All Categories

History

This section provides an overview for resin tubes as well as their applications and principles. Also, please take a look at the list of 16 resin tube manufacturers and their company rankings. Here are the top-ranked resin tube companies as of July, 2025: 1.Nihon Pisco Co., Ltd., 2.Reflection Surf Co., 3.W.E. Aubuchon Co., Inc..

Table of Contents

Categories Related to Resin Tubes

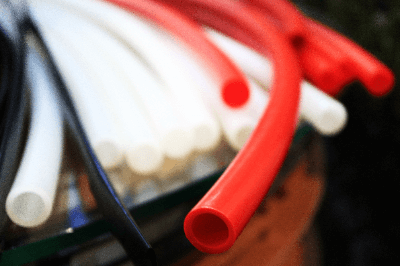

Resin tubes are tubes made from plastic.

Materials include polyolefin, polyurethane, and fluoropolymers. The durability, chemical resistance, and hardness of the tubing vary depending on the material and thickness. Therefore, the appropriate tubing should be selected according to the application.

Resin tubes are used to transport chemicals at various manufacturing sites for pharmaceuticals, chemicals, and inorganic materials. They are also useful as conductor sheathing due to their excellent electrical insulation properties. Resin tubes are also useful for coating conductors. While Resin tubes are conductive, some products have been developed to be electrically conductive, although normal tubes are easily electrically charged.

Resin tubes play a vital role in the medical industry. They are used for intravenous catheters, conduits, drain tubes, and tubes for blood tests. The flexibility and smooth inner surface of resin tubes ensure patient comfort and safety during medical procedures.

In the automotive industry, resin tubes are widely employed in engine components, brake systems, and fuel delivery systems. Resin tubes are increasingly being used as alternatives to metal tubing in automotive parts where durability and chemical resistance are required.

Resin tubes are used for piping and transportation in the food industry. The tubing is suitable for transferring food and beverage fluids, exhibits high chemical resistance, and meets food safety standards. Resin tubes are commonly used in production lines for dairy products, beverages, and seasonings.

In the electronics industry, resin tubes serve as insulating material for electrical wires and coating circuit boards. The properties of resin tubes are crucial because they require high electrical insulation and heat resistance.

Resin tubes also find applications in the agricultural and horticultural industries. They are used as sprinkler tubes for watering and fertilizer application and are sometimes integrated into agricultural machinery parts. Being lightweight and durable, they enhance the efficiency of agricultural operations.

Resin tubes are also extensively employed in various industrial applications. They are used in piping for a range of industrial machinery, including hydraulic and pneumatic equipment, gas supply systems, etc. Notably, their light weight and ease of handling facilitate installation and replacement work.

Resin tubes are crafted from flexible resin material. Thanks to this flexibility, they adapt easily to bending, twisting, and other deformations, making them suitable for installation in tight spaces and complex geometries.

Resin tubes are made from durable resin material, providing them with exceptional durability for long-term use. Resin materials are also generally resistant to chemicals, playing a crucial role in industries handling chemicals due to their resistance to corrosion and deterioration.

The smooth, low-friction inner surface of resin tubes enables smooth fluid movement, making them suitable for transporting liquids and gases with minimal energy loss.

Resin tubes typically exhibit high electrical insulation properties, making them widely used as insulating materials for electric wires and electrical equipment. They prevent the leakage of electrical signals, ensuring the safety of electrical systems.

Resin tubes are constructed from lightweight materials, making them easy to handle. Particularly in industrial fields where they are used in large quantities, their light weight contributes to cost reduction.

PVC tube is the most popular type of resin tube in general. Due to its flexibility and cost-effectiveness, it is widely used in various applications, including industrial and domestic applications such as water and air supply, drainage, and plumbing. Its excellent chemical resistance also makes it suitable for chemical transfer.

PU tubing is characterized by excellent abrasion and oil resistance, high strength, and flexibility. These qualities make PU tubing widely used in industrial fields requiring high reliability, such as pneumatic tools, robots, and automotive braking systems.

Silicone tubing offers excellent heat resistance and is suitable for high-temperature environments. It is commonly used in medical equipment and the food industry and is ideal for transporting chemicals and high-temperature liquids. Silicone tubing is highly durable and can withstand long-term use.

A Fluorine tube is a specialized resin tube with high chemical and heat resistance. It exhibits excellent resistance to strong acids, strong alkalis, and organic solvents, making it suitable for use in the semiconductor and chemical industries. It is also appropriate for transferring chemicals and solvents at high temperatures.

