All Categories

History

This section provides an overview for non-destructive testing (ndt) services as well as their applications and principles. Also, please take a look at the list of 20 non-destructive testing (ndt) service companies and their company rankings. Here are the top-ranked non-destructive testing (ndt) service companies as of February, 2026: 1.RNDT, Inc., 2.MISTRAS Group, Inc., 3.Superior Joining Technologies, Inc..

Table of Contents

Categories Related to Non-Destructive Testing (NDT) Services

Non-destructive testing (NDT) services are tests to determine the presence, size, shape, distribution, etc., of scratches on a surface or interior surface without destroying the object being tested.

Destructive testing is a testing method in which pressure, temperature, vibration, etc., are applied to an object until it is destroyed, and the permissible limit of defect generation is directly examined. NDT service is an indirect testing method and has the disadvantage of not being able to reliably determine the conditions under which defects can occur. It can detect defects without damaging the shape or function of the object. This makes it possible to test buildings, plants, railways, aircraft, etc., while they are in operation.

NDT services are used in a wide variety of fields.

Depending on the type of NDT Services, the purpose of use and the materials that can be used will vary. For example, eddy current testing can detect flaws on the surface of conductors without contact and at high speed. However, it cannot be used on non-conductive materials and can only detect internal flaws to a limited extent. Therefore, it is necessary to select the appropriate test for the intended use.

Various NDT services exist, each with different principles. The following is a description of the principles of typical NDT Services:

