All Categories

History

This section provides an overview for erv core as well as their applications and principles. Also, please take a look at the list of 3 erv core manufacturers and their company rankings. Here are the top-ranked erv core companies as of February, 2026: 1.CLEAN AIR NANO TECH, 2.HANNURI Co., Ltd., 3.Oji Industrial Materials Management Co.Ltd.,.

Table of Contents

Categories Related to ERV Core

ERV Core is a mechanical component that safely and efficiently bridges the temperature difference between two fluids.

ERV Core (Heat Exchange Element) is the core component in a ventilation system that regulates temperature and humidity when exchanging exhaust air and supply air to reduce fluctuations in indoor temperature and humidity and provide a comfortable indoor environment. The basic structure consists of a partition plate that allows temperature and humidity to move back and forth and a spacing plate that forms a flow path. Paper, resin, and metal are commonly used as materials.

Total heat efficiency and sensible heat efficiency are used as indicators of efficiency, and the higher the efficiency, the better the control of fluctuations in the indoor environment. The higher the efficiency, the lower the fluctuation of the indoor environment, thereby reducing the load on air conditioning equipment and contributing to cost reductions through energy conservation.

ERV Core is used in the following applications

Large ERV Core are widely used because of the need for both ventilation and air conditioning in large spaces such as manufacturing plants.

This improves energy efficiency and reduces wasteful energy consumption while improving IAQ (indoor air quality) by exhausting dust, gases, odors, etc. generated at manufacturing sites, and is widely used as a technology to support sustainable production.

Fixed Plate (cross flow or counter flow) and rotary types are mainly used to increase the efficiency of heating and cooling and to reduce energy consumption through temperature exchange with outdoor air. This provides a comfortable environment with low operating costs and contributes to reducing environmental impact.

Fixed Plate (cross flow or counter flow) and rotary types are mainly used, and are incorporated in various types of ventilation systems. These systems efficiently regulate indoor temperatures and exchange temperatures with outdoor air to reduce the load of heating and cooling, thereby realizing energy conservation.

*Including some distributors, etc.

