All Categories

History

This section provides an overview for urethane rolls as well as their applications and principles. Also, please take a look at the list of 13 urethane roll manufacturers and their company rankings. Here are the top-ranked urethane roll companies as of February, 2026: 1.Rol-Tec, Inc,, 2.Diversified Plastics, Inc., 3.Universal Urethane Products Inc..

Table of Contents

Categories Related to Urethane Rolls

Graduated with a master's degree in mechacanical engineering from the Department of Mechanical Engineering, University of Tokyo.

As a student, he was engaged in research on thermophysical properties and materials, such as thermal interface materials and heat insulating materials.

After that, he mainly engaged in the development of coating equipment and CAE work at a chemical manufacturing company. Currently, he is engaged in research and development related to CFD, molecular dynamics, chemical equilibrium, and gas-liquid equilibrium at a food manufacturing company.

A Urethane Roll is a metal roll or roller lined with urethane and baked on its surface.

It has excellent soundproofing, sound absorption, sound insulation, oil and chemical resistance, mechanical strength, repulsive elasticity, rolling resistance, heat resistance, heat storage, and abrasion resistance. Depending on the application, urethane color, material, hardness, and length are selected and adjusted.

It has a wide range of uses, including use as cushioning material for chairs, sofas, and mattresses, and is also widely used in general households because of its easy processing. It can also be cleaned at home.

Urethane rolls are used in a wide range of applications, from automobile interior components to sound deadening and sound absorption. They are also used in the medical field, particularly in nursing care facilities, where they are suitable for everything from beds and examination rooms to rehabilitation floors.

In addition, it can be used as a packing material for packing and transporting products of various categories (fruits, fresh foods, precision equipment, etc.).

As sports mats, they are used in almost all categories of athletic equipment, including indoor, ground, and pool mats, as well as in homes and gyms, such as yoga mats.