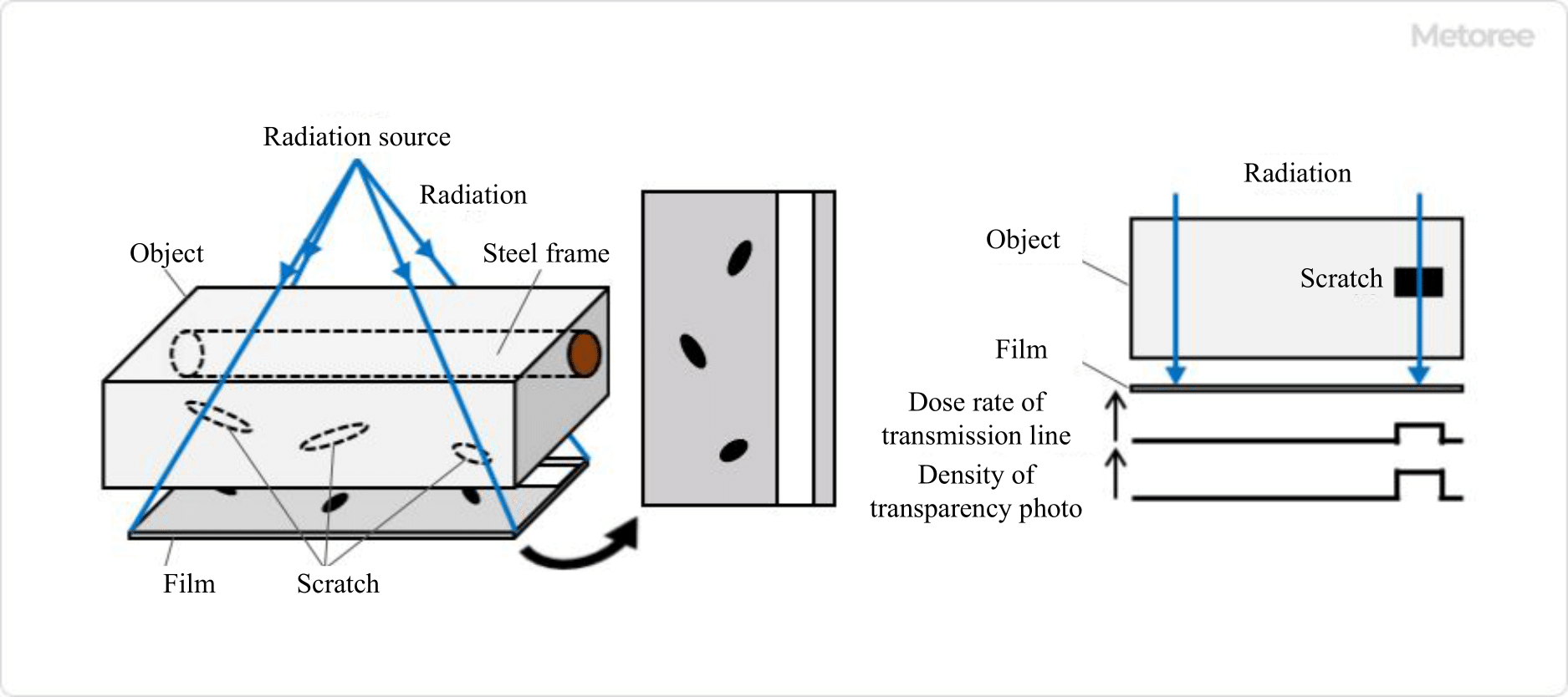

Figure 1. Principle of radiation transmission testing

In a radiation transmission test, an object is exposed to X-rays or γ-rays, and the images projected on a film or image plate are used to determine the internal state of the object.

Radiation has the property of penetrating through materials, but the ease of penetration depends on the condition of the object's interior. For example, a damaged part of an object is generally more easily penetrated by radiation than a healthy part, resulting in a darker appearance on the film. The shading of the film is caused by the reaction of the emulsion that makes up the film to radiation.

Radiation transmission tests are classified into several methods, depending on the method of photography and other factors. For example, image data is obtained by using an image plate instead of a film.

