All Categories

History

This section provides an overview for autoclaves as well as their applications and principles. Also, please take a look at the list of 57 autoclave manufacturers and their company rankings. Here are the top-ranked autoclave companies as of July, 2025: 1.Didon, 2.JBT., 3.Beta Star Life Science Equipment.

Table of Contents

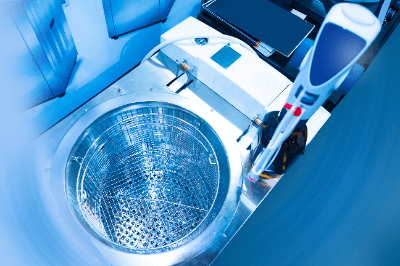

An autoclave is a device that pressurizes and heats an object by blowing saturated steam into it.

An autoclave is primarily used as a sterilization process in molecular biology experiments because the high temperature and pressure of the steam can denature and effectively kill bacterial and microbial proteins. Handling autoclaves requires great care due to the use of steam at high temperatures and pressures.

As saturated steam is blown into the container, if the autoclave is used for industrial purposes on a large scale, it is subject to safety laws, and it is illegal to fail to report the use of the autoclave. The specific requirements are "a container" used at a gauge pressure of 0.1 MPa or higher with a content of 0.04m3 or more, or an autoclave with an inner diameter of 200mm or more for the body and a length of 1,000mm or more.

When using an autoclave that falls under this category, pre-use and annual inspections must be conducted.

Autoclaves are mainly used as sterilization equipment in molecular biology experiments. In molecular biology experiments, flasks and petri dishes used to culture Escherichia coli and other bacteria, as well as tools used to handle bacteria, must be sterilized before reuse to prevent contamination by bacteria from previous use. For this sterilization process, autoclaves capable of heating to high temperatures are used.

In addition, genetic engineering experiments involve the use of genetically modified bacteria and cells that do not exist in the world. To prevent these from leaking outside the laboratory, not only reusable tools but also unwanted bacteria, and cell culture media. They are also used for solid media and must not be disposed of directly in trash bins or water sinks. Autoclaves are also used before the disposal of these bacteria.

In addition, the high temperature and pressure conditions of autoclaves can be used for special chemical reaction processes (Kolbe-Schmidt reaction, metal-catalyzed hydrogenation) and for molding plastics.

The structure of autoclaves is similar to that of a pressure cooker. As with a pressure cooker, care must be taken in handling the amount of water to be put inside, opening and closing the lid, pressure relief valve, and so on. When water reaches 100°C or higher, it boils and vaporizes if the pressure is the same as atmospheric pressure.

However, if water is further heated to 100°C in an airtight container, the water hardly vaporizes and the temperature rises above 100°C. The internal pressure of the airtight container gradually rises above atmospheric pressure. A pressure cooker is a cookware that intentionally creates this condition to shorten cooking time. By placing moist food in a sealed container and placing it over heat, the water content rises to over 100°C and the food is cooked with more energy than boiling water.

Autoclaves also put moist intermediate products into a sealed container. In the case of autoclaves, the container will start on fire, but rather the internal pressure is increased by blowing in saturated steam. After the treatment process is completed, the pressure relief valve is opened to lower the internal pressure to about atmospheric pressure, and the treated product is removed. Since the energy that can be contained varies depending on the pressure of the saturated steam, the steam pressure is reduced according to the treatment process.

For contents to be autoclavable, use glass containers, glass flasks, glass Petri dishes, metal containers, and other items with excellent heat resistance. If plastic, rubber, fabric, or other items with low heat resistance temperatures are used, there is a risk that they will melt. Be sure to check the heat resistance temperature of the contents beforehand. Containers made of plastic or other materials must be sterilized by a method other than autoclaves.

When sterilizing glass flasks or glass Petri dishes used for culturing bacteria, etc., the autoclaves should be heated to 135-145°C for 3-5 hours, 160-170°C for 2-4 hours, 170-180°C for 1 hour, and 180-200°C for 30 minutes. Since water in autoclaves is subjected to high temperature and pressure during use, the amount of water and the strength of the lid closure must be thoroughly checked before operation to avoid accidents.

