All Categories

History

This section provides an overview for arc welding robots as well as their applications and principles. Also, please take a look at the list of 9 arc welding robot manufacturers and their company rankings. Here are the top-ranked arc welding robot companies as of February, 2026: 1.Kawasaki Robotics, 2.Kobe Steel USA Inc., 3.Dixon Automatic Tool, Inc..

Table of Contents

Categories Related to Arc Welding Robots

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

Arc welding robots are robots that perform arc welding in place of humans.

Arc welding robots are robots that perform arc welding in place of humans.

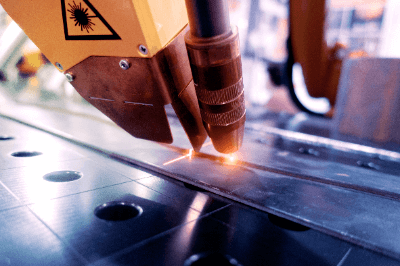

Compared to other welding robots, arc welding robots are somewhat smaller. Arc welding emits intense light and powerful ultraviolet rays from the arc discharge, so the welding point becomes very hot. Therefore, there is a high risk of burns, even when protected by goggles and work clothes.

Inhalation of fumes from metal vapors is also harmful and is one of the tasks for which robots are in high demand as an alternative. Robots have the advantage of being able to perform welding at high speeds and with stable quality, which also contributes to cost reduction.

Arc welding is used to connect metals such as steel to steel, aluminum, and titanium. It is a welding method applicable to almost all metal structures.

The following are examples of products for which arc welding robots are used:

Arc welding robots are used in manufacturing plants for the above products. In recent years, the rationalization of welding has been progressing, and the number of cases in which arc welding robots have been introduced is on the rise. Arc welding robots can also be used for TIG welding and mag welding, which are types of arc welding.

Arc welding is a welding method that uses electrical discharges into the air. An electric current is passed through the welding rod, which serves as the electrode, and when it comes into contact with the metal to be joined and is slowly pulled apart, an arc discharge occurs. The arc is so hot, reaching temperatures of up to 20,000°C, that the metal is quickly melted and joined.

The robot has six to seven vertically mounted articulated axes for precise motion. Each axis has a specific angle and speed at which it can move, and a qualified operator teaches the robot the welding conditions. The conditions and positioning at this time are important and are sometimes determined while performing actual welding.

The part that actually performs the welding is called the welding torch, which is fixed to the tip of the robot. The torch and contact tip must be selected according to the object to be welded.

The structure of an arc welding robot consists of a manipulator, a controller, and a programming pendant.

The manipulator consists of a base, motor and end-effector. The welding torch attached to the end-effector can be replaced to accommodate various welding conditions. It also has a multi-axis articulated structure with servo motors.

The controller consists of data storage and communication equipment with the manipulator. Welding conditions and other data are stored in the controller.

The programming pendant is an interface through which a person teaches welding conditions to the robot. Data describing the manipulator's operating procedures can be created, changed, or modified. Control parameter changes and teaching are also performed by the programming pendant.

Arc welding robots must be selected according to the welding material, stroke, and installation method. Welding materials include steel and aluminum. Select a robot that corresponds to the material to be welded.

The stroke is the distance the robot can extend its arm. The longer the stroke, the farther the robot can work, but the more expensive it is. When welding large parts, multiple robots may be installed.

Installation methods include wall-hanging and ceiling-suspension, depending on the conditions in which the robot is to be installed. Select an installation method suitable for the location where the robot is to be installed.

The global arc welding robot market is expected to reach US$11.7 billion by 2026. In addition, the automotive industry is expected to remain strong and demand will continue to grow beyond 2024. The prevalence of automation, especially in developed countries, and labor shortage issues are also factors driving demand.

Arc welding robots are generally sold at prices starting at around several million yen. The amount varies depending on the materials to be welded and the conditions of use.

*Including some distributors, etc.

Sort by Features

Sort by Area

Dixon Automatic Tool, Inc. was originally founded in 1946 in Rockford Illinois. Dixon Automatic Tool is an automated assembly products and services supplier. Dixon Automatic Tool offerings include automatic screwdrivers, automatic nut-runners, automatic part placers, automatic setting systems, robotic end effectors, assembly work cells, hand-held drivers, feeder bowls and feed systems, and features Stöger products for customers’s automation needs. Dixon Automatic Tool also offers two escapement types that can be tooled to escape and transfer piece parts, as well as electric hand-held screwdrivers.

