All Categories

History

This section provides an overview for operation boxes as well as their applications and principles. Also, please take a look at the list of 4 operation box manufacturers and their company rankings. Here are the top-ranked operation box companies as of July, 2025: 1.ATEN INTERNATIONAL Co., Ltd., 2.SEIWA ELECTRIC MFG CO.Ltd.

Table of Contents

Categories Related to Operation Boxes

An operation box, often referred to as a control box, switch box, cabinet box, or enclosure, is designed for housing and organizing control equipment and operating switches. These boxes facilitate the remote control of machines, devices, or equipment from a location separate from the main control panel.

Operation boxes serve a wide range of applications, including:

These boxes typically accommodate input and display devices such as pushbutton switches, selector switches, indicators, programmable displays, and panel computers.

An operation box includes a main body and a cover that opens via screws or hinges. It mounts control devices for input and display on the cover, allowing operation and visibility even when closed. Inside, a mounting board may be present for attaching additional control devices like control relays and terminal blocks. Cable glands and through holes facilitate the connection of control cables.

Operation boxes vary by their opening mechanism—fixed or retractable—and may include locking features or hand grips for easy adjustment. The size selection depends on the internal components and required cable management.

Materials range from steel, stainless steel, aluminum casting, to polycarbonate and polybutylene terephthalate resins. The choice depends on the application environment, including indoor/outdoor placement and the need for protection against the elements.

Operation boxes are classified by dust and waterproof grades (IP Code) and explosion-proof construction for hazardous locations. Selection should match the environmental conditions.

Installation methods include wall-mounted, handheld, and stand types, chosen based on the operation location and user preference.

*Including some distributors, etc.

Sort by Features

Sort by Area

ATEN INTERNATIONAL Co., Ltd. is a company based in Taiwan, a manufacturer produces wide range of products including KVM switches, video matrix switches, video extenders, video splitters, and other connectivity and management solutions. ATEN International, founded in 1979, was established with their service to simplify and enhance the control and management of various computing and multimedia environments. The company has received several awards including the Taiwan Excellence Award, which honors outstanding Taiwanese products.

Seiwa Electric MFG Co., Ltd is a manufacturer of information display systems, lighting and noise countermeasure equipment, based in Kyoto, founded in 1945 (Samsung Electric Co., Ltd.,) and established in 1949. Their products include: electromagnetic noise countermeasure (EMC), waterproof and shockproof LED information display, their own blue light-emitting diode and white light-emitting diode, tunnel disaster prevention system and road & tsunami information display system. Seiwa Electric acquired ISO14001:2004 certification at all offices. Outside of Japan, they have offices and subsidiaries in Thailand, Vietnam and China.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ATEN INTERNATIONAL Co., Ltd. |

50.0%

|

| 2 | SEIWA ELECTRIC MFG CO.Ltd |

50.0%

|

Derivation Method

The ranking is calculated based on the click share within the operation box page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

3 | 75.0% |

Taiwan

Taiwan

|

1 | 25.0% |

55 products found

55 products

Earth Power Co., Ltd.

560+ people viewing

Last viewed: 10 hours ago

A professional solar power generation control panel equipped with an internal status monitoring function as a new feature. Both lead-acid batteries...

Minatec Co., Ltd.

340+ people viewing

Last viewed: 10 hours ago

■ Overview The general-purpose control panel MTCP series is equipped with a power supply circuit, PLC circuit, and safety circuit, and can be used ...

Minatec Co., Ltd.

260+ people viewing

Last viewed: 2 hours ago

■ Overview The general-purpose control panel MTCP series is equipped with a power supply circuit, PLC circuit, and safety circuit, and can be used ...

Nakamura Electric Manufacturing Co., Ltd.

800+ people viewing

Last viewed: 43 minutes ago

Lineup from 1 point to 15 points, and a wide variety of mounting equipment. ■Notes ・Wiring/operation/maintenance/inspection work should be carrie...

7 models listed

Minatec Co., Ltd.

300+ people viewing

Last viewed: 9 minutes ago

■ Overview The general-purpose control panel MTCP series is equipped with a power supply circuit, PLC circuit, and safety circuit, and can be used ...