*Including some distributors, etc.

Sort by Features

Sort by Area

Benchmark Scientific, founded in the US in 2004, is a manufacturer and supplier of laboratory equipment used for life scientific research. It provides research laboratories with cost-effective products to enhance efficiency, safety, and results. Company’s product line includes a range of buffet laboratory equipment, such as orbital/rocking, incubated shakers, hotplates-stirrers/magnetic stirrers/overhead stirrers, and more. It also offers incubators, scales/balances, thermal cyclers, cell counters, and other instruments. With an emphasis on technology, Benchmark Scientific aims to support scientific advancements and improve laboratory practices.

JBT Corporation, established in 1894 and headquartered in Chicago, Illinois, is a manufacturer and designer of automated systems. Its diverse product portfolio includes airport ground support equipment, cargo handling systems, automated guided vehicles (AGVs), labeling machinery, evaporators, as well as brine-making equipment, and food processing machines. The company also offers comprehensive engineering, maintenance, and repair services, catering to industries such as automotive, food and beverage, healthcare, and paper. Its products are utilized for automating processes, increasing efficiency, ensuring product quality, and reducing manual labor.

Beta Star Life Science Equipment, founded in 1982, is a supplier of cutting-edge sterilization equipment and contamination control solutions, located in the United States. The company specializes in designing and manufacturing autoclaves, sterilizers, and bio-decontamination systems. As a credible manufacturer, it serves a diverse clientele, including pharmaceutical companies, research laboratories, and healthcare facilities worldwide. Its state-of-the-art products adhere to strict quality standards and ensure the safety and efficacy of sterilization processes. With a rich history of constant improvements, it has established itself as a key player in the life sciences industry.

Labstac LLC, founded in 2012, is a manufacturer and supplier of laboratory, scientific, and medical equipment headquartered in Pittsfield, MA, USA. The company operates in over 34 countries with an extensive distributor network covering American, European, the Gulf, and South Asian regions. The company's product lineup includes biosafety cabinets, centrifuges, incubators, autoclaves, and various other medical laboratory supplies. With an annual turnover of $50K USD, the company specializes in both buying and selling as a Limited Liability Partnership. The company's products are used in the pharmaceutical and medical industries as well as in biotechnology, hospitals, and research centers.

Heller Industries, Inc., established in 1960 and based in Florham Park, New Jersey, USA, is a manufacturer and supplier of thermal process solutions. The company's product range includes convection reflow ovens, vacuum/voidless reflow ovens, formic/fluxless reflow ovens, pressure curing ovens, and vertical curing ovens. These products are used for convection reflow soldering, void-free soldering, fluxless soldering, and curing applications. It serves industries such as consumer electronics assembly, semiconductor advanced packaging, SMT surface mount technology, and power electronics. The company offers advanced manufacturing, custom solutions development, in-house values training, and global technical support.

Didion, established in 1977 in Bellevue, Ohio, USA, specializes in the manufacture and supply of industrial equipment for various applications such as welding, code welding, millwright work, and mechanical engineering. The company’s product portfolio includes pressure vessels, autoclaves, separators, heat exchangers, cryogenic vessels, and more. The separators are used for separating mixtures in the oil, food, and wastewater treatment industries. The company also specializes in the maintenance of sterilization equipment for healthcare and laboratory application. It offers radiographic testing, pressure vessel designs, PMI testing, and heat treatment services to customers.

Leadsonics is a company located in Austin, Texas, specializing as a distributor of autoclaves, sterilizers, and ultrasonic cleaning products. Its product line includes readers, covers, baskets, glass beakers, and holders, as well as a range of ultrasonic cleaners suitable for various needs, spanning from portable solutions to industrial-grade equipment. The extensive selection of ultrasonic cleaners are designed to accommodate diverse budgets and requirements, providing options for homes, offices, and businesses alike.

