11 Raised Access Floor Manufacturers in 2024

This section provides an overview for raised access floors as well as their applications and principles. Also, please take a look at the list of 11 raised access floor manufacturers and their company rankings. Here are the top-ranked raised access floor companies as of October, 2024: 1.Access Floor Systems.com, Inc., 2.DIRTT, 3.AirFixture, L.L.C..

Table of Contents

What Is a Raised Access Floor?

A Raised Access Floor is a floor with a fixed height space under the floor. The purpose is to pass network wiring, etc., which tend to become cluttered, through the space under the floor. It is also known as free-access floor or a double-layered floor.

A Raised Access Floor is a floor with a fixed height space under the floor. The purpose is to pass network wiring, etc., which tend to become cluttered, through the space under the floor. It is also known as free-access floor or a double-layered floor.

Raised Access Floors do not affect the placement of desks and cabinets, making it easy to change wiring later. They also prevent damage to wiring and other hazards caused by human traffic and moving chairs.

Raised Access Floors have many advantages, such as improved aesthetics and easier cleaning.

Uses of Raised Access Floors

Raised Access Floors are installed in offices, factories, commercial facilities, schools, and other locations where many computers, servers, printers, network equipment, telephones, video equipment, and other electronic devices are used.

In the past, Raised Access Floors were used in computer rooms where large computers were installed in large organizations such as large corporations. Recently, however, due to the increase in the number of PCs and other OA equipment, and the spread of network environments such as LAN and Ethernet, OA floors are commonly used regardless of the size of the office.

When installing, it is important to estimate in advance the number of wires and load required. After installation, the wiring paths cannot be followed visually without opening the floor, so it is necessary to attach tags with numbers and destinations to the wiring ends and record them in drawings and management books.

Principle of Raised Access Floors

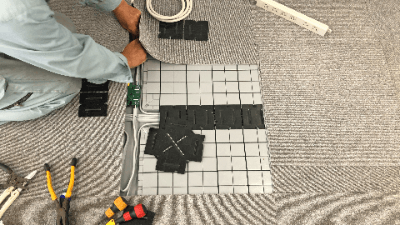

Raised Access Floors can be broadly classified into two types according to its structure: laid-in type and pillar separation type.

In addition, the wiring system can be roughly classified into two types: under-panel wiring system and groove wiring system.

1. Laid-In-Place Type

In the laid-in-place type, the pillar and panel are laid out as a single block. Most of them are made of resin, which makes on-site processing relatively easy, and the materials themselves are inexpensive, making them cost-effective. In this type, the floor height is fixed and cannot be changed later.

Because the degree of freedom in height adjustment is limited, this type is inherently unsuitable for installation in locations where the floor slab of a building has a difference in height and is not flat. However, there are products that can adjust the height using spacers. Due to the load-bearing capacity of the material used, these products are not suitable for installation of heavy objects.

2. Pillar Separation Type

In the pillar separation type, a pillar is erected on the floor and a board-like panel is placed on top of it. The height can be freely adjusted and the load capacity is excellent. The panel that makes up the floor and the support columns that determine the height are independent components, and the height of the columns can be adjusted, allowing the height of the floor to be adjusted as desired.

Therefore, the panel is suitable for use where there are steps or height differences in the floor of a building. And since metal products are the main material used for the panels, they are suitable for installation of heavy objects. In addition, there are products in which the panels are filled with mortar, which improves heat and sound insulation.

3.Under-Panel Wiring Method

The under-panel wiring method is a method of storing wiring in the cavity between the posts and legs, and has the advantages of large wiring storage capacity and a high degree of wiring flexibility. In the case of the separate-pillar type, the storage capacity can be further increased by increasing the height of the pillars. The disadvantage is that there is a possibility of interference.

4. Groove Wiring Method

In the groove wiring method, wiring is done along the groove of the panel, and a cover is placed over the top to protect the wiring. This method has the advantage of facilitating wiring changes and additions. Although the wiring storage capacity is small, wiring is done in an orderly fashion along the grooves, preventing interference. The groove wiring method is suitable when the number of wires is small or when there are plans to change the layout or increase the floor space.

Other Information on Raised Access Floor

Advantages and Disadvantages of Raised Access Floors

Advantages

- It has a cleaner appearance and improves work efficiency.

- Wiring outlets can be changed, allowing free layout changes of desks and PCs.

- Reduces problems such as falling over due to feet getting caught in wiring or data errors due to wiring disconnections, etc.

- Floor cleaning becomes easier.

Disadvantages

- Raised Access Floors have a limited load-bearing capacity and are restricted to heavy equipment. Also, since the height cannot be adjusted, they are not suitable for floors with slopes.

