30 Drive Chain Manufacturers in 2024

This section provides an overview for drive chains as well as their applications and principles. Also, please take a look at the list of 30 drive chain manufacturers and their company rankings. Here are the top-ranked drive chain companies as of July, 2024: 1.Makelsan Chain, 2.Stock Drive Products/Sterling Instrument - SDP/SI, 3.TIMKEN.

Table of Contents

What Is a Drive Chain?

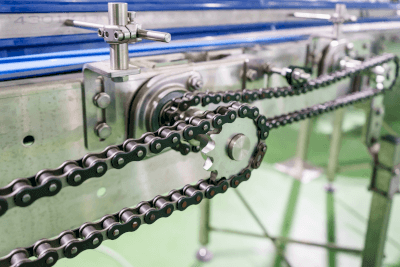

A drive chain is a chain utilized to transmit power between rotating shafts that are spaced apart.

Most drive chains consist of metal roller chains. These roller chains operate in tandem with sprockets and thin gears to transfer power from the input to the output shaft.

Altering the sprocket teeth count on both the drive and driven ends can modify the rotation speed. Beyond drive chains, conveyor chains are also used in factories for product transportation along production lines.

Uses of Drive Chains

Drive chains find application in driving the wheels of bicycles and motorcycles, in automobile engines and transmissions, and industrial machinery. Bicycle drive chains represent a common example of their application in everyday life.

Drive chains in sports bicycles, like road and mountain bikes, must not only convey power but also adapt to various speed shifts. The chainring and the rear wheel sprockets, featuring different teeth counts, can be swapped to alter gear ratios.

The design of the drive chain allows significant lateral movement based on the sprocket's position, enhancing its versatility. In automobiles, drive chains are integral to engine timing, transferring power in 4-wheel drives, linking transmissions to drive wheels in motorcycles, and operating in chainsaws and forklifts.

Principle of Drive Chains

The drive chain transmits power as the teeth of the driven sprocket engage the chain's rollers, thus pulling the chain. Rollers, maintained in position by pins and bushings, with plates affixed on either side, facilitate continuous power transmission.

Structure of Drive Chains

The drive chain comprises four main components: pins, bushings, rollers, and plates.

1. Pin

Pins support rollers that directly receive power from sprockets and connect the plates. They must withstand significant shear stress during power transmission.

2. Bushing

Bushings facilitate the smooth sliding action between pins and rollers, essential when rollers engage with sprockets under pressure, thereby minimizing friction and wear.

3. Plate

Plates, connected by pins, transmit power under tension. Inner and outer plates are arranged alternately, and chains must be linked by connecting these plates.

4. Sealing Rings

Certain drive chains include sealing rings to encase lubricating grease for the bushings.

Other Information on Drive Chains

1. Standards for Drive Chain

Drive chains adhere to various domestic and international standards. Chain sizes are denoted in inches, with a three-digit number representing the pitch and inner pin width.

2. Alternatives to Drive Chain for Power Transmission

Aside from drive chains, rubber belts, gears, and shafts also transmit power. Nevertheless, drive chains are prevalent in daily-use products like cars and motorcycles due to their reliability and cost efficiency. Metal belts are commonly used in continuously variable transmissions (CVTs) for vehicles, though metal chains are sometimes preferred for their torque transmission efficiency despite being noisier, limiting their market presence.

List of 30 Drive Chain Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- China

- Germany

- India

- Italy

- Japan

- Turkey

- United Kingdom

-

-

-

Donghua USA Inc.

Driving Chains

Manufacturer Overview

Donghua USA Inc., established in 1991 and headquartered in Carol Stream, United States of America, is a manufacturer of various types of chains. The company manufactures driving chains, conveyor chains, auto & motorcycle chains, and agricultural chains. It also crafts leaf & hoisting chains, escalator chains, bulk material conveyor chains, and stainless steel chains. The products are specifically used for power transmission and conveyance systems. It has passed ISO 9001, ISO/TS16949:2002, ISO10012, and ISO14001 certifications.

-

-

-

-

-

Bobcat Company

DRIVE CHAIN

Manufacturer Overview

Bobcat Company, founded in 1958 and headquartered in West Fargo, USA, is a manufacturer of compact equipment for landscaping, forestry, snow removal and to operate touch surfaces. The company's product line includes a range of loaders, mowers, excavators, tractors and light compaction equipment like rammers, trench rollers and compactors. It also offers utility vehicles, utility work machines and a range of tools and attachments for all of its machinery. These equipment are also used in construction, agriculture, grounds maintenance, acreage management, utility, industrial and mining markets. The company offers product safety and training courses, safety schedules, rental services and warranty plans.