Figure 1. Typical roll structure

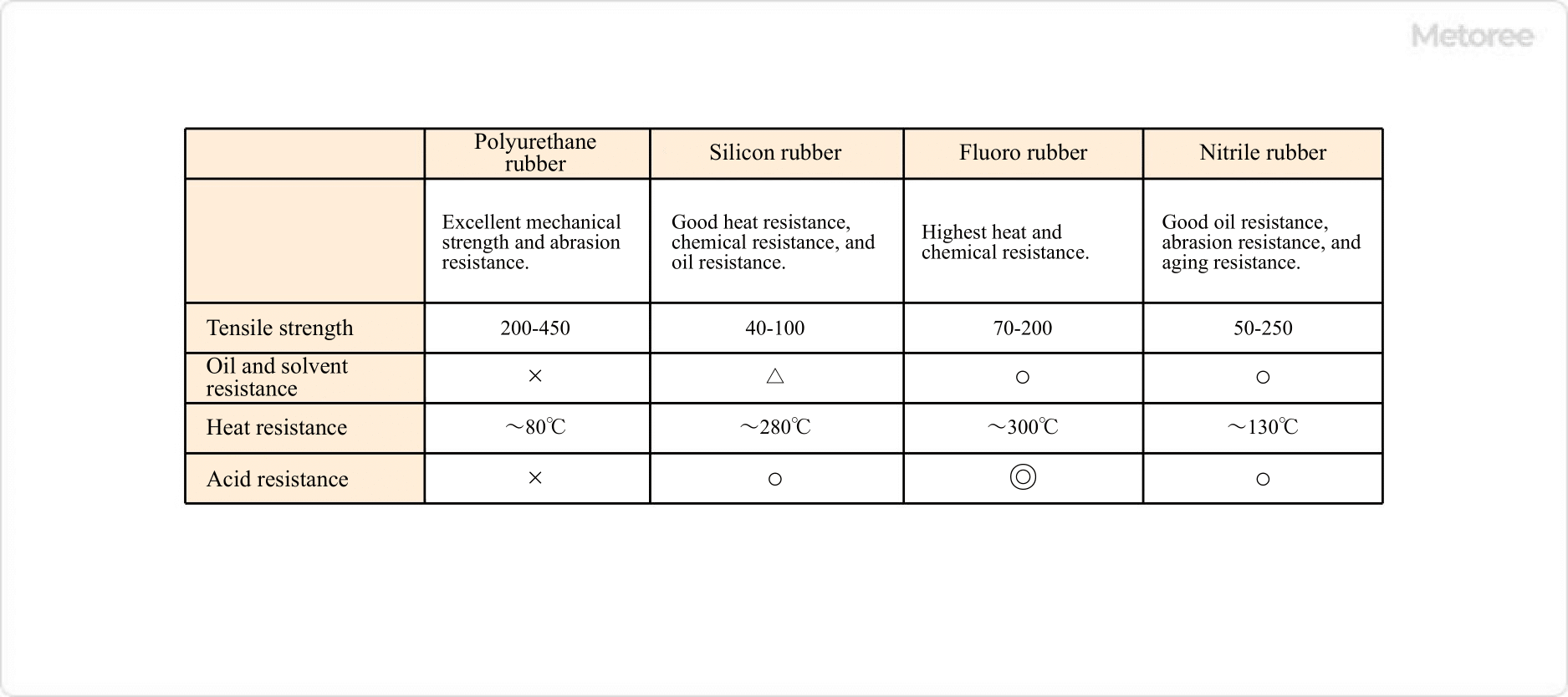

The material polyurethane is soft, abrasion-resistant, elastic, and oil-resistant like rubber. Rubber can be broadly classified into two types: natural rubber, made from natural sap, and synthetic rubber, made by molecular polymerization.

Its soft texture makes it suitable for cushioning materials for chairs and mattresses. It is highly versatile in processing, and can be processed into various shapes ranging in thickness from a few millimeters to cubes of several meters. Therefore, it can be widely used as a packaging material for a wide range of genres.

It is also available in a wide range of color variations. The material has soundproofing, sound absorption, and sound insulation properties, as well as high elasticity, making it suitable as a cushioning material. It has excellent elasticity and is difficult to tear even when stretched.

By changing the material, you can choose from a variety of features such as chemical resistance, solvent resistance, low temperature resistance, water resistance, alkali resistance, oil resistance, low and high temperature resistance, load resistance, permanent strain resistance, sulfuric acid resistance, solvent resistance, hydrochloric acid resistance, heat resistance, and tear resistance.