Ceramic Instruments, established in 1977 and headquartered in Fiorano Modenese, Italy, is a manufacturer and supplier of laboratory instruments. The company's products include laboratory planetary rapid mills, laboratory knives, and hard porcelain jars. These products are used in laboratory environments for the crushing, grinding, and mixing of powders. It also provides equipment for screening and refining, devices for weighing powders, and portable equipment. Its services include standardized testing for ceramic tiles and bricks. It serves industries that include pharmaceuticals, chemical processing, and food processing.

Last Technology, founded in 2013 and headquartered in Prata di Pordenone, Italy, is a manufacturer of custom-made washing, disinfection, and sterilization equipment. The company also produces decontamination and depyrogenation equipment and has lab and pharma divisions. The lab division provides life science R&D and microbiology industries with decontamination, washing, and disinfection equipment. The pharma division serves the pharmaceutical industry by offering products like ethylene oxide sterilizers, saturated steam autoclaves, and clean steam generators. The company is ISO 9001 and ISO 45001 certified and has a network in 50 countries worldwide.

Panasonic Healthcare was founded in 1969 in Tokyo, Japan as a manufacturer of healthcare devices and services and operates under PHC Holding Corporation. With a strong hold on Diabetes Management, Diagnostics, Life Sciences, and Healthcare Solutions, Panasonic Healthcare is here to adress global needs in energy, food, housing, health, and information technology. Panasonic Healthcare has a capital of 47.0 billion yen and employs approximately 9,374 individuals worldwide as of March 2022. The company's shareholders include KKR (Kohlberg Kravis Roberts & Co. L.P.), Mitsui & Co., Ltd., Life Science Institute, Inc., Panasonic, and L Catterton.

JISICO CO., LTD., established in 1967 in Seoul, Korea, is a manufacturer of chemical and physical apparatus instruments for research agencies, hospitals, universities, and industrial research institutes. Its product catalog includes constant temperature and humidity chambers, water purification tools, analytical and measuring apps, and electric mule furnaces. It also offers accessories such as vacuum pumps, glove boxes, heating apparatus, and water baths. The company obtained the BS EN ISO 9001:2000/KS A 9001:2001 and ISO 14001:2004/ KS Q 14001:2004 certifications.

HIRAYAMA Manufacturing Corporation, incorporated in 1943 with headquarters in Saitama, Japan, is a manufacturer of sterilizers, medical and laboratory devices, and environmental testing equipment. The company's product line includes autoclaves (high-pressure steam sterilizers), retort cookers, incubators, and testing chambers. These products are used for cooking foods sealed in plastic or aluminum seal bags, in electronics components and semiconductor testing, and can be customized to suit industry applications to create equipment such as pressure defoaming chambers and plywood testing chambers. The company serves markets that include agriculture, pharmaceuticals, consumer product manufacturing, and food processing.

Matest is an Italy-based company founded in 1986 and a manufacturer of testing equipment for the construction sector. The ISO 9001 company provides various products such as asphalt analyzers, aggregate rocks, bitumen, steel, and general equipment. It also provides testing equipment and machines for concrete. Also, it deals with electromechanical and hydraulic devices for testing steel as well. The products ensure safety in the construction process. The company also provides training and technical support services.

Heidolph Instruments GmbH & Co. KG is an ISO 9001:2015 certified manufacturer of premium laboratory equipment founded in 1938 and headquartered in Schwabach, Germany. The company mainly produces rotary evaporators, shakers, overhead stirrers, peristaltic pumps, and magnetic hotplate stirrers. It also offers laboratory line autoclaves and smart cell cultivation systems. The company provides product demonstration, configurator tools, calibration certificates, on-site repairs, and on-site installation to its clients. It supplies products to over 80 countries worldwide, serving multiple industries, including pharmaceutical research, the cosmetics sector, chemicals, and food and beverage.

Amar Equipment Pvt. Ltd., established in 1974 and headquartered in Mumbai, India, is a manufacturer of high-pressure reactors (autoclaves). Apart from the company's main product, pressure reactors, the company's product line includes flow reactors, agitated Nutsche filters and dryers, and heating and cooling circulators. It also produces a range of accessories that includes back pressure regulators, auto-cooling systems, and forward pressure regulators. These products are used in paint production, fabric dying, as well as wastewater treatment. The company welcomes inquiries for custom-built pilot skids and application-specific autoclaves.

