All Categories

History

This section provides an overview for conveyor curves as well as their applications and principles. Also, please take a look at the list of 17 conveyor curve manufacturers and their company rankings. Here are the top-ranked conveyor curve companies as of March, 2026: 1.SpanTech, 2.Forbo Siegling LLC., 3.Excel Conveyors.

Table of Contents

Categories Related to Conveyor Curves

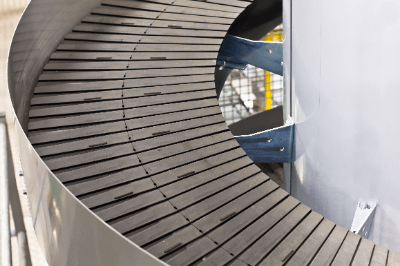

Curved Conveyors are devices that move goods where a change of direction is required.

Curved conveyors are mainly used in fields where goods are frequently moved. Curved conveyor contributes to labor saving in conveying goods by efficiently changing the direction and branching the goods.

Curved Conveyor are available with rollers or belts designed specifically for curves.

Curved Conveyors are installed at intersections where two straight conveyor lines with different conveying directions need to be connected and function to change the direction of parts. When goods are to be moved horizontally within a limited site, it is necessary to change the direction of the goods.

Specifically, they are used to transport various parts and ingredients on production lines for manufacturing automobiles, electronic devices, and foodstuffs through flow operations. They are also useful for transporting and sorting goods in warehouses, transport centers, and other goods transfer lines. The most common places where we see Curved Conveyors in our daily lives are inside conveyor-belt sushi restaurants and in baggage claim areas at airports.

When using a Curved Conveyor, centrifugal force causes items to move toward the outside of the curve. To prevent goods from falling, guide rails machined in the shape of an arc are generally installed together.

Curved Conveyor can be divided into three main categories, each with a different principle.

Curved roller conveyors have a structure that is a reworking of a straight roller conveyor into a circular arc. Roller conveyors use multiple rollers that are arranged in an arc.

The rollers can be straight or tapered rollers. The outside diameter of straight rollers is constant. Tapered rollers have a smaller outside diameter on the inside of the curve and a larger outside diameter on the outside of the curve.

Curved roller conveyors are available with or without a motor to rotate the rollers. In the case of roller conveyors without a motor, the rollers rotate automatically as the material to be conveyed moves.

Due to its structure, a curved roller conveyor can only convey materials that are more than the distance between the rollers. On the other hand, because they are inexpensive and can be made large, curved roller conveyors are applied to heavy or corrugated materials to be conveyed.

Curved belt conveyors consist of a continuous belt formed into a conical shape and crossed over tapered pulleys. The belt is a curved belt that is conically formed to match the curvature of the curve. Curved belt conveyors are equipped with a motor as the power source.

When conveying heavy loads, the "head drive system" is mainly used, in which the belt is moved by rotating the downstream pulley with a motor. The conveyor can also be driven by the upstream pulley.

When conveying lightweight materials or materials that require reverse rotation, an intermediate drive system may be used, in which a belt drive pulley is installed between the upstream pulley and downstream pulley, and a motor and inverter are installed.

The top chain conveyor consists of a continuous top chain with a top plate, which is crossed over sprockets. A motor is attached as a drive source to move the top chain.

In the case of a top chain conveyor, the overlapping state of the top plate fluctuates at the curve. Curved Conveyors found inside conveyor-belt sushi restaurants and in airport baggage claim areas are top-chain conveyors.

When selecting a Curved Conveyor, it is important to consider the type of material to be conveyed and the ease of maintenance.

Roller conveyors are suitable for conveying materials with a flat underside, but are not suitable for conveying materials with an uneven underside or bag-shaped materials. On the other hand, belt conveyors and top chain conveyors can convey not only materials with a flat underside, but also materials with an uneven underside or bag-shaped materials.

Roller conveyors and top chain conveyors are not suitable for conveying granular materials. In this case, belt conveyors are more suitable.

Belt conveyors require periodic adjustment of belt tension, and top chain conveyors require periodic lubrication of the chain. Therefore, the maintainability of belt conveyors and top chain conveyors is not good. On the other hand, roller conveyors do not require such adjustments and are easy to maintain.

*Including some distributors, etc.

Sort by Features

Sort by Area

Honeywell International Inc. was founded in 1885 and headquartered in Charlotte, North Carolina. Honeywell is a diversified technology and manufacturing company to global customers in many industries such as aerospace, building technologies, performance materials, manufacturing, and safety. Honeywell produces hardware and software solutions for each industry it serves. In building technologies, Honeywell designs access controls, electrical and wiring, fire life safety, and employee training services. In aerospace, Honeywell designs cockpit systems and displays, engines, cabin management and cleaning, and health and usage monitoring.