-

-

-

-

-

Promac International, Inc.

Engineering Class Drive Chain

Manufacturer Overview

Promac International, Inc. is an Ohio-based supplier of Engineering and Conveyor Chains sourced from ISO 9001-certified manufacturers from Brazil and Asia. The company offers a wide range of products including Roller Conveyor Chains, Steel Bushing Chains, Bucket Elevator Chains, Welded Steel Drag Chains, as well as Caterpillar Drive Chains, and Forged Rivetless Chains primarily used in trolly and tow applications, and industries such as oil & gas, glass & bottle, and mining.

-

-

-

-

-

PEER Chain

ENGINEERING DRIVE CHAIN

Manufacturer Overview

PEER Chain, founded in Waukegan, Illinois, in 1969 is a manufacturer of Industrial Roller Chains. The company's product portfolio includes Standard Roller Chains, ANSI Standard Roller Chains, Multi-Strand Roller Chains, Quest Solid Bushing Standard Roller Chains and C-Type Standard Roller Chains. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

-

-

-

-

-

Big John Grills & Rotisseries

Drive Chain

Manufacturer Overview

Big John Grills & Rotisseries, established in 1962, is a manufacturer of outdoor commercial cooking equipment and accessories based in Bellefonte, Pennsylvania. The company offers a wide range of products including Commercial Gas Grills, Charcoal Grills, Charcoal Rotisseries as well as Charcoal Tow Behinds used widely by hotels, universities, amusement parks, and Caterers. Big John Grills & Rotisseries also offers Residential Built-ins and Residential Mobile Grills as well as Wood Pellets and various accessories such as Leg Braces.

-

-

-

-

-

Wisconsin Oven Corporation

Drive Chains

Manufacturer Overview

Wisconsin Oven Corporation has operated since 1973 and is located in East Troy, Wisconsin. Wisconsin Oven designs, engineers, and manufactures industrial ovens and other heating equipment for numerous applications including heat treating, powder coating, paper pulp drying, finishing, drying, and curing in the aerospace, automotive, composite, energy, finishing, foundry, heat treating, annealing, military, and pharmaceutical industries. Types of ovens and equipment include custom and standard batch ovens, conveyor ovens, pollution control equipment, and walk-in ovens.

-

-

-

-

-

TIMKEN

Drive Chains

Manufacturer Overview

The Timken Company (Timken) was founded in 1899 and is headquartered in North Canton, Ohio. Timken designs, manufactures, and manages engineered bearings and industrial motion products worldwide. Timken operates in two segments, Mobile Industries and Process Industries. The Mobile Industries segment’s portfolio includes bearings, seals, and lubrication devices and systems. The Process Industries segment provides industrial bearings and assemblies; industrial motion components, such as gears and gearboxes; and linear motion products, couplings, seals, lubricants, chains, belts, and related products and services to OEMs and end users in various industries.

-

-

-

-

-

Stock Drive Products/Sterling Instrument - SDP/SI

Drive Chains

Manufacturer Overview

SDP/SI was founded in 1950 and is situated in New Hyde Park, New York. SDPP/SI is a manufacturer of precision gears and high-quality mechanical components used in the aerospace, industrial manufacturing, medical technology, and robotics fields. The company manufactures parts in a variety of materials including alloy steel, stainless steel, bronze, brass, nylon, and titanium. The company also provides coating services such as heat treating, zinc plating, and painting. Additional custom options are available including manufacturing to customer drawings and specifications.

-

-

-

-

-

Rubin Engineering & Sales, LLC.

Drive Chains

Manufacturer Overview

Rubin Engineering & Sales, LLC., established in Milwaukee, WI , in 1987 is a manufacturer of machine tool components, such as ball screws, electric controls and drives. Their product portfolio includes electric controls that deliver advanced automation and precision control, enhancing the efficiency and accuracy of machine tools and electric drives that power machine tool movements with precision and speed. The company also offers services including, CNC Repair and Replacement Parts, maintenance and repair services. The company serves industries such as Industrial Machinery, Robotics and Automation and Medical Equipment.