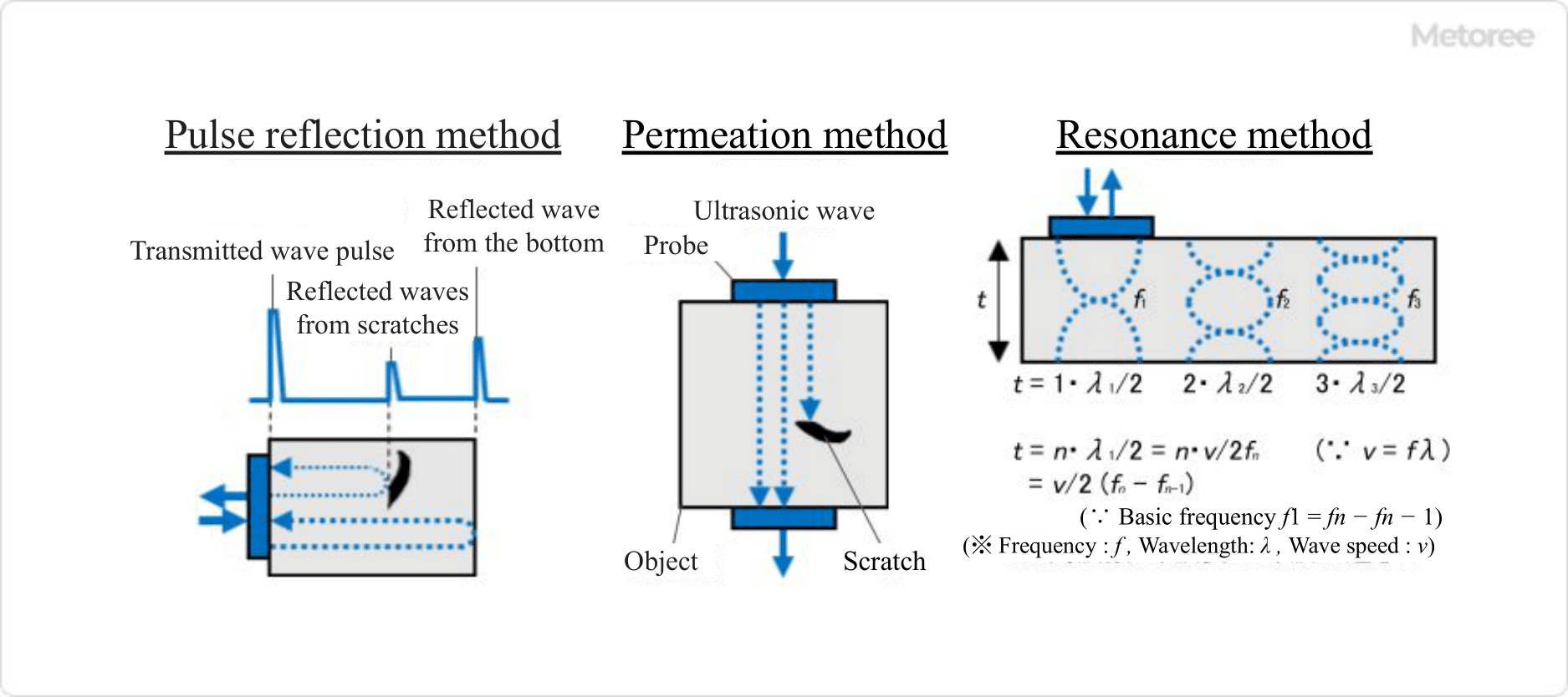

Figure 2. Principle of ultrasonic testing

Ultrasonic flaw testing is a test used to estimate the internal condition and thickness of an object by applying ultrasonic waves to the object.

Ultrasonic testing can be broadly classified into three methods: transmission, pulse reflection, and resonance. The methods are further classified according to the type of ultrasonic wave and the method of application. They are used in different ways depending on the intended use.

Transmission method

The transmission method estimates internal conditions by comparing the strength of transmitted and received ultrasonic waves.

A probe is positioned on the surface of the object to introduce ultrasonic waves, and another probe is placed at the bottom of the object to receive these waves. The ultrasonic waves, initiated by the surface probe, penetrate the interior of the object and reach the probe at the bottom. If there is a flaw within the object, the ultrasonic wave is unable to pass beyond it, resulting in a weakening of the wave. This attenuation of ultrasonic waves reveals internal defects through the formation of ultrasonic shadows.

Pulse Reflectometry

The pulse reflection method uses the reflection of ultrasonic waves to identify the presence, location, size, etc. of a flaw.

A probe capable of transmitting and receiving ultrasonic waves is placed on the surface of the object. Ultrasonic waves incident inside the object from the probe reflect off the bottom surface and return to the probe. Ultrasonic waves are also reflected if there are scratches or other defects inside the object. The internal condition of the object is estimated by receiving the transmitted pulse, the reflected wave from the scratch, etc., and the reflected wave from the bottom surface.

Resonance Method

The resonance method is a method to measure the thickness of an object by utilizing the resonance of the object.

When ultrasonic waves are injected into an object while continuously changing the wavelength, the object resonates when an integer multiple of half wavelength equals the thickness of the object. The vibration energy for resonance is supplied by the oscillator, and the occurrence of resonance can be confirmed by detecting the increase in current. The thickness of the object is estimated from the sound velocity, frequency, and resonance order at resonance. It is also possible to estimate the presence or absence of scratches inside the object from the strength of the resonance.