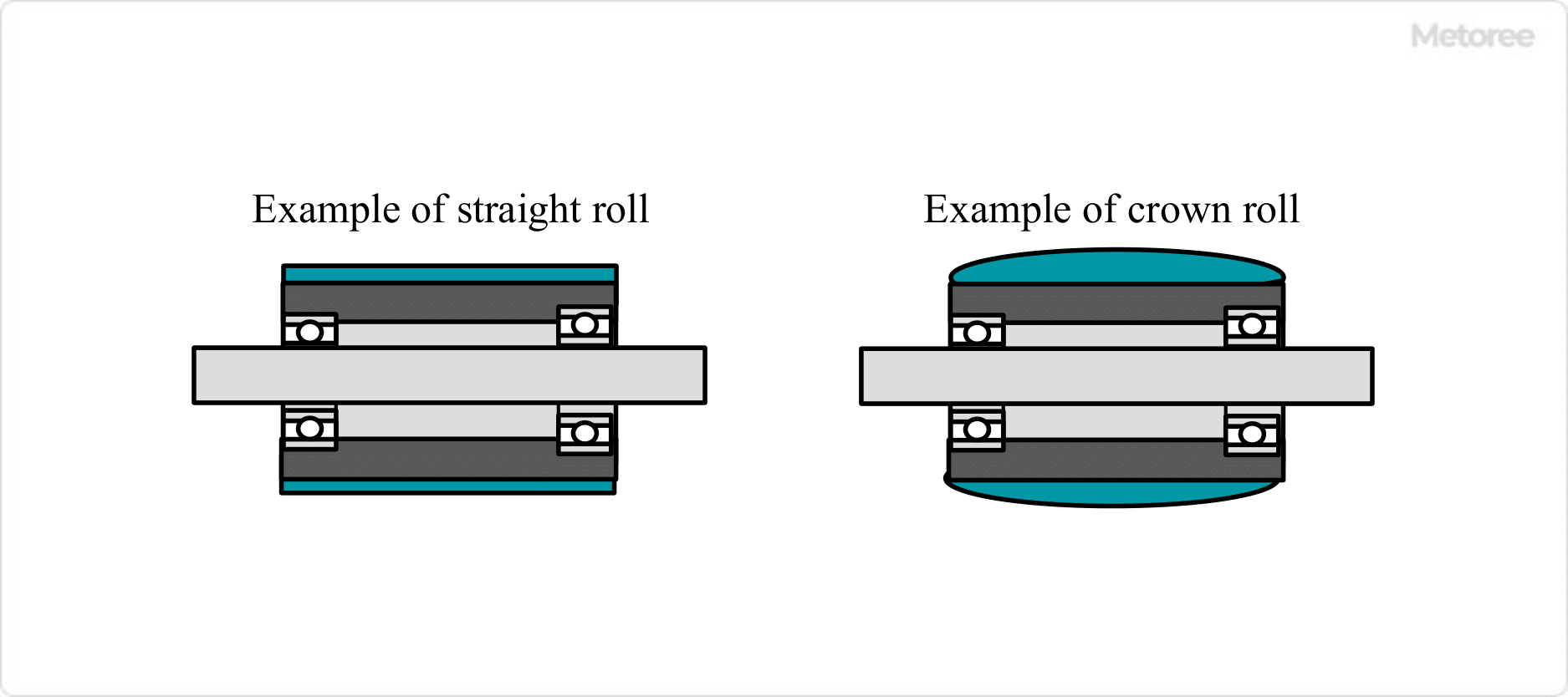

The rolls themselves are also available in a variety of shapes, including regular and crown rolls.

Figure 2. Characteristics of rubber materials

Even if they have the same name of "urethane", each urethane material has different performance depending on its composition type and hardness. Even hard products have elasticity and shock-absorbing properties compared to other rubber materials.

In particular, it is characterized by excellent mechanical properties. While it has the advantage of high tensile strength and abrasion resistance, its disadvantage is inferior oil resistance performance, heat resistance, and chemical resistance. There are different types of urethane: rigid urethane, soft urethane, ether-based, and ester-based.

1. Hard urethane roller (hardness: 50-95 degrees)

This type of roller is mainly used in industrial applications where strength is required, such as crimping rollers, conveyance rollers, and guide rollers. Urethane has a property of hydrolysis when combined with water.

Hydrolysis is a chemical reaction that occurs when moisture is added to a material due to rain or humidity, causing the previously lumpy material to disintegrate. Hydrolysis occurs after manufacturing and the surface becomes sticky in a few years.

As hardness increases, urethane becomes more hydrophobic (i.e., water does not mix with it easily), making hydrolysis more difficult, and thus urethane is relatively resistant to hydrolysis. Furthermore, even with the same hardness, hydrolysis is more likely to occur with ester-based materials, while it is less likely to occur with ether-based materials.

2. Soft urethane roller (hardness: approx. 20 to 30 degrees)

Soft urethane rollers are used for letterpress printing and printmaking. Generally, ester type rollers are used. Therefore, hydrolysis is more likely to occur.

