All Categories

History

This section provides an overview for flange bolts as well as their applications and principles. Also, please take a look at the list of 11 flange bolt manufacturers and their company rankings. Here are the top-ranked flange bolt companies as of February, 2026: 1.Elgin Fastener Group, 2.U.S. BOLT MANUFACTURING, INC., 3.Norwood.

Table of Contents

Categories Related to Flange Bolts

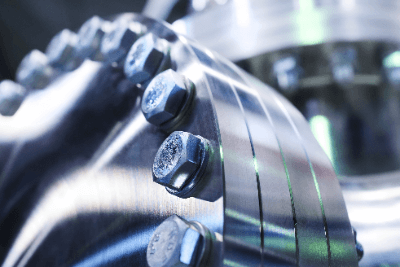

A flange bolt is a screw that can be inserted without a washer. They are called flange bolts because there is a flange attached to the bolt. The advantage is that it is difficult to loosen because it has a seat attached, and it eliminates the need to assemble a washer.

There are two types of flange bolts: Type 1 and Type 2, with Type 1 having a flat washer flange and Type 2 having a tapered flange top.

Flange bolts are used in a wide range of applications, from consumer products such as automobiles to industrial products, such as various types of manufacturing equipment. Since flange bolts have a larger seating surface than hexagonal bolts, they do not sink into the bolt hole to be fastened, thus improving the appearance of the bolt.

In addition, the incorporation of washers is not necessary, which improves work efficiency. Therefore, this type of bolt is used when a clean appearance is desired or when work efficiency is to be improved.

The head shape and height of flange bolts are often determined at the discretion of the manufacturer, and many varieties exist.

In the case of M6 bolts, both Type 1 and Type 2 have the same "seat diameter 14.0 mm - hexagonal head 10 mm - head height 6.0 mm" and differ only in the surface shape of the seat surface. In some manufacturers' standards, the back side of the washer may be processed with serrations (serrations). The serration allows the washer to bite into the fastening object easily, thereby improving stability.

In most cases, steel or stainless steel is used as the material. However, depending on the surrounding environment, titanium may be used. By appropriately selecting from a wide variety of flange bolts, stable and efficient fastening can be achieved.

Incorrect use of flange bolts can result in damage to nuts and equipment to be fastened. To prevent this, the following points should be taken into consideration when using flange bolts.

Flange bolt materials include steel, stainless steel, and titanium. Since each material has different strengths, it is necessary to fully consider these materials at the equipment design stage.

Electrical corrosion is also an important factor. If the material of the flange bolts differs from the material of the object to be fastened, electrical corrosion will occur. Particular attention should be paid to the case of aluminum and stainless steel.

Surface treatments for flange bolts include copper plating, black paint, trivalent chromate, uni chromate plating, hot-dip zinc plating, chromate plating, nickel plating, chrome plating, Parker, and necrotized. As mentioned above, selection is made according to electric corrosion protection, appearance, etc.

Flange bolts may loosen over time. If flange bolts loosen and come off, there is a risk of a serious accident involving human life. Loosening can be caused by the following two factors:

Tightening flange bolts too hard has the effect of preventing loosening, but there is a danger of the flange bolts breaking or the threaded hole tearing. Therefore, it is important to calculate the allowable range of fastening force at the time of design.

When retightening is used to prevent loosening, the bolts should be tightened according to the specified torque. Other measures to prevent loosening rather than retightening include the use of anti-loosening adhesives and double nuts. Although there is no guarantee that a machine will never loosen, it is necessary to take measures to prevent loosening to ensure the safe use of the machine.

*Including some distributors, etc.

Sort by Features

Sort by Area

Elgin Fastener Group, established in 1980 and headquartered in Brecksville, Ohio, is a manufacturer and supplier of specialty fasteners and related products. Some of the products offered by Elgin Fastener Group include bolts, nuts, screws, washers, as well as pins and rivets. These products are used for various applications such as construction, automotive, and industrial. With a complete line of materials, machinery, and methods to meet every product challenge, their team will custom engineer the fastener you need. The company holds several certifications, including the ISO 9001:2015 certification for its quality management system.