-

-

-

-

-

Allied-Locke Industries

Drive Chains

Manufacturer Overview

Allied-Locke Industries., established in Dixon, IL, in 1965 is a supplier of Agricultural Chain, Industrial Chain, Environmental Products & Sprockets. Their product portfolio includes Agricultural Roller Chain Assemblies, Aprons, Flights & Slats. Their products are used for agricultural machinery, including tractors, combines, and harvesters, and material handling for grains, seeds, and other agricultural products. The company also provides services including national distribution, product selection, installation, repair and customer and technical service.

-

-

-

-

-

-

-

Caltric

Caltric Drive Chain

Distributor Overview

Caltric is one of the largest aftermarket suppliers of replacement parts and accessories based in Los Angeles, California. The company offers various replacement parts for Powersports and Marine. Caltrics has a large collection of replacement parts for the power sports and automobile sectors including Upper and Lower Ball Joints, Fuel Pump for Honda, Speed Sensors for Kawasaki, Air Filters as well as Oil Filters and Intake Valves for motorcycles, automobiles, and marine vehicles.

-

-

-

-

-

Reasontek Corp.

Drive Chains

Distributor Overview

Reasontek Corporation was founded in 2009 and is headquartered in Brea, California. The company is a distributor of products that primarily serves the technology and domestic and global oilfield equipment and industrial supplies industries. The company has two primary business segments: accumulator production and oilfield equipment and industrial supplies. The accumulator production segment includes accumulators and other energy storage and surge protection devices as well as CAD services. The oilfield equipment and industrial supplies segment includes bladder accumulators, repair kits, and related accessories.

-

-

-

-

-

Emerson Bearing

Drive Chains

Distributor Overview

Emerson Bearing is based in Boston, Massachusetts and serves both domestic and international customers of industries ranging from mining to machine tools to power generation to wood products to wastewater treatment to robotics and more with bearings and casters. Emerson Bearing’s product list includes adhesives, sealants, ball bearing, roller bearing, mounted nut bearings, linear motion bearings, rod ends, belts, sheaves, chains, sprockets, couplings, clutches, brakes, locknuts, washers, lubricants, pullers, tools, retaining rings, seals, and shaft collars.

-

-

-

-

-

Accent Bearings Co., Inc.

Drive Chains

Distributor Overview

Accent Bearings Co. Inc. was established in 1993 and is a distributor for industrial bearings. Accent Bearings offers a full range of bearing-related parts including ball, cylindrical, radial, thrust, and standard, as well as CAM followers, rod ends, belts, sheaves, busings, bronze busings, bar stock, pulleys, chains, sprockets, gears, speed reducers, motors, clutches, brakes, couplings, shafts, shaft accessories, oil seals, gauges, retaining rings, air cylindeers, conveyor belts, and fluid power process control equipment.

-

-

-

-

-

HANGZHOU CHINABASE MACHINERY CO., LTD.

Transmission chain Driving Chain

Manufacturer Overview

Hangzhou Chinabase Machinery Co., Ltd., founded in 1992 and based in Hangzhou, China, is a manufacturer specializing in an array of products, including power transmission components. Its key products encompass chains and sprockets for industrial power transmission, gearboxes to enhance torque and reduce speed, couplings for shaft connections, and gears used across industrial applications. Its products find applications in automation, conveyor technology, packaging, food, pharmaceuticals, and more. The company maintains quality and sustainability, holding certifications like ISO 9002, ISO 9001, API, ISO/TS 16949:2002, and ISO 10012 measurement management system.

-

-

-

-

-

Katayama Chain, Co., Ltd.

Roller Chains

Manufacturer Overview

Katayama Chain, Co., Ltd., established in 1958 and located in Higashi-Osaka-shi, Osaka, is a manufacturer of power transmission equipment and transport equipment. Their comprehensive product range includes chains, gears, shaft couplings, and roller conveyors. These products are engineered to deliver efficient power transmission in various industries, such as automotive, industrial machinery, agriculture, and construction. Katayama Chain, Co., Ltd. adheres to stringent control measures, ensuring that their power transmission solutions meet or exceed industry standards that are reflected in their certifications, such as ISO 9001.

-

-

-

-

-

KettenWulf, Inc.

Drive chains

Manufacturer Overview

KettenWulf Betriebs GmbH, founded in 1925 with headquarters in Eslohe-Kückelheim, Germany, is a manufacturer of conveyor chains, drive chains, and sprockets. The company's product line includes custom special conveyor and transport chains, custom drive chains for agricultural machinery, and a diverse range of gear sprockets, such as divided sprockets and pinion sprockets. The company also offers a range of custom assemblies that include fully assembled drive shaft units and double-strand chains with fitted conveyor cells or support plates. The company serves various markets, including agriculture, industrial equipment and machinery, material handling, and mining.

