All Categories

History

This section provides an overview for liquid nitrogen containers as well as their applications and principles. Also, please take a look at the list of 14 liquid nitrogen container manufacturers and their company rankings. Here are the top-ranked liquid nitrogen container companies as of February, 2026: 1.KANSAL INDUSTRIAL GASES, 2.MDC Precision, 3.PHC Holdings Corporation.

Table of Contents

Categories Related to Liquid Nitrogen Containers

Postdoctoral researcher, conducting research on the production of cathode composite particles for solid-state batteries in the Equipment Engineering Group of Osaka Prefecture University.

Belongs to the Resource and Energy Recycling Laboratory, Nagaoka University of Technology, and conducts research on the development of DDR-type zeolite membranes for CO2 separation and the capture of CO2 from digestion gas generated from sewage treatment plants.

https://researchmap.jp/eiji-hayakawa

Thesis

https://doi.org/10.3390/membranes11080623

http://www.ijcea.org/index.php?m=content&c=index&a=show&catid=109&id=1177

https://www.sciencedirect.com/science/article/abs/pii/S1387181119305529?via%3Dihub

https://www.sciencedirect.com/science/article/abs/pii/S138358661833154X?via%3Dihub

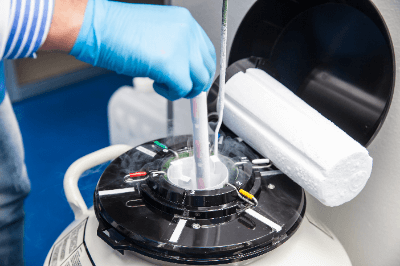

A liquid nitrogen container is a container used for storing, preserving, and transporting liquid nitrogen. Liquid nitrogen is nitrogen in liquid form at temperatures below -196°C and is mainly used to cool objects.

A liquid nitrogen container is a container used for storing, preserving, and transporting liquid nitrogen. Liquid nitrogen is nitrogen in liquid form at temperatures below -196°C and is mainly used to cool objects.

If used incorrectly, it can cause explosions, asphyxiation, frostbite, and other serious accidents, so it must be handled with care. By using liquid nitrogen storage containers, it is possible to safely and efficiently store, preserve, and transport liquid nitrogen.

Liquid nitrogen containers are used for storage and transportation when liquid nitrogen is used in laboratories and medical institutions where samples are stored and experiments are conducted, in food-related flash freezing, and as a coolant for IT-related equipment. Liquid nitrogen is also used in special analysis equipment.

