All Categories

History

This section provides an overview for weld nuts as well as their applications and principles. Also, please take a look at the list of 5 weld nut manufacturers and their company rankings. Here are the top-ranked weld nut companies as of February, 2026: 1.Engineered Source, Inc., 2.Aspen Fasteners Inc., 3.Monroe JHP Fasteners, Inc..

Table of Contents

Categories Related to Weld Nuts

A Weld Nut is a nut with a protruding "pilot" shape that is welded into place.

A Weld Nut is a nut with a protruding "pilot" shape that is welded into place.

There are several types of Weld Nuts, each with a different number of corners and shape, so it is important to select the right one for the application.

Weld Nuts are mainly used in products made of multiple thin metal sheets such as home appliances, 2-wheelers, 4-wheelers, and parts for golf clubs. When securing bolt fastening torque, at least 5 pitches are required between the bolt and nut threads to prevent loosening.

Since 1.5 mm threads are generally used per pitch, the thickness of the metal plate must be at least 7.5 mm to set the taps for bolt fastening on the metal plate. Therefore, since taps cannot be cut on metal sheets thinner than 7 mm, Weld Nuts are used to secure the threads and provide a connection point for bolt fastening on the thin sheet.

In addition, when using Weld Nuts, metal plates are not welded to each other, so they can be easily removed and attached, and many Weld Nuts are used for structures with large sizes.

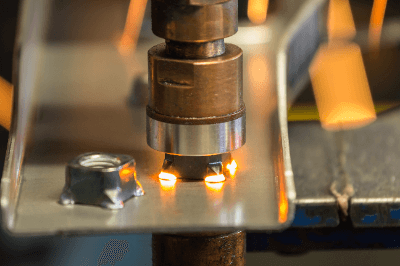

Weld Nuts are held in place by a welding pilot, which is a welding projection provided on the nut that is welded to the base metal. This pilot is the most distinctive feature of the Weld Nut and plays an important role.

The pilot is a protruding shape designed to reduce the contact area with the base metal and to facilitate pinpoint temperature rise only in the pilot area during welding. The shape of the pilot also serves to position the nut.

Some types of Weld Nuts do not have a pilot, and are generally joined to the base metal by projection welding if they have a pilot, or by arc welding if they do not.

There are three main types of Weld Nut:

Hexagonal weld nuts are hexagonal in shape, with three protrusions in each of the six corners as pilots for welding to the metal plate. The advantage of the hexagonal type is that welding work is easy to perform because there are few welding points. On the other hand, the disadvantage is that the strength of the joint is inferior to other types because the joint with the metal plate is limited to three points.

The square type is square in shape and the pilot is set at all four corners, so all four points are welded to the metal plate. The four welding points provide a stronger joint than the hexagonal type, which has three welding points, and thus higher torque can be applied. The square type is most commonly used in automobiles.

The T-shape is flanged at the nut, which allows for a larger welding area and thus a stronger joint. On the other hand, its disadvantage is that the welding time is longer than that of other nuts.

By welding Weld Nut, the pilot that the nut has and the base material are welded together and secured. Since they are joined by welding, the joint is highly stable and strong.

Weld Nuts are mainly used when the base metal plate is too thin to allow tapping for bolts. For example, when the thickness of an automobile body shell is only 1 to 2 mm, the metal plate is too thin to secure threads even if tapping for bolts is performed.

By installing a Weld Nut in such a situation, it is possible to provide threads only in the area where the bolt fastening is desired, without changing the thickness of the entire metal plate. Another advantage is that because nuts are used, removal after welding is easier than spot welding, in which metal plates are joined by overlapping each other.

*Including some distributors, etc.

Sort by Features

Sort by Area

Engineered Source Inc was founded in 1990 and operates out of Orange, California. Engineered Source Inc is a distributor of precision parts for numerous industries including automotive manufacturers, construction, electronics & robotics, fabrication & assembly, farm & agricultural equipment, gun manufacturers, marine & water treatment, medical manufacturers, and aerospace. Examples of specific products include custom internally threaded square pins, stainless steel pins, steel hex nuts, short dog point socket set screws, zinc plated steel material, custom stamped L brackets, painted self-drilling screws, and custom-locating dowel pins for transit gear units.

Monroe JHP Fasteners, Inc., founded in 1970, is a supplier of fastening products and services used in the metal fabrication industry. The company, which changed its name from John H. Powers to Monroe JHP Fasteners, Inc in 2000, is based in Walker, Michigan, and supplies customers across the United States, Canada, and Mexico. They supply fasteners, including self-clinching, welding, and miscellaneous. Other products supplied by Monroe JHP Fasteners include rivets, sockets, flat and button head cap screws. The company has partnered with Captive Fastener, Sherex Rivet Nuts, and Industrial Rivet and Fastener Company, which manufacture the products they supply.

Zygology is a UK-based distributor for technical fastening products. Zygology has ISO 9001 and UKAS quality management accreditation. Zygology’s product line includes breakstem rivet systems, speed fasteners, structural breakstem fasteners, earthing products, sealing plugs, nutserts, jack nuts, versanuts, POP MFX fasteners, lock bolts, installation tools, PEM assembly solutions, placing tools, Tesa tapes, self-locking nuts, and rivet nuts. Zygology offers engineering design and consulting solutions for customer production line problems. Zygology also offers tool rentals and tool repair.