-

-

-

-

-

GROB GmbH

LINEARCHAINS

Manufacturer Overview

GROB GmbH is based in Mindelheim, Germany, and is a drive technology products manufacturer that was established in 1952 as a subsidiary of GROB-WERKE GmbH & Co. KG. The company’s products include linear actuators for precise positioning applications, electric motors for energy-efficient drive applications, and various gearbox models. It also offers control systems for its portfolio products, along with a range of custom manufacturing capabilities for unique projects. The company provides after sales services such as personnel training, maintenance, and repair for its clients.

-

-

-

-

-

Framo Morat

PushPull chain LinearChain

Manufacturer Overview

Framo Morat, headquartered in Eisenbach, with subsidiaries in the United States, Turkey, and Poland, has been a gear and drive engineering product manufacturer since 1912. The company products include spur gears, ring gears, pinion shafts, worm gear sets, etc., with material selection including steel, bronze, fabric laminate, or plastic. The company produces 1 million gear sets in a 26,500 m2 production area. The company serves automation, material handling, automotive, and medical industries. In medical industries, worm gear sets are utilized to adjust operating tables and stair lifts. In energy industries, gear sets are ideal for rotary heads for solar trackers.

-

-

-

-

-

Octaforce Engineering

Caterpillar Drive Chain

Manufacturer Overview

Octaforce Engineering, headquartered in Mumbai, India, is a manufacturer and supplier of mechanical power transmission parts and components. The company manufactures types of couplings, sprockets, gears, pulleys, industrial chains and belts. It also provides custom made transmission products and moulded & extruded rubber spare products like couplings, bushes and scraper spares. These products comply with the ISO ISO 9001:2015 quality standards. The company's products are used in steel, agriculture, sugar, pulp & paper, chemical, cement and other industries.

-

-

-

-

-

Cross+Morse

Roller Chain Drives

Manufacturer Overview

Cross+Morse, founded in 1984 and headquartered in Birmingham, England, is a manufacturer of power transmission products and solutions. The company's product portfolio includes various belt drives and roller chain drives, shaft couplings, clutches, gears and torque limiters. It offers custom made bespoke components as well as rework services like reboring, keywaying and setscrewing of standard sprockets, pulleys and gears to turn it around to a required specification. The company is ISO 9001:2015 accredited and has a range measuring equipment like Coordinate Measuring Machine (CMM), digital tri-bore gauges and micrometres which are calibrated to comply with ISO standards.

-

-

-

-

-

Renold

Transmission Drive Chain

Manufacturer Overview

Renold, established in 1947, and based in Manchester, UK, is a manufacturer and supplier of industrial chains, gearboxes, and couplings. Their product portfolio includes tooth chains, transmission drive chains, gear and gearboxes, couplings, conveyor chains, leaf chains, sprockets, and accessories. The company offers the latest innovation with high precision-engineered power transmission products. The products are used in various industries which include agriculture, construction, energy, environment, food and drink, transportation, and machinery.

-

-

-

-

-

W.M. Berg

BELTS, CHAINS & CABLES

Manufacturer Overview

W M Berg, founded in 1967 and based in Cudahy, Wisconsin, is a manufacturer and supplier of precision industrial parts. The company delivers ISO 9001:2015 certified products and services, including assemblies, bearings, belts & chains, couplings & shafts, gears, fasteners & hardware, pulleys & sprockets and more. W M Berg provides designing, developing, manufacturing and testing facilities to its clients in the aerospace, medical and motion control industries. Its distributors include Applied Industrial Technology and Motion Industries.

-

-

-

-

-

Suzhou Universal Technology Co., Ltd

Drive Chains

Manufacturer Overview

Suzhou Universal Technology Co. Ltd, founded in 1970 and headquartered in Jiangsu, China, is a manufacturer of chain transmission solutions. The company's transmission chains are categorised in drive and conveyor chains, car parking, escalator and engineering chains, leaf chains and agricultural machinery chains. These products also find application in industries like aerospace, medical, packaging, mining and sewage treatment. It supplies its products in the Chinese market and OEM in the overseas market. The company has a National Enterprise Technology Centrer for R&D and a quality control and inspection system. It has acquired ISO certifications as well as API, KS and CSAIII certifications.

-

-

-

-

-

U.S. Tsubaki Inc.