Nylon tubes offer excellent abrasion and oil resistance. They are used in fuel supply and brake systems in the automotive industry and pipelines for industrial machinery. The high tensile strength of these tubes makes them suitable for pneumatic tools and power transmission in robots.

*Including some distributors, etc.

Sort by Features

Sort by Area

Hach Company, a subsidiary of Danaher Corporation (DHR), is an American manufacturer established in 1933 and headquartered in Loveland, Colorado, specializing in analytical instruments and reagents for testing water quality and other liquid solutions. Hach offers a diverse range of products, including chemicals, laboratory equipment and supplies, as well as portable and digital (online) instruments. Specific instruments like spectrophotometers, turbidimeters, and colorimeters are also available. These products are used for various applications, for example in analyzing industrial water to reduce fresh water consumption and validate contaminant removal, and monitoring nutrient for long-term water health using the Real Time Control (RTC) system.

Advanced Technology Products (ATP), established in 1990 in Ohio, the United States, is a manufacturer of precision-made tubing, fittings, and pneumatic accessories. The company began as a joint venture between a Japanese tubing manufacturer and an American distribution organization to provide service to the Japanese automotive industry within the US. It has been providing cutting-edge solutions for multiple industries. Its product range includes a wide range of pneumatic, push-to-connect fittings, and a complete offering of FRL’s. It is ISO 9001:2015 Certified, and is also continuing to expand its offerings and capabilities to meet the changing needs of its customers.

Reflection Surf Co., established in 2021 in Wilmington, North Carolina, is a manufacturer in the surf and paddleboard industry. The company specializes in crafting advanced surfboards and paddleboards, offering a broad range of products, including shortboards, longboards, and performance paddleboards. It holds ISO 9001 certification, and the features of its surfboards and paddleboards include ideal design, durability, and enhanced performance in various wave conditions. Serving surfing enthusiasts of all skill levels, its products find applications in recreational surfing, competitive events, and fitness activities.

W.E. Aubuchon Co., Inc., originally establshed in 1908 by William E. Aubuchon, is a family-owned and operated chain of hardware stores consisting of over 100 stores across the Northeast United States, Maryland, Virginia, and Pennsylvania in addition to the online store, HardwareStore.com. The company is a distributor of hardware goods, garden and lawn supplies, nuts and bolts, electrical devices, outdoor living products, and home goods. The store works with manufacturers and distributors to offer more product categories and product choices.

Sebastian Inlet Surf & Sport, established in 2012 in Melbourne Beach, Florida, is a provider of surf equipment serving the needs of water sports enthusiasts. The company offers a broad range of products, including surfboards, apparel, and accessories. It offers surfing items from major brands, and the advantages of its products include access to advanced surfing equipment, personalized customer service, and an emphasis on promoting the surfing lifestyle. Serving both beginners and seasoned surfers, its products find applications in recreational surfing, competitive events, and beach-related activities.

The Whole Package, LLC, founded in 2003 and headquartered in Sarasota, Florida, is a supplier of machinery and cosmetic tube products. The company specializes in providing tube sealer machines, aluminum tube crimpers, tube filling machines, and closing machines. It offers new machinery, used machinery, and rental machinery. The company also provides services that include tooling, changing parts, engineering, and contract filling of plastic tube packaging. These products and services find applications in product pharmaceutical, dentifrice, food, household, and industrial.

Nihon Pisco Co. Ltd., founded in 1976 and based in Nagano, Japan, is a manufacturer and distributor of pneumatic equipment and is ISO 9001 and ISO 14001 certified. The company stocks various products like valves, actuators, and vacuum accessories used in several industries, including semiconductor, medicine, and rechargeable battery. The company started selling push-in fitting for pneumatic piping in 1977 and launched the industry’s first push-in fitting built-in type speed controller in 1981. In 1993, it launched a few products, including a quick exhaust valve, a digital pressure sensor, and a vacuum generator with a digital pressure sensor.

SMC corporation was founded in 1959 and is headquartered in Tokyo, Japan. SMC Corporation manufactures and sells automatic control equipment and filtration equipment. SMC has production facilities in 30 countries, technical development centers in Japan, the United States, Europe, and China, and sales offices, globally. SMC product lines divided by them include filter replacements, condensation prevention, heat resistance, thermos-chilling, and others. SMC provides a video library as well as product selection guide to assist customers in finding solutions and optimizing product efficiency.