Kobe Steel USA Inc. serves as the US headquarters for Kobe Steel, Ltd. (KOBELCO), a Japanese manufacturer established in 1905. The company specializes in steel, aluminum, and copper products, as well as welding, industrial, and construction machinery. KOBELCO offers a wide range of products for the automotive industry, construction sites, civil engineering projects, energy infrastructure, and transportation systems. The company also develops technologies for environmental cleanup and recycling, including water treatment. Notably, KOBELCO implements strategies to reduce carbon dioxide emissions during production, such as generating electricity from steam and warm water discharge.

Kawasaki Robotics (U.S.A.), Inc., founded in 1989 as a subsidiary of Kawasaki Heavy Industries, Ltd., is a manufacturer headquartered in Wixom, Michigan, specializing in industrial robots and robotic automation systems. The company offers robotic solutions, including pick and place robots, general-purpose robots with payloads spanning 3 to 1,500 kg, as well as palletizing robots, capable of handling payloads from 80 to 700 kg, Additionally, the company develops the duAro series, featuring dual-arm Selective Compliance Assembly Robot Arm (SCARA) collaborative robots. Furthermore, the company provides robots for specific functions, such as arc welding robots, explosion-proof paint robots, sealing robots, and water transfer robots.

NACHI-FUJIKOSHI CORP. is a Japanese manufacturer of industrial machinery and tools, such as bearings, hydraulic equipment, robots, and cutting tools. They also provide services such as machine maintenance and repair. The company's products are used in automotive, aerospace, construction, and electronics. One of NACHI-FUJIKOSHI's renowned products is their robotic arm, the "MZR series," which is designed for precision assembly and inspection tasks in industries. They received several awards for their technological advancements and contributions to the industry, including the 2021 Japan Society of Mechanical Engineers Medal for new hydraulic equipment technology and the 2020 Nikkan Kogyo Shimbun Grand Technology Award.

Arrowtek Robotic Private Limited is a manufacturer of Industrial Robotic Automation and Integration solutions established in 2007, located in Tamil Nadu, India. Its expertise lies in producing and distributing robotic welding machines, ABB robotic welding machines, ABB welding robots, robotic welding fixtures, robotic welding cells and more. They have been associated with ABB as a channel partner. ABB awarded the company as the promising ABB robotics system integrator in 2022.

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

Shandong Mining Machinery Group Co., Ltd., established in 1955 and headquartered in Shandong, China, is a manufacturer that specializes in the manufacturing of mining machinery and equipment. The company manufactures and sells mining machinery and equipment, including coal mining machinery, hydraulic equipment, and engineering machinery. It also provides It also provides technical mining, equipment installation, and leasing services. Its products are designed to improve the safety of coal mining operations. The company has achieved ISO9001:2008 Certification for its quality management systems. Moreover, it serves the coal mining industry.

KUKA AG was founded in 1898 in Augsburg, Germany. The company is a subsidiary of GD Midea Holding Co., Ltd. and is an automation developer, designing and manufacturing robot-based automation solutions for medical, automotive, warehousing, and distribution industries. The company’s product segments include robot systems, production machines, and systems, mobility as a driver of Industry 4.0, and process technologies that provide special welding processes to factories. The company’s services include repair and servicing for robots and machines and engineering services for designing and programming robotic systems.

Panasonic Connect Co. Ltd. is based in Tokyo, Japan, and is a manufacturer and service provider specializing in B2B products that was established in 2022 as a spin-off from Panasonic Corporation. The company offers its Zetes brand supply chain manager that utilizes RFID and facial recognition technologies, and its Autonomous Supply Chain brand planning solution which integrates an AI-based supply chain platform. It also offers installation and personnel training services for customers requiring additional assistance. The company mainly serves clients in the retail, transportation, and logistics industries.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Kawasaki Robotics |

12.1%

|

| 2 | Kobe Steel USA Inc. |

11.5%

|

| 3 | Dixon Automatic Tool, Inc. |

11.4%

|

| 4 | Arrowtek Robotic Private Limited |

11.1%

|

| 5 | NACHI-FUJIKOSHI CORP. |

11.0%

|

| 6 | KUKA AG |

10.9%

|

| 7 | SHANDONG MINING MACHINERY GROUP CO.,LTD |

10.8%

|

| 8 | Panasonic Connect Co., Ltd. |

10.7%

|

| 9 | FANUC |

10.6%

|

Derivation Method

The ranking is calculated based on the click share within the arc welding robot page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 50.0% |

Japan

Japan

|

2 | 33.3% |

India

India

|

1 | 16.7% |

47 products found

47 products

Linkwith Co., Ltd.

550+ people viewing

Last viewed: 10 hours ago

We have packaged automated equipment for sheet metal TIG welding by combining "L-ROBOT" and collaborative robots. The "L-ROBOT Sheet Metal Welding ...