US Bolt Manufacturing Inc., founded in 1991 and currently a subsidiary of WN Global, is a bolting manufacturer in Houston, Texas, United States. The company is ISO 9001:2015 and ISO 17025:2005 certified, and offers bolting solutions for hostile environment and safety-related applications. Some of its products include bolts for subsea oil and gas drilling, connecting bolts for fracking pump fluid end connections, and rotor and coupling bolts for gas turbines. The company also provides a range of nuts, screws, and studs, and is affiliated with several associations, including the American Petroleum Institute (API) and the Association of Wellhead Equipment Manufacturers (AWHEM).

Norwood Screw Machine Parts (NSMP) is an American contract manufacturer specializing in custom and Swiss screw machine parts that was established in 1958. Located in Mineola, New York, the company is equipped to handle short and long run prototype to large-scale production operations, offering capabilities such as standard and Swiss screw machining, as well as CNC milling and turning. These are geared to the production of various precision parts including bushings, fasteners, fittings, couplings, and flanges. NSMP chiefly serves clients in the military, transportation, telecommunication, and marine sectors.

Regal Sales Corporation is a manufacturer of hot forged fasteners, established in 1992 and based in Mumbai, Maharashtra, India. Certified with ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018, the company offers fasteners made from materials like stainless steel and titanium, shaped at high temperatures using compressive forces to ensure flexibility and strength. Its product range includes flange, hex, and stud bolts for applications in industries like oil and gas, petrochemicals, and power generation. These products are exported to countries such as the United States, the United Kingdom, and Australia.

YUHUANG Electronic Technology Co., Ltd. is a Chinese manufacturer of precision screws and fasteners. Established in 1998, the company is based in Dongguan, China. Its main activity include the design, production, and distribution of precision screws and fasteners. YUHUANG has a strong presence with a wide range of products, hence it serves a number of industries such as electronics, automotive, and machinery. The company also offer customization on diverse product lines including standard screws, bolts, and nuts, that are dependable and usable.

Bhansali Fasteners is a manufacturer included in the Bhansali Group, founded in 1970 in Mumbai, India. The company is specialized in all kinds of fasteners, including but not limited to bolt, nuts threaded rod and coated fasteners. In addition, it manufactures custom fasteners. Its products are made by materials such as stainless, carbon and mild steel, as well as inconel, monel, and more. The firm has participated in successful projects in the power plant, petroleum and gas, aerospace and automobile fields. Its products conform to Indian and international standards, for instance: DIN, ISO, BS, ANSI, and ASTM.

FerroBend, founded in Mumbai, India, in 1981 is a manufacturer of alloys, stainless steel and carbon steel. The company's product portfolio includes carbon steel and tool steel alloys, copper alloys, aluminum alloys, titanium alloys, and nickel alloys. Their products find applications in markets such as aerospace, medical devices, automotive, electronics, and more. The company also provides services including surface treatment, national distribution, product selection, customized services, quality assurance technical support and customer service.

Raaj Sagar Steels is a manufacturer of nickel alloys and stainless steel products. The company was founded in 1978 and is headquartered in Mumbai, India. Raaj Sagar Steels is primarily involved in the design, development, and manufacture of nickel alloys, including Inconel, Monel, and Hastelloy. The company also offers a wide range of stainless steel products, including bars, plates, and tubes. Raaj Sagar Steels' products are used by a wide range of customers, including the chemical, oil and gas, and power industries.

GHS Fasteners is an industrial fastener manufacturer and supplier based in Ludhiana, Punjab, India. Adhering to global standards such as Deutsches Institut für Normung (DIN) and American Society for Testing and Materials (ASTM) codes, the company offers standard and customized fasteners, particularly for the automotive, structural, and railway sectors. It also provides road crash barrier fasteners, commonly utilized in crossroads, highways, and pedestrian pathways. The company further serves the agricultural sector by supplying tractor components, including cylinder engines, hydraulic controls, and steering wheels.

