All Categories

History

This section provides an overview for nanofibers as well as their applications and principles. Also, please take a look at the list of 6 nanofiber manufacturers and their company rankings. Here are the top-ranked nanofiber companies as of February, 2026: 1.American Elements, 2.US Research Nanomaterials, Inc., 3.Kato Tech.

Table of Contents

Categories Related to Nanofibers

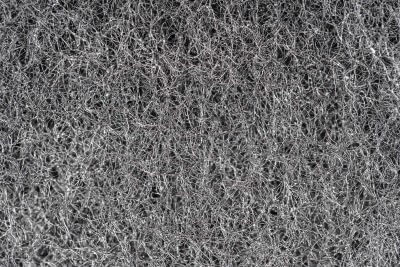

Nanofiber is a fibrous material in which each strand has a diameter of 1 to several hundred nm and a length 100 times greater than its diameter.

It is a representative of nanotechnology and one of the materials attracting attention for future application development. It has a high specific surface area and porosity, and is highly absorbent, permeable, and lightweight.

There are a wide variety of types of nanofibers, including polymeric nanofibers, plant-derived cellulose nanofibers, and carbon nanofibers with high electrical conductivity and strength.

Nanofibers are still in the process of being researched and developed for use. Compared to conventional fibers, nanofibers have superior properties such as high strength, light weight, flexibility, water absorption, heat resistance, electrical conductivity, and biocompatibility.

Each material has different properties and is used in various applications.

Cellulose nanofibers are used in construction materials, automotive parts, and sporting goods because of their light weight and high strength. Cellulose nanofibers are also used in sanitary and medical products due to their high-water absorbency.

Carbon nanofibers are used in the aerospace industry, automotive industry, and sporting goods because of their extremely high strength and light weight. Carbon nanofibers are also used in electronic devices and fuel cells due to their high thermal conductivity.

Polymeric nanofibers have a wide range of applications because their properties can be adjusted depending on the polymer used as a material. For example, they are used in filters with improved water absorbency and strength, and in electronic devices with improved thermal and electrical conductivity. Their range of applications is extremely wide, including tissue regeneration in the medical field and water purification filters in the environmental field.

There are three main methods of manufacturing Nanofiber: electrospinning, composite melt spinning, and melt blowing.

Nanofiber is prepared by applying high voltage to a polymer solution in a spinning nozzle. Since the applied voltage is only 10 to 40 kV, energy-saving production is possible. This method can produce nanofibers down to a few nm in diameter and can be called the current mainstream production method, but mass production requires a large number of nozzles.

Nanofiber is prepared by extruding molten polymer through a special nozzle to produce fibers with a sea-island structure, and then dissolving and removing only the sea component. This method has the disadvantage of only producing nanofibers with diameters of up to 20 nm.

Molten polymer is extruded through a nozzle and simultaneously blown with hot air to produce this material. This method is also used to produce non-woven fabrics such as masks. However, since the lower limit is about 0.5 μm in diameter, the range of use is limited.

There are various types of nanofibers, depending on the manufacturing method and materials used.

Cellulose is a component of plants such as trees and grass, and is one of the most abundant organic substances in nature. Cellulose nanofibers are made from this cellulose, which is finely divided down to the nano-level and have both lightness and strength. It is also a plant-derived material, so it has a low environmental impact and can be recycled.

Carbon nanofiber is a nanofiber composed mainly of carbon and has extremely high strength and lightness. It also conducts electricity well.

Polymeric Nanofibers are made from synthesized polymer compounds. Polypropylene, polyethylene, polyester, etc. can be used depending on the required properties.

Their properties vary depending on the type of polymer used, but in general they are characterized by light weight, high strength, and chemical stability.

*Including some distributors, etc.

Sort by Features

Sort by Area

American Elements was founded in 1997 in California and currently has research and production facilities in Utah, Mexico, China, and the United Kingdom. AE manufactures and distributes advanced materials from a catalog of over 30,000 products for bulk industrial use as well as small scale laboratory use. AE also provides testing and analyses services including spectroscopy along with structural, thermal, and electrical analyses. AE holds sustainable development as a core corporate value and is committed to work to protect the health of the environment.

US Research Nanomaterials Inc, headquartered in Houston, Texas, is a manufacturer and supplier of nanomaterials. Their diverse product portfolio includes graphene, metal nanoparticles, carbon nanotubes, quantum dots, and more. These nanomaterials find applications in industries such as electronics, energy, healthcare, and aerospace. Their products enable advancements in areas like flexible electronics, energy storage, drug delivery systems, and sensor technology. Their nanomaterials offer enhanced properties at the nanoscale, revolutionizing industries and driving innovation in various industrial applications.