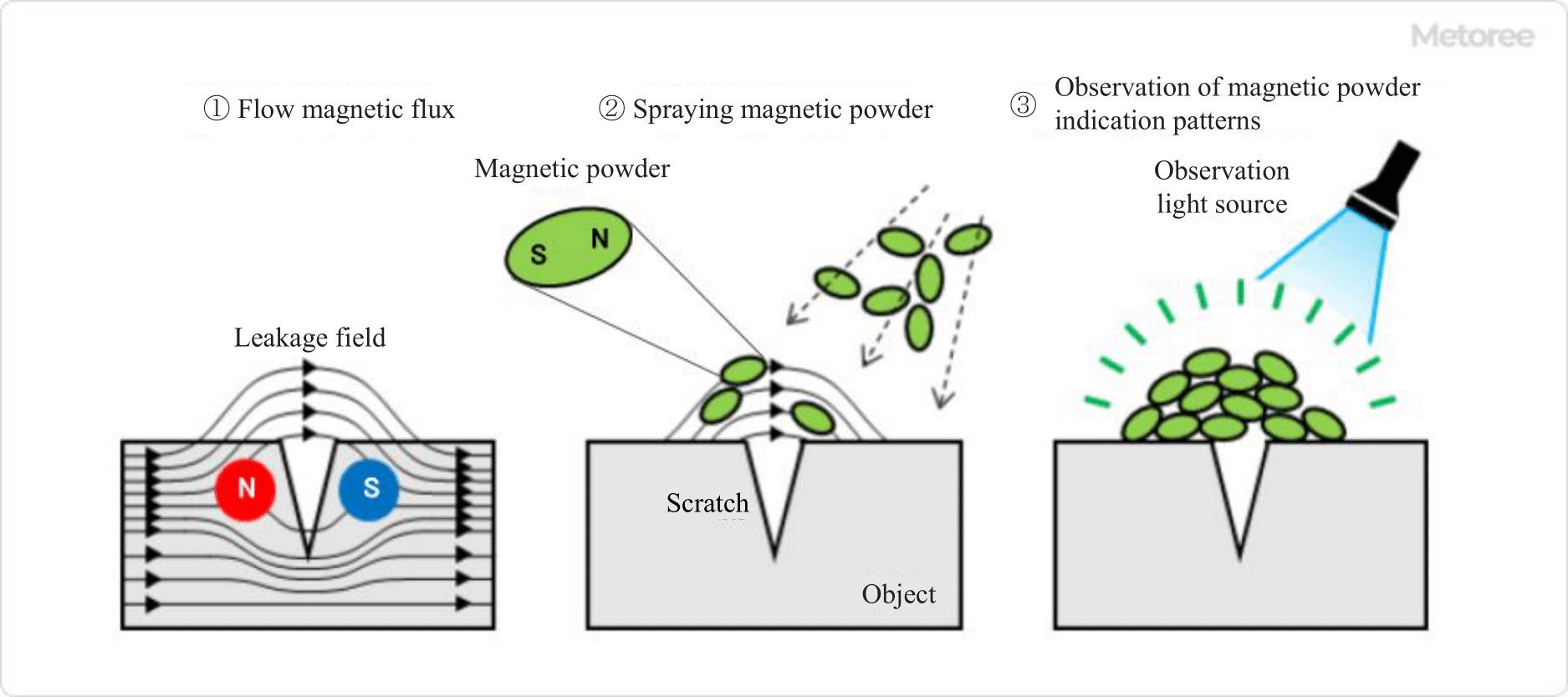

Figure 3. Principle of magnetic particle inspection testing

The magnetic particle flaw test is a test used to visually check for flaws near the surface of an object using a leaking magnetic field.

As the magnetic flux flows through the ferromagnetic object and increases, a portion of the flux leaks into the external space in the area where the flaw is located. When the magnetic powder is sprinkled in this leaking magnetic field, the magnetic powder adheres to the area around the flaw and a magnetic powder indication pattern appears. By observing this pattern, even minute scratches can be detected.

Magnetic powder testing is directional in detecting flaws and is classified as a method to magnetize the flaw detection point in the appropriate direction. It can also be classified into several methods, depending on the magnetic powder used and the light source for observation. These methods should be used appropriately depending on the shape of the object and the flaw to be detected.

