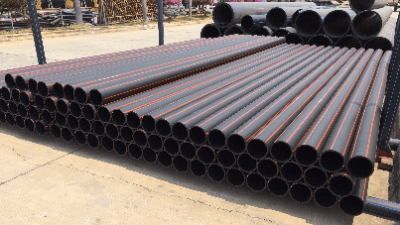

Polyethylene pipes are made of polyethylene (Figure 1). They are used for gas piping, chemical piping in chemical plants, and water supply and distribution pipes.

Polyethylene has excellent weather ability and chemical resistance, so there is no need to worry about red water caused by rust as is observed with steel piping. In addition, because polyethylene is a resin material, it is flexible, which has the advantage of making buried piping networks more resistant to earthquakes and other disasters. One of the major manufacturers of polyethylene pipes is Sekisui Chemical, which specializes in manufacturing and processing resin materials.

Polyethylene pipes have been attracting attention in recent years mainly as infrastructure piping for delivering water and gas. Polyethylene pipes can be used in all applications except high-temperature fluids, such as water distribution pipes because they are rust-resistant and have excellent water hygiene properties, sewage pipes because they are chemically stable and do not cause blockages in pipes due to red rust, and air conditioning pipes because they are lightweight and can be quickly installed.

In addition, cross-linked polyethylene pipes can be used at temperatures of 95°C or lower for hot water supply without deterioration over a long period.

Compared to steel pipes conventionally used for buried pipes, polyethylene pipes are superior in that they do not rust, do not corrode even in corrosive soil or salt-affected areas, have excellent electrical insulation properties, do not cause electrical corrosion, and are less likely to become blocked due to scale adhesion.

The resin material also has the advantages of being lightweight for efficient transportation and installation, easy bending, and earthquake resistance due to its flexibility.

Pipe joints for polyethylene pipes include fusion joints, mechanical joints, and electro-fusion joints. Infusion joint joining, the insertion point on the polyethylene pipe side, and the receiving end on the joint side are heated in a heating machine to melt them and then joined.

Since this method requires control of the heating temperature, it is desirable to use a dedicated heating machine, and there are some problems in terms of workability. Electrofusion (EF), a type of electrofusion joining, is a method that overcomes this difficulty.

This method is very superior in terms of simplicity of operation, and heating is performed by energizing a joint with a built-in electric heating wire, which simultaneously melts and fuses the pipe and the joint, thereby completing a completely integrated joint.

Because of these advantages, polyethylene pipes are often introduced as an alternative to conventional steel piping and are expected to help build disaster-resistant cities, which have recently become more important in society, and ultimately help realize a sustainable society.

A polyethylene dual-layer pipe is a polyethylene pipe consisting of two layers: an outer layer (polyethylene with carbon black) with high weather resistance and an inner layer (natural polyethylene) with high chlorinated water resistance, and is widely used mainly for water supply pipes, drainage pipes, temporary piping, and other water supply applications.

Its excellent flexibility allows it to flexibly follow ground subsidence, earthquakes, etc. It also has excellent chemical stability. It also has excellent chemical stability, so there is no risk of corrosion to the soil in which it is buried.

Furthermore, it is hygienic because no harmful additives are used. In this regard, the pipes are ideal for drinking water piping in terms of water quality retention and hygiene, as there is no rusting and very little scale adhesion.

The inner surface of this piping is extremely smooth and has low frictional resistance, resulting in very little scale adhesion. This pipe has an excellent characteristic of extremely low flow reduction over time.

Because both types of piping are made of plastic materials, these two materials are often confusedly understood, but it is important to note that their characteristics and applications are different.

As explained at the beginning of this article, polyethylene pipes are made of polyethylene and have excellent flexibility, making them very earthquake resistant when buried underground.

On the other hand, PVC pipes are pipes made of polyvinyl chloride, and although they have a certain degree of flexibility, the degree of flexibility is not as high as that of polyethylene pipes. Structural differences between polyethylene and polyvinyl chloride

Polyethylene pipes are known for their long service life. In Japan, there is a demand for water pipelines with a service life of 100 years or longer, and polyethylene pipelines for water distribution are also required to have high durability.

An example of a study in this regard is a 2013 report by the Polyethylene Pipe System Association for Water Distribution (POLITEC). This study examined verification against internal and external pressure, earthquakes (seismic resistance), and residual chlorine (chlorinated water resistance). As a result, the results of all verifications exceeded 100 years under the specified assumed conditions, indicating that polyethylene pipelines for water distribution have a service life well in excess of 100 years.

Polyethylene pipes made from high-density polyethylene (polyethylene with a density of 0.942-0.970) have excellent impact resistance and flexibility (bending and flexing characteristics).

Therefore, the pipes are resistant to damage even in the event of a disaster. Because of these excellent physical properties, the material is used in the fields of civil engineering, agriculture, and mining, including drainage pipes for longitudinal road crossings, canal rehabilitation, small-scale canal culvert conversion, various rainwater drainage works, and industrial waste disposal sites.

*Including some distributors, etc.

Sort by Features

Sort by Area

Inline Plastics, Inc. is a Canadian manufacturer of extrusion dies and custom plastic extrusions founded in 1996 and based in Ontario. The company manufactures custom plastic profiles, tubing, molds, and dies working with over 20 thermoplastic materials such as PVC, polyethylene, acrylic, polycarbonate, and polypropylene, additionally providing secondary finishing services including embossing, deburring, drilling, packaging, and assembly. They produce grow tubes, point-of-purchase displays, poly siphon tubes, and road delineators, notably serving construction and roadwork, food and beverage, medical, and agricultural industries.

