All Categories

History

This section provides an overview for carbide punches as well as their applications and principles. Also, please take a look at the list of 23 carbide punch manufacturers and their company rankings. Here are the top-ranked carbide punch companies as of February, 2026: 1.Reynolds Carbide Die Co., Inc., 2.Swiss Craft Precision Grinding Inc., 3.Intricate Grinding & Machine Specialties, Inc..

Table of Contents

Categories Related to Carbide Punches

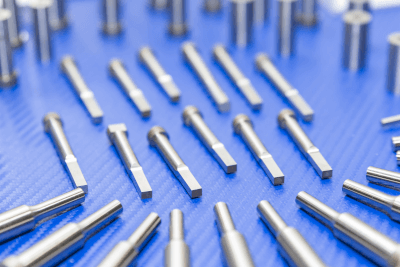

A carbide punch is a punch made of cemented carbide.

It is also called cemented carbide. Cemented carbide is a metal alloy made by adding tungsten carbide (WC) and titanium carbide (TiC), using cobalt (Co) powder as a binder, and sintering (pressing and solidifying the material at a temperature of 1300° to 1500° by heating it near its melting point) in a pressurized mold.

A carbide punch is a challenging and heat-resistant punch used for wear resistance. Regular punch material (equivalent to SKD11) becomes hard to cut when the cutting edge of the punch begins to sag due to frictional heat (around 1330°).

Carbide punches are a wear-resistant measure because they are made of carbide metal.

They are mainly used for precision dies and as punches for press dies. It is possible to maintain stable dimensions using carbide punches, which have little dimensional fluctuation due to wear.

Carbide punches have excellent wear resistance and are robust against compressive stress but weak against tensile stress, so the punch holding section must be reinforced when used.

Gold has the property of elongation when struck at room temperature.

However, iron does not elongate when struck at room temperature.

By adding heat to iron (around 1330°), it begins to elongate when struck.

In other words, gold has the same property at room temperature, and iron has the same property when heated to 1330°.

This is the difference between gold and iron.

The wear mechanism of the metal is that the part of the metal that comes in contact with the iron with the binder will be at around 1330° and

The metal becomes soft and wears by having the same properties as gold.

This is the wear mechanism.

If this is the case, to make a metal resistant to wear, it should not become soft even at a temperature of around 1330°.

This is called SKH51 (high-speed steel).

This is SKH51 (high-speed steel), a cemented carbide.

HSS is often used as a heat-resistant wear-resistant material because it begins to wear when heated to around 1550°.

Therefore, it is often used as a heat-resistant wear-resistant material.

Some cemented carbide materials do not wear out at temperatures above 2000° and even at 4000°.

You can understand how heat-resistant and hard they are.

However, it is not all merit.

Because of its hardness, it is less pliant and easily broken.

It is vital in compression but weak in tension and lateral force.

*Including some distributors, etc.

Sort by Features

Sort by Area

Swiss Craft Precision Grinding Inc. was founded in 1982 in Northeastern Indiana as manufacturer of automotive and electronic parts and tools and suppliers of grinding and other related services. The company holds the finest equipment required for precision grinding of various materials across industries. To tackle interior dimensions and achieve excellent surface finishes, there are EDM and Wire EDM machines. CNC milling and turning services are provided to fulfil machining needs across various industries along with polishing facilities that are capable of producing a mirror finish of micro3 on steel and tungsten carbide.

Reynolds Carbide Die Co., Inc was founded in 1998 as a designer, manufacturer, and supplier of carbide parts for precision dies, knitting, sewing, and shoe manufacturing. The company, headquartered in Thomaston, Connecticut, produces replacement parts or custom precision tooling, including Steel Alloys or Tungsten Carbides. They supply textile, battery, eyelet, paper, and cardboard manufacturing equipment. Their circular steel or carbide cutters, knives, and wear parts for equipment are used in diverse industries.

PUNCH INDUSTRY USA INC. is a manufacturer that specializes in precision tools and machinery solutions which is headquartered in the USA. The company specialize in automotive parts and assemblies, electronic connectors, and aerospace components, by delivering excellent products for various businesses. With an intention to deliver excellent products and services, The company has established itself as a dependable partner for clients worldwide and allegiance to engineering expertise and customer satisfaction allows them to consistently provide cutting-edge solutions that meet the diverse needs of customers.

PSM Industries is a family business founded in 1956 and is based in Los Angeles, California. PSM provides solutions in parts fabrication through powder metal technology. Through this, PSM serves industries including medical, sporting goods, food service, and aerospace. PSM Industries consists of 4 categories of divisions throughout the United States. High-Performance PM includes Pacific Sintered Metals, PM Engineered Solutions, and BestMetal. High Wear Carbides Includes PM Krupp High-Speed Steels and Yilik Precision Carbides. The other two categories are metal injection molding featuring PolyAlloys and engineered plastics featuring W.M. Guliksen.