Sort by Features

Sort by Area

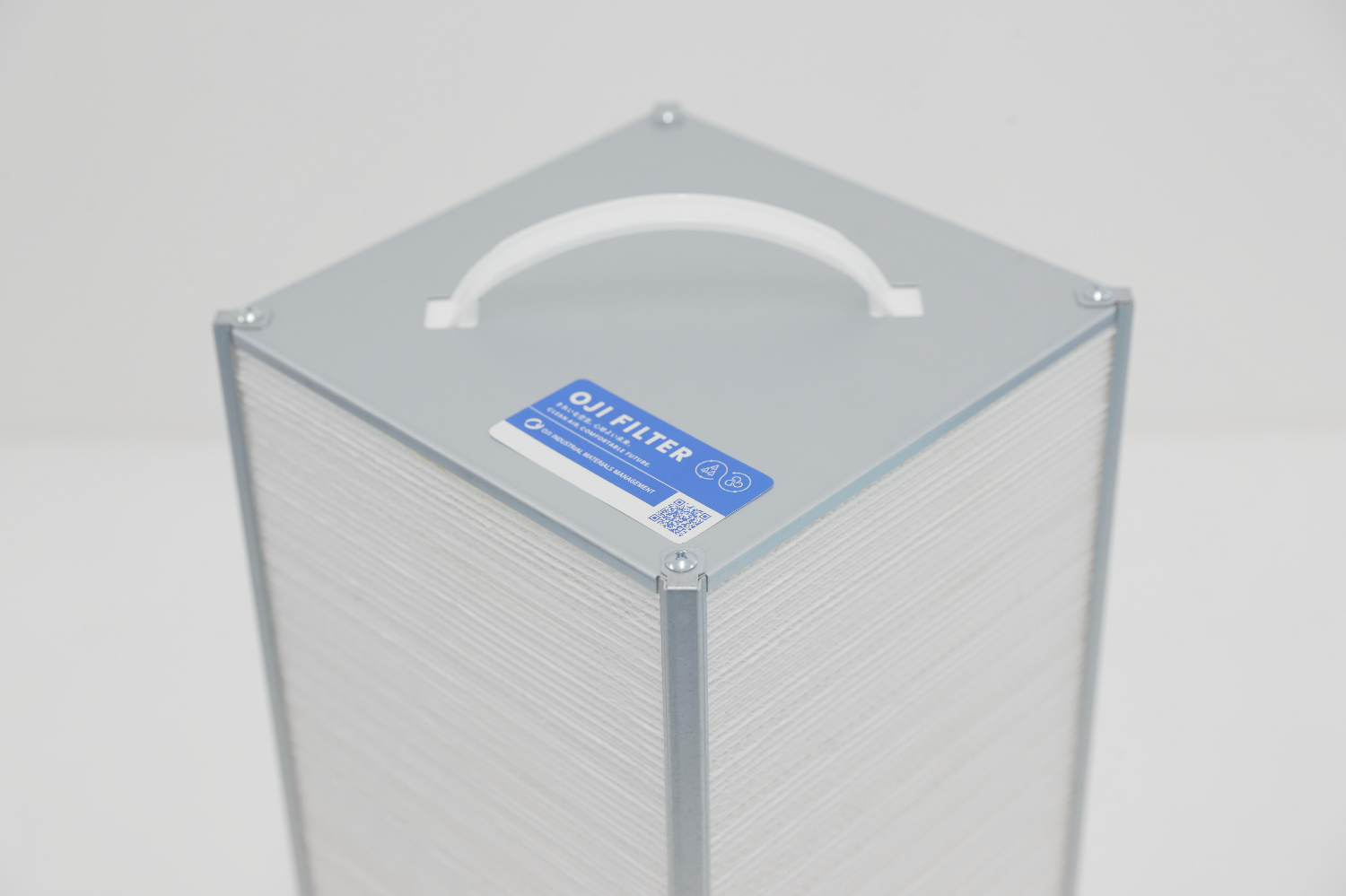

Oji Industrial Materials Management Co., ltd. filter business division is a part of Oji Holdings.Oji Holdings, founded in 1873, is the largest paper manufacturer in Japan. With its history spanning some 150 years, the Oji Group has cultivated challenging manufacturing based on insight gained from paper making and forest development. Filter technologies based on wood resources are one such example. Our mission is to conserve energy and improve air quality. To shape a livable future, we will harness nature's gifts to provide innovative products.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CLEAN AIR NANO TECH |

66.7%

|

| 2 | HANNURI Co., Ltd. |

16.7%

|

| 3 | Oji Industrial Materials Management Co.Ltd., |

16.7%

|

Derivation Method

The ranking is calculated based on the click share within the erv core page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

1 | 100.0% |

32 products found

32 products

Tada Electric Co., Ltd

980+ people viewing

Last viewed: 1 day ago

■ Our unique manufacturing method converted finchbub The heat exchanger can be compact and lighter. The aluminum tube is formed by our company's un...

SGL Carbon Technique Japan Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Summary It consists of a cubic-shaped main body in which a large number of rows of holes are perpendicularly intersecting each other in the monobl...

10 models listed

SGL Carbon Technique Japan Co., Ltd.

380+ people viewing

Last viewed: 3 hours ago

■Summary It consists of a cubic-shaped main body in which a large number of rows of holes are perpendicularly intersecting each other in the monobl...

6 models listed

Sanko Shokai Co., Ltd.

330+ people viewing

Last viewed: 18 hours ago

■Differences in technology that utilize materials produce high quality. Fluoroex® injection type With the remarkable development of Japanese indust...

Sanko Shokai Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Product overview A heat exchanger made of various fluoropolymer tubes processed into a coil shape. ■Applications ・For chemical cooling applicati...

Sanko Shokai Co., Ltd.

390+ people viewing

■Product overview A heat exchanger made of various fluoropolymer tubes processed into a coil shape. ■Applications ・Steam heating in processes tha...

Sanko Shokai Co., Ltd.

270+ people viewing

■Product overview A heat exchanger made of various fluoropolymer tubes processed into a coil shape. ■Applications For heating and cooling applicat...

Oji Industrial Materials Management Co.Ltd.,

170+ people viewing

■ Achieving both ventilation and energy savings simultaneously: Total heat exchange element The total heat exchange element is the heart of ventila...