All Categories

History

This section provides an overview for tapping services as well as their applications and principles. Also, please take a look at the list of 9 tapping service companies and their company rankings. Here are the top-ranked tapping service companies as of February, 2026: 1.ABT Metals Manufacturing, LLC, 2.Automated Production Assemblies, Inc., 3.LB WATER.

Table of Contents

Categories Related to Tapping Services

A tapping service is a process used to form a female thread in a part into which a screw is to be screwed.

A tapping service is a process used to form a female thread in a part into which a screw is to be screwed.

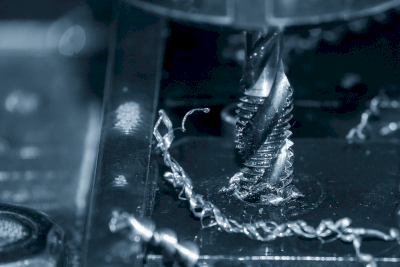

Using a tool with an uneven profile called a tap. The tap is inserted into a pre-drilled hole to form a female thread.

Tapping services are widely used for metal parts that are to be fastened with screws. Threaded fasteners are used in a wide variety of industrial machinery, buildings, and household appliances. Tapping service is required to form the female threads of the part to be threaded.

In addition to tapping services, there are several other methods of forming female threads. Tapping service is one of the most widely used methods. Tapping services are often used to form relatively small-diameter female threads in particular.

Tapping services can be performed in two major ways. One is to cut a pre-drilled hole to form a female thread, and the other is to form the thread shape by plastic forming. In either case, tapping services requires a pre-drilled hole and the diameter of the pre-drilled hole must be correctly finished.

Cutting tapping services is performed by turning with a lathe or milling with a milling machine. Cutting tapping services involves the cutting of metal, which results in the generation of chips.

The advantage is that relatively little torque is required during machining, but care must be taken to remove the chips. Especially when tapping services is performed on a non-through hole called a stop hole, it is necessary to select a spiral tap that discharges the chips to the front side.

Threading is performed while deforming the material using a thread rolling machine. Since it is plastic deformation, not cutting, no chips are generated. However, the diameter of the hole must be more precise than that of the cutting type.

Although tapping services requires more torque than cutting tapping services, it is suitable for mass production because no chips are generated and the machining time is shorter than that of cutting tapping services.

Also, since the fiber flow (metallurgical flow) is not cut, high-strength female threads can be produced. The disadvantage is that the initial cost of tapping services is higher than that of cutting tapping services because it requires the preparation of taps that matches the shape of the desired female thread.

The following types of tapping service are available. It is important to select one according to the type of the intended female screw.

This is a tap with a straight groove shape. Tapping services can be performed manually by using a hand tap. Since it takes time to process, it is used for purposes such as repairing prototypes and quit screws. Hand taps are available from No. 1 to No. 3, which are used in turn for tapping services.

The outer circumference of the tapping services is processed in a spiral shape, and during tapping services, the facets are discharged in the opposite direction. Choose a spiral tap when you do not want to eject the chips in the direction of travel, such as in a stop hole.

To ensure that the facets are ejected correctly, use a spiral tap with a right-hand thread with a right-hand thread and a left-hand thread with a left-hand thread. Since the facets are ejected in the direction of the taproot, it is easy for the facets to become entangled in the tap, and if tapping services are performed with the facets entangled, the threaded hole will widen.

Point taps have a groove called a point groove and are characterized by low cutting torque, which reduces stress caused by chips. Unlike spiral taps, chips are ejected in the direction of travel, so point taps are mainly used for through holes. However, they can also be used for tapping services for stop holes, as long as the hole is deep enough and the chips are ejected in such a way that they do not damage the threads.

Roll taps are used in rolling tapping services. It is especially applied to threaded holes in soft materials such as rolled aluminum.

Since it is a rolling process, no chips are generated, and the tapping services time is shorter than that of cutting tapping services. Also, the durability of the tool is high. Since no facets are generated, there is no waste of material, making it an environmentally friendly machining method.

*Including some distributors, etc.

Sort by Features

Sort by Area

Automated Production Assemblies, Inc. is a manufacturer production assemblies company offering production tapping, drilling, and light assembly that is headquartered in Fraser, Michigan and was established in 1973. The company offers tapping and drilling services catering to metal parts that require drilling or tapping or holes. The company has an in-house tool room and CNC waterjet cutting machine that aids in the process of production. The company also provides in-die tapping and secondary process for clients.

SendCutSend is an online manufacturing and fabrication platform for laser and waterjet cutting services that is headquartered in Reno, Nevada, and was established in 2014. The company offers a wide range of materials that can be laser cut or waterjet cut, including acrylic, metal, wood, and plastic. SendCutSend also offers multiple finishing services, such as drilling, Laser Cutting, CNC Routing, Waterjet Cutting, Anodizing, and bending. Its customers include makers, engineers, and businesses of all sizes. SendCutSend is a certified member of the Fabricators & Manufacturers Association International (FMA).

Yorkshire Profiles Ltd, founded in the United States in 1945, is a supplier of laser cutting and fabrication services to a wide range of industries. The company is ISO9001 registered and offers laser cutting services including precision cutting of various materials, such as metals, plastics, and composites, CNC machining capabilities ensure accurate and efficient manufacturing of parts and components, welding and assembly services, and stom fabrication services for diverse applications, from prototyping to large-scale production.

Rangeline Tapping is a supplier of pipeline services, established in the 1990s and based in West Palm Beach, United States of America. The company provides hot taps, wet tapping, concrete pressure pipe, and pipe-freezing services. It also offers valve maintenance, hydrant assist valve, hydrant maintenance, and mechanical services. Hot taps can be used to tie into new construction by allowing the installation of new junctions. It has a team of technicians and welders to install and repair the customers’ piping systems 24 hours a day 365 days per year.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ABT Metals Manufacturing, LLC |

39.5%

|

| 2 | Automated Production Assemblies, Inc. |

18.6%

|

| 3 | LB WATER |

14.0%

|

| 4 | GAP Engineering Pty Ltd |

9.3%

|

| 5 | Rangeline Tapping |

7.0%

|

| 6 | Yorkshire Profiles Ltd |

4.7%

|

| 7 | De Wiel Services |

2.3%

|

| 8 | Trojan Special Fasteners Limited |

2.3%

|

| 9 | SendCutSend |

2.3%

|

Derivation Method

The ranking is calculated based on the click share within the tapping service page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 42.9% |

United Kingdom

United Kingdom

|

2 | 28.6% |

Netherlands

Netherlands

|

1 | 14.3% |

Australia

Australia

|

1 | 14.3% |