- Raised Access Floors with separate support columns have heavy metal parts, which may cause problems in workability and load-bearing capacity of the building.

- Depending on the equipment used, durability and walking feel may be defective. It is important to confirm this through testing.

List of 11 Raised Access Floor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- Japan

-

-

-

Access Floor Systems.com, Inc.

Access Floor Systems

Manufacturer Overview

Access Floor Systems.com, Inc, established in 1982 in Los Angeles, USA, is a manufacturer of raised access floor solutions, including access floor panels, pedestals, stringers, and other accessories. The products are designed to create flexible and efficient underfloor spaces, allowing for easy installation of electrical, data, and HVAC systems while providing easy access for maintenance. These products are ideal for office buildings, data hubs, command centers, and other environments where adaptability and accessibility are essential. The benefits include improved cable management, enhanced air circulation, reduced energy consumption, and the ability to accommodate future technology for modern workplaces and tech-centric industries.

-

-

-

-

-

AirFixture, L.L.C.

THE GUIDE TO RAISED ACCESS FLOORS

Manufacturer Overview

AirFixture, L.L.C., established in 2001 in Kansas City, USA, is a manufacturer of underfloor air distribution (UFAD) systems. The products include advanced underfloor air diffusers, raised access floor systems, and other components essential for efficient and flexible HVAC solutions. The company’s UFAD systems offer benefits like improved indoor air quality, energy savings, enhanced occupant comfort, and more efficient space utilization. These systems are frequently utilized in office spaces, information centers, clinics, and schools and colleges, among other commercial, institutional, and industrial buildings where it is essential to maintain a healthy and effective indoor atmosphere.

-

-

-

-

-

DIRTT

ACCESS FLOORS

Manufacturer Overview

DIRTT (Doing It Right This Time), established in 2004 in Calgary, Canada, is a manufacturer of unique, sustainable, and customized interior products. The company offers a unique approach to interior construction through its prefab modular walls, raised access floors, power and data distribution, and integrated technology solutions. The products allow for flexible and adaptable spaces, rapid installation, reduced waste, and easy reconfiguration, making them ideal for commercial offices, healthcare facilities, education centers, and other industries. The benefits include improved efficiency, reduced environmental impact, and the ability to create urging and functional spaces that can evolve with changing needs.

-

-

-

-

-

Netfloor USA

Access Floor

Manufacturer Overview

Netfloor USA, established in 1996 in Charlotte, North Carolina, USA, is a manufacturer of raised access cable flooring systems for cable management, improved airflow, and adaptable workspace environments. The company offers various products, including low-profile access floor systems, cable management solutions, and underfloor air distribution systems, for flexible, efficient, and aesthetically pleasing environments for office spaces, data centers, educational facilities, and other commercial applications. The equipment comes with improved cooling efficiency, reduced construction costs, enhanced design flexibility, and the ability to adapt to evolving technology needs suitable for various industries, including IT, telecommunications, finance, healthcare, government, and more alike.

-

-

-

-

-

Tate Access Floors, Inc.

Raised Floor

Manufacturer Overview

Tate Access Floors, Inc., established in 1962 in Jessup, Maryland, USA, is a manufacturer of unique raised access flooring systems for improved building flexibility, energy efficiency, and enhanced air quality. The product portfolio includes raised floor systems for data centers, office spaces, cleanrooms, and various applications. These systems allow for efficient distribution of power, data, and HVAC, promoting adaptable and sustainable building environments. The benefits cover improved cooling efficiency, reduced energy consumption, simplified cable management, increased space utilization, and easy access to building systems for maintenance. These are used in data centers, commercial offices, government buildings, educational facilities, and healthcare institutions.

-

-

-

-

-

FreeAxez, LLC.

raised floor

Manufacturer Overview

FreeAxez, LLC, established in 2011 in New Jersey, USA, is a manufacturer of unique cable management products for modern office spaces that seamlessly integrate power, data, and HVAC infrastructure. The company’s flagship product, the Gridd system, offers adaptable and accessible cable pathways under the floor, enabling easy reconfiguration of office layouts, efficient cable management, and flexibility to adapt to changing technology needs. The Gridd system enhances office aesthetics, reduces construction costs, simplifies maintenance, and promotes a sustainable environment. The benefits include improved office space utilization, quick installation, reduced downtime during modifications, enhanced workplace safety, and the ability to accommodate evolving technology.

-

-

-

-

-

CleanAir Solutions, Inc.