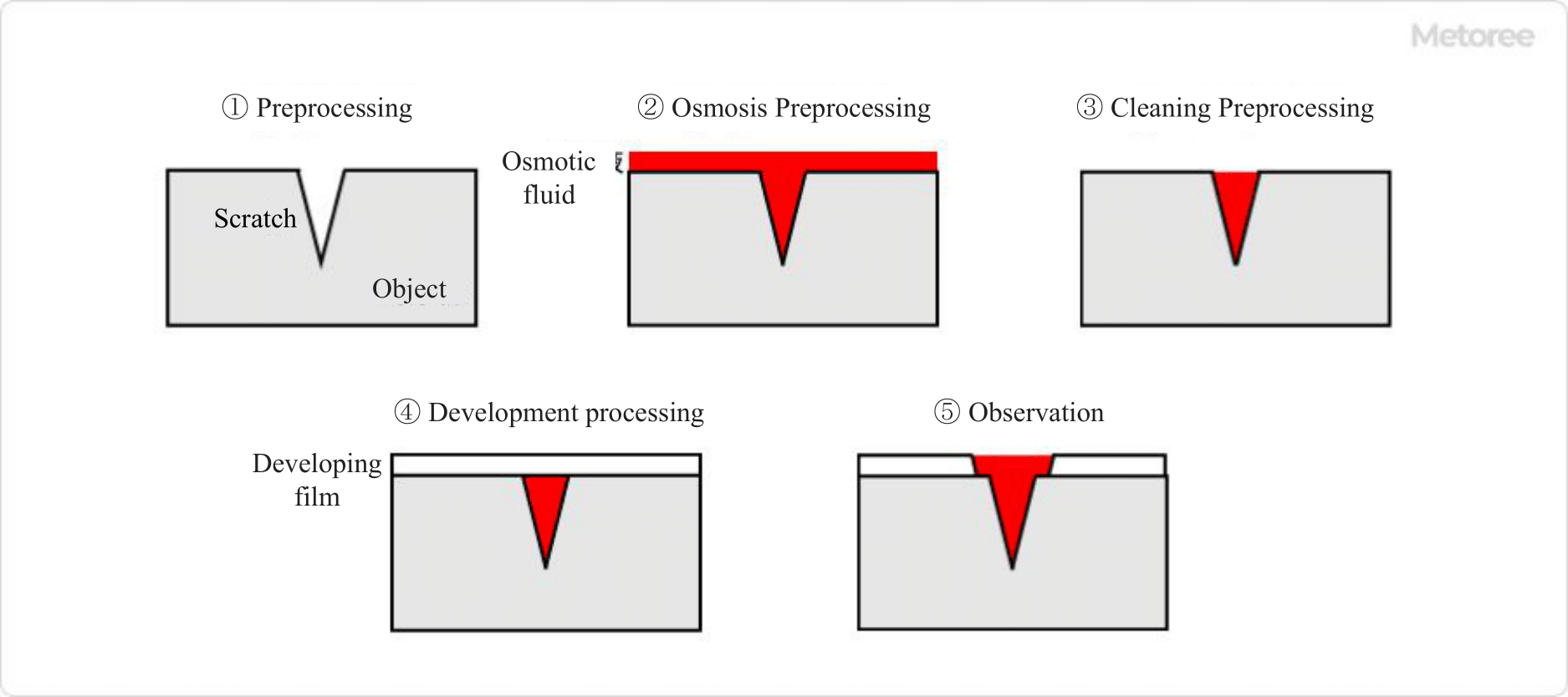

Figure 4. Principle of penetrant testing

Penetration testing is a test used to detect flaws on the surface of an object using a penetrant.

First, the surface of the object is cleaned as a pretreatment, and the inside of the flaw is opened and dried. Next, the penetrant is applied to the surface of the object, and the excess penetrant is removed. Finally, a developing film is applied to absorb the penetrant that has penetrated into the flaw, and the enlarged penetrant indication pattern is observed.

There are two types of observation methods, three types of penetration fluid removal methods, and four types of development methods in the penetration test, and the appropriate combination is selected according to the application.