De Lama S.P.A. is an Italian ISO 9001 certified manufacturer of sterilizers established in 1949 and based in San Martino Siccomario, Pavia. The company produces various sterilizers, passboxes, and washers for decontamination purposes. These include laboratory glassware and components washers, air-steam mixture sterilizers, and ethylene oxide (ETO) autoclaves. It also offers superheated water sterilizers and vacuum degassing passboxes. Aside from its products, the company offers retrofitting, personnel training, and customization services for its clients in the research, cosmetics, and medical device production sectors.

Hermasa Canning Technology, S.A., started in 1972 and based in Pontevedra, Spain, is a manufacturer of automatic machinery and technological solutions for the sardine and tuna canning industry. Some of the machines it stocks include vacuum tuna cookers, defrosters, and griller systems. The company also provides a turnkey construction service, and since it began, it has registered over 70 trademarks and patents. It sells its equipment under several names, including Tunipack, Tunivac, and HCT, and is ISO 9001 and ISO 14001 certified. In 1975, the company introduced the first continuous sardine cooker that directly steamed sardine.

Magnabosco SRL, established in 1960 and headquartered in Zugliano, Italy, is a thermal treatment machine and systems manufacturer. The company's products include homogenizers, pasteurizers, and autoclaves used for composite materials, retreading tires, and laboratory research. These products are used for the manufacture of composite materials, carbon fibers, and dairy products. It also provides complete, custom turnkey lines and full, custom processing plants. The company's services include planning, installation, and maintenance programs.

Jeio Tech has been a manufacturer of laboratory, and environmental testing equipment since it was established in 1988 in South Korea. The company provides industrial equipment, environmental test chambers, laboratory equipment, medical devices, and related components inclusive of ovens, incubators, baths and circulators, heating and cooling blocks, and more that can provide variations in size, temperature range, and controller types. The apparatus and the machines have applications in the fields of biology, chemistry, medicine, pharmacology, and so on serving various sectors like semiconductors, high-tech digital electronics, health care, food and drug, and eco-friendly product manufacturing fields.

ESTS GB Ltd. is a designer and manufacturer of autoclaves and steam sterilizers ranging from 100 to 6,000 liters based in Northamptonshire, UK, and was established in 2003. The company offers autoclaves, washers, autoclave discard bins, loading equipment, and the LogiclaveRemote. It also provides HTM testing and refurbishments for autoclaves, as well as servicing and maintenance, spare parts, and commissioning to relevant standards. The company's products and services are utilized in multi-purpose laboratories, high-security containment labs, hospital sterile services, and pharmaceutical and veterinary sterilization rooms.

iLABOT, established in 2018, based in Delhi, India, is a laboratory and scientific equipment manufacturer. The company products include various laboratory equipment and scientific instruments such as autoclaves, test chambers, incubator and ovens, and laboratory water bath and shakers, among others. Their products are used in universities and academic areas, food laboratories, pharma and biotech laboratories, research centers, and other related fields. The company has a team of experienced engineers, technicians, and field staff who provide services installing, repairing, and maintaining machines anywhere in India.

Systec GmbH & Co. KG, founded in 1994, is a manufacturer of laboratory sterilizers, autoclaves, and media preparators based in Hessen, Germany. It offers vertical floor-standing autoclaves, horizontal bench-top autoclaves, and double-door autoclaves, along with media preparators, plate pourers, and tube fillers. These products comply with international production and quality requirements, including DIN EN ISO 9001 and DIN EN ISO 14001. The company also provides services for its products, including installation and start-up, qualification and validation, after-sales service, and training. It serves the needs of modern laboratories, science and research, biotechnology, pharmacy, and production.

ZIRBUS technology GmbH is a global manufacturer of autoclaves, thermal plants, and freeze dryers established in 1984 and is headquartered in Lower Saxony, Germany. It offers laboratory and bench autoclaves, high-pressure autoclaves, production freeze dryers, vacuum dryers, and steam generators. The company also develops and produces customized products ranging from single instruments to complete systems. The company adheres to ISO quality management systems. Likewise, it caters to the food and pharmaceutical industries and customers in research and medicine in over 30 countries globally.