HAKKO Corporation, established in 1952 and has its headquarters in Osaka, Japan, is a manufacturer and distributor of soldering equipment and solutions. It offers a wide range of products including soldering stations, desoldering tools, and soldering pots. These products are used for various thermal control needs such as in electronics manufacturing, hobbies, and crafts. The company operated globally and holds both the ISO 9001 quality management and ISO 14001 enviornmental management certifications.

XHnotion Pneumatic, founded in 2007 and based in Ningbo, China, is a manufacturer and supplier of pneumatic power products. The company is certified to ISO 9001:2015 and has a CE, ROHS, and REACH certificate for the international market. The company’s customers include Johndeere, Univer, Sulzer, MEIDEN, Metalworks, and Wurth. It offers pneumatic fittings, air hoses, solenoid valves, air guns, and coupling products. The company’s pneumatic fittings include plastic pneumatic fittings, metal pneumatic fittings, mufflers, and push-button couplers.

Nitta Corporation is an Osaka-based manufacturer and distributor of various industrial products founded in 1885. The company offers power transmission and mechatronic products, as well as intermediate components like tubings and fittings. These are used in conveyor machines, hydraulic systems, and medical devices. The company also produces industrial parts, such as molded rubber products like gaskets or diaphragms, as well as air filters and monitoring equipment like particle counters or decontamination devices. Nitta Corporation maintains a network of manufacturing facilities and sales locations in 22 countries across four continents.

F.I.E. Balconi SRL, established in 1963 and headquartered in Vimercate, Lombardy, Italy, is a temperature-resistant flexible insulating sleeve manufacturer and B2B supplier. The company's primary products include braided fiberglass sleeves, basalt sleeves, and carbon fiber sleeves. It also produces ultra-flexible thin-walled heat-shrinkable sleeves, locked anti-fraying fiberglass sleeves, and extruded silicone fiberglass tubes. These products are used in various applications, including high-temperature industrial equipment, food processing machines, and firefighting equipment. The company's products are available online worldwide through the company's web store.

McKesson Medical-Surgical, located in the United States, is a distributor of medical supplies established in 1833. The company offers healthcare solutions, clinical resources, and distribution services. They provide a wide range of medical products with the largest delivery vehicle fleet and over 900 delivery professionals nationwide. In addition to their distribution services, they provide laboratory and pharmaceutical services, as well as solutions for inventory management. Their technology consultants offer a no-cost evaluation of the customers' supply and inventory workflow, providing with recommendations on how to drive savings and efficiencies to help uncover opportunities and match solutions to customers' specific needs.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Nihon Pisco Co., Ltd. |

14.8%

|

| 2 | Reflection Surf Co. |

11.1%

|

| 3 | W.E. Aubuchon Co., Inc. |

11.1%

|

| 4 | The Whole Package, LLC |

11.1%

|

| 5 | Nitta Corporation |

11.1%

|

| 6 | Sebastian Inlet Surf & Sport |

7.4%

|

| 7 | Rock West Composites, Inc. |

7.4%

|

| 8 | McKesson Medical-Surgical Inc. |

7.4%

|

| 9 | Advanced Technology Products |

7.4%

|

| 10 | Hach Company |

7.4%

|

Derivation Method

The ranking is calculated based on the click share within the resin tube page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 50.0% |

Japan

Japan

|

6 | 42.9% |

China

China

|

1 | 7.1% |

718 products found

718 products

Aritosukai Co., Ltd.

530+ people viewing

Last viewed: 17 hours ago

In the Yunshi Shokai, there is a handling of tubes. We have a track record of handling both manufacturer standard products and ordered products. It...

Sakai Chemical Industry Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Summary "Fulcon Tube" is a tube that is made using PET resin, PVC resin, PS resin, etc. as the main raw materials, using a special manufacturing m...

Hakko Co., Ltd.

760+ people viewing

Last viewed: 1 day ago

Multi-purpose barrier tube / Barrier performance more than twice that of commercially available PE tubes. A highly functional barrier tube that pre...

4 models listed

Yagyu Shokai Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■Features ・PEEK tube for HPLC. ・High precision with inner and outer diameter tolerance of ±30μm. ・Comes with a removable identification tag that...

Yagyu Shokai Co., Ltd.

200+ people viewing

Last viewed: 11 hours ago

■Features - Excellent weather resistance, UV resistance, and moisture resistance. ・It has self-extinguishing properties and is designed for safety...

Yagyu Shokai Co., Ltd.