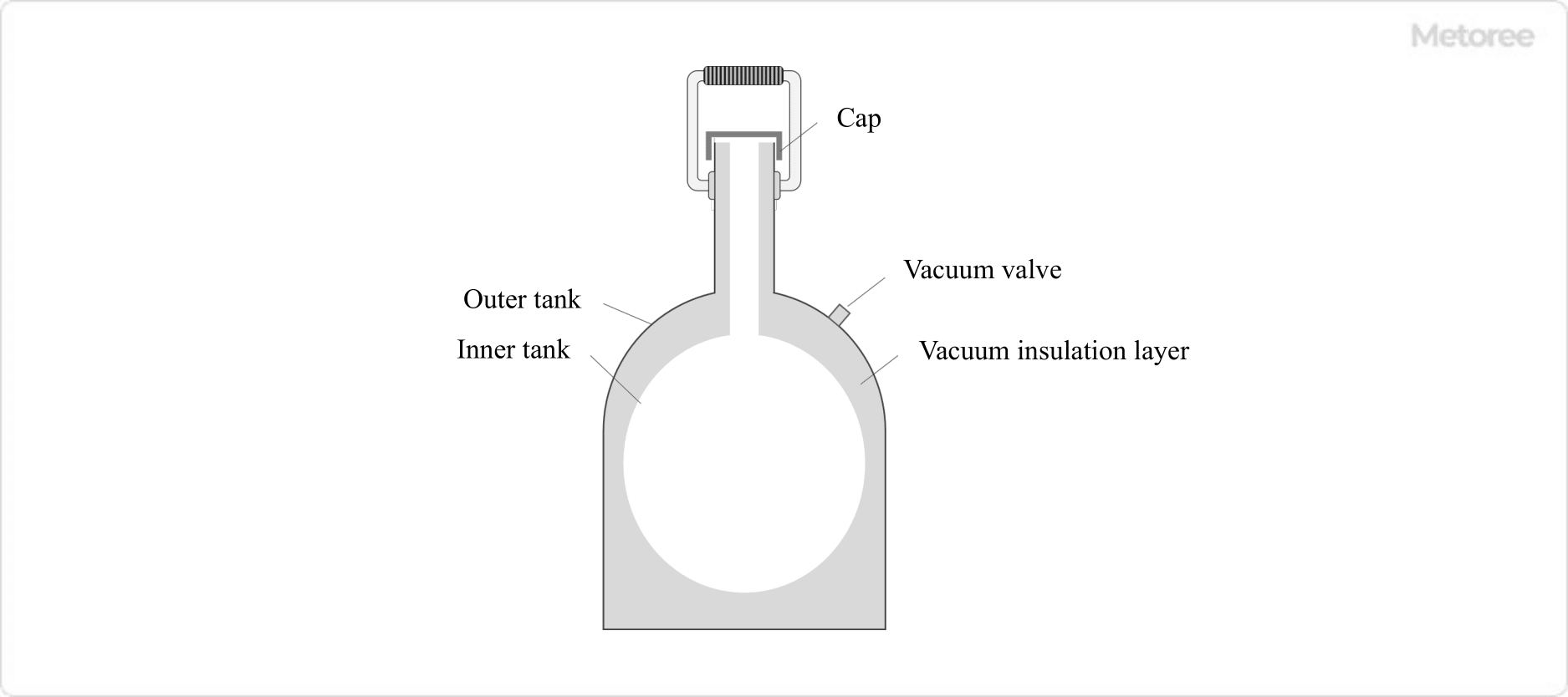

There are two types of liquid nitrogen containers: open containers and sealed containers. The most common open containers are small to medium-sized containers, while the most commonly sealed containers are large containers with a large capacity. An open container is one in which a cap is simply placed over the mouth of the liquid nitrogen containers and is not fixed, while a closed container is one in which the cap is fixed and the container is hermetically sealed.

Liquid nitrogen containers are not suitable for long-term storage, but they are suitable for daily or short-term use. Liquid nitrogen containers can be used for short-distance transportation, short-term storage and preservation, and periodic replenishment.

Nitrogen expands approximately 700 times in volume when it changes from a liquid to a gas, leading to accidents such as explosions and lack of oxygen. Therefore, liquid nitrogen containers are insulated with a double-layered vacuum structure to stabilize the temperature with high thermal insulation.

In addition, the structure is resistant to shock and vibration to withstand breakage. However, even when stored in liquid nitrogen containers, it will vaporize little by little.

Liquid nitrogen containers consist of an outer tank that forms the outside of the container an inner tank that is filled with liquid nitrogen, and a vacuum insulation layer is placed between the outer and inner tanks. Open-type liquid nitrogen containers have a simple structure that is not fixed by simply placing a cap over the open end of the inner tank and is widely used in university laboratories.

In the open type, the outer tank is generally made of aluminum, and the inner tank is generally made of hard glass, metal, or FRP (fiberglass reinforced plastic).