Hiirex Corporation Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

It is an operation lever of the ship. The disk -type brake mechanism makes it possible to navigate at a constant speed, and you can fine -tune the ...

Taiyo Electric Co., Ltd.

270+ people viewing

Last viewed: 2 hours ago

This panel provides the optimal control system for all forms of power and heat demand, making full use of cutting-edge electronics technology that ...

Densei Comtech Co., Ltd.

250+ people viewing

Last viewed: 10 hours ago

This device protects transformers and power transmission lines when installed at interconnection substations, and protects transformers and distrib...

Motoda Giken Co., Ltd.

200+ people viewing

Last viewed: 12 hours ago

■Handle & additional operation box ・Some additional operation boxes can be installed directly next to the standard operation box, while others can...

CTC Co., Ltd.

310+ people viewing

Last viewed: 6 hours ago

■Features - Made of UV-resistant polycarbonate, ideal for outdoor use. - Resistant to corrosion and provides high protection even in harsh environm...

Mita Rika Kogyo Co., Ltd.

300+ people viewing

Last viewed: 2 hours ago

This is a device designed for use in safety and disaster prevention education at chemical factories, fire departments, etc. You can experience and ...

Rittal GmbH & Co. KG

550+ people viewing

Last viewed: 13 hours ago

■Summary Housing solutions with cutouts for push buttons that meet the requirements of the food and luxury goods industry. The silicone packing fit...

5 models listed

Takachi Electric Industry Co., Ltd.

160+ people viewing

Last viewed: 1 day ago

A tilted aluminum case suitable for tabletop controllers. The side plates are made of resin and the frame is made of extruded aluminum, making it l...

Taikatsu Sangyo Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Points ・We have a wide range of tools and equipment needed for everyday use. ・A wide variety of products including chip saws, lawn mowers, ceili...

Sannikki Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

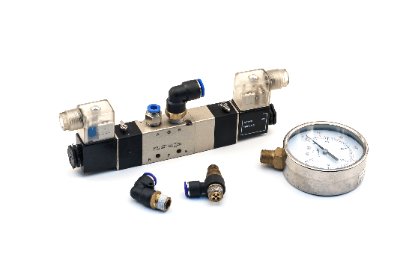

■Summary This is a control panel that uses horizontal double-acting solenoid valves.

Odori Electronics Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

■Summary - A 5-line control panel that can control typical electric locks from each manufacturer. - Advanced control of electric locks including lo...

Maxpull Industries Co., Ltd.

210+ people viewing

Last viewed: 7 hours ago

■Features of the MECB series, a centralized control panel for electric winches This is a centralized control panel for multiple electric winches th...

P-One Shop

250+ people viewing

Last viewed: 1 day ago

■Electrical safety and legal supplies (PSE) ・This product allows you to drain water from a distance. - The area of the operation panel is now 2/...

Odori Electronics Co., Ltd.

180+ people viewing

Last viewed: 16 hours ago

This is a 15-line control panel that can control electric locks that lock when energized, such as emergency stairs.

P-One Shop

170+ people viewing

Last viewed: 13 hours ago

■Electrical safety and legal supplies (PSE) This product allows you to drain water from a distance.

Hishiko Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■Applications Power supply device for small lifters KLF and KLR. ■Features ・When inputting single-phase AC200V, the output voltage is DC180V. ・W...

Tenma Electric Industry Co., Ltd.

170+ people viewing

■Features We manufacture control panels for various cranes according to the intended use (outdoor, indoor, on-machine, room).

Wave Energy Co., Ltd.

160+ people viewing

Last viewed: 22 hours ago

Are you having trouble with power receiving and substation equipment being installed outdoors and far away, or the electrical room being far away? ...

Wako System Control Co., Ltd.

210+ people viewing

Last viewed: 2 hours ago

■Summary We handle boxes and racks that protect electronic equipment and control equipment from water droplets and dust. As we design and manufactu...

CAREL Japan Co., Ltd.

140+ people viewing

Last viewed: 1 day ago

This product makes it very easy to control the temperature and water level of display case trays in catering and cafeterias where food needs to be ...

CAREL Japan Co., Ltd.

150+ people viewing

Last viewed: 10 hours ago

The compressor rack series controller can manage racks with up to two compressors. One of the compressors has a fixed speed, and the other has a ch...