200+ people viewing

Last viewed: 4 hours ago

■Features - Excellent flame retardancy (UL94 V-O low outgas). - Excellent acid and alkali resistance at high temperatures. ・It has excellent hydro...

Yagyu Shokai Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

*Sold in 10m units.

Daiji Co., Ltd.

1370+ people viewing

Last viewed: 11 minutes ago

A thin-walled heat shrink tube that is highly versatile and can be used for multiple purposes. A handy size box type that is compact and convenient...

10 models listed

Yagyu Shokai Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

■Features - Highly flexible and can be easily and firmly attached to glass, metal pipes, etc. - Has excellent chemical resistance and can be used w...

Yagyu Shokai Co., Ltd.

170+ people viewing

Last viewed: 8 hours ago

*Sold in 10m units.

Sanwa Shoko Co., Ltd.

850+ people viewing

Last viewed: 32 minutes ago

■Features ・More than 20 years in accelerated testing machines ・Inner layer is heat resistant to 120℃ ■Caution Only the outer covering is UV prot...

5 models listed

Daiji Co., Ltd.

760+ people viewing

Last viewed: 4 hours ago

It has a high shrinkage ratio of 3:1, has excellent flexibility and flame resistance, and comes with adhesive to prevent moisture and protect the i...

6 models listed

Yagyu Shokai Co., Ltd.

250+ people viewing

Last viewed: 14 hours ago

■Features - Highly flexible and can be easily and firmly attached to glass, metal pipes, etc. - Has excellent chemical resistance and can be used w...

Yagyu Shokai Co., Ltd.

240+ people viewing

Last viewed: 1 hour ago

■Features ・Insulation is possible by passing a tube inside. - Suitable for heat retention and freezing prevention. *Sold in 1m units.

Daiji Co., Ltd.

1030+ people viewing

Last viewed: 19 minutes ago

In addition to having excellent mechanical strength, insulation properties, and chemical resistance, it is a semi-rigid, heat-resistant tube that i...

10 models listed

Yagyu Shokai Co., Ltd.

290+ people viewing

Last viewed: 14 hours ago

■Features ・Excellent internal smoothness. ・Because it is platinum vulcanized, there is very little elution and it is unlikely to affect the fluid...

Yagyu Shokai Co., Ltd.

200+ people viewing

Last viewed: 1 day ago

■Features ・Excellent vacuum holding performance. *Sold in 1m units.

Daiji Co., Ltd.

1060+ people viewing

Last viewed: 3 hours ago

Highly flexible shrink tubing has excellent oil resistance, chemical resistance, and high flame resistance, and can be used in a wide range of appl...

8 models listed

Yagyu Shokai Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

*Lengths and color tubes other than the standard length can also be manufactured. *Standard length 1m products may be slightly curved due to the ma...

Yagyu Shokai Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■Features ・Excellent internal smoothness. ・Because it is platinum vulcanized, there is very little elution and it is unlikely to affect the fluid...

Yagyu Shokai Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

■Features ・This is an environmentally friendly vacuum hose that does not generate dioxins. ・Excellent ozone resistance and weather resistance. *S...

Daiji Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

Soft heat shrink tubing has excellent flexibility, is environmentally friendly, produces low smoke when burned, and is halogen-free. Please specif...

3 models listed

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

Yagyu Shokai Co., Ltd.

180+ people viewing

Last viewed: 22 hours ago

■Features - A tube for medium and low pressure that uses thermoplastic polyurethane elastomer and has excellent abrasion resistance, water resistan...

Yagyu Shokai Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Features - Has excellent heat and cold resistance and can be used in a wide range of temperatures from -40 to +150℃. *Sold in 1m units.

Daiji Co., Ltd.

930+ people viewing

Last viewed: 18 minutes ago

A heat shrinkable tube with green and yellow stripes that can be used for insulation and protection as a grounding connector and cable identificati...

7 models listed

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 22 hours ago

■Features - A pure fluorine resin tube that does not contain fillers, plasticizers, or other additives. ・It is suitable for electrical insulation ...

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■Features ・It maintains its properties as an elastic body in a temperature range of -60 to +200℃, and exhibits excellent resistance to ozone, humi...

Kiriyama Manufacturing Co., Ltd.

210+ people viewing

This column can be packed with Sulzer packing or your own packing material. (Blank column) We can also deliver the column with Sulzer packing upon ...

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 4 hours ago

■Features - A PTFE tube that has been cleaned with ultra-pure water and clean-packed under class 100 high cleanliness conditions. ・This product is...