Japan MDA Robo Co., Ltd.

380+ people viewing

Last viewed: 9 hours ago

The most suitable type of robot and hand can be selected depending on the workpiece mass, operating range, and transfer speed. Hard ones, square on...

7 models listed

CORETEC Inc.

390+ people viewing

Last viewed: 10 hours ago

It is a state -of -the -art automation facility that makes full use of mechatronics and accumulated know -how. In response to your FA needs, we pro...

2 models listed

Makitec Co., Ltd.

930+ people viewing

Last viewed: 10 hours ago

We offer total solutions for production factories, including the introduction of robots and pre- and post-processes. ■Features 1. Labor saving: Au...

Japan Flash Co., Ltd.

600+ people viewing

Last viewed: 10 hours ago

Automatically supplies CD stud bolts and automatically welds to the set welding position. We manufacture automatic stud welding machines with vario...

Kotobuki Environmental Equipment Co., Ltd.

670+ people viewing

Last viewed: 10 hours ago

6 sides (3 × 3) Cylinder 180 ° rotation front and back can be welded without using a positioner with a jig. To secure equipment space, the control ...

Asia Giken Co., Ltd.

750+ people viewing

Last viewed: 10 hours ago

The stud welding robot is a dedicated welding system based on our CD stud welding machine. By inputting a program according to the welding conditio...

KUKA AG

530+ people viewing

Last viewed: 10 hours ago

The KR CyberTech Nano ARC series is optimized for route applications such as carbon dioxide arc welding, adhesive and sealant application. This ind...

KUKA AG

470+ people viewing

Last viewed: 10 hours ago

The KR CyberTech Nano ARC series is optimized for route applications such as carbon dioxide arc welding, adhesive and sealant application. This ind...

KUKA AG

470+ people viewing

Last viewed: 10 hours ago

The KR CyberTech Nano ARC series is optimized for route applications such as carbon dioxide arc welding, adhesive and sealant application. This ind...

KUKA AG

360+ people viewing

Last viewed: 10 hours ago

The KR CyberTech Nano ARC series is optimized for route applications such as carbon dioxide arc welding, adhesive and sealant application. This ind...

KUKA AG

550+ people viewing

Last viewed: 10 hours ago

The KR CyberTech Nano ARC series is optimized for route applications such as carbon dioxide arc welding, adhesive and sealant application. This ind...

KUKA AG

250+ people viewing

Last viewed: 10 hours ago

The new industrial robot of the KR CyberTech ARC series offers the highest level of precision and the best performance. This series with excellent ...

Asia Giken Co., Ltd.

710+ people viewing

Last viewed: 10 hours ago

The stud welding robot is a dedicated welding system based on our CD stud welding machine. By inputting a program according to the welding conditio...

Asia Giken Co., Ltd.

550+ people viewing

Last viewed: 10 hours ago

The stud welding robot is a dedicated welding system based on our CD stud welding machine. By inputting a program according to the welding conditio...

Sanmei Co., Ltd.

470+ people viewing

Last viewed: 10 hours ago

The birth of a new cable-built-in robot that has evolved in every aspect of its performance. ■Fast Achieves industry-leading operating speed. Shor...

DOBOT JAPAN Co., Ltd.

380+ people viewing

Last viewed: 10 hours ago

The high-performance collaborative robots and professional welding software developed by Dobot help you quickly integrate the required arc or laser...

DOBOT JAPAN Co., Ltd.

550+ people viewing

Last viewed: 10 hours ago

Sanmei Co., Ltd.

480+ people viewing

Last viewed: 10 hours ago

DAIHEN's new welding process approaches the limit of low spatter, synchro-feed GMA welding robot package ■Realizes low heat input welding of ultra...

Panasonic Industry Co., Ltd.

400+ people viewing

Last viewed: 10 hours ago

■Summary This is the flagship model of welding robots. We use a variety of approaches to solve customer issues, including improved weldability, eas...

Panasonic Industry Co., Ltd.

470+ people viewing

Last viewed: 8 hours ago

WG4: Welding power source integrated type (TAWERS-TIG) / G4: Welding power source separate type ■Features ・High welding and high speed welding ach...

Panasonic Industry Co., Ltd.

390+ people viewing

Last viewed: 1 hour ago

■Super Active TAWERS (high-end model) ・Contributes to improved productivity with high-speed welding + ultra-low spatter ・Up to 99% reduction in s...

Panasonic Industry Co., Ltd.

410+ people viewing

Last viewed: 10 hours ago

■GⅢ (robot system) ・Realizes stable, high-quality welding in combination with a full digital welding power source ・Can be selected according to t...