Alfa Chemistry, founded in the year 2015 is based in New York, USA as a biotechnology company and manufacturer of graphene materials. Their product portfolio includes graphene oxide, CVD graphene film, graphene modification services, graphene series, graphene-like material, carbon nanomaterials, quantum dots, upcoming nanoparticles, and graphene transfer services. The company also provides services in custom manufacturing, and graphene analysis with quality assurance. The products are used in various industries which include energy, digital electronics, environment, textile, coating, and biomedical science.

Katō Tech Co. Ltd., founded in 1961, is a Japanese manufacturer and supplier headquartered in Minami-ku, Kyoto, specializing in texture measuring instruments. The company offers electronic instruments to evaluate texture quality regarding compression, friction, puncture strength, and other elements. These products are developed based on the Kawabata Evaluation System (KES), introduced in 1970 by Dr. Sueo Kawabata of Kyoto University and Dr. Masako Niwa of Nara Women's University, aiming to convert subjective evaluations into objective data. The company also manufactures customized industrial machinery, such as monofilament stretching machines, surface processing equipment, and tube pressure testers.

Founded in Mumbai, India in 2006, Otto Chemie Pvt. Ltd. is an ISO 9001:2015 & GMP certified chemical manufacturing company and distributor. Otto Chemie serves customers in many industries including agriculture and food processing, pharmaceuticals, oil & gas, cement, as well as educational and R&D industries. Product offerings include antibiotics, amino acids, vitamins, detergents, ionic liquids, materials science compounds, labware, oil, metal & ceramic science compounds and tools, oils, reagents, solvents.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | American Elements |

33.6%

|

| 2 | US Research Nanomaterials, Inc. |

16.3%

|

| 3 | Kato Tech |

15.2%

|

| 4 | Alfa Chemistry |

14.3%

|

| 5 | Otto Chemie Pvt. Ltd |

14.0%

|

| 6 | Oji Holdings Co., Ltd. |

6.6%

|

Derivation Method

The ranking is calculated based on the click share within the nanofiber page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 40.0% |

| United States | 1 | 20.0% |

Japan

Japan

|

1 | 20.0% |

India

India

|

1 | 20.0% |

19 products found

19 products

Oji Holdings Co., Ltd.

550+ people viewing

Last viewed: 36 minutes ago

Cellulose NanoFiber (hereinafter referred to as CNF) is wood fiber (pulp) that has been refined to nano-order (one millionth of 1 mm). CNF is an ex...

ASPiAJAPAN Co., Ltd.

420+ people viewing

Last viewed: 10 hours ago

■Suction performance is bulk type “60 times its own weight” It has excellent adsorption properties and quickly absorbs only oil. One bulk type (20g...

Oji Holdings Co., Ltd.

630+ people viewing

Last viewed: 13 hours ago

Cellulose NanoFiber (hereinafter referred to as CNF) is wood fiber (pulp) that has been refined to nano-order (one millionth of 1 mm). CNF is an ex...

ASPiAJAPAN Co., Ltd.

460+ people viewing

Last viewed: 1 day ago

■Suction performance is bulk type “30 times its own weight” It has excellent adsorption properties and quickly absorbs only oil. It uses less than ...

Oji Holdings Co., Ltd.

710+ people viewing

Last viewed: 1 day ago

Cellulose NanoFiber (hereinafter referred to as CNF) is wood fiber (pulp) that has been refined to nano-order (one millionth of 1 mm). CNF is an ex...

ASPiAJAPAN Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Strong water repellency that does not absorb any water Conventional products absorb water, which not only reduces the amount of oil adsorbed, but ...

Oji Holdings Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

Cellulose NanoFiber (hereinafter referred to as CNF) is wood fiber (pulp) that has been refined to nano-order (one millionth of 1 mm). CNF is an ex...

Oji Holdings Co., Ltd.

600+ people viewing

Last viewed: 1 day ago

Cellulose NanoFiber (hereinafter referred to as CNF) is wood fiber (pulp) that has been refined to nano-order (one millionth of 1 mm). CNF is an ex...

Oji Holdings Co., Ltd.

580+ people viewing

Last viewed: 7 minutes ago

AUROVISCO" is an aqueous dispersion of ultrafine wood fiber cellulose nanofiber (CNF) with a fiber diameter of approximately 3 nm. It has unique ph...

Mori Machinery Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

It can be obtained by breaking down cellulosic biomass. This fiber is 1/5th lighter than steel, 5 times stronger, and has a low thermal expansion t...

Gengen Chemical Industry Co., Ltd.

490+ people viewing

Last viewed: 1 day ago

CNF Sealer, an innovative undercoat that contains the new material cellulose nanofiber (CNF), offers overwhelming durability. A revolutionary in wo...

Microphase Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

Using carbon metallization, CNTs can be heavily doped with titanium to transform them into titanium carbide (TiC) alloys. The obtained TiC transfor...