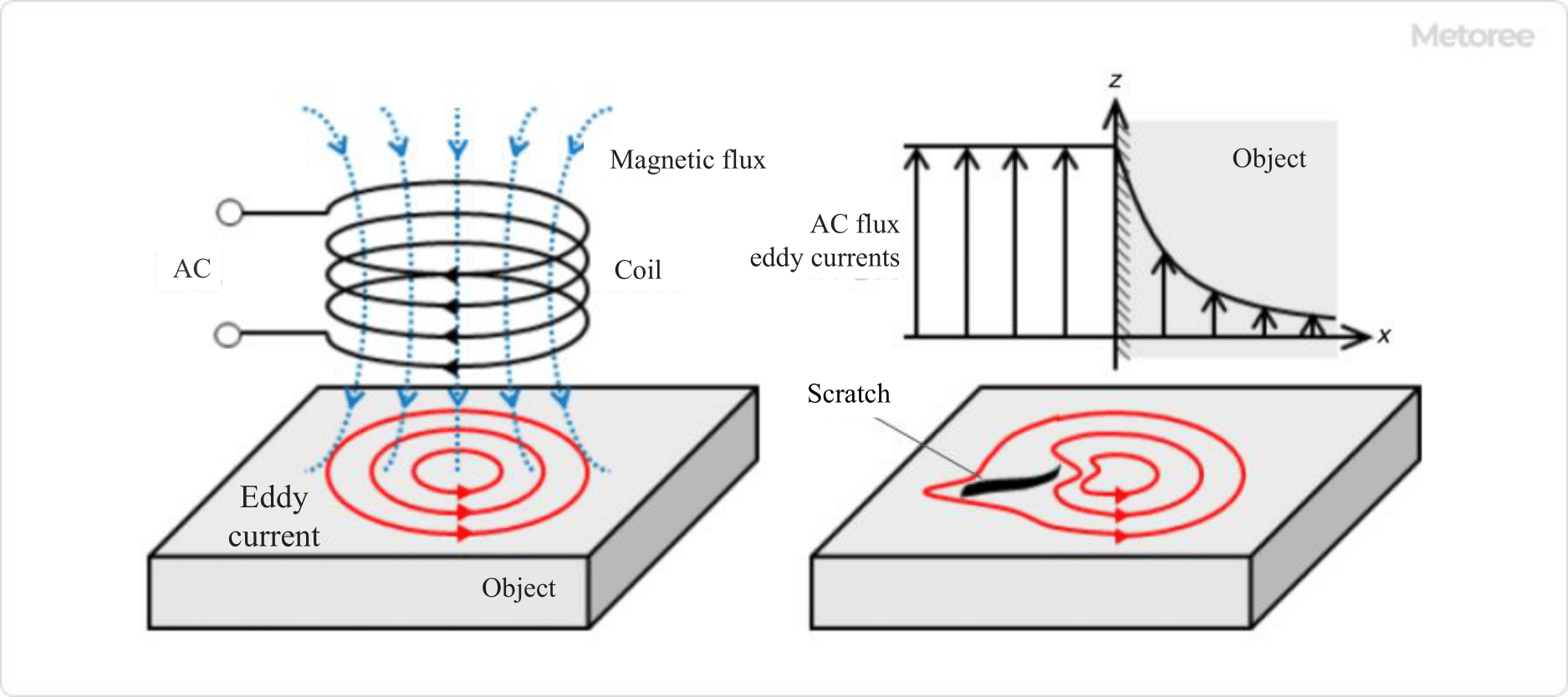

Figure 5. Principle of eddy current testing

The eddy current test induces eddy currents on the surface of a conductive object and detects the turbulence of the eddy currents to determine whether a flaw exists.

When a coil with alternating current is brought close to the object, eddy currents are generated near the surface of the object due to electromagnetic induction. If the surface of the object is scratched, the eddy currents are disturbed. The disturbance of the eddy currents causes a change in the magnetic flux inside the coil, resulting in a change in the electromotive force of the coil, and by detecting this change in electromotive force, the disturbance of the eddy currents, in other words, the presence or absence of a scratch, can be confirmed.