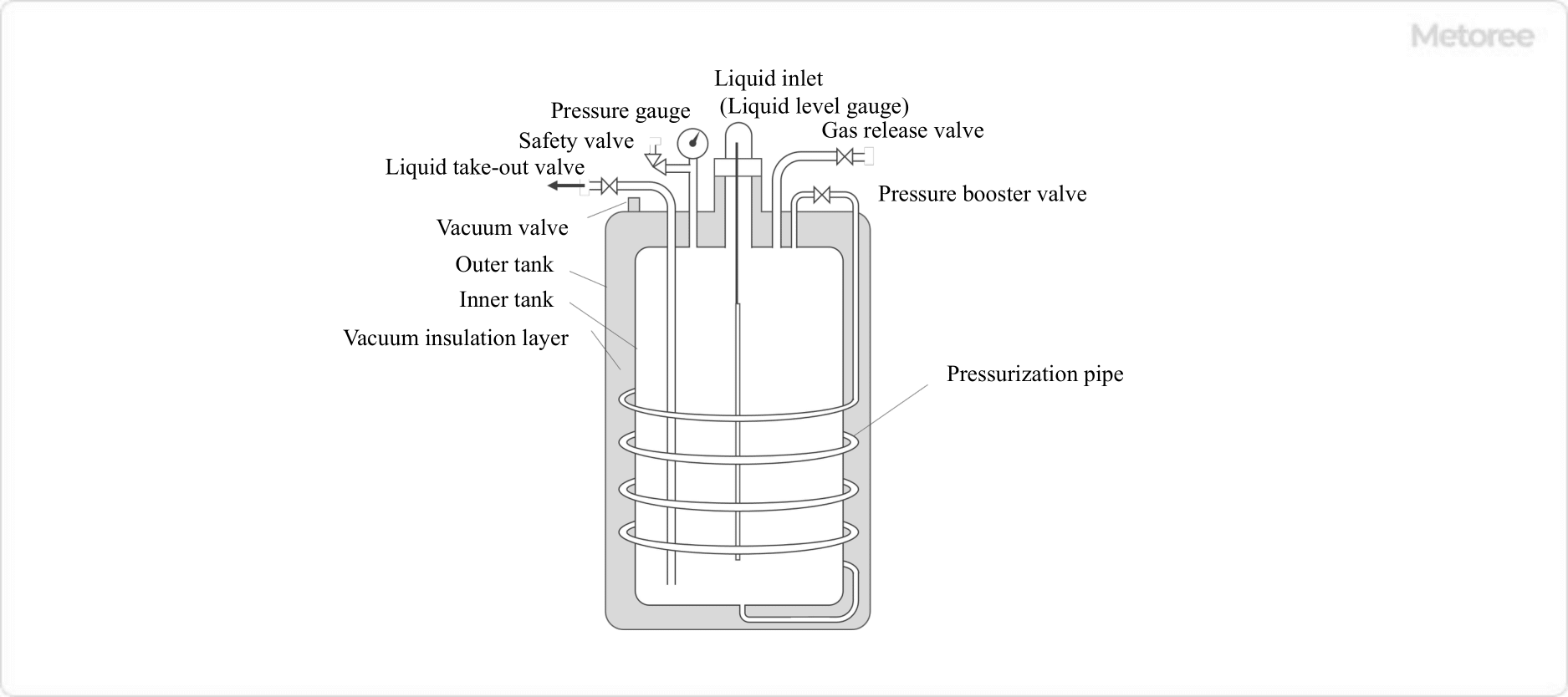

A self-pressurizing (sealed) liquid nitrogen container has a structure in which a pressurizing coil is placed between the outer and inner tanks, and liquid nitrogen is extracted by increasing the pressure of the inner tank to pressurize the liquid nitrogen in the inner tank.

The self-pressurizing type has a liquid takeout valve placed on the liquid nitrogen takeout side, a pressure boosting source valve used to increase the pressure of the inner tank, and a gas release valve to control an excessive increase in the internal pressure in the inner tank, and by adjusting these control valves, the required amount of liquid nitrogen can be taken out.