Aspen Fasteners was founded in 1961 and headquartered in Las Vegas, Nevada. Aspen Fasteners is a distributor for industrial fasters. Aspen Fasteners offers an extensive line in both metric and inch standards of anchors, bolts, nuts, screws, washers, rings, pins, pipe plugs, rivets, inserts, rods, studs, spacers, standoffs, panel fasteners, and tools including adapters, drivers anchor setting tools, keys, measuring tools, screwdriver insert bits, and screwdriver power bits. Material types include aluminum, brass, copper, iron, lead alloy, monel nickel copper alloy, nylon, phosphor bronze, plastic, silicon bronze, stainless steel, steel, and zinc.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Engineered Source, Inc. |

33.3%

|

| 2 | Aspen Fasteners Inc. |

22.8%

|

| 3 | Monroe JHP Fasteners, Inc. |

17.5%

|

| 4 | Zygology |

14.0%

|

| 5 | Sugiura Seisakusho Co., Ltd. |

12.3%

|

Derivation Method

The ranking is calculated based on the click share within the weld nut page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 50.0% |

Japan

Japan

|

1 | 25.0% |

United Kingdom

United Kingdom

|

1 | 25.0% |

67 products found

67 products

Fuji Precision Co., Ltd.

5090+ people viewing

Last viewed: 4 minutes ago

Standard U-nuts and locking nuts that have built up trust and a proven track record for more than 50 years since their birth. ■Features ・Exhibits...

9 models listed

Seikou Giken Co., Ltd.

410+ people viewing

Last viewed: 19 hours ago

■Specifications ・The deviation of the screw hole from the side of the nut shall be within 0.4mm. ・The screw should be perpendicular to the top su...

Seikou Giken Co., Ltd.

350+ people viewing

Last viewed: 19 hours ago

■Specifications ・The deviation of the screw hole from the side of the nut shall be within 0.4mm. ・The screw should be perpendicular to the top su...

Osaka Forming Co., Ltd.

590+ people viewing

Last viewed: 19 hours ago

■Safe and reliable anti-loosening effect The [E-LOCK series] is available in a wide variety of sizes, shapes, and functions to meet the various nee...

Sugiura Seisakusho Co., Ltd.

410+ people viewing

Last viewed: 19 hours ago

This nut has a wall all around it that prevents water from entering the threaded part after welding.

Hoshimoto

350+ people viewing

Last viewed: 18 hours ago

■Material Iron (SS) ■Surface treatment Raw material ■Application Welded to objects that cannot be tapped. ■Notes - No pilot is also available, s...

PEM Japan Co., Ltd.

630+ people viewing

Last viewed: 59 minutes ago

■Projection welding nut PEM® brand WN™/WNS™ weld nuts are designed to be welded onto another metal surface in an appropriately sized hole. PEM® wel...

Kishu Fastener Co., Ltd.

410+ people viewing

Last viewed: 19 hours ago

A nut welded to a steel plate. The main shapes are hexagonal, square, and round. Mainly used in automobiles, construction machinery, agricultural m...

Bosei Captive Co., Ltd.

370+ people viewing

Last viewed: 18 hours ago

■Features ・Since it is round, it can be installed without worrying about direction. - Equipped with a pilot so troublesome positioning is not nece...

Kishu Fastener Co., Ltd.

450+ people viewing

Last viewed: 18 hours ago

A nut welded to a steel plate. The main shapes are hexagonal, square, and round. Mainly used in automobiles, construction machinery, agricultural m...

Owari Seiki Co., Ltd.

330+ people viewing

Last viewed: 18 hours ago

■Weld nut A low-cost nut with added locking function. We propose the number and size of projections considering the flange diameter and welding str...

Osaka Forming Co., Ltd.

460+ people viewing

Last viewed: 19 hours ago

■Features A weld nut, also called a weld nut, is a nut that is tightly fixed to a metal steel plate using a special machine. There are two types of...

Osaka Forming Co., Ltd.

420+ people viewing

Last viewed: 18 hours ago

■Features A weld nut, also called a weld nut, is a nut that is tightly fixed to a metal steel plate using a special machine. There are two types of...

Yoshikawa Shoko Co., Ltd.

360+ people viewing

Last viewed: 19 hours ago

Square welded stainless steel nuts are often used by tightly fixing them to a stainless steel plate using a special machine. Welding protrusions ar...

Yoshikawa Shoko Co., Ltd.

340+ people viewing

Last viewed: 18 hours ago

Hexagonal welded iron nuts are often used by tightly fixing them to a metal steel plate using a special machine. Welding protrusions are used to we...

Yoshikawa Shoko Co., Ltd.

380+ people viewing

Last viewed: 18 hours ago

Hexagonal welded stainless steel nuts are often used by tightly fixing them to a stainless steel plate using a special machine. Welding protrusions...

Yoshikawa Shoko Co., Ltd.

480+ people viewing

Last viewed: 18 hours ago

Hexagonal welded stainless steel nuts are often used by tightly fixing them to a stainless steel plate using a special machine. Welding protrusions...

Yoshikawa Shoko Co., Ltd.

360+ people viewing

Last viewed: 3 hours ago

Hexagonal welded stainless steel nuts are often used by tightly fixing them to a stainless steel plate using a special machine. Welding protrusions...

Yoshikawa Shoko Co., Ltd.

390+ people viewing

Last viewed: 19 hours ago

Square welded nut iron is also called square welded nut iron, and is often used by closely fixing it to a metal steel plate using a special machine...

Yoshikawa Shoko Co., Ltd.

390+ people viewing

Last viewed: 14 hours ago

Square welded nut iron is also called square welded nut iron, and is often used by closely fixing it to a metal steel plate using a special machine...

Yoshikawa Shoko Co., Ltd.

350+ people viewing

Last viewed: 19 hours ago

Square welded nut iron is also called square welded nut iron, and is often used by closely fixing it to a metal steel plate using a special machine...

Yoshikawa Shoko Co., Ltd.

350+ people viewing

Last viewed: 19 hours ago

Square welded stainless steel nuts are often used by tightly fixing them to a stainless steel plate using a special machine. Welding protrusions ar...