Bionics Scientific Technologies, founded in New Delhi, Delhi, is a manufacturer and supplier of laboratory and scientific equipment. The company's product portfolio includes incubators, Autoclaves, Test Chambers, Measuring Meters, and Deep Freezers that are used in laborites. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

Thymol Autoclave India was established in 2011 and is a manufacturer and supplier of autoclaves headquartered in Ambala, India. The company specializes in manufacturing different types of autoclaves, including horizontal, vertical, rectangular, and portable models. Its product line offerings include B-class tabletop autoclaves, triple-walled high-pressure wing nut autoclaves, and double-walled radial locking autoclaves. These products are designed to sterilize equipment and materials for medical, dental, manufacturing, and research applications. It has obtained ISO 9001:2008, WHO GMP, and CE certifications with a high-tech infrastructural unit assisting its production process in adherence to these international standards.

ASTELL SCIENTIFIC was founded in 1884 and is a manufacturer and supplier of laboratory, pharmaceutical, and hospital autoclaves and sterilizers based in Kent, UK. The company's product line consists of laboratory equipment, including autoclaves, steam generators, and effluent decontamination systems. These products are designed to sterilize and decontaminate laboratory equipment, materials, and waste. It also offers installation, servicing, technical assistance, and training to assist customer needs. It is accredited in accordance with ISO/IEC 17025:2017 and caters to diverse industries, including healthcare, pharmaceutical, food and beverage, and research.

Ningbo Life Medical Technology Co. Ltd. is a manufacturer and exporter of medical sterilizers and autoclaves based in Zhejiang, China, and was established in 2012. It produces different types of autoclaves, such as premium, classic, compact, DASLAV, and Hummingbird autoclaves. It also offers accessories such as the RO system, handpiece washing and maintenance machine, sealer, ultrasonic cleaner, and water distiller. The company’s products find application in hospitals, dental offices, pharmaceutical, and food processing industries. It has over 30 technical patents in small CLASS B/N autoclaves, exporting to more than 50 countries globally.

TOMY DIGITAL BIOLOGY CO., LTD., founded in 1958 and headquartered in Tokyo, Japan, is a manufacturer of laboratory centrifuges and autoclaves. The company provides autoclave sterilizers and centrifuges for various industry segments, including biotechnology, biological engineering, and medical science. These products are used by customers in Japan, Asia, North America, and beyond. The company has acquired quality standard certificates including ISO9001 and CE, as well as a Manufacture License of Medical Equipment in Japan.

Inovia Technology is a manufacturer of laboratory consumables and equipment established in 2012 and located in Esenler, Istanbul, Turkey. The company primarily offers consumables, reagents, and kits for syndromic testing and genetic disease research. It also offers PCR devices for DNA or RNA testing, centrifuges for sample separation, and nucleic acid separation systems for molecular biology analysis processes. The company is ISO 9001:2008 and TSE-certified, and mainly serves the biotech industry as well as clients in laboratory research operations.

Sümer A.Ş., established in 1981 and headquartered in Ankara, Turkey, is a medical device and related technology solution developer, distributor, and manufacturer. The company offers solutions for biohazards, laboratories, and medical gases, among others. Its primary products include Adela Series steam sterilizers, medical oxygen generators, and laboratory-type vertical and horizontal autoclaves. It also offers industrial oxygen generators, nitrogen generators, and carbon towers. The company's services include complete product lifecycle asset management, including repairs and the supply of consumables.

Frigojollinox Srl is a manufacturer of stainless steel agri-food systems and products established in 1977 and based in Campobasso, Italy. The company’s product lineup includes its Casaro branded small-scale pasteurization systems for cheese production, and its BM50 branded multifunction bench which combines sterilization, vacuum concentration, and cooking functionalities. It also offers tanks and coolers in a range of dimensions and capacities for milk transportation or storage. The company’s products are commonly used in the dairy, food and beverages, and snack foods industries.

