All Categories

History

This section provides an overview for abrasion testing services as well as their applications and principles. Also, please take a look at the list of 11 abrasion testing service companies and their company rankings. Here are the top-ranked abrasion testing service companies as of February, 2026: 1.GT Certification Ltd, 2.KMLPL, 3.Touchstone Research Laboratory.

Table of Contents

Categories Related to Abrasion Testing Services

An abrasion testing service is a test to evaluate whether burning occurs, how wear progresses, the amount of wear, etc. Using test specimens in order to understand the wear phenomenon that occurs in various industrial products.

In the friction test, a test specimen, such as a pin or ball is continuously moved under a constant load and at a constant speed. The frictional force generated and the amount of friction after a specified period are then evaluated. In industrial products, there are many areas where parts rub against each other. If seizure occurs in such parts, the parts stick to each other and the amount of wear increases, preventing the parts from functioning properly, so countermeasures are necessary.

In addition, the amount of wear varies depending on the conditions, even when the same parts are used in combination with each other. Therefore, abrasion testing services that can reproduce the conditions under which various types of friction occur are conducted to measure the frictional force and the amount of friction.

Friction testing is used in the development process of various industrial products. The durability of a product is mainly related to how long it can be used in areas where metal parts come into contact with each other and rub against each other. Friction testing is an important evaluation method to confirm the ability of a product to maintain its required functionality over the targeted period of use.

Friction testing is also used to investigate the causes of defects in the marketplace. Wear phenomena are very complex and must take into account the effects of temperature, load, load variation, and even the presence of lubricants, even when the materials are the same.

When unexpected wear occurs in the market, abrasion testing services may be performed under various conditions to investigate the factors that accelerate wear.

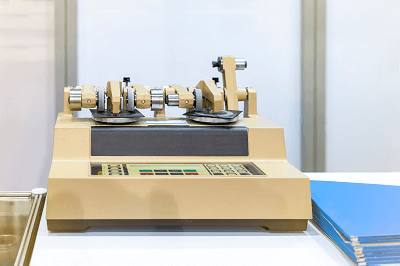

In most abrasion testing services, two specimens are brought into contact with each other while a load is applied and is subjected to relative motion to check for seizure or to measure the amount of wear over time. Industrial standards are determined by the shape of the test specimen and other factors depending on the test method.

As mentioned above, wear phenomena are complex, so the effects of temperature, humidity, the presence or absence of lubricant, the type of lubricant, and the amount of lubrication must also be considered. It is necessary to consider test conditions other than the test specimen so that the product can be evaluated in the environment required for the product.

Abrasion testing services are specified in JIS and other industrial standards. There are five typical test methods as follows:

A pin (hole) is pressed against a fixed disk-shaped specimen, which is then subjected to a rotating or horizontal reciprocating motion to measure the coefficient of friction and the amount of abrasion testing services. In the ball-on-disk method, the test starts with point contact, so it is easy to get good contact between the specimens. The contact area increases as the ball abrasion testing services, and the surface pressure of the contact surface decreases even if the load during the test is the same.

A hollow cylindrical specimen is pressed against a flat plate specimen and rotated to measure the amount of wear. Unlike in the ball-on-disk method described above, the surface pressure does not change with the progress of the test.

A block-shaped test piece is pressed against the side of a hollow cylindrical test piece and rotated to measure the amount of friction and coefficient of kinetic friction. At the start of the test, the specimens are in linear contact with each other, but as abrasion testing services progress, the contact area increases and the contact surface pressure decreases.

Four spheres of the same size are piled up in a pyramid shape, and the top sphere is rotated while being pressed against the rotating sphere to measure the wear scar diameter. This method is mainly used to evaluate seizure characteristics under lubrication conditions. The Sone-type test uses a 3/4-inch steel ball, while the Shell-type uses a 1/2-inch steel ball.

A rod-shaped specimen is sandwiched between blocks on both sides and the rod is rotated to measure the abrasion testing services. It is mainly used to evaluate seizure characteristics under lubrication conditions.

*Including some distributors, etc.

Sort by Features

Sort by Area

American Roller Company, LLC, established in 1938, is an American manufacturer based in Union Grove, Wisconsin, specializing in industrial rollers and plasma coatings. The company's product offerings include heat transfer and chill rollers, idler rollers, roller coverings, as well as specialty rollers. The company also provides services including roller repair and testing, cladding and welding, design and core fabrication, as well as industrial coatings. The company serves various industries, including battery and power storage, food and beverages, packaging, and transport rolls. Other industries served include glass, medical products, plastic films and sheets, printing, pulp and paper, as well as steel and aluminum.