Calpex Plastics is a custom plastic extrusions manufacturer founded in 1980 and based in Oceanside, California. The company specializes in pipe, spiral wrap, tubing, and profiles for use in irrigation, water filtration, construction and packaging. The company also produces abrasion-resistant urethane extrusions for more demanding applications such as in gaskets or bumpers, as well as 3D printing filaments for prototyping and modeling. Some of Calpex Plastics' clients include Amcor, Crown Holdings and Berry Global.

Speed Field Services, founded in 2014 and headquartered in Baytown, Texas, is a manufacturer of standard and custom spill containment products. The company offers a range of essential products, including berms, liners, and pipes, all crafted from geomembrane materials such as PE, Coolguard, XR5, vinyl, PVC, RPP, and RPE. Moreover, its services extend to custom fabrication and installation of HDPE, PVC, CPP, and polypropylene products, providing tailored solutions, and serving the marine, mining, and agricultural industries.

Asahi/America was born in 1971 to be the distributor for Asahi Yukizai Corporation products on the East Coast of the United States. Asahi/America serves the aquarium & entertainment, chemical processing, data center, metal finishing, and the water/wastewater industries. The company offers a selection of valves and actuators including many types of valves, high purity piping, air & gas handling, double containment, and welding equipment. The company alos offers a wide assortment of custom fabrication of parts and components.

IPEX by Aliaxis is headquartered in Oakville, Ontario. IPEX is a producer of pipe-related solutions defined in 6 categories: municipal, plumbing & mechanical, industrial, electrical, PE electrofusion, and irrigation. The company's municipal solutions include pressure piping and sewer piping systems in addition to specialty products. Plumbing & Mechanical solutions also include fire protection, gas venting systems, and potable water systems. Compressed air and acid waste systems are used in industrial systems. Light fixtures and ducts are keystones of the electrical solutions segment.

Nelson Plastics, Inc., founded in Longwood, in 1993 is a manufacturer of acrylic frames in different sizes, custom shapes and multiple colors. The company's product portfolio includes acrylic multi or single layered magnets, key chains, ornaments and license plates. The company serves markets such as Food and Beverage, consumer goods, Automotive, Pharmaceutical and Biotechnology and Chemical and Petrochemical. The company provides services such as Product Selection Guidance, New Product Design and Development and Custom Manufacturing.

K. Jabat, Inc., established in Middlesex, NJ in 1973, is a manufacturer of Custom Tubing and Profile Solutions. The company's product range includes Custom Tubing Solutions, Profile Extrusions, Fabricated Tubing Assemblies and CNC Machined Components. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers customer services that include technical support, custom research projects and customized services.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Nelson Plastics, Inc. |

20.1%

|

| 2 | Inline Plastics, Inc. |

15.2%

|

| 3 | Speed Field Services |

10.1%

|

| 4 | Asahi/America, Inc. |

9.2%

|

| 5 | K. Jabat, Inc. |

8.9%

|

| 6 | Calpex Plastics, Inc. |

8.6%

|

| 7 | IPEX |

8.3%

|

| 8 | Idrotherm 2000 S.p.a. |

6.9%

|

| 9 | Pore Technology, Inc. |

6.9%

|

| 10 | LA.RE.TER. SPA |

5.7%

|

Derivation Method

The ranking is calculated based on the click share within the polyethylene pipe page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 80.0% |

Canada

Canada

|

1 | 20.0% |

58 products found

58 products

Sanwa Shoko Co., Ltd.

630+ people viewing

Last viewed: 16 hours ago

■Features ・For water supply/hot water supply ・5mm/10mm/with high weather resistance coating

Yamaichi Kako Co., Ltd.

420+ people viewing

■Main specifications/applications 10 substances of the revised RoHS Directive Manufactured with raw materials that are not intentionally used. Dire...

WB Energy Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

R-K is a leading European heat pipe manufacturer headquartered near Linz, Austria. The company's products have a reputation for their durability an...

Japan Plastic Industry Co., Ltd.

470+ people viewing

It is easy to cut and does not generate chips when cut with a blade, so it is possible to cut the film together after winding it up. It can be used...

WB Energy Co., Ltd.

400+ people viewing

R-K is a leading European heat pipe manufacturer headquartered near Linz, Austria. The company's products have a reputation for their durability an...

Sanwa Shoko Co., Ltd.

780+ people viewing

Last viewed: 1 day ago

■Features ・Reheating piping for baths / Piping for heating ・Excellent heat resistance and creep properties. - Excellent flexibility and easy cons...

Sanwa Shoko Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

■Features ・For water supply/hot water supply ・5mm/10mm/with high weather resistance coating ・Long type

6 models listed

Nimatsu Electric Co., Ltd.

530+ people viewing

Last viewed: 9 hours ago

Swun Yuan is a Taiwanese plastic injection molding products manufacturer founded in 1990. LLDPE tubing is made from durable low-density polyethylen...

Bakuma Kogyo

230+ people viewing

Last viewed: 21 hours ago

■ Characteristics ・ The reheating member is piped from the water heater to the circulating port with a crosslinked polyethylene tube. ・ It can be...

10 models listed

Sunhope Co., Ltd.

240+ people viewing

Last viewed: 19 minutes ago

■Summary Ensures drip irrigation to the points you want to irrigate. For any cultivation method, from greenhouses to open fields. ■Excellent featu...

3 models listed

Bakuma Kogyo

290+ people viewing

WSQ System Series Hard Lock Safe, easy, speed construction by one -touch connection ■ Characteristics ・ One -touch connection with just insertin...

10 models listed