Thomas Conveyor and Equipment Company, Inc. founded in 1976 and based in Oakbrook Terrace, Illinois is a manufacturer of industrial automation products. The company was founded by Thomas Lisy, Sr and is currently run by William Lisy- Tom’s son. The company mainly caters to warehousing facilities and distribution centres. The company designs turn-key material handling systems with easy-to-use controls and maintenance software. The company specializes in manufacturing various ranges of conveyor belts, sortation systems, mezzanines and lifts, ergonomic equipment and packaging products.

QC Conveyors was founded in 1981 and is based in Cincinnati, Ohio, U.S.A., and is a manufacturer of conveyor systems for food packaging, marking & coding, medical, and, metalworking industries. The company provides Flextrac series modular plastic chain conveyors, Automation Series conveyors with a rigid aluminum frame, hydro-clean Series conveyors built on stainless steel frames, and Industrial Series conveyors, and all these items have applications in packaging, automation, assembly, stamping, and, pharmaceutical industries as well as have uses in medical, material handling, brewery, robotics, and, printing sectors.

Uni-Pak Corp was founded in 1970 and is based on East Coast, Southern US is a manufacturer of machinery & conveying systems for the beverage, food, paint & pharmaceutical industries. The company produces warmers, gravity can rinsers, case conveyors, vertical case elevators, and, operators along with high & low-level bulk plastic, glass&can palletizers, steam & gas-fired heating equipment, and empty can conveying systems. Their services include custom-designing equipment, engineering & layout facilities, turnkey systems, cable splicing, and, conveyor & fitting modifications.

Span Tech LLC., founded in 1988 and based in Glasgow, Kentucky, is a manufacturer of plastic chain conveyors that are capable of vertical, horizontal, and helical bends. The company stocks several types of conveyors like helical, wedge, and twist conveyors, and it also sells the accompanying components like drives, support structures, and chains. It serves industries like food production, manufacturing, and packaging and also offers services that include breakdown repairs, regular conveyor inspections, and service training. The company has its university with training programs to teach users about its conveyor systems.

Forbo Movement Systems is based in North Carolina since 1919 and is known as the manufacturer and distributor of conveyor belts, power transmission belts, and modular belting solutions. The company also deals in plastic modular belts, timing and flat belts made of synthetic materials,, and processing belts. These have various applications in a wide range of industries. Such as the food belts are used for dough processing, packaging, for seafood, meat and poultry processing and etc. Other industries that benefit include the logistics and the airports for baggage handling and also the textile industry, printing industry, and lots more.

Ergonomic Partners is a branch of Tri-State Overhead Crane, located in St. Louis, Missouri. Ergonomic Partners has a 50-year history as a turnkey solution manufacturer for material handling applications. Ergonomic Partners provides customer solutions for repetitive lifting application, precise product placement, and awkward load handling. Additionally, Ergonomic Partners provides off-the-shelf ergonomic material handling and workstation equipment with custom designed and engineered handling devices and special equipment solutions. Custom lifting devices include ergonomic lift assists, easy arms, manipulator arms, vacuum lifters, tool balancers and more

Inpak Systems, Inc. was founded in 1986 and is based in Wisconsin, U.S.A., and is a distributor of industrial bagging and packaging equipment for various industrial and commercial applications. The company offers bagging scales, bag fillers in net & gross weigh models, bag closers, conveyors, and, metal detectors as well as robotics systems, and palletizing equipment such as wrappers, lifts, tables, and pallet trucks for the bagging equipment manufacturing industries related to aggregate, almond, animal feed, bakery powder, and, chemicals & fertilizers.

TK Systems, Inc. established in 1987 and based in California, United States, is a supplier of material handling equipment. The company offers various products, such as pallet racks, mezzanine structures, conveyor systems, and industrial equipment. The company has licensed contractors across the US to perform material handling installations. The company offers turnkey projects to customers. TK systems cater equipment to warehouses, offices, and distribution centers. The company offers material handling solutions and uses proven methods to manufacture code-compliant products.

TOYO KANETSU K.K. is a logistics and distribution solutions manufacturer headquartered in Koto Ward, Tokyo, and established in 1955. The company specializes in providing conveyance systems, baggage handling systems, and the integration of warehouse and logistics solutions. Its primary business activities encompass planning, engineering, manufacturing, construction, sales, and maintenance of logistics and distribution systems. Notably, its Wakayama Plant serves as the manufacturing facility for material handling equipment. This plant is a one-stop production system, covering everything from sheet metal fabrication to final assembly.