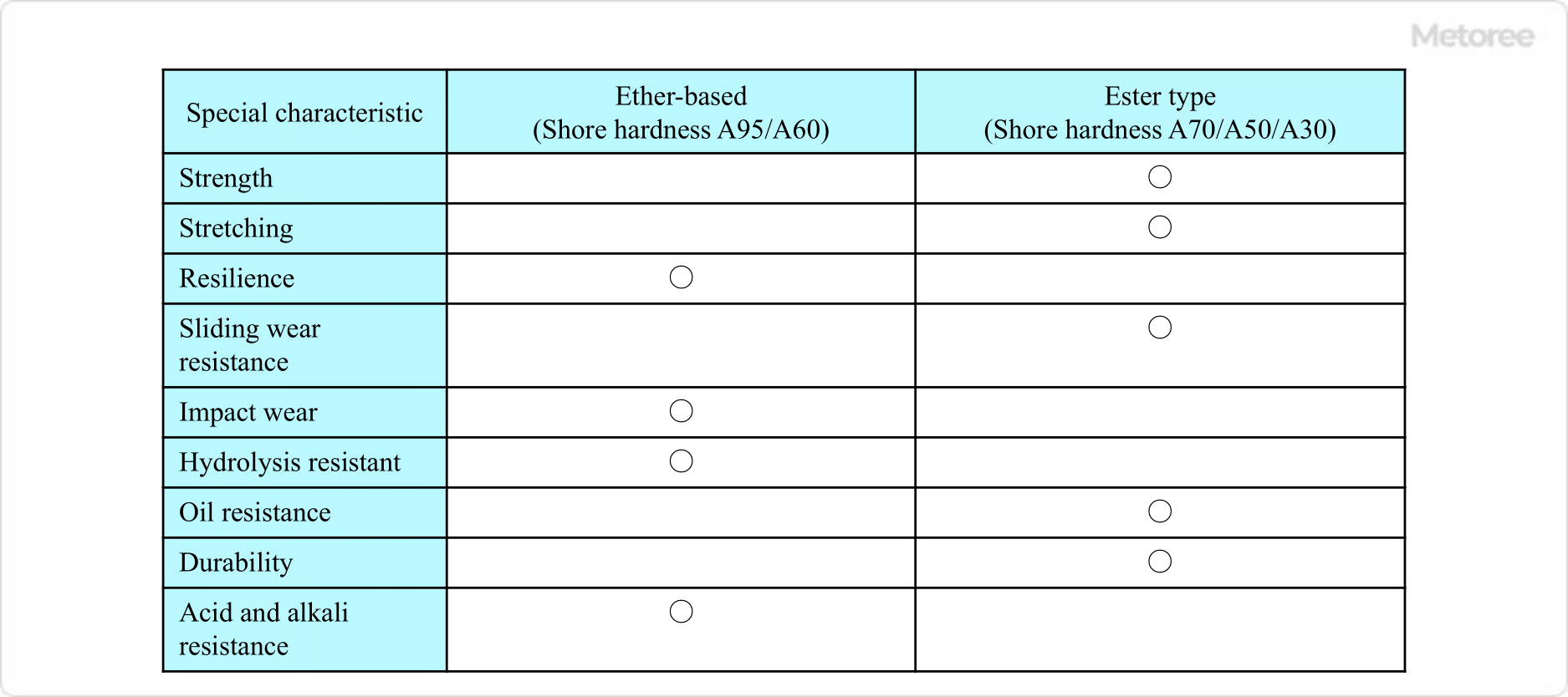

3. Ether-based roller

Figure 3. Characteristics of ether and ester systems

Urethane rubber is produced by combining ether-based polyols with urethane. The advantage of this type is that it is relatively resistant to hydrolysis, which is a weak point of urethane rubber. Soft materials as well as hard materials are available, ranging from 20 to 30 degrees Celsius for soft materials and 70 to 90 degrees Celsius for hard materials. However, mechanical strength and abrasion resistance are slightly lower than those of ester-based materials.

4. Ester type

This urethane material has ester bonds in its composition. It has higher mechanical strength, tensile strength, tear resistance, and oil resistance than ester-based materials. As mentioned above, its disadvantage is that it is more prone to hydrolysis than ether-based materials.

*Including some distributors, etc.

Sort by Features

Sort by Area

Rol-Tec, Inc., founded in 1991, is an American manufacturer based in Green Bay, Wisconsin, specializing in elastomer covering solutions. The company's offerings include elastomer molded parts and rubber rollers. Additionally, through its subsidiary, Sleeve Solutions LLC, the company provides both parallel and tapered fiberglass sleeves. It also offers services like laser engraving combined with polymer compounds for cutting rollers and sleeves, along with thermal coatings using aluminum titanium, brass, ceramic, stainless steel, and tungsten carbide. These products and services serve various industries, including coating, laminating, and varnishing, converting and packaging, food processing, oil and gas, as well as paper making and printing.