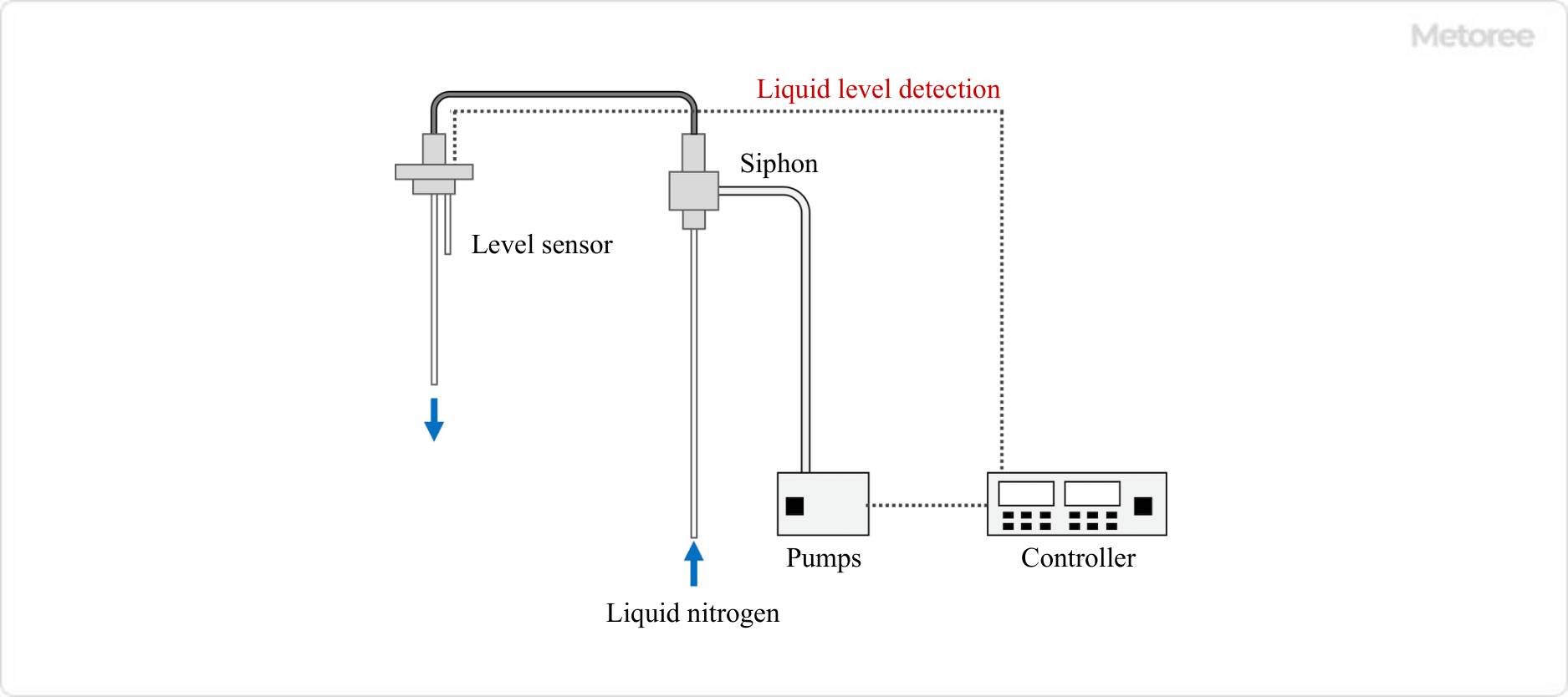

Since open-type liquid nitrogen containers are small and relatively lightweight, liquid nitrogen can be taken out by lifting and tilting the container. However, for safety reasons, it is recommended that a siphon or similar device be used to remove the liquid nitrogen.

There are two types of siphons: a manual type using a rubber ball and a type that automatically pumps liquid using a controller. In particular, since it is difficult to see the liquid level inside a dewar for cooling the EDX detector of an electron microscope, a siphon with a level sensor can prevent liquid nitrogen from overflowing and cover precision instruments with liquid nitrogen.

When storing containers, special lids must be used to prevent water from freezing inside and blocking extraction. In the unlikely event that the lid is lost or otherwise inaccessible, the container should be covered with a dry rag to prevent it from opening to the atmosphere while avoiding hermetic sealing.

The inner tank has only the minimum necessary structure and is fixed in place. For this reason, it is vulnerable to lateral forces and requires careful storage. Self-pressurized (sealed) liquid nitrogen containers have a structure in which gas is extracted by adjusting multiple valves, and care must be taken in handling each adjusting valve.

To remove liquid from the container, start by closing the gas release valve and opening the pressurization valve and then confirm the internal pressure of the container is rising. Then, open the liquid takeout valve and take out the liquid nitrogen containers while making sure that the pressure inside the container does not rise excessively.

After the liquid nitrogen has been taken out, close the liquid nitrogen withdrawal valve and the pressurizing valve in turn, and then open the gas release valve to lower the internal pressure of the container.

When handling liquid nitrogen, care must be taken to avoid asphyxiation, frostbite, and explosions. To prevent frostbite, use gloves and face guards during use, and wear footwear that is impervious to liquid nitrogen, since slippers and the like may come into direct contact with liquid nitrogen when it is spilled.

Similarly, it is recommended to use dry, specialized gloves, as military gloves and the like may be penetrated. If liquid nitrogen is to be moved in and out indoors, the room must be well ventilated. Also, when using an elevator, do not share the elevator with liquid nitrogen because the interior is a closed room.

If liquid nitrogen is placed in an elevator, put up a sign or other warning so that others will not get on the elevator. For rooms where liquid nitrogen is frequently used, we recommend installing oxygen monitors.

If it is an open type, of course, it is not designed to be sealed, so sealing is strictly prohibited. It is also strictly prohibited to leave the equipment without a lid, as explained in the instructions for use. This is not only because liquid nitrogen vaporizes faster, but also because water and oxygen may liquefy and mix inside the storage container.

Liquid oxygen, in particular, can react rapidly when it comes into contact with organic matter (liquid oxygen has a bluish tint). Ensure to cover the container with a dry cloth or other covering if the lid is misplaced. The open type is structurally vulnerable to shaking and shock and should be used with care, as the vacuum insulation layer may break.

In the self-pressurizing type, a safety valve maintains the internal pressure in a safe condition, so it should be checked regularly to ensure that the safety valve is functioning properly. It is also dangerous to look into the outlet as it may not be taken out correctly or may blow out suddenly if freezing occurs in the piping.