Drive Chains

Manufacturer Overview

U.S. Tsubaki Power Transmission LLC., founded in 1971 and based in Wheeling, Illinois, is a manufacturer and supplier of motion control and power transmission products and is ISO 9001 certified. Its products include sprockets, conveyor chains, and roller chains used in several industries, including automotive, primary metals, and forest products. It’s a subsidiary of the Tsubakimoto Chain Company, and it has several manufacturing facilities in the United States, including Milwaukee (WI), Sandusky (OH), and Chicopee (MA). The company sells its products through distribution channels but can sell directly to qualified OEMs.

-

-

-

-

-

SENQCIA CORP.

Conveyor Chain

Company Overview

Senqcia Corporation, founded in 1972 and headquartered in Tokyo, Japan, is a manufacturer and distributor specializing in building structural components. Its product portfolio includes pioneering raised floor systems, developed with advanced technology since the 1960s, providing free-access flooring solutions. It also offers structural products like HIBASE and HIRING, along with dampers, crucial devices for mitigating oscillatory or vibratory motions. The company's solutions play an essential role in ensuring safety and security in building structures, whether in underground foundations, steel frames, or under floorings.

-

-

-

-

-

Tsubaki of Canada Limited

Drive Chains

Company Overview

Tsubaki of Canada was founded in 1973 as a Canadian subsidiary of Tsubakimoto Chain Company, originally founded in Japan in 1917. The company is a producer and distributor of precision roller chains and other power transmission products to industries including food & beverage, aggregate & cement, automotive, forestry, and primary metals. The company’s primary product lines are roller & engineering class chains, sprockets, cable & hose carriers, PT components, and backstops & clutches. The company also offers advanced customer service including chain, sprocket, and system analysis, optimization, maintenance, and training.

-

-

-

-

-

-

-

Melucci S.r.l.,

Chain drives

Distributor Overview

Melucci, founded in 1974 and headquartered in Rimini, Italy, is a distributor of components for industrial plants and machinery. The company specializes in precision linear systems and offers complete solutions in the sizing of the linear axis by offering various products, ranging from linear ball guides to roller guides up to miniature guides, screws, ring nuts and other accessory components which allow application in any industrial sector. It offers tailor-made solutions with 3D CAD resources that allows its product's technical drawings to be downloaded and integrated in customer's projects.

-

-

Drive Chain Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Makelsan Chain |

17.6%

|

| 2 | U.S. Tsubaki Inc. |

8.8%

|

| 3 | Stock Drive Products/Sterling Instrument - SDP/SI |

8.8%

|

| 4 | TIMKEN |

8.8%

|

| 5 | Donghua USA Inc. |

7.4%

|

| 6 | Renold |

7.4%

|

| 7 | Wisconsin Oven Corporation |

7.4%

|

| 8 | Melucci S.r.l., |

4.4%

|

| 9 | Big John Grills & Rotisseries |

4.4%

|

| 10 | Suzhou Universal Technology Co., Ltd |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the drive chain page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- SENQCIA CORP.: 301

Newly Established Company

- Reasontek Corp.: 2009 (15 years ago)

- HANGZHOU CHINABASE MACHINERY CO., LTD.: 1992 (32 years ago)

- Donghua USA Inc.: 1991 (33 years ago)

Company with a History

- Framo Morat: 1912 (112 years ago)

- GROB GmbH: 1945 (79 years ago)

- Allied-Locke Industries: 1965 (59 years ago)

Drive Chain Manufacturers in United States

*Including some distributors, etc.

- Donghua USA Inc.

- Bobcat Company

- Promac International, Inc.

- PEER Chain

- Big John Grills & Rotisseries

- Wisconsin Oven Corporation

- TIMKEN

- Stock Drive Products/Sterling Instrument - SDP/SI

- Rubin Engineering & Sales, LLC.

- Allied-Locke Industries

- pewag USA

- Caltric

- Reasontek Corp.

- Emerson Bearing

- Accent Bearings Co., Inc.

Global Distribution of Drive Chain Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

15 | 55.6% |

Germany

Germany

|

3 | 11.1% |

Japan

Japan

|

2 | 7.4% |

United Kingdom

United Kingdom

|

2 | 7.4% |

China

China

|

1 | 3.7% |

India

India

|

1 | 3.7% |

Canada

Canada

|

1 | 3.7% |

Turkey

Turkey

|

1 | 3.7% |

Italy

Italy

|

1 | 3.7% |