All Categories

History

This section provides an overview for brake linings as well as their applications and principles. Also, please take a look at the list of 10 brake lining manufacturers and their company rankings. Here are the top-ranked brake lining companies as of July, 2025: 1.Sundaram Brake Linings Ltd, 2.NeoBrake Systems, Inc., 3.Tolomatic, Inc..

Table of Contents

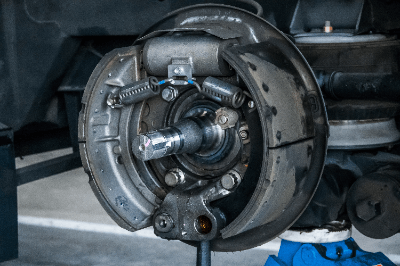

Brake Lining is a friction material that is a component of the brake system. Brakes convert kinetic energy into thermal energy through friction. Brake lining is the friction material that provides that friction.

Brake Lining is a friction material that is a component of the brake system. Brakes convert kinetic energy into thermal energy through friction. Brake lining is the friction material that provides that friction.

However, brake lining is not used in regenerative braking where there is no physical contact. Generally, those attached to disc brakes are called pads, while those attached to drum brakes are called shoes.

Brake Lining is used for equipment in which a braking system is incorporated. They are used in a wide range of applications, from industrial to consumer products, and the main examples of their use are as follows:

Brake devices that use brake lining include Disc Brakes, Drum Brakes, and Band Brakes.

The principle of each is as follows:

All brakes convert kinetic energy into thermal energy. When selecting brake lining, there are conditions such as operating temperature and coefficient of friction.

In addition, factors such as discomfort noise and vibration during braking also exist, so the types and blends of friction material materials vary widely, with more than 10 different raw materials blended together to make the product.

Brake Lining and Brake Pads are both wear parts used in brakes. For drum brakes, they are called "Brake Lining" and for disc brakes, they are called "Brake Pads".

Both are abrasion materials, which wear during braking to slow down the object. In the case of automobiles, materials are used that function reliably even when affected by snow and mud.

In the case of a vehicle that repeatedly drives at high speed and stops abruptly, such as a racing car, the brake linings generate a lot of heat and turn bright red. A material that does not impair braking performance under these conditions should be used. In order to use brake linings that are appropriate for the vehicle, it is preferable to use the manufacturer's original brake linings when replacing them.

Brake Lining is designated as a periodic replacement part because it wears out with use. Replacement timing is determined by checking the mileage and measuring the amount of wear. Longer mileage increases the frequency of braking, and thus the wear of brake lining is more likely to progress.

Even when the mileage is short, premature wear may occur due to frequent emergency braking or overloading. The amount of wear should be measured during periodic inspections, and if it is close to the replacement threshold, replacement of brake lining is recommended. In many cases, brake lining wear can be detected by a change in brake sound.

As the brake lining wears down, a high-pitched "squealing" sound is heard when the brakes are applied. This is because the metal parts of the brake linings begin to contact each other due to wear. If you hear this unpleasant sound when braking, you should replace the brake lining as soon as possible. Continued driving under this condition may result in a serious accident due to reduced braking force.

*Including some distributors, etc.

Sort by Features

Sort by Area

NeoBrake Systems, Inc. is a Wisconsin, US-based brake system and automation equipment manufacturer that began its business in 1988. The company's products include lightweight cast iron brakeshoes, truck brakes, extra-duty truck brakes, non-TFT brake linings, and air disc brakes. The company invented Neokinetic Friction Technology, the asbestos-free brakes after the asbestos brakes were discontinued. It also distributes throughout the continental United States and all of Canada. One of its products, Matrix NeoCast, was included as one of the final four top-selling products by Trucks Parts & Service Magazine.

Marathon brake systems have been established since 1991 in Cartersville, GA as a manufacturer and supplier of brake components. The company offers various products, such as brake lining, brake pads, brake shoes and Air Disc Rotors. These products have different variants based industry applications and vehicle type. The company manufactures these products with ratings suitable for axle loads ranging from 20,000 to 28,660 pounds. The products have utilization mostly in severe service applications like fire trucks, liquid tankers, intra-city & intercity bus fleets and over-road hauling.

Tolomatic was founded in the 1950s and operates out of Hamel, Minnesota. Tolomatic Is a manufacturer of automation components for industries such as aerospace, agriculture, automotive construction, life sciences, semiconductor, and utilities. Tolomatic has three main product lines which are electric linear actuators, pneumatic linear actuators, and power transmissions. Electric linear actuators include rodless electro-mechanical actuators, electric rod actuators, as well as custom & modified products. Pneumatic linear actuators include rodless pneumatic actuators, rod-style pneumatic linear thrusters, and custom & modified products. Power transmission includes roller screws, industrial caliper brakes, industrial gearboxes, and industrial cone clutches.