American Roller Company, LLC, established in 1938, is an American manufacturer based in Union Grove, Wisconsin, specializing in industrial rollers and plasma coatings. The company's product offerings include heat transfer and chill rollers, idler rollers, roller coverings, as well as specialty rollers. The company also provides services including roller repair and testing, cladding and welding, design and core fabrication, as well as industrial coatings. The company serves various industries, including battery and power storage, food and beverages, packaging, and transport rolls. Other industries served include glass, medical products, plastic films and sheets, printing, pulp and paper, as well as steel and aluminum.

Southern Rubber Co. Inc. was chartered in 1925 and is headquartered in Greensboro, North Carolina. The company is an ISO 9001:2015 certified manufacturer and fabricator of rubber-based products. The company’s product segments include gaskets, extrusions, industrial hoses & tubing, adhesives, and O-rings & seals. The company provides both stock and custom offerings compatible with military and various commercial standard requirements. The company also produces prototypes of various components from customer drawings.

Imperial Rubber Products Inc., founded in 1989, is a precision roller manufacturer and supplier headquartered in Chino, California, United States. The company’s product range includes new and used rollers for standard industrial and graphic art applications, as well as one-way press and composite rollers. It also offers products from other manufacturers, such as non-woven mill rollers from FKM Walzentechnik and the Link-Belt series of spherical roller bearings from Regal Rexnord Corporation. Serving customers in the United States and Mexico, the company supplies these products for applications in converters and commercial printers handling materials like aluminum, plastic, and steel.

Universal Urethane Products Inc., established in 1973 and based in Toledo, Ohio, USA, is a manufacturer and supplier of custom urethane roll coverings. The company's product range includes polyurethane disk bearings, coil pads, forklift coil rams, coil saddles (double), and coil saddles. These products are designed for applications like coil storage, power transmission, and damage prevention. It serves industries such as steel, aluminum, fiberglass, corrugated containers, and automotive glass. The company offers services such as roll recovery, ultrasonic and magnetic particle testing, CNC lathe machining, and CNC milling.

Precision Pulley & Idler (PPI), established in 1977, is a supplier of engineered conveyor components and solutions, based in the United States. The company is catering to a diverse group of industries including aggregate, mining, forestry, unit handling and food processing. It has developed a unique Finite Element Analysis program (PFEA) that has brought a new understanding to the dynamics of a conveyor pulley system. It operates 27 facilities in 16 different locations including manufacturing, warehousing, service centers and a training center in the United States. Its global facilities are located in Chile, Mexico, Peru and Canada.

Henning Gasket of Chicago, Illinois, has a 100 year history of serving industries including agriculture, power generation, transportation, construction, electronics, pharmaceutical, and food processing as a distributor for gasket materials, seal materials, gaskets, seals, and related tools. Hennig Gasket also offers gasket manufacturing, of over 30 varieties including roll and sheet gasket material, and cutting services. Custom gasket manufacturing includes many types such as paper gaskets, ceramic fiber gaskets, pipe seals, flame resistant, neoprene gaskets, and chiller gaskets.

Luff Industries, Ltd. established in 1979 and based in Calgary, Alberta, Canada, is a to manufacturer and supplier of quality conveyor components. The company's product range includes idlers with patented polymer end caps, pulleys with an industry-leading rim thickness, impact beds, and accessories. These products are used in sectors such as aggregate, mining, forestry, original equipment manufacturers (OEM), and construction. The components are essential for enhancing the performance of conveyor systems, ensuring smooth and efficient material handling. Its services emphasize quick turn-around times, industry-leading warranties, and ideal product development.

Pulisen Polyurethane products Co.,Ltd. was established in 2016 and headquartered in liyang city, jiangsu, China, is a manufacturer in the field of extruded polyurethane belt, custom-molded urethane products and solutions. They provide custom cast urethane roller, polyurethane wheels and cast urethane parts, such as urethane lined rollers, polyurethane sheets, rods, blocks and polyurethane pads, Besides that. They also provide replacement blades for primary and secondary belt cleaning systems, Its polyurethane scrpaer blades are high resistance to abrasion polyurethane formula.