Siddhagiri Metals & Tubes, founded in 2002, is a supplier, distributor, and exporter of ferrous and non-ferrous metal products. The company's products are made from stainless steel and nickel alloys and include tubes, pipes, valves, flanges, tube fittings, and pipe fittings. Others are sheet plates, round bars, fasteners, forged fittings, compression fittings, and more. The company is ISO 9001:1515 certified, USAC certified and FIEO certified, and its products are supplied to over 70 countries worldwide in accordance with global standards like ASTM, ASME, and PED Certified.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Elgin Fastener Group |

19.2%

|

| 2 | U.S. BOLT MANUFACTURING, INC. |

11.5%

|

| 3 | Norwood |

11.5%

|

| 4 | Boltport Fasteners LLP |

11.5%

|

| 5 | GHS Fasteners |

10.3%

|

| 6 | Siddhagiri Metals & Tubes |

9.0%

|

| 7 | Regal Sales Corporation |

6.4%

|

| 8 | Topura Co., Ltd. |

6.4%

|

| 9 | Raaj Sagar Steels |

5.1%

|

| 10 | Bhansali Fasteners |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the flange bolt page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

5 | 50.0% |

United States of America

United States of America

|

3 | 30.0% |

Japan

Japan

|

1 | 10.0% |

China

China

|

1 | 10.0% |

225 products found

225 products

Yamashina Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

Yamashina has been working on the development of aluminum bolts for nearly 10 years. After much trial and error, including benchmarking European ex...

Topura Co., Ltd.

690+ people viewing

Last viewed: 1 day ago

■ Characteristics During the high -growth period, it was manufactured mainly in screws in the home appliance industry, but has expanded the product...

Topura Co., Ltd.

750+ people viewing

Last viewed: 20 hours ago

■ Characteristics A bolt with a strength of 1,400 MPa due to the burning and destructive process. Compared to conventional high -strength bolts, th...

Azumaneji Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Screw with hexalobular hole A hexalobular hole is a star-shaped hexagonal recess developed by Textron in the United States in 1971, and is also ca...

Ikeda Metal Industry Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■Features ・No need to install washers ・Prevents forgetting to insert them ・Large seating area prevents fastening members from sinking ・Effectiv...

Bossard Co., Ltd.

370+ people viewing

Last viewed: 20 hours ago

This is a hex bolt with a flange (skirt-like brim) all the way around the hem of the head. Also called flange hex bolt or flange bolt. You can use ...

Wilco Co., Ltd.

370+ people viewing

Last viewed: 12 hours ago

A hexagon socket head bolt with a flat washer-shaped bearing surface. Made of iron and treated with trivalent chromate. The wide seat surface preve...

Topura Co., Ltd.

700+ people viewing

Last viewed: 1 day ago

■ Characteristics Bolt with a tapping function at the tip of the screw. ■ Advantages By eliminating the screw tap processing, you can reduce man -...

Topura Co., Ltd.

740+ people viewing

Last viewed: 3 hours ago

■ Characteristics Bolt specializes in lighter with pure titanium and alloy titanium. ■ Advantages High corrosion resistance and lighter weight. ■...

Ikeda Metal Industry Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■Features ・No need to install washers ・Prevents forgetting to insert them ・Large seating area prevents fastening members from sinking ・Effectiv...

Topura Co., Ltd.

580+ people viewing

Last viewed: 11 hours ago

■ Characteristics It is a stainless steel bolt with high strength and high corrosion resistance of SUS304 or higher. ■ Advantages No regular repla...

Topura Co., Ltd.

760+ people viewing

Last viewed: 1 hour ago

■ Characteristics A complex function screw with a paint peeling function at the tip and a ground function on the screw. * Protight® is a kind of ea...

Japan Flash Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

Reliable welding comes from reliable quality. We produce our stud bolts in-house and all of them are produced domestically. We have introduced our...

10 models listed

Bossard Co., Ltd.

230+ people viewing

Last viewed: 22 hours ago

Generally, a male threaded part used in combination with a nut is called a bolt. Hexagonal bolts with heads shaped like hexagonal columns are commo...

10 models listed

Cains Co., Ltd.

300+ people viewing

Last viewed: 13 hours ago

Trusco Nakayama Lever Hoist TLH-050 Parts Chain Bolt Nut TLH050-705A-05

Cains Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

Insulating sleeves and insulating washers insulate between flanges and between flanges and bolts, preventing corrosion and galvanic corrosion. Bolt...