RAPCO Inc was established in 1981 and is based in Heartland, Wisconsin as a manufacturer of replacement aircraft parts. The product portfolio includes brake wear parts, de-ice components, fuel pumps, pneumatic equipment and gaskets. These parts are used in the engine, braking, exhaust and propeller parts of general aviation aircraft. the company provides tools to facilitate the proper installation of these components. The company has distributors in the USA, South America, Australia and Europe.

Potter Associates, Inc. was founded in 1964 and is based in Rochester, New York. Potter Associates is a manufacturer and distributor industrial materials, tools, and machinery. Manufacturing capabilities include V packaging sets, O-rings, gaskets, sheet material, rubber extrusions & sheet material, heat exchangers, compression braided packing, non-asbestos brake linings, urethane molding, and PTFE machining. Other product offerings include valve packing, pulp and paper packing, soot blower sets, copper packing, metallic packing, and wastewater treatment packing.

The Rowland Company was founded in 1732 in Philadelphia, Pennsylvania when Benjamin Franklin was just 25 years old. Today the Rowland Company specializes in the distribution, fabrication, and assembly of industrial power transmission products, including application engineering, and modification of products to customer needs. Industries served include commercial laundry, amusement parks, marine, metalworking, power generation, pulp & paper, transit, water treatment and wastewater treatment Rowland Company’s product categories include air starters, brakes, clutches, crane controls & electrification, flexible couplings, friction and wear materials, gearboxes, industrial lighting & signals, mobile crane brake parts, universal joints, and driveshafts.

Sundaram Brake Linings Ltd is a manufacturer of automotive, non-automotive, railways, and industrial friction materials, established in 1976 and headquartered in Padi, Chennai, India. The company specializes in crafting premium brake linings, PV pads, and clutch facings. Its products are extensively used in commercial vehicles, passenger cars, agricultural tractors, railways, and two-wheelers. The company is a holder of ISO 9001:2015, ISO 14001: 2015, and IATF 16949:2016 certifications, ensuring its products meet industry standards.

Ferodo was established in 1897 and is based in High Peak, Derbyshire as the first and foremost manufacturer of brake components for almost all types of vehicles. The product portfolio includes brake pads, brake discs, calipers, brake fluids and other related accessories. These products are used in drum brake, disc brake, ABS brake and hydraulic brake depending upon the nature of braking system. The company is manufacturing brake components for automotive industry giants like Mercedes, Ford and Volkswagen.

Ceco Friction Products, Inc., established in 1973 and based in Landis, North Carolina, is a manufacturer specializing in custom friction materials and related products. Serving diverse industries such as mining, construction, agriculture, and transportation, their products, including brake pads, brake linings, clutch facings, and roll linings, find wide-ranging applications. Their offerings comprise molded and woven friction materials, integrally molded organic, semi-metallic and full metallic disc pads, OEM quality caliper pistons, as well as seal kits, and roll lining for industrial machinery.

Clutch Engineering Co. was established in 1960 and is headquartered in Canton, Connecticut. The company is a distributor and specialty fabricator of industrial power transmission components, providing specialized engineering solutions to their specific needs. Customers typically come from industries such as mining, power generation, water treatment, shipbuilding, and transit. The company works with manufacturers such as Easton, Wichita Clutch, SEW-Eurodrive, and Lesson. Products typically used in customers’ products include couplings, electrification units, friction & wear materials, and air starters.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Sundaram Brake Linings Ltd |

18.6%

|

| 2 | NeoBrake Systems, Inc. |

14.5%

|

| 3 | Tolomatic, Inc. |

10.3%

|

| 4 | CECO Friction Products, Inc. |

9.7%

|

| 5 | Marathonbrake |

9.5%

|

| 6 | RAPCO, inc. |

8.3%

|

| 7 | Ferodo |

8.3%

|

| 8 | The Rowland Company |

7.1%

|

| 9 | Clutch Engineering |

6.9%

|

| 10 | Potter Associates, Inc. |

6.7%

|

Derivation Method

The ranking is calculated based on the click share within the brake lining page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 85.7% |

India

India

|

1 | 14.3% |

51 products found

51 products

Fuseas Co., Ltd.

300+ people viewing

Last viewed: 12 hours ago

Metal wire (1PLY) This product is made by woven from a special fiber-based material and impregnated with a specially formulated synthetic resin, th...

Fuseas Co., Ltd.