Intricate Grinding & Machine Specialties, established in 1968 and based in Muskegon, MI, is a manufacturer of industrial equipment. The company's product line includes CNC machining and turning, CNC grinding, wire EDM, and deep draw tooling. It operates in the defense, military, and metalworking machinery industries, and its deep draw tooling service is used in manufacturing automotive body and structural parts, aircraft components, utensils, and more.

General Carbide Corporation, established in 1968, is a vertically integrated manufacturer of finished tooling and wear parts based in Greensburg, PA. As an ISO 9001:2015-certified company, they employ more than 250 highly-skilled professionals and have four facilities. With Mona Pappafava-Ray as CEO since 2002, they have achieved the Outstanding CEOs & Top Executives, Business Women First Award, Torch Award, and EY Entrepreneur Of The Year 2019 Award. The company offers a wide range of tungsten carbide and steel tooling products for over two dozen market segments, including automotive, oil and gas, and stamping, among others.

Alpha Carb Enterprises, Inc., established in 1974 and situated in Pittsburgh, Pennsylvania, is a manufacturer specializing in precision carbide progressive stamping dies, carbide and steel die components, and precision metal stampings. The company has a comprehensive product catalog featuring an array of offerings, including die components, stamps, prototype parts, and electrical discharge machining. These precision products find crucial applications across a spectrum of industries, catering to the specific needs of sectors such as automotive, aerospace, medical, electronics, and more.

Endurance Carbide, established in 1961 and headquartered in Saginaw, Michigan, USA, is a manufacturer specializing in precision wear parts designed for rugged industrial use. It has the ability to hold tolerances of 0.00002". Its product lineup includes carbide bushings, dies, gages, punches, and grinding quills, all utilized for its wear resistance and precision. Its products find extensive use in various industries, including manufacturing and machining, where they enhance productivity and provide quality finished products. The company is accredited with ISO 9001 for quality management and is a member of the SMALL BUSINESS Association of Michigan and MMA.

Metalloy was founded in 1969 and is based in St. Charles, Illinois. Metalloy is a distributor of industrial and construction supplies. Metalloy offers tube & pipe products, PVF, die sets & plates, die & mold tooling, general tooling, steel storage, and SK hand tools. Tube & tube products include mechanical tubing, stainless steel tubing, and piping. PVF includes piping, fittings, flanges, valves, studded outlets, and machined rings. Die sets & plates include parallels, risers, and steel tools. Die & mold tooling include die punches, die buttons, drill busings, and mold components.

H.B. Carbide, established in 1983 and headquartered in Lewiston, Michigan, is a manufacturer and supplier of carbide cutting tools and precision wear parts. The company offers a diverse range of products, including carbide inserts, end mills, reamers, drills, and special tooling solutions. These products are designed to be utilized in various industrial applications such as metalworking, machining, and fabrication. Its Grade Selection Tool available assists individuals in identifying the most suitable match for their specific project requirements.

Founded in 2007, and based in Haryana, India, Jain Tools is a manufacturer of Dies and Molds. The company produces High-Pressure Casting Dies, Zinc Casting Dies, Trimming Tools, Plastic injection molds, and Blow molds. They also provide Aluminum Die Casting Dies, Injection Molds, Roto Molds, and Tungsten Carbide Dies with applications in the Automobile and Wire drawing industries. They offer Tool related services for product design, precision machining, and heat treatment that have applications in various engineering industries.

Dongguan JLS Precision Mold Parts Co., Ltd, founded in 2004, is a manufacturer of precision carbide components, based in Dongguan, China. Its product lineup comprises precision carbide punch, carbide dies, bushes, carbide rod, and ejector pins. These components serve diverse industries, including automobile parts metal stamping, plastic mold & die makers, and tool design & die making sectors. Utilized for its hardness and remarkable wear & corrosion resistance, its products enhance productivity and efficiency by extending the lifespan of tungsten wear parts. The company upholds ISO 9001 certification, a testament to its adherence to quality and precision.

Dongguan Langdi Precision Mould Co, Ltd. is a precision parts manufacturer, founded in 2010, and headquartered in Dongguan, Guangdong. The company offers stamping die components and punches in steel, HSS, or carbide, as well as precision mold parts and components for plastic injection molds. Additionally, the company provides custom-made parts for automation machines and precision fixture components for molds and automation systems. The company has a precision level of +/- 0.001 mm and a surface roughness of RA 0.05.

DIC TOOLS, established in Patiala, Punjab in 2012 is a manufacturer of cutting tools which include HSS Cutting Tools and Gear Cutting Tools. Their product portfolio includes solid carbide end mills used for precise milling, high-speed steel (HSS) and HSS-Co drills, high-speed steel (HSS) and HSS-Co drills used in turning and milling operations, and boring bars and tool holders for hole machining. The company serves industries such as Electronics and Semiconductors, Metalworking and Fabrication and Precision Engineering.