*Including some distributors, etc.

Sort by Features

Sort by Area

MDC Precision is a manufacturer of precision components since 1975 and is headquartered in Hayward, California with additional Pflugerville, TX, Sarasota Florida, Lyon, France, Milton Keynes, UK, and Vietnam. Its product portfolio includes viewports & glass components, electrical feedthroughs, vacuum flanges, roughing components, and vacuum valves such as hybrid adapters, elbows, watercooled clamps, flexible couplings, and crosses. They have fulfilled the ISO 9001:2015 certification and their products are used in life science & medical, semiconductor manufacturing, aerospace, food processing, and research sectors.

Panasonic Healthcare was founded in 1969 in Tokyo, Japan as a manufacturer of healthcare devices and services and operates under PHC Holding Corporation. With a strong hold on Diabetes Management, Diagnostics, Life Sciences, and Healthcare Solutions, Panasonic Healthcare is here to adress global needs in energy, food, housing, health, and information technology. Panasonic Healthcare has a capital of 47.0 billion yen and employs approximately 9,374 individuals worldwide as of March 2022. The company's shareholders include KKR (Kohlberg Kravis Roberts & Co. L.P.), Mitsui & Co., Ltd., Life Science Institute, Inc., Panasonic, and L Catterton.

KANSAL Industrial Gases is a manufacturer of liquid nitrogen and Cryogenic containers located in India, was established in 1996. The company has become a sought-after business partner in liquid nitrogen and allied products market. It maintains the largest fleet of cryotankers which specifically moves for liquid nitrogen. Its yearly lifting of liquid nitrogen is approximately 12000 KL from almost all manufacturers in India. It offers a range of products including ripening gas, chlorine gas, emergency tool kit, breathing equipments, etc. It also impart gas refilling service. Supported with well-furnished infrastructural unit which assists it in offering a supreme range of products.

BIOBASE GROUP is a Chinese manufacturer of medical and laboratory equipment founded in 1999 and headquartered in Jinan, Shandong. The company offers over 200 different products including laboratory and medical cryogenic equipment, clinical analytical instruments, air protection devices, and specialized storage products. It also produces various medical consumables such as gloves, masks, and syringes. Biobase Group has branches in the US, India, Dubai, Singapore, and Kazakhstan. It offers global distribution and additional customization services to its clients in the biotechnology, environmental, cosmetic, and educational sectors.

Abhijit Enterprises, established in 1996, is a manufacturer and trader of Liquid Nitrogen and Cryogenic Containers located in Pune, India. The company caters to multiple industries like automobile, packaging, etc. Its product range includes Cryocan, liquid nitrogen pump, low pressure Dura Cylinder for liquid nitrogen, etc. It has been able to maintain a winning edge over its competitors due to its capability of supplying-200 Ton LN2 per/month, serving 5000 veterinary doctors, connecting with 3000 villages and covering 11 major districts of Maharashtra. Its infrastructural unit is fully empowered with technologically advanced machines and equipment for dispatching impeccable range in the markets.

Biologix Limited Group was established in 2007 and is located in Shandong, China. The company is a manufacturer of disposable medical detection reagents and supplies. The company's range of products includes PCR and Cell Culture consumables, Virus detection kits, Industrial Storage Containers, and COVID-19 Nucleic Acid Detection kits. The company is also into the R&D of disposable medical detection reagents. Biologix is also an OEM provider of plastic laboratory consumables and has locations in Europe and the United States.

Salasar Carbonics Pvt. Ltd. was founded in 1995 in Jaipur, India, as a manufacturer and supplier of industrial gases. The company's product lineup encompasses Oxygen Gas Containers, Carbon Dioxide Gas and Cylinders, Argon Gas and Cylinders, and storage tanks. Its service offerings include Liquid Nitrogen Cryocan Rental Services, CO2 Gas Pipe Line Work, and Customized solutions. They are used as shielding gases in welding and high-temperature processes, in food processing for cooling, preservation, and pH control, and for medical breathing applications in medical facilities. The company serves industries including hospitals, welding and metal fabrication, medical, and research.

LabGeni is a manufacturer and supplier of laboratory equipment and consumables that was established in 2004 and is headquartered in Wuhan, China. LabGeni's main activity is the design, development, and manufacturing of laboratory equipment, including microplate readers, centrifuges, and incubators. The company also offers a wide range of laboratory consumables, such as pipette tips, microcentrifuge tubes, and cell culture media. Its products are used by a wide range of customers, including academic institutions, research laboratories, and pharmaceutical companies. LabGeni has over 200 employees and operates in more than 20 countries.