400+ people viewing

Metal wire (2PLY) A product made by impregnating special heat-resistant fibers, synthetic resin, and special heat-resistant chemicals, and then rol...

Fuseas Co., Ltd.

320+ people viewing

Last viewed: 8 hours ago

This product is made by impregnating heat-resistant woven fabric with metal wires with phenolic resin, heating and press-molding it to the specifie...

Ask Technica

990+ people viewing

Last viewed: 16 hours ago

composition It is a brake system that generates a frictional part called a lining, which is used in a drum brake, one of the front wheels or rear w...

4 models listed

Fuseas Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

This product is made by impregnating heat-resistant woven fabric with metal wires with phenolic resin, heating it, and press-molding it. It is less...

Tokai Material Co., Ltd.

300+ people viewing

Last viewed: 57 minutes ago

■Summary Tokai Carbon Group's friction material products create reliable performance ■Resin mold friction material Tokai Material Variations and ...

Tokai Material Co., Ltd.

300+ people viewing

Last viewed: 2 hours ago

■Summary Tokai Carbon Group's friction material products create reliable performance ■Sintered metal friction material “TOYOKAROY” Tokai Carbon V...

Fuseas Co., Ltd.

290+ people viewing

Last viewed: 9 hours ago

A friction material made by hot press molding of special heat-resistant fibers and specially blended resin. It maintains a stable friction coeffici...

Tokai Material Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Summary Tokai Carbon Group's friction material products create reliable performance ■Paper friction material “Toyoka FC” Tokai Carbon Variations...

Fuseas Co., Ltd.

320+ people viewing

A product made by heating and press-molding a mixture of special heat-resistant fibers, synthetic resin, heat-resistant chemicals, and metal powder...

Fuseas Co., Ltd.

360+ people viewing

This product is made of #1600 (resin mold standard type) with an iron plate baked and bonded.

Fuseas Co., Ltd.

250+ people viewing

This product is made of #1610 with an iron plate baked and bonded.

Tokai Material Co., Ltd.

200+ people viewing

Last viewed: 7 hours ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Fuseas Co., Ltd.

350+ people viewing

This product is made by impregnating heat-resistant wire with metal wire such as brass wire with phenolic resin and finishing it with a mold to the...

Tokai Material Co., Ltd.

180+ people viewing

Last viewed: 1 hour ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Tokai Material Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Tokai Material Co., Ltd.

290+ people viewing

Last viewed: 7 hours ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Tokai Material Co., Ltd.

210+ people viewing

Last viewed: 15 hours ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Tokai Material Co., Ltd.

200+ people viewing

Last viewed: 23 hours ago

■Summary Electromagnetic brake linings and clutch facings are used for control in a wide range of fields, from industrial machinery to small office...

Tokai Material Co., Ltd.

180+ people viewing

■Summary Electromagnetic brake linings and clutch facings are used for control in a wide range of fields, from industrial machinery to small office...

Tokai Material Co., Ltd.

250+ people viewing

Last viewed: 1 hour ago

■Summary Electromagnetic brake linings and clutch facings are used for control in a wide range of fields, from industrial machinery to small office...

Tokai Material Co., Ltd.

200+ people viewing

■Summary Electromagnetic brake linings and clutch facings are used for control in a wide range of fields, from industrial machinery to small office...

Tokai Material Co., Ltd.

180+ people viewing

Last viewed: 11 hours ago

■Summary Electromagnetic brake linings and clutch facings are used for control in a wide range of fields, from industrial machinery to small office...

Tokai Material Co., Ltd.

180+ people viewing

Last viewed: 18 hours ago

■Summary Electromagnetic brake linings and clutch facings are used for control in a wide range of fields, from industrial machinery to small office...

Tokai Material Co., Ltd.

160+ people viewing

Last viewed: 12 hours ago

■Summary They are required to withstand harsh use, with excellent operability and safety. ■Main use Brakes and clutches for use in oil ■Friction ...

Tokai Material Co., Ltd.

200+ people viewing

Last viewed: 17 hours ago

■Summary They are required to withstand harsh use, with excellent operability and safety. ■Main use Steering brake for bulldozer (for use in oil) ...

Tokai Material Co., Ltd.

130+ people viewing

Last viewed: 1 day ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Tokai Material Co., Ltd.

140+ people viewing

Last viewed: 13 hours ago

■Summary We also supply friction materials for everyday products such as bicycles and home appliances. ■Main use Washing machine brake and light l...

Tokai Material Co., Ltd.

150+ people viewing

Last viewed: 7 hours ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...

Tokai Material Co., Ltd.

120+ people viewing

Last viewed: 1 day ago

■Summary Precise control and safety are required for friction materials for industrial machinery, including large presses used for automobile body ...