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd., established in 2007 and headquartered in Zhuzhou, Hunan Province, China, is a manufacturer specializing in precision wear parts. The company produces a wide array of cemented carbide and tungsten steel products, including raw materials, blanks, and precision components. These items are utilized for their durability, precision, wear resistance, and dimensional accuracy, making them crucial in various industries. The company holds ISO 9001:2015 international quality certification, demonstrating its adherence to industry standards.

Smit Engineering, established in 1980, and based in Pune, India, is a manufacturer and supplier of tools, die castings, and other allied products. The product portfolio includes stamping dies, punch, sheet metal progressive tool, brass ball cage, round die button, V-notching blade, and other tool components. The company provides high precision, accurate tools, and engineering excellence. The products have high-quality durability, with innovative technology. The company has ISO certification for all products.

Tokyo Byora Koki Co., Ltd., established in 1961, and headquartered in Niiza City, Japan, is a manufacturer of carbide dies and machinery components. The company utilizes and applies its micro deep hole processing technology to a range of product fields, including medical applications, aerospace, and precision components related to semiconductors. It is actively involved in precision processing of challenging materials, with a limit of 0.1mm, such as titanium alloy and iridium.

HPL Stampings, Inc., established in 1941 and located in Lake Zurich, Illinois, is a manufacturer specializing in precision metal stampings, sheet metal fabrications, and laser cutting services. Its services include punch press stamping, prototype and short run production, blanking, piercing, and engraving, which serve industries such as aerospace, agricultural, automotive, construction, and packaging. Its services are employed to manufacture precise metal components such as stamped clips for control systems, steel stamped fuse brackets, and circuit board stiffeners, for diverse applications, ensuring efficient production and accurate designs.

Vardhman Dies and Mould Tools, founded in 1999 and headquartered in Mumbai, Maharashtra, India, is a manufacturer and supplier, specializing in press tool accessories, die springs, and mould & mould base accessories. Its product catalog includes essential items such as the mould ejection system, mould alignment products, slide retainers, mould latches, and mould parting locks. These offerings find indispensable utility in the injection moulding, die casting, and compression moulding industries. The company maintains ISO 9001:2008 certification, adhering to quality and international standards.

Sundi Tools, founded in 2002, in Wuxi, China, is a manufacturer specializing in precision cutting tools and tooling components. Its offerings encompasses punch and die tooling components, CNC machining parts, ceramic components (Al2O3, ZrO2, SiC, Si3N4), and cutting tools in carbide, PCD, CBN, and ceramic. These precision tools cater to industries such as automotive, aerospace, electronics, oil devices, and heavy equipment manufacturing. With ISO 9001:2015 certification, the company ensures rigorous quality control throughout the production process, from raw material procurement to final inspection, all while providing attentive customer service.

Founded in 1948, and, located in Tarentum, PA, Oberg Industries is a manufacturer of stamped metal components and precision tooling. The company offers surgical instruments, Automation systems, special devices, and, finishing solutions for the medical sector along with stamped metal components for jet engines, submarines, munitions, firearms, and rotary-wing aircraft. that are used in the defense sector. They also offer Precision Grinding, Special / Secondary Processes, and Assembly Cells for the construction industry besides automotive parts including Clutch plates. Fuel injectors. Staked motor laminations, Airbag components that have applications in the Automotive industry.

Amtek Tool and Supply, Inc. based in Madison Heights, MI. Amtetk is an online super market for tools, supplies, and other hardware for individual, professional, and corporate customers. Product types include milling, threading, and turning devices, tooling systems, saws, broaching and deburring bits, cutting tool blanks and spares, abrasives, power tools, hand tools, safety equipment, measuring devices, lubrication, sanitation supplies, storage, pneumatics, shipping supplies, transmissions, and various other hardware and shipping supplies. Amtek’s online storefront offers precise filters to help find exact products to meet customer needs.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Reynolds Carbide Die Co., Inc. |

8.8%

|

| 2 | Swiss Craft Precision Grinding Inc. |

8.4%

|

| 3 | Intricate Grinding & Machine Specialties, Inc. |

7.9%

|

| 4 | PSM Industries, Inc. |

7.4%

|

| 5 | General Carbide Corporation |

6.5%

|

| 6 | Endurance Carbide |

6.0%

|

| 7 | Imperial Carbide, Inc. |

5.6%

|

| 8 | PUNCH INDUSTRY USA INC. |

5.1%

|

| 9 | Metalloy |

5.1%

|

| 10 | H.B. Carbide |

4.2%

|

Derivation Method

The ranking is calculated based on the click share within the carbide punch page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

10 | 58.8% |

India

India

|

3 | 17.6% |

China

China

|

3 | 17.6% |

Japan

Japan

|

1 | 5.9% |

16 products found

16 products

Engineer

360+ people viewing

Last viewed: 1 day ago

■ Features ・ Replacement for TZ-14 (auto punch). ・ With tip carbide chip. ・ With spring. ■ Use ・ For parts replacement of auto punch.