Dion Ltd. is based in Rousse, Bulgaria, and is a designer and manufacturer of pasteurization equipment established in 1997 as a subsidiary of Dion Engineering Ltd. The company specializes in pasteurization and drying products for eggs, milk, and juice. These products include egg pasteurizers for killing undesirable microorganisms, spray dryers for processing eggs or dairy, and filling machines for efficient packaging of powdered or liquid products. It also offers complete egg processing lines for production of egg melanges or powders. The company is ISO 9001-certified, and mainly serves clients in the food, beverage, and snack foods industries.

HMG has been a manufacturer of laboratory equipment since 1986 and is located in Mumbai, India. The company produces laboratory autoclaves, incubators, stability chambers, deep freezers, moisture meters, and more. It also provides services, including laboratory design and commissioning, calibration and validation of equipment, and maintenance and repair of laboratory instruments. The company is certified to CE and ISO 9001:2015 and has been verified by Dun & Bradstreet. It caters to various customers in the pharmaceutical, research, food, and educational sectors worldwide.

EMCLAB Instruments GmbH, established in 2013 and headquartered in Nordrhein-Westfalen, Germany, is a manufacturer of laboratory equipment and supplier of laboratory instruments The company manufactures chemical, pharmaceutical, and food laboratory equipment. It specializes in UV/VIS spectrophotometers, including single and double beam variants, and the EMC-NANO-UV for DNA/protein analysis with sample volumes from 0.2 to 2.5 µl. It provides liquid handling solutions such as bottle dispensers, titration stations, and inductive magnetic and hotplate stirrers. The company is developing the EMC-NANO 2 spectrophotometer, which can measure ultra-small sample volumes and standard cells.

Witeg Labortechnik GmbH, founded in Germany in 1960, is a manufacturer and supplier of laboratory equipment and consumables. Its wide product range includes glass measuring devices, electric laboratory devices, liquid handling, heating baths, and laboratory consumables, while also providing a repair service as well as quality management services. It is officially certified according to DIN EN ISO 9001 and participates in a number of exhibitions, including Analytica 2024 and ACHEMA 2024.

LeadTop Pharmaceutical Machinery Co. Ltd is a manufacturer and supplier of pharmaceutical production equipment that was established in Ruian, Zhejiang, China in 2002. The company primarily produces gelatin encapsulation machines for producing gel tabs in different sizes or shapes, capsule filling machines for measuring and dispensing exact dosages of granules or powder, and rotary tablet presses for compressing powder or compounds into uniform shapes and sizes. The company is ISO 9001 and CE-certified, and mainly serves clients in the pharmaceutical industry.

PRIORCLAVE LTD has been a global manufacturer and supplier of steam autoclaves since 1988 and is headquartered in London, UK. It produces different configurations and sizes of autoclaves, including front-loading, rectangular, double-door/pass-through, large capacity, and custom autoclaves. It also offers autoclave accessories like loading baskets, cassettes, discard containers, and load sense probes. The company has a global network of exclusive distributors and factory-trained authorized service agents to carry out autoclave specification, installation, and maintenance. It complies with the ISO 9001:2008 quality management standard to serve the needs of research institutions, hospitals, and pharmaceutical industries.

Tuttnauer, founded in 1925 and based in Breda, Netherlands is a manufacturer and supplier specializing in sterilization and infection control equipment for medical, industrial and laboratory use. The company’s product line includes hospital autoclaves, plasma sterilizers, biological indicators, glassware washers, and more. These sterilization equipment finds application in various sectors including medical facilities, dental practices, research labs, the pharmaceutical industry, and more. Tuttnauer's extensive network of distributors covers five continents, providing customized service to healthcare providers and labs with skilled sales and service teams.

Medline Scientific Limited., founded in 1992 and headquartered in Oxfordshire, United Kingdom, is a supplier and distributor of scientific equipment and laboratory consumables. The company's product portfolio includes analytical balances, biohazard bags, cryogenic freezers, flammable storage cabinets, and other scientific equipment. These products find applications in various industries, including healthcare, industrial, life sciences, biotechnology, and food and beverage. The company provides services including preventative maintenance, calibration, technical support, and refrigeration storage solutions. The company is certified with ISO 9001 and ISO 14001, and it represents brands such as Sonics, Genlab, Priorclave, Hanna Instruments, and others.