Yodogawa Steel Works, Ltd., a company founded in 1935 and headquartered in Osaka, Japan, is a manufacturer and supplier of steel products. The company's product portfolio includes polished steel sheets, cast iron rolls, cast steel rolls, household utensils, and residential equipment. These products have applications in various sectors, including construction, consumer goods, automotive, real estate development, and various other industries. The company's factories and plants are ISO 9001 and ISO 14001 certified, with offices in Thailand, China, and Taiwan for global expansion.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Rol-Tec, Inc, |

22.7%

|

| 2 | Hennig Gasket & Seals, Inc. |

13.6%

|

| 3 | Diversified Plastics, Inc. |

9.1%

|

| 4 | Universal Urethane Products Inc. |

9.1%

|

| 5 | PRECISION PULLEY AND IDLER |

9.1%

|

| 6 | Southern Rubber Co. Inc. |

9.1%

|

| 7 | Dreambird SIA |

4.5%

|

| 8 | Roller Manufacturers |

4.5%

|

| 9 | Imperial Rubber Products Inc |

4.5%

|

| 10 | Luff Industries, Ltd. |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the urethane roll page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 70.0% |

Canada

Canada

|

1 | 10.0% |

China

China

|

1 | 10.0% |

Japan

Japan

|

1 | 10.0% |

30 products found

30 products

OS Polymer Co., Ltd.

430+ people viewing

Last viewed: 4 hours ago

Nanshin Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

■Features ・1.2t can be transported manually Achieves unprecedented low rotational resistance with excellent high repulsion. Traditionally, hard wh...

OS Polymer Co., Ltd.

440+ people viewing

Last viewed: 20 hours ago

JRC Co., Ltd.

360+ people viewing

Last viewed: 10 hours ago

■Product features ・With shaft & bearing ・Urethane lining ・With shaft

JRC Co., Ltd.

360+ people viewing

Last viewed: 8 hours ago

■Product features ・Bearing straight type ・Urethane lining

JRC Co., Ltd.

440+ people viewing

■Product features ・Bearing crown type ・Urethane lining

JRC Co., Ltd.

290+ people viewing

Last viewed: 10 hours ago

■Product features ・Shaft fixed type ・With key groove ・Urethane lining

JRC Co., Ltd.

340+ people viewing

Last viewed: 10 hours ago

Fixed shaft type

Yukosha Shito Trading Co., Ltd.

560+ people viewing

Last viewed: 21 hours ago

■What is Flute Roller CE? Conveyance roll used for counter ejector This is a urethane roll for transportation used in the unit (counter ejector pa...

Yonei Co., Ltd.

490+ people viewing

■Super Polyforte (urethane roll) - Due to the special formulation, there is little change in surface roughness, and there is less adhesion of sizin...

OS Polymer Co., Ltd.

370+ people viewing

Last viewed: 1 hour ago

Sugatsune Industries Co., Ltd.

380+ people viewing

Last viewed: 22 hours ago

■Features - A urethane roller that is resistant to cracking and peeling, and has both high durability and abrasion resistance. - Also available wit...

Techno Roll Co., Ltd.

440+ people viewing

Ether-based special urethane material TPU-T with excellent rebound resilience and water resistance ■Applications ・Film related: Laminating roll,...

Techno Roll Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

Ester-based special urethane roll TPU-S with excellent mechanical strength and oil resistance ■Applications ・Steel related: Ringer roll, deflect...

Techno Roll Co., Ltd.

370+ people viewing

It is a material with the highest strength among high-strength urethanes, and has excellent wear resistance and water resistance. ■Features ・A ma...

OS Polymer Co., Ltd.

330+ people viewing

Last viewed: 4 hours ago

Chubu Sangyo Co., Ltd.

550+ people viewing

Last viewed: 28 minutes ago

■Selection of urethane bearings Please select the size based on the load and speed of the usage conditions. ■Explanation - For guide rollers such ...

Chubu Sangyo Co., Ltd.

450+ people viewing

Last viewed: 5 hours ago

■Selection of urethane bearings Please select the size based on the load and speed of the usage conditions. ■Explanation - For guide rollers such ...

Chubu Sangyo Co., Ltd.

460+ people viewing

■Selection of urethane bearings Please select the size based on the load and speed of the usage conditions. ■Explanation - For guide rollers such ...

Kokugo Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

Urethane pipe inner diameter 6φ x outer diameter 15φ x 500L ■Features It is a polymer compound with a high degree of elasticity and mechanical str...