All Categories

History

This section provides an overview for tungsten machining as well as their applications and principles. Also, please take a look at the list of 11 tungsten machining companies and their company rankings. Here are the top-ranked tungsten machining companies as of February, 2026: 1.Petersen Precision Engineering, LLC, 2.MarverMed, 3.ER Machining.

Table of Contents

Categories Related to Tungsten Machining

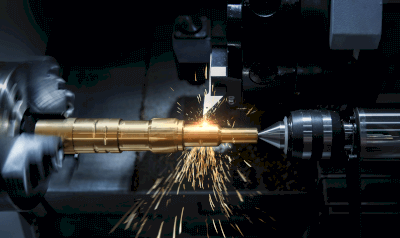

Tungsten machining refers to the processing of tungsten, a metal known for its high melting point and hardness. This metal's name is derived from the Swedish word for heavy stone. It exhibits a silver-gray color and is characterized by metallic stability and high electrical resistance. Tungsten's exceptional heat resistance makes it ideal for ultra-high temperature applications, such as in heat treatment furnaces, while its low thermal expansion and high shape stability at extreme temperatures are noteworthy.

Machining tungsten is crucial in industries requiring mechanical stability, including industrial and medical sectors. Despite the challenges posed by its hardness, tungsten's applications range from electromagnetic wave sources in microwave ovens to weights in fishing and sports equipment, and its radiation shielding properties are valuable in medical devices. Though once common in incandescent light bulb filaments, tungsten has largely been supplanted by LEDs.

Machining methods for tungsten include turning, milling, and tapping, each with specific considerations:

Surface roughness in lathe turning varies with the insert material. Cermet inserts, known for their larger rake angle and lower cutting resistance, produce finer finishes, whereas cemented carbide inserts, with their smaller rake angles, result in rougher textures due to thicker chip formation and higher resistance.

For milling, a combination of wet roughing to reduce speed and dry finishing ensures stable surface quality, as wet finishing can lead to inconsistencies.

Tapping a challenging material such as tungsten requires careful control of the feed rate to prevent tap breakage, with planetary cutters recommended after initial drilling to shorten machining time.

Selection criteria for machining tungsten involve choosing the appropriate tools and processes to mitigate its inherent processing challenges. Recommendations include using cermet inserts for smoother lathe turning surfaces, wet roughing and dry finishing in milling for optimal surface quality, and employing planetary cutters for efficient tapping.

Tungsten, symbolized as W and with an atomic number of 74, boasts the highest melting point among metals at 6,192 °F (3,422 °C) and the lowest coefficient of thermal expansion. Its density, comparable to gold, and superior radiation shielding capabilities make it preferable to lead in medical and industrial applications. Tungsten's combination with carbon forms tungsten carbide (WC), a compound with a Mohs hardness of 9, extensively used in cutting tools for its exceptional hardness.

*Including some distributors, etc.

Sort by Features

Sort by Area

Petersen Precision Engineering, LLC, established in 1966 and headquartered in Redwood City, CA, is a manufacturer specializing in small to medium-sized precision metal parts. its product portfolio encompasses precision metal components produced through processes like fine blanking, CNC machining, EDM machining, precision grinding, and lapping/honing. These parts find applications in diverse industries, including aerospace, electronics, transportation, medical, machine tools, and laboratory instrumentation. The company holds ISO9001 and AS9100 certifications, along with ISO13485 compliance, reflecting its adherance to quality and precision in the production of essential components.

MarverMed is a manufacturer of precision machined parts for numerous industries, such as the medical, aerospace, defense, and gamma radiography industries. Originally called Marver Cam, the company was founded in 1947, and later in 2007, Marver Cam changed its name to Marver Med to more accurately represent its main industry of manufacturing parts for medical instruments ranging from spine implants to cranial screws to drills, guide pins, and reamers. Aside from CNC Swiss-Screw Machine-made parts, the company also provides several engineering services such as Finite Element Analysis (FEA), rapid prototyping, and verification testing and protocols.

Elmet Technologies Inc., established in 1929 and headquartered in Lewiston, United States of America, is a manufacturer of tungsten and molybdenum refractory metal products and machining services. The company manufactures tungsten and molybdenum foil, sheets, cubes, and powders. It also produces heavy alloys, rods, wire, foil, and sheet products. These products are exemplary in refractory metals, that cover a wide array of pure metals and alloys. It serves customers globally in Europe, Japan, Korea, and Taiwan. It is ITAR registered and has production management systems certified to AS9100 and ISO 9001.