Raised Access Floor Panels

Company Overview

CleanAir Solutions, Inc. was established in California to fill a void in the cleanroom industry by providing technical assistance to end-users and contractors for the supply of design and implementation of cleanroom facilities and related products. Overall, the company can be characterized as a cleanroom technology specialist. The portfolio of the company includes FIlters, Cleanroom Lights, Monitoring Systems, Filter Accessories, File Control Systems, and many more. The company follows the practices, standards, and requirements for certification of cleanrooms, laminar flow hoods, and mini-environments, such as Federal Standard 209E, ISO 14644-1, IES-RP-cc006.2, etc.

-

-

-

-

-

XiangLi Anti-static Decorative Material Co., Ltd.

Raised Acsess Floor

Manufacturer Overview

XiangLi Anti-static Decorative Material Co., Ltd., established in 1996 in Suzhou, China, is a manufacturer of anti-static decorative materials, with an emphasis on creating safe and aesthetically pleasing workplace. The company provides equipment for use in ESD-sensitive environments, including static-dissipative vinyl flooring, anti-static elevated access floors, and other such products. The benefits include keeping dangerous items contained, avoiding damage to pricey devices, and stopping dirt and dust from spreading. These devices are used in electronics, clean rooms, data centers, laboratory settings, medical centers, and other facilities that must maintain a low electrostatic potential.

-

-

-

-

-

Lindner Group

Raised Floors

Manufacturer Overview

Lindner Group, founded in 1965 in Arnstorf, Germany, is a manufacturer of interior fit-out, building envelope, and insulation technology. The company specializes in offering advanced building envelope, acoustics, and interior design equipment. Raised access floors, partition systems, ceiling systems, and facade solutions are among the offered products to boost energy efficiency, enable flexible space management, improve aesthetics, and improve acoustic performance. The advantages include the flexibility to design individualized and sustainable environments, greater workplace comfort, improved building performance, and lower energy usage. These are employed in workplaces, hospitals, schools, airports, and other commercial structures.

-

-

-

-

-

SENQCIA CORP.

Office Floor Systems

Company Overview

Senqcia Corporation, founded in 1972 and headquartered in Tokyo, Japan, is a manufacturer and distributor specializing in building structural components. Its product portfolio includes pioneering raised floor systems, developed with advanced technology since the 1960s, providing free-access flooring solutions. It also offers structural products like HIBASE and HIRING, along with dampers, crucial devices for mitigating oscillatory or vibratory motions. The company's solutions play an essential role in ensuring safety and security in building structures, whether in underground foundations, steel frames, or under floorings.

-

-

-

-

-

Access Floor Store

Raised Access Flooring Systems

Company Overview

Access Floor Store, established in 2005, with headquarters in Changzhou City, China, is a manufacturer and distributor of various access flooring solutions for both commercial and industrial environments. The company offers various products, including raised access floors, floor tiles, underfloor air distribution systems, cable management solutions, and more. The products are designed to optimize space, improve airflow, enhance cable management, and create adaptable environments suitable for data centers, office spaces, server rooms, cleanrooms, and other industries requiring advanced flooring solutions. The benefits include improved energy efficiency, easy access to building systems, reduced construction costs, increased space utilization, and enhanced aesthetics.

-

-

Raised Access Floor Manufacturer Ranking

*Including some distributors, etc.Ranking as of October 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Access Floor Systems.com, Inc. |

18.7%

|

| 2 | DIRTT |

13.5%

|

| 3 | AirFixture, L.L.C. |

10.3%

|

| 4 | Netfloor USA |

9.7%

|

| 5 | Tate Access Floors, Inc. |

9.3%

|

| 6 | FreeAxez, LLC. |

7.8%

|

| 7 | CleanAir Solutions, Inc. |

7.6%

|

| 8 | XiangLi Anti-static Decorative Material Co., Ltd. |

7.4%

|

| 9 | Lindner Group |

6.7%

|

| 10 | Access Floor Store |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the raised access floor page as of October 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- SENQCIA CORP.: 301

- XiangLi Anti-static Decorative Material Co., Ltd.: 280

Newly Established Company

- Access Floor Store: 2005 (19 years ago)

- DIRTT: 2004 (20 years ago)

- AirFixture, L.L.C.: 2001 (23 years ago)

Company with a History

- SENQCIA CORP.: 1972 (52 years ago)

- Lindner Group: 1990 (34 years ago)

- Access Floor Systems.com, Inc.: 1994 (30 years ago)

Raised Access Floor Manufacturers in United States

*Including some distributors, etc.

- Access Floor Systems.com, Inc.

- AirFixture, L.L.C.

- DIRTT

- Netfloor USA

- Tate Access Floors, Inc.

- FreeAxez, LLC.

- CleanAir Solutions, Inc.

Global Distribution of Raised Access Floor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 63.6% |

China

China

|

2 | 18.2% |

Germany

Germany

|

1 | 9.1% |

Japan

Japan

|

1 | 9.1% |