Buchiglas (Büchi AG), founded in 1946, is a manufacturer headquartered in Uster, Switzerland, specializing in reactor systems. The company provides both standard and custom solutions tailored for the chemical and pharmaceutical industries as well as research institutions. Its product lineup includes glass reactors and process equipment constructed from borosilicate glass, glass-lined steel, and other corrosion-resistant materials. Additionally, Buchiglas offers pressure reactors and stirred autoclaves made from various metals and glass, which are specifically designed for applications such as catalyst screening, corrosion testing, and hydrogenation. The company also provides comprehensive engineering, manufacturing, and installation services that meet regulatory and operational requirements.

BIOBASE, established in 1999, is a high-tech manufacturing enterprise whose business covers biomedical, e-commerce, intelligent manufacturing, scientific equipment In Vitro Diagnosis (IVD) instrument and reagent based in China. Specialized in research, development, and manufacturing of laboratory and medical equipment, catering to life sciences, healthcare, and environmental protection industries. Their product range includes biological safety cabinets, incubators, centrifuges, and more. The company has branch offices in 24 provinces in China, with overseas establishment in USA, Dubai, India, Algeria, Singapore, and business partners in 130 countries.

U-THERM International HK Limited, established in 2008 and headquartered in Tsim Sha Tsui, Kowloong, Hong Kong, is a supplier of laboratory analysis, testing, and measuring instruments and equipment. Its extensive product range includes analytical balances for precise laboratory weighing, spectrophotometers for quantitative analysis across scientific fields, DRS spectrometers, as well as ICP (Inductively Coupled Plasma) instruments for detecting metals and nonmetals in liquid samples, and lab or medical refrigerators for storage purposes.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | JBT. |

7.1%

|

| 2 | Didon |

5.9%

|

| 3 | Beta Star Life Science Equipment |

4.5%

|

| 4 | Benchmark scientific |

4.1%

|

| 5 | Labstac LLC. |

3.3%

|

| 6 | Tuttnauer |

3.3%

|

| 7 | leadsonics |

2.9%

|

| 8 | JEIO TECH |

2.7%

|

| 9 | PHC Holdings Corporation |

2.7%

|

| 10 | Heidolph Instruments GmbH & Co. KG |

2.5%

|

Derivation Method

The ranking is calculated based on the click share within the autoclave page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 20.0% |

Italy

Italy

|

5 | 14.3% |

Germany

Germany

|

5 | 14.3% |

India

India

|

4 | 11.4% |

United Kingdom

United Kingdom

|

4 | 11.4% |

China

China

|

4 | 11.4% |

Japan

Japan

|

2 | 5.7% |

Republic of Korea

Republic of Korea

|

2 | 5.7% |

Spain

Spain

|

1 | 2.9% |

Switzerland

Switzerland

|

1 | 2.9% |

89 products found

89 products

Namioka Manufacturing

240+ people viewing

Last viewed: 23 hours ago

■TAC series/single reactor/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeolite synt...

SK Medical Electronics Co., Ltd.

520+ people viewing

Last viewed: 11 hours ago

■Features ・Uses a unique saturated steam displacement mechanism for highly reliable sterilization. - Real-time digital display of temperature and ...

2 models listed

Namioka Manufacturing

210+ people viewing

Last viewed: 2 hours ago

■PAC series/single reactor/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeolite synt...

Namioka Manufacturing

340+ people viewing

Last viewed: 10 minutes ago

■TV series/reactor unit/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeolite synthes...

Hanyuta Iron Works Co., Ltd.

190+ people viewing

Last viewed: 5 hours ago

This is our completely original packaging product. Although it is a small autoclave that is rare in the world, it has 5 heating steps, a design tem...

Namioka Manufacturing

300+ people viewing

Last viewed: 6 hours ago

■PV series/reactor unit/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeolite synthes...

Hanyuta Iron Works Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

DANDELION-FORTE is a higher-end model of Dandelion that can be molded using resin in a wide temperature range with a maximum temperature of 380℃ an...

SK Medical Electronics Co., Ltd.