Portland Precision Manufacturing Co. is an AS9100D and ISO certified component manufacturer founded in 1967 and based in Portland, Oregon, USA. The company utilizes precision CNC machining, 5-axis machining, and turning to manufacture components made of steel, plastic, tungsten, teflon, and various other alloys and materials, additionally offering secondary value-added operations such as assembly, grinding, honing, and heat treating. The company is also a member of the Pacific Northwest Defense Coalition and primarily serves optics, electronics, medical, sport knife, and military aerospace industries.

Midwest Tungsten Service is based in Willowbrook, Illinois since 1958 as manufacturers and suppliers of fabricated tungsten products. The company produces sheets, rods, wires, bars, and related materials made of pure Tungsten, Tungsten alloy, Tungsten Copper Alloy, Pure Molybdenum and Pure Tantalum. These products have diverse uses in the Medical, Aerospace, Electrical, Automotive and Die Casting industries, to name a few. Tungsten has various uses because of its highest tensile strength, high melting point and lowest vapor pressure of all metals.

Top Seiko Co., Ltd., founded in 2001 and headquartered in Nagahama City, Japan, is a manufacturer specializing in engineering ceramics, glass, and refractory metals. The company offers custom ceramics, quartz glass, and refractory metal components widely utilized in industries such as semiconductor and electronics, measuring and analytical, aerospace, automotive, and more. It offers not only materials from Japanese manufacturers but also from those outside Japan. In 2006, it acquired ISO 9001:2000 and JISQ 9001:2000 certifications, two international standards of quality management systems.

Shenzhen DEK Manufacturing Co., Ltd. was founded in 2002 and is headquartered in Shenzhen, Guangdong, China, as a manufacturer of precision parts and prototypes. The company's range of products encompasses CNC machining services, vacuum casting, 3D printing services, sheet metal, injection moulding services, precision machining, and fabrication. These products facilitate precise part production, prototyping, and component fabrication. From design to mass production, the company caters to a range of sectors, including aerospace, medical, automotive, consumer products, agriculture, and sports, among others.

MGS Precision Limited, headquartered in Stone, Staffordshire, UK, is a precision engineering manufacturer specializing in complex high-precision machining of hard and exotic materials. The company excels in machining materials like tungsten, titanium, zirconium, Inconel, Hastalloy, Nimonics, and marine bronzes, primarily producing 5-axis complex machined components. Its products find application in diverse industries, including industrial power generation, aerospace, and motorsport. Also accredited by the Nadcap Management Council for Non-Destructive Testing, underscoring its adherence to quality and service.

M&I Materials/WOLFMET, established in 1901, is a manufacturer of advanced materials for various industries, based in the United Kingdom. The company specializes in providing solutions for demanding applications, including electrical, energy, and industrial sectors. With a legacy spanning over a century, M&I Materials/WOLFMET offers a range of products, including high-density tungsten alloys, under the WOLFMET brand. These alloys are vital for radiation shielding in medical, aerospace, and defense applications, ensuring safety and precision. M&I Materials/WOLFMET's strengths include their technical expertise, adaptability to industry needs, and collaboration with global organizations. Their investment in research and development reflects their application of cutting-edge solutions.

ER Machining, headquartered in Houston, Texas, is a manufacturer specializing in precision machined parts and components. The company offers a wide range of machining services, including CNC turning, CNC milling, Wire EDM, Sinker EDM, grinding, as well as welding, and assembly. These products find applications in diverse industries such as aerospace, automotive, medical, and oil and gas. It also provides emergency custom machining and rapid machining services on an emergency basis.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Top Seiko Co., Ltd. |

19.0%

|

| 2 | Petersen Precision Engineering, LLC |

17.9%

|

| 3 | MarverMed |

14.7%

|

| 4 | ER Machining |

12.0%

|

| 5 | Portland Precision Manufacturing Co. |

10.3%

|

| 6 | Elmet Technologies, Inc. |

6.5%

|

| 7 | MGS Precision Limited |

5.4%

|

| 8 | Shenzhen DEK Manufacturing Co., Ltd. |

4.3%

|

| 9 | M&I Materials |

4.3%

|

| 10 | Midwest Tungsten Service, Inc. |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the tungsten machining page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 50.0% |

Japan

Japan

|

2 | 20.0% |

United Kingdom

United Kingdom

|

2 | 20.0% |

China

China

|

1 | 10.0% |