Excel Conveyors, established in 2016 and located in Pune India is a manufacturer of conveyor rollers. The company specialises in making both flat belt conveyors and gravity rollers. The types of flat belt conveyors manufactured by the company are modular slat and belt conveyors, chain-driven conveyors, and pallet and spiral conveyors. The rollers manufactured by the company are sprocket-driven groove-driven rollers and time pulley rollers. The products designed and manufactured by this company are low-cost and a superior mode of transporting diverse goods like HDPE bags, carton boxes, wooden and plastic pallets and metallic drums.

Kramer & Duyvis B.V., located in Waalwijk, Netherlands and established in 2015 is a manufacturer of curved conveyor belts. The company specializes in Type R (15°-360°), Type KDC (25°-180°), Type KDZ (180°), Type BMK (15°-180°) and Type VEHO Curve (45°/ 90°/ 180°). The belts are dry and clean and come with an aluminium frame. Moreover, the company also produces safe plastic modular conveyors. The company has a team that specializes in engineering, production, and delivering curved conveyors worldwide through a network of system integrators and OEM-ers. The workshops are well-equipped with the latest machinery for superior custom products.

Royal Conveyor Solutions, founded in 2014 in Brantford, Ontario, Canada is a manufacturer of superior-quality custom-built conveyors. The company specializes in manufacturing sanitary conveyors for food and beverage movements, bulk moving conveyors for composites and heavy-duty materials, versatile conveyors, magnetic and curved and roller conveyors for warehouses. The in-house team are experts and experienced in making new custom design conveyors, to suit specific factory requirements. The company also manufactures tools and machinery and helps in the seamless installation of conveyor belts. The company also offers maintenance services for the conveyor belts.

FMH Conveyors, established in 2015, is a UK-based manufacturer and supplier specializing in the design, manufacture, and supply of conveying equipment. The company's diverse product portfolio features flexible conveyors, telescopic conveyors, loaders, and mobile reconfigurable conveyors. These products offer solutions for fluid and loose loading and unloading in material handling, serving sectors such as airports, distribution centers, manufacturing, and logistics. With the support of an application-driven team of design and configuration experts, FMH Conveyors assists customers across various industries in integrating automation to enhance productivity through its solutions.

VC999 is a global manufacturer of vacuum packaging machines with a parent company in Herisau, Switzerland, and offices in Kansas City, Missouri, Germany, Canada, Austria, Colombia, and over 70 other countries. The brand name VC999 is an acronym for vacuum capacity 99.9%. It refers to the highest vacuum performance achievable, which echoes VC999 quality and performance. From small tabletop vacuum machines to dryers and thermoformers, VC999 stocks different types of vacuum machines to cater to various client needs.

Okura Yusoki Co., Ltd. established in 1960 and based in Hyogo, Japan, is a manufacturer specializing in material handling equipment. The company offers an extensive and diversified product portfolio including conveyor equipment, advanced 3D robot picking systems, efficient automated storage systems, precise picking and sorting equipment, and palletizing equipment picking equipment among others. In addition, the company also provides end-to-end support, from system consultation and design to manufacturing and after-sales service to engineers.

Nitta Corporation is an Osaka-based manufacturer and distributor of various industrial products founded in 1885. The company offers power transmission and mechatronic products, as well as intermediate components like tubings and fittings. These are used in conveyor machines, hydraulic systems, and medical devices. The company also produces industrial parts, such as molded rubber products like gaskets or diaphragms, as well as air filters and monitoring equipment like particle counters or decontamination devices. Nitta Corporation maintains a network of manufacturing facilities and sales locations in 22 countries across four continents.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | SpanTech |

10.4%

|

| 2 | Forbo Siegling LLC. |

10.4%

|

| 3 | Excel Conveyors |

7.8%

|

| 4 | UNI-PAK Corp. |

7.8%

|

| 5 | Ergonomic Partners |

7.8%

|

| 6 | Honeywell International Inc |

7.8%

|

| 7 | TK Systems, Inc. |

6.5%

|

| 8 | Thomas Conveyor and Equipment Company, Inc. |

5.2%

|

| 9 | Inpak Systems, Inc. |

5.2%

|

| 10 | QC Conveyors |

5.2%

|

Derivation Method

The ranking is calculated based on the click share within the conveyor curve page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 56.3% |

Japan

Japan

|

2 | 12.5% |

India

India

|

1 | 6.3% |

Netherlands

Netherlands

|

1 | 6.3% |

Canada

Canada

|

1 | 6.3% |

United Kingdom

United Kingdom

|

1 | 6.3% |

Switzerland

Switzerland

|

1 | 6.3% |

713 products found

713 products

Thanko

930+ people viewing

Last viewed: 1 hour ago

When moving a heavy cardboard, it is quite difficult to move a few one with just one. What you want to use in such a case is [connected roller conv...