Since eddy currents are induced intensively only near the surface of an object and hardly ever inside the object, eddy currents are mainly used for flaw detection on the object's surface. The phenomenon in which eddy currents decay rapidly inside an object is called the skin effect. However, the depth of the flaw can sometimes be estimated by using the properties of the eddy current phase.

*Including some distributors, etc.

Sort by Features

Sort by Area

MISTRAS Group, established in 1978, is a manufacturer and global supplier headquartered in Princeton, New Jersey, specializing in non-destructive testing (NDT) equipment and asset protection solutions. The company’s product portfolio includes NDT technologies such as advanced acoustic emission (AE) and ultrasonic testing (UT) equipment. It also offers field inspections, lab testing, maintenance, monitoring, and data management services. These offerings serve diverse sectors such as academia, aerospace, defense, infrastructure, and manufacturing. The company adheres to ISO 9001:2015 quality standards with locations worldwide, serving clients across North America, Europe, Asia, and beyond.

Superior Joining Technologies, Inc. was founded in 1992 and is a manufacturer of precision welding products and services based in Machesney Park, Illinois, United States. The company offers various precision welding services such as manual welding, microscopic welding, laser welding, seam welding, and resistance spot welding. Various industries have been served by the company including aviation, medical, defense, nuclear, and maritime. The company has been certified with ITAR, Nadcap Accreditation, and Military Critical Technical Data Agreement.

RNDT, Inc. founded in Johnstown, Pennsylvania, USA, in 2001, is a supplier of nondestructive testing (NDT) services to different industries. It provides services of ultrasonic testing, liquid penetrant testing, magnetic particle testing, visual inspection, and positive material identification. The company’s NDT services are used to inspect materials for defects without damaging them. The company’s services are ISO-17025 certified. It provides radiographic testing services in its laboratory and in the field at customer locations. It serves the industries of manufacturing, construction, and energy.

Able Aerospace Services Inc. founded in Mesa, Arizona, USA, in 1982, is a distributor of aircraft replacement parts and provides services of aircraft repairing and overhauling. The company offers replacement parts including aircraft engine components, seats, adapters, bearings, and magnetic seals. It provides services of general repairing and overhauling for helicopters, fixed-wing aircraft, and rotor-wing aircraft. It serves airlines, corporate aviation departments, plane owners, and the military. The company’s services extend the life of aircraft and are necessary for the safety of passengers and crew.

Challenge Testing, Inc., founded in the United States in 1953, is a service supplier of field testing, geotechnical examinations, and non-destructive testing. The company offers comprehensive sampling services including geotechnical soil borings, marine sediment sampling, hydrographic engineering surveys, and well monitoring. The company has worked with the Jacksonville office of the US Army Corps of Engineers in sediment sampling projects covering the state of Florida from the Keys through the Everglades to waterways through the Panhandle.

American Testing Services, founded in the United States in 2002, is a supplier of metallurgical testing, calibration, and industrial rope access services. The company offers non-destructive testing (NDT) refers to a wide group of inspection methods used to analyze the soundness of a material, component, or structure without physically or chemically altering it and metallurgical testing that helps to predict the future, and prevent failure and strengthen results. It serves industries including aerospace, amusement parks, commercial manufacturing, and construction.

PROTECT, founded in the United States in 2020, is a supplier of safety, reliability, and compliance services. The company offers services including advanced and conventional non-destructive testing, engineering support, environmental compliance, general safety, industrial hygiene (leak detection and repair), and pipeline integrity. The company's consultants and technicians provide a variety of services to keep employees that service in the industries including aerospace, power generation, food and beverage, and industrial manufacturing.