Bud Labs, Inc., established in 1998 and based in Rochester, New York, is a service supplier specializing in tribology services. The company offers a comprehensive range of services, including friction testing to assess resistance to motion, wear testing to evaluate material loss due to mechanical interactions, and erosion testing to measure material removal from solid surfaces caused by particle impact. With an extensive test lab and a complete machine shop, the company possesses tribotesting equipment that includes the Pin-on-disk continuous sliding tester, Falex block-on-ring tester, and Falex multi-specimen tester, among others.

T,C & A LAB, founded in New York, USA, is a supplier of custom testing, characterization, and analysis of a variety of materials. The company provides services including troubleshooting, R&D screening, raw materials retesting, and diagnosis for industries such as packaging, medicine, food and beverage, biomedical, and automotive. the company also offers corrosion testing that detects the chemical or physical (or mechanical)-chemical damage process caused by the interaction of metals or other materials with the environment.

Touchstone Research Laboratory, founded in the United States in 1983, is a supplier of failure analysis and testing services for various sectors. The company provides failure investigation for crevice corrosion, stress corrosion cracking, intergranular corrosion, marine corrosion, and liquid metal embrittlement. It serves industries such as aerospace, automotive, construction, oil and gas, and nuclear power plants. The company also has an R&D center spoliates on aliminum research and coal product development.

YASUDA SEIKI SEISAKUSHO, LTD., founded in 1955 with headquarters in Japan, is a manufacturer of material testing machines. The company's wide range of products includes rubber testing machines, electrical and magnetic wire testing machines, leather testing machines, and dye testing machines. YASUDA SEIKI SEISAKUSHO, LTD.'s testing machines are used to evaluate and quantify the physical properties of materials and can be found in research, industrial, commercial, and governmental organizations. The company offers customer support, including repairs and troubleshooting services.

Ueshima Seisakusho Co., Ltd., established in 1977 and headquartered in Osaka, Japan, is a manufacturer that provides rubber testing equipment. The company offers a wide range of products, including blow point Analyzers, Rubber Process Analyzers, and Rubber Rheometers. It also provides services related to rubber testing equipment. Its product measures the viscoelastic properties of rubber and other elastomers. The company has been certified for ISO 9001 quality management and ISO/IEC 17025:2005. It provides testing equipment to industrial sectors such as rubber, plastics, and paints.

GT Certification Ltd, founded in the UK, is a supplier of measurement services specializing in construction materials testing and torque and force calibration services and holds current UKAS accreditation in both fields. The company offers concrete sampling and testing services to many of the UK’s major construction and industrial flooring companies and also offers a range of more specialized services, ranging from abrasion resistance testing, slip and skid resistance testing, to adhesion testing.

KMLPL, founded in India in 2010, is a supplier of NABL and ISO-certified material testing, reverse engineering and services, and abrasion testing services. The company has ISO 17025:2017 and NABL accredited testing laboratories that offer chemical, mechanical, analytical, electrical, and environmental safety analyses. The company provides services to industries such as automobiles, metals, polymers, toys, and electrical. the company also offers services including metal testing, polymer testing, water testing, and hardness testing.

Element is a global supplier of materials testing and certification services headquartered in the US since 1827. They offer testing and inspection solutions worldwide, including tensile testing machines, impact testers, hardness testers, SEM, XRF analyzers, and environmental chambers, used to evaluate materials like metals, polymers, and composites in various sectors. including academic institutions, research labs, and industries. With a rich history spanning over a century, Element excels in precision instruments for scientific and engineering applications.

Aston Services, founded in the UK in 1982, is a supplier of consulting, research, development, and materials testing services to the civil engineering and construction industries. The company offers testing and inspection services ranging from microscopic analysis of samples for asr, carbonation, hac, chloride, sulfate attack, and reinforcement corrosion. In addition, it specialises in developing procedures for assessing the performance and durability of materials and also provides services to clients outside the UK.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | GT Certification Ltd |

22.2%

|

| 2 | KMLPL |

22.2%

|

| 3 | Touchstone Research Laboratory |

22.2%

|

| 4 | T,C & A LAB |

11.1%

|

| 5 | Aston Services |

11.1%

|

| 6 | Metallurgical Engineering Services, Inc. |

11.1%

|

Derivation Method

The ranking is calculated based on the click share within the abrasion testing service page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 45.5% |

United Kingdom

United Kingdom

|

3 | 27.3% |

Japan

Japan

|

2 | 18.2% |

India

India

|

1 | 9.1% |