630+ people viewing

Last viewed: 7 hours ago

■Features - Laboclave II/V ensures sterilization with two settings: ``132℃/121℃'' and Laboclave IIB/ⅤB with ``121℃/115℃.'' ・Continuous sterilizati...

4 models listed

Namioka Manufacturing

220+ people viewing

Last viewed: 19 hours ago

■ZV series/reactor unit/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeolite synthes...

Hanyuta Iron Works Co., Ltd.

150+ people viewing

The high-cycle autoclave uses a direct heating and cooling method, making it possible to significantly reduce molding time and energy consumption c...

Namioka Manufacturing

240+ people viewing

Last viewed: 1 day ago

■SCW-SV series/Reactor unit/Individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeolite syn...

Hanyuta Iron Works Co., Ltd.

150+ people viewing

Last viewed: 1 day ago

■Eff-Cube, a square autoclave born from a customer's thoughts ・I am molding composite materials and would like to apply a little pressure. ・I fee...

Namioka Manufacturing

220+ people viewing

Last viewed: 5 hours ago

■OC series/OCN type/single reactor/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeol...

Hanyuta Iron Works Co., Ltd.

140+ people viewing

Last viewed: 1 day ago

■Features ・Composite material molding, glass/film lamination, thermal polymerization, plaster drying, etc. - Controls are pre-programmed for easy ...

Namioka Manufacturing

260+ people viewing

Last viewed: 1 day ago

■OC series/OCT type/single reactor/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, zeol...

Hanyuta Iron Works Co., Ltd.

170+ people viewing

Last viewed: 12 hours ago

■Features ・The number of sterilized bottles is from 100 to 15,000. (in 16 containers) ・A type compatible with shelf carts for bag cultivation is ...

Namioka Manufacturing

220+ people viewing

Last viewed: 15 hours ago

■OCL series/OCNL type/single reactor/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, ze...

Namioka Manufacturing

260+ people viewing

Last viewed: 1 day ago

■OCL series/OCTL type/single reactor/individual introduction Hydrothermal synthesis, hydrothermal reaction, functional materials, nanomaterials, ze...

Yagyu Shokai Co., Ltd.

210+ people viewing

Last viewed: 6 hours ago

■Features - No water leakage due to argon welding. - Made of thick board material and has excellent durability. (Body/t0.6mm, lid/t0.7m).

Yagyu Shokai Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

・You can choose the most suitable size for your storage equipment from a wide variety of sizes. ・As it is made of aluminum, it has excellent dura...

Yagyu Shokai Co., Ltd.

180+ people viewing

Last viewed: 9 hours ago

・A test tube holder that matches the size of the autoclave can. ・A large number of test tubes can be autoclaved at once. -Equipped with a handle,...

Yagyu Shokai Co., Ltd.

160+ people viewing

Last viewed: 11 hours ago

■Features ・Even if the autoclave bag is torn, there is no need to worry about contaminating the inside of the autoclave. ・No lid *If containers a...

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 4 hours ago

■Features - Sterilization is performed at two temperature settings, allowing continuous sterilization in a short period of time. ・This is a semi-a...

Yagyu Shokai Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Features - A sterilized can with a lid that has been sterilized by dry heat and can be used as a tweezers holder.

Yagyu Shokai Co., Ltd.

240+ people viewing

Last viewed: 19 hours ago

■Features ・Continuous sterilization is possible in a short period of time. - Compact size does not take up much space and is suitable for steriliz...

Yagyu Shokai Co., Ltd.

180+ people viewing

Last viewed: 12 hours ago

■Features - Numerous soft pins made of silicone protect the equipment from impact. ・The roughened surface promotes steam flow and increases steril...

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■Features - Lid can be locked simply by sliding the lock lever. -Equipped with a safety feature that prevents the lid from being unlocked until the...

Yagyu Shokai Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

■Features Just by placing it in the autoclave, it neutralizes and deodorizes the bad odors that occur during sterilization.

Yagyu Shokai Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

■Features ・This autoclave is equipped with a deodorizing function that suppresses unpleasant odors and steam. -Equipped with a color touch panel t...