Applus+ was founded in 1996 and is a manufacturer of inspections equipments and services for automotive industries based in Madrid, Spain. The company offers various services related to the automotive inspection such as off lease inspections, statutory vehicle inspections, vehicle emission inspection, road safety education, and public service vehicle inspections. The Energy and Industry Division also offers 3D laser scanning, materials testing, geo-hazard assessment, and asset integrity management. The company has certification of inspection procedures such as ENAC, CBTL/IECEE, ISO/IEC 17025, and IEC 17020.

NOV Inc. is an ISO 9001-certified manufacturer specializing in equipment used in the oil and gas industry. It was founded as Oilwell Supply in 1862 before merging with National Supply in 1987. The company produces equipment, consumables, and digital products used in oil drilling operations. These include drilling rigs, coiled tubing units for well intervention, and data analysis software or hardware. The company also provides customers with oilfield services such as equipment inspection, maintenance, and repair. Some of its notable clients include Halliburton, ExxonMobil, and Transocean.

FORCE Technology, in Brøndby, Denmark, in 2005 is a technology consultancy and service company that help companies with their technological transformation. The company provides services such as electronic product compliance and testing to ensure the reliability of the product and compliance with regulations, Calibration of meters and measuring instruments, integrity management, Hydrodynamic test for vessels and Aerodynamic services related to the operation of aircraft and planning of related facilities. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and IT.

Axess Group, founded in Norway, is a sustainable solution supplier for the oil and gas, wind energy, marine, and infrastructure industries worldwide. The company offers services inspection services for elevators, lifting appliances, drilling equipment, dropped object management, and static pressurized equipment. The company has 5 other offices in Norway in Oslo, Bergen, Trondheim, Orkanger, and Stavanger and it operates globally in Rio de Janeiro, Houston, Singapore, Cape Town, and Luanda.

Element is a global supplier of materials testing and certification services headquartered in the US since 1827. They offer testing and inspection solutions worldwide, including tensile testing machines, impact testers, hardness testers, SEM, XRF analyzers, and environmental chambers, used to evaluate materials like metals, polymers, and composites in various sectors. including academic institutions, research labs, and industries. With a rich history spanning over a century, Element excels in precision instruments for scientific and engineering applications.

Intertek, established in 1885 and headquartered in London, England, is a provider and supplier of quality assurance services. The company offers several services, including testing, inspection, and certification services. Its services adhere to nationally recognized standards and cater to a wide array of electric, gas, and oil-fueled products. The range of these products spans from commercial and consumer appliances to HVACR equipment and manufactured wood products. It formally ensures that all products and services of a company meet the external and internal standards.

thyssenkrupp Supply Chain Services, founded in the United States in 1966, is a supplier of supply chain solutions for industries including automotive, renewable energy, industrial manufacturing, and electric vehicles. The company offers a full line of services including warehousing, transportation, quality inspection, and consulting. It uses GPS technology that gives visibility to drivers and products anytime and anywhere. The company also specializes in solar logistics for solar projects and renewable energy.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | RNDT, Inc. |

18.5%

|

| 2 | MISTRAS Group, Inc. |

10.6%

|

| 3 | Superior Joining Technologies, Inc. |

8.4%

|

| 4 | PURE PRIME SOLUTIONS |

7.6%

|

| 5 | Challenge Testing, Inc. |

6.5%

|

| 6 | American Testing Services |

6.4%

|

| 7 | Able Aerospace Services Inc. |

5.6%

|

| 8 | PROTECT |

5.2%

|

| 9 | Applus+ |

5.0%

|

| 10 | NOV Inc. |

4.5%

|

Derivation Method

The ranking is calculated based on the click share within the non-destructive testing (ndt) service page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

8 | 50.0% |

United Kingdom

United Kingdom

|

3 | 18.8% |

Spain

Spain

|

1 | 6.3% |

Japan

Japan

|

1 | 6.3% |

Denmark

Denmark

|

1 | 6.3% |

Germany

Germany

|

1 | 6.3% |

Norway

Norway

|

1 | 6.3% |