De-Luxe Trading Company, established in 1966 and based in Pune, Maharashtra, India, is a manufacturer and supplier providing gas cylinders, safety equipment, and welding products. Besides its industrial and medical gas cylinders, the company offers Dewar flasks, concept air kits, and bump caps. It also produces a range of cryogenic valves and face shields. The company further provides welding products, including liquid nitrogen containers and stainless steel self-pressurized total plaque volume vessels. Its services include gas pipeline installation and welding equipment repair.

Revital Cryogenic & Biotech Systems is a manufacturer and supplier of veterinary products, established in 2010 and based in Jaipur, Rajasthan, India. Adhering to ISO 9001:2008, the company offers liquid supplements, boluses, and medicines for cattle, poultry, and other animals. It also provides veterinary gloves, injections, and surgical equipment. The company further produces artificial insemination guns and sheaths, along with other related items, such as liquid nitrogen containers and transfer devices.

Singhal Gas Products is an industrial gas manufacturer and supplier, established in 2009 and based in Ghaziabad, Uttar Pradesh, India. The company provides industrial gases with precise isotopic purity, composition, and chemical ratios. These products include argon gas, hydrogen gas, and gas mixtures. These gases find applications across diverse sectors, including medical and research and development laboratories. The company further offers fabrication of mild steel (MS) and stainless steel (SS) tanks as well as large-diameter pipes. It also engages in structural, pre-engineering, and heavy fabrication. Some of the company's notable customers are Hero MotoCorp and Jubilant Life Sciences Ltd.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | KANSAL INDUSTRIAL GASES |

14.0%

|

| 2 | MDC Precision |

11.0%

|

| 3 | PHC Holdings Corporation |

10.5%

|

| 4 | Kailash Gases |

8.5%

|

| 5 | Biologix Group Limited |

8.0%

|

| 6 | Abhijit Enterprises. |

6.5%

|

| 7 | BIOBASE GROUP |

6.5%

|

| 8 | Salasar Carbonics Private Limited |

6.0%

|

| 9 | LabGeni |

5.5%

|

| 10 | DE-LUXE TRADING COMPANY |

5.0%

|

Derivation Method

The ranking is calculated based on the click share within the liquid nitrogen container page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

5 | 55.6% |

China

China

|

2 | 22.2% |

United States of America

United States of America

|

1 | 11.1% |

Japan

Japan

|

1 | 11.1% |

56 products found

56 products

Astec Co., Ltd.

640+ people viewing

Last viewed: 1 hour ago

IC BIOMEDICAL's liquid nitrogen freezing storage containers are recognized in 80 or more countries with high heat insulation performance due to sup...

3 models listed

Astec Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

Manage the remaining amount of liquid nitrogen by weight ■ Characteristics ・ Display the weight of the liquid nitrogen storage container just by ...

3 models listed

Astec Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

IC BIOMEDICAL's liquid nitrogen freezing storage containers are recognized in 80 or more countries with high heat insulation performance due to sup...

6 models listed

Astec Co., Ltd.

690+ people viewing

Last viewed: 1 hour ago

IC BIOMEDICAL's liquid nitrogen freezing storage containers are recognized in 80 or more countries with high heat insulation performance due to sup...

4 models listed

Astec Co., Ltd.

700+ people viewing

Last viewed: 1 day ago

IC BIOMEDICAL's liquid nitrogen freezing storage containers are recognized in 80 or more countries with high heat insulation performance due to sup...

4 models listed

Astec Co., Ltd.

650+ people viewing

Last viewed: 1 day ago

IC BIOMEDICAL's liquid nitrogen freezing storage containers are recognized in 80 or more countries with high heat insulation performance due to sup...

5 models listed

Yagyu Shokai Co., Ltd.

420+ people viewing

Last viewed: 6 hours ago

Yagyu Shokai Co., Ltd.

520+ people viewing

Last viewed: 10 hours ago

■Features - Suitable for cooling small samples. -Can be used on a stirrer. ・G9C, G12C, and G16C come with a grip. *Cork stopper (lid) is not incl...

Yagyu Shokai Co., Ltd.

620+ people viewing

Last viewed: 23 hours ago

■Features - Container insulated with stainless steel vacuum double structure. ・Vacuum insulation provides high heat retention, and the impact on t...

Matsuzawa Works Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

You can design the optimal cooling equipment according to your purpose and use.