Maruyasu Machine Co., Ltd.

460+ people viewing

Features ■Food-specific conveyor This is a dedicated conveyor for transporting food.The frame, rollers, etc. are made of stainless steel or resin, ...

ITS Co., Ltd.

930+ people viewing

■Summary This conveyor is specially designed for easy cleaning, and we have thoroughly pursued belt cleaning, guide cleaning, and frame cleaning, m...

Maruyasu Machine Co., Ltd.

900+ people viewing

Last viewed: 5 hours ago

Features ■Food-specific conveyor This is a dedicated conveyor for transporting food.The frame, rollers, etc. are made of stainless steel or resin, ...

ITS Co., Ltd.

680+ people viewing

■Summary A standard feature of stainless steel is that it can be washed. By introducing opening specifications and cleaning equipment, cleaning tim...

Maruyasu Machine Co., Ltd.

770+ people viewing

Last viewed: 20 hours ago

Features ■Food-specific conveyor This is a dedicated conveyor for transporting food.The frame, rollers, etc. are made of stainless steel or resin, ...

Maruyasu Machine Co., Ltd.

380+ people viewing

Features ■Food-specific conveyor This is a dedicated conveyor for transporting food.The frame, rollers, etc. are made of stainless steel or resin, ...

3 models listed

Maruyasu Machine Co., Ltd.

640+ people viewing

Last viewed: 1 day ago

Features ■Food-specific conveyor This is a dedicated conveyor for transporting food.The frame, rollers, etc. are made of stainless steel or resin, ...

Maruyasu Machine Co., Ltd.

340+ people viewing

Last viewed: 19 hours ago

■Features We respond to all needs from transportation to palletizing. Each model is a standard unit that can be freely combined to meet all logisti...

2 models listed

Maruyasu Machine Co., Ltd.

260+ people viewing

Last viewed: 21 hours ago

■Features We respond to all needs from transportation to palletizing. Each model is a standard unit that can be freely combined to meet all logisti...

2 models listed

Maruyasu Machine Co., Ltd.

450+ people viewing

Features ■World's first. Transport drive using magnetic force The world's first Resveyor uses the principle of magnetic attraction and repulsion to...

Maruyasu Machine Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

Features ■World's first. Transport drive using magnetic force The world's first Resveyor uses the principle of magnetic attraction and repulsion to...

Maruyasu Machine Co., Ltd.

330+ people viewing

Features ■Two drive units strongly clip Realizes a powerful drive reminiscent of a bulldozer. The belt is sandwiched between two "drive units" and ...

4 models listed

Maruyasu Machine Co., Ltd.

720+ people viewing

Features ■Two drive units strongly clip Realizes a powerful drive reminiscent of a bulldozer. The belt is sandwiched between two "drive units" and ...

Maruyasu Machine Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

Features ■Two drive units strongly clip Realizes a powerful drive reminiscent of a bulldozer. The belt is sandwiched between two "drive units" and ...

4 models listed

Maruyasu Machine Co., Ltd.

630+ people viewing

Last viewed: 11 hours ago

Features ■Standard for conveyor selection The compact belt conveyor "Mini Series" uses a frame made of high-precision aluminum extrusion, allowing ...

Maruyasu Machine Co., Ltd.

660+ people viewing

Last viewed: 14 hours ago

Features ■Standard for conveyor selection The compact belt conveyor "Mini Series" uses a frame made of high-precision aluminum extrusion, allowing ...

Maruyasu Machine Co., Ltd.

440+ people viewing

Features ■Standard for conveyor selection The compact belt conveyor "Mini Series" uses a frame made of high-precision aluminum extrusion, allowing ...

Maruyasu Machine Co., Ltd.

460+ people viewing

Features ■Standard for conveyor selection The compact belt conveyor "Mini Series" uses a frame made of high-precision aluminum extrusion, allowing ...

Maruyasu Machine Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

Features ■Standard for conveyor selection The compact belt conveyor "Mini Series" uses a frame made of high-